Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41 results about "Portlandite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Portlandite is an oxide mineral. It is the naturally occurring form of calcium hydroxide (Ca(OH)₂) and the calcium analogue of brucite (Mg(OH)₂).

Ceramic bovine flame retardant polymer composite material and application thereof

InactiveCN104650441AImprove high temperature strengthImprove flame retardant performanceInsulatorsPolyolefinPlasticizer

The invention provides a ceramic bovine flame retardant polymer composite material based on polyolefin or a thermoplastic polyurethane elastomer. The ceramic bovine flame retardant polymer composite material is prepared from the following components in parts by weight: 30-40 parts of polyolefin resin or the thermoplastic polyurethane elastomer, 25-45 parts of a ceramic forming filler, 20-30 parts of a halogen-free flame retardant, 1-5 parts of a flame-retardant synergist, 1-3 parts of a plasticizer, 0.5-2 parts of an antioxidant and 0.02-0.15 part of a crosslinking agent, wherein the ceramic forming filler is prepared from the following components including low softening point glass powder and a silicate mineral filler. The invention also provides application of the ceramic bovine flame retardant polymer composite material in the field of cables. According to the ceramic bovine flame retardant polymer composite material disclosed by the invention, a dense ceramic bovine product can be formed within a range from 600 DEG C to 1000 DEG C, and the formed ceramic bovine product is good in high-temperature strength and flame retardancy and is also good in mechanical properties under room temperature.

Owner:SICHUAN UNIV

Composition and process for wet stripping removal of sacrificial anti-reflective material

InactiveUS6849200B2Low toxicityEasy to prepareSemiconductor/solid-state device manufacturingPhotosensitive material processingMaterials sciencePortlandite

A composition and process for wet stripping removal of sacrificial anti-reflective silicate material, e.g., from a substrate or article having such material deposited thereon, particularly where the sacrificial anti-reflective material is present with permanent silicate materials desired to be unaffected by the wet stripping composition.

Owner:ENTEGRIS INC

Method for preparing organic and inorganic hybridization modified polyurethane chemical grouting material

The invention discloses a method for preparing an organic and inorganic hybridization modified polyurethane chemical grouting material. The method adopts water-soluble end isocyanate-polyether prepolymer, special expandable phenol-formaldhyde resin and a surfactant to form a component A; and inosilicate liquor, an amine catalyst and an organic tin catalyst form a component B, and the component A and the component B are mixed and stirred uniformly. The chemical grouting material has the advantages of wide raw material sources, low cost, stable performance, appropriate viscosity, accurate gelation time control, low toxic chemical composition content, good flame retardant property, high adhesive strength, high stone forming rate, low permeability, high mechanical strength and good corrosion resistance and aging characteristic.

Owner:HEBEI TONGCHENG MINING TECH

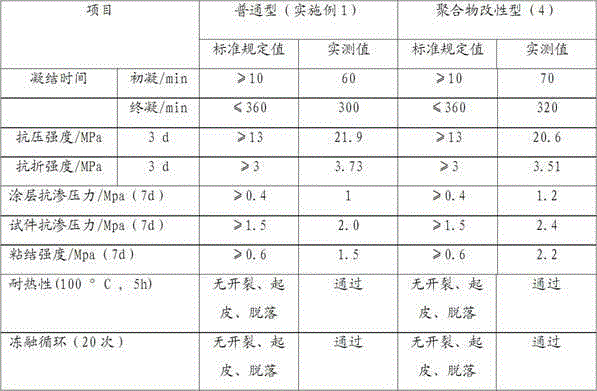

Slow-setting type waterproof mortar having self-repairing function and secondary permeability resistance as well as preparation method thereof

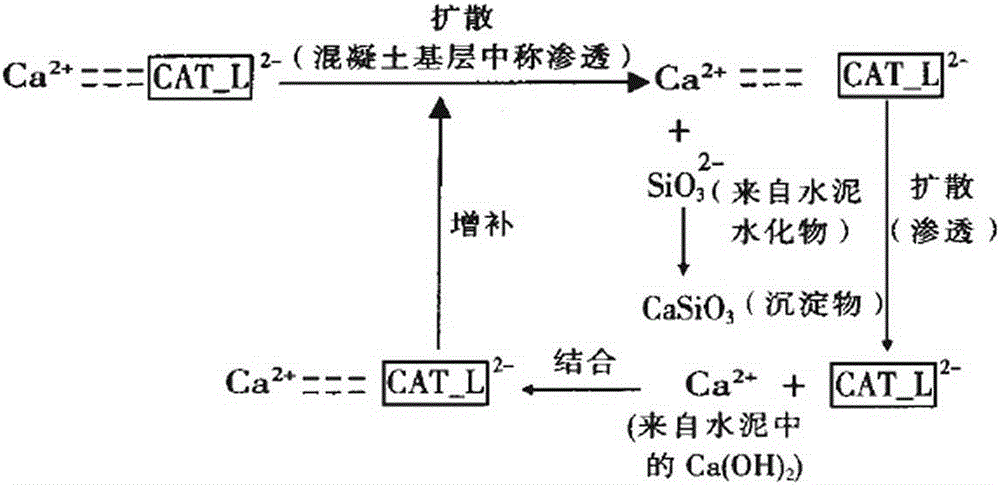

The invention discloses a slow-setting type waterproof mortar having self-repairing function and secondary permeability resistance as well as a preparation method thereof. The slow-setting type waterproof mortar having self-repairing function and secondary permeability resistance is prepared by using the following raw materials and water: a mixed cement, quartz sand, silica fume, heavy calcium, a capillary crystalline active master, a water reducer, an antifoaming agent, a coagulation accelerator and cellulose ether; and the mixed cement is composed of an ordinary portland cement and a quick-setting type sulphoaluminate cement. The slow-setting type waterproof mortar is used for repairing construction, if secondary leakage is happened, the capillary crystalline active master, the repairing mortar and a cement hydration product portlandite in concrete are continuously reacted for realizing self restoration, so that secondary anti-permeability effect can be reached, and secondary or multi-time restoration for regenerated cracks can be avoided.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

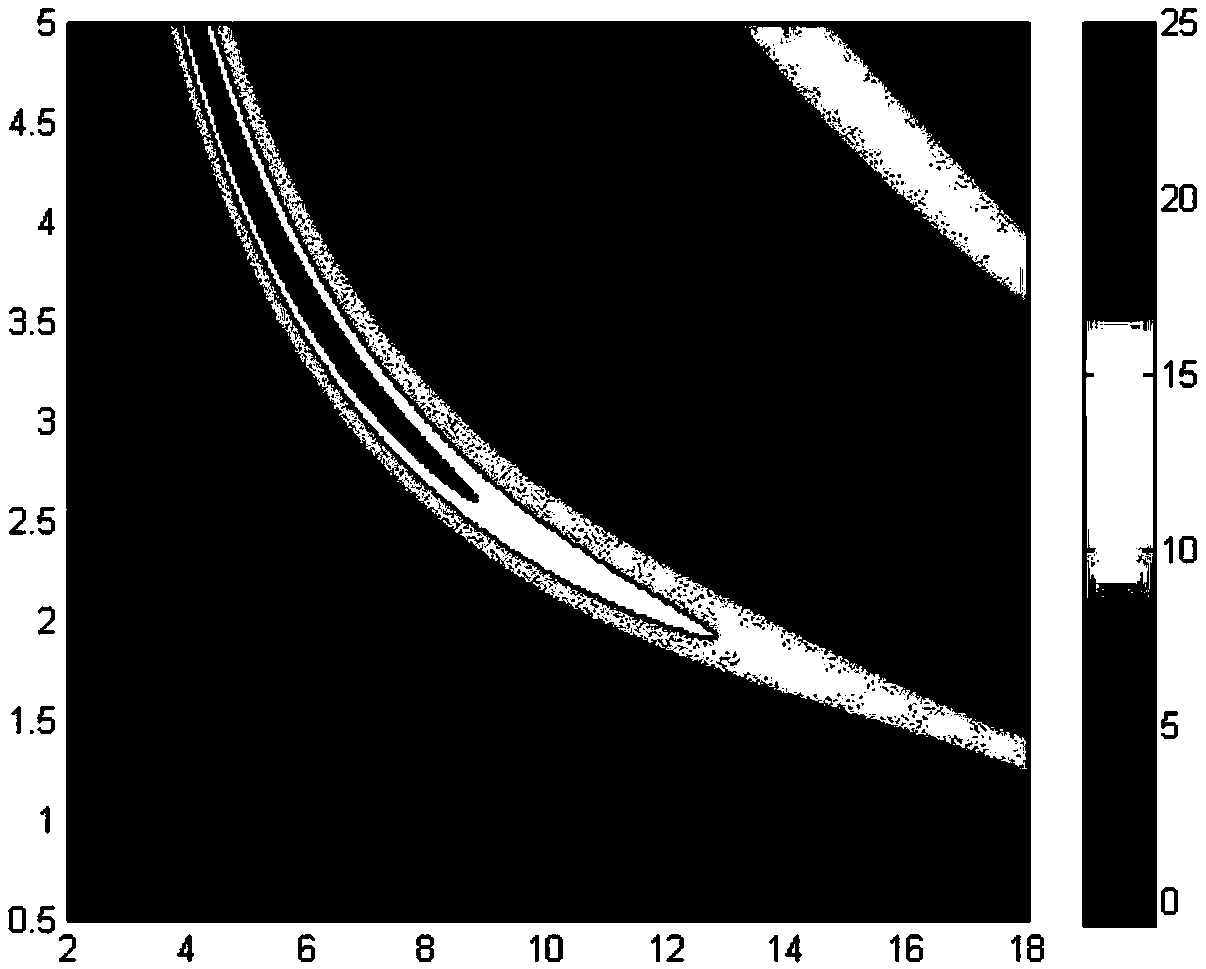

Diatomite/ground limestone composite humidity controlling material and preparation method thereof

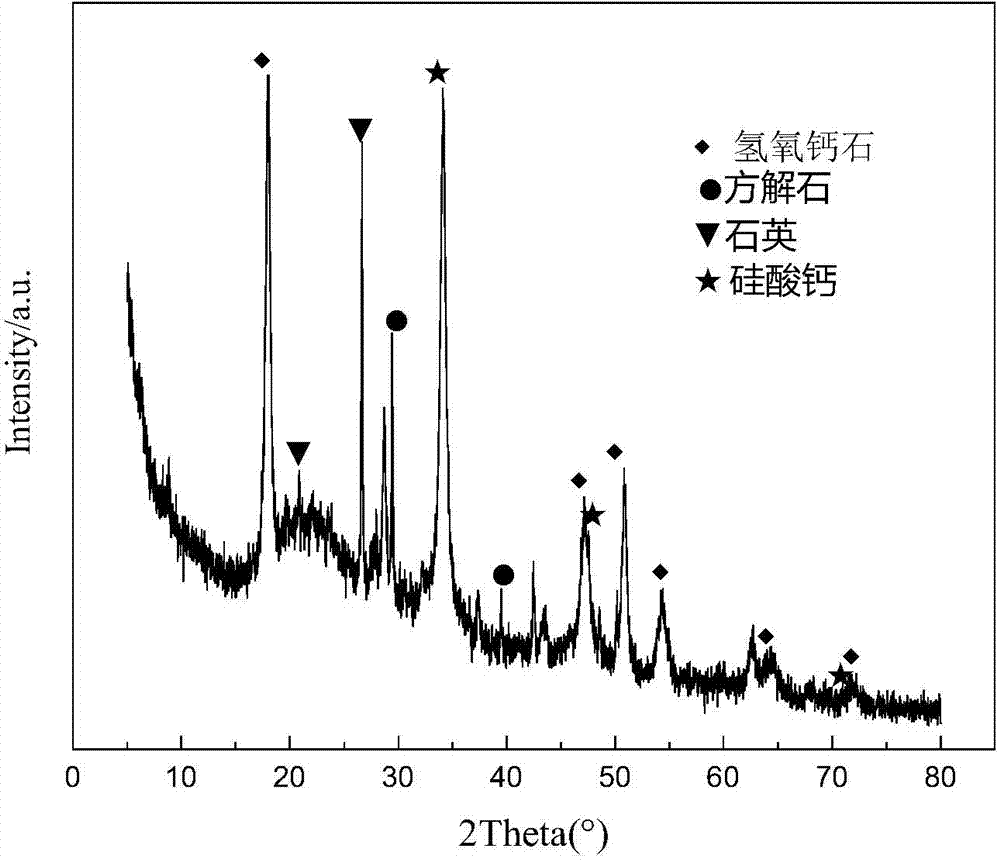

ActiveCN104841361AImproved humidity controlSimple preparation processOther chemical processesCalcium silicateCalcite

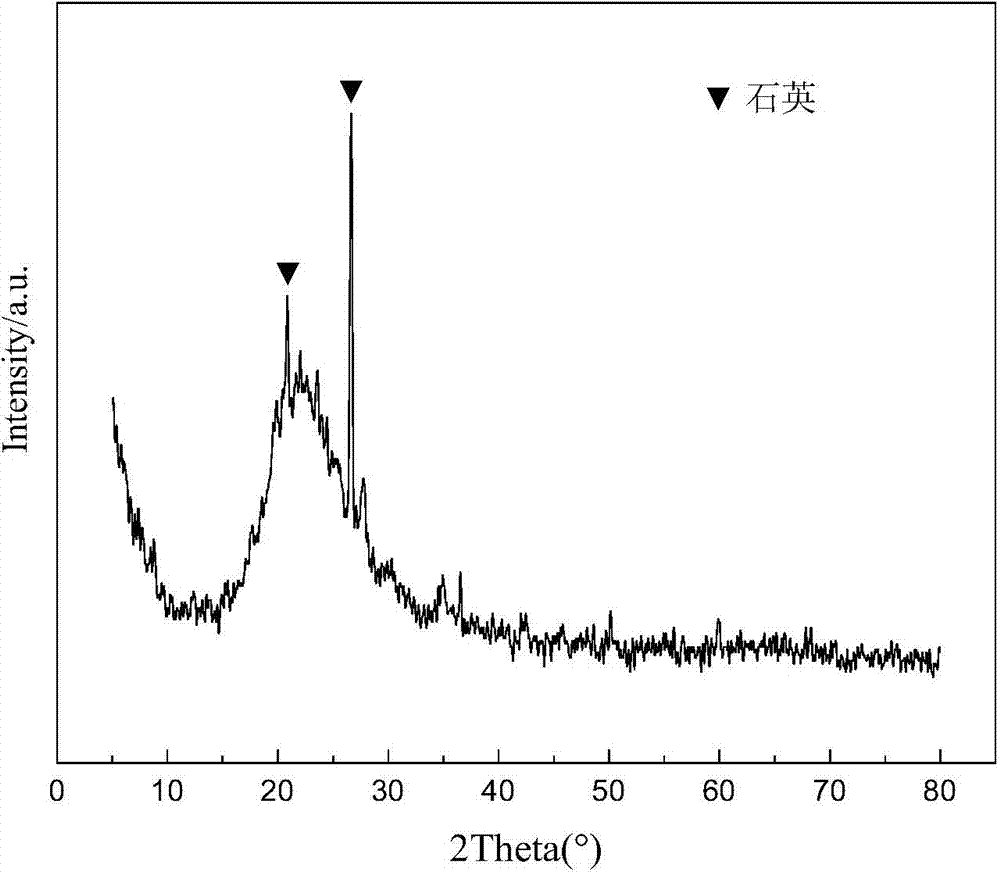

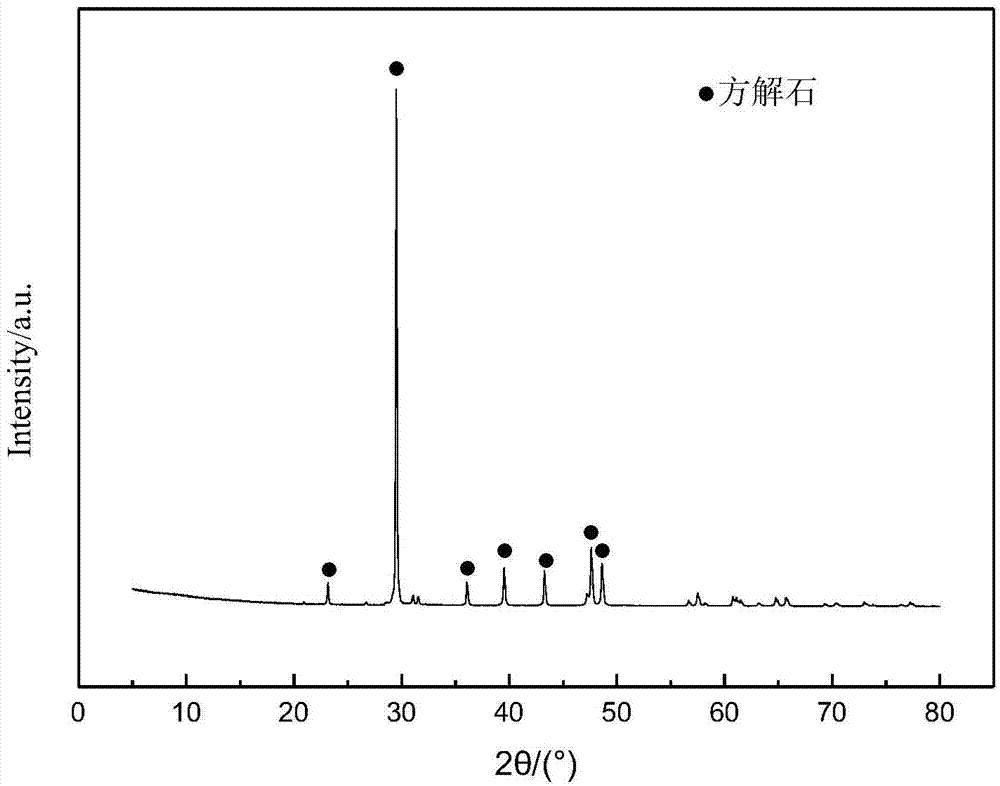

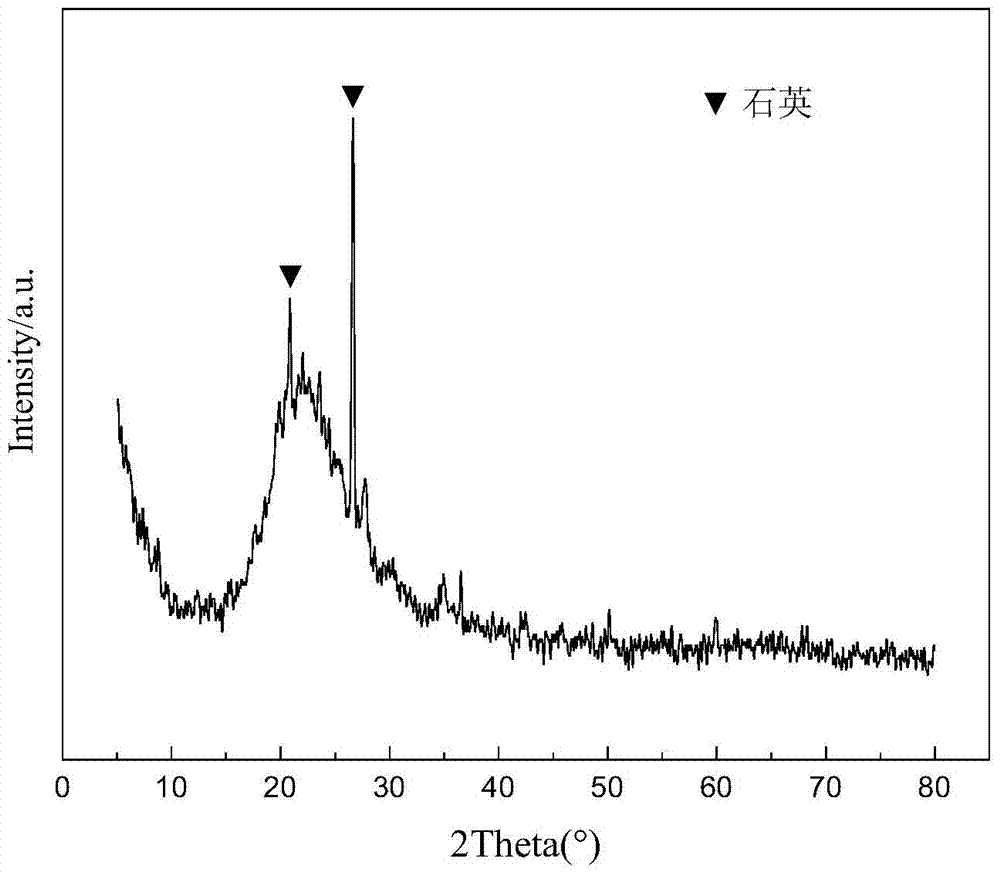

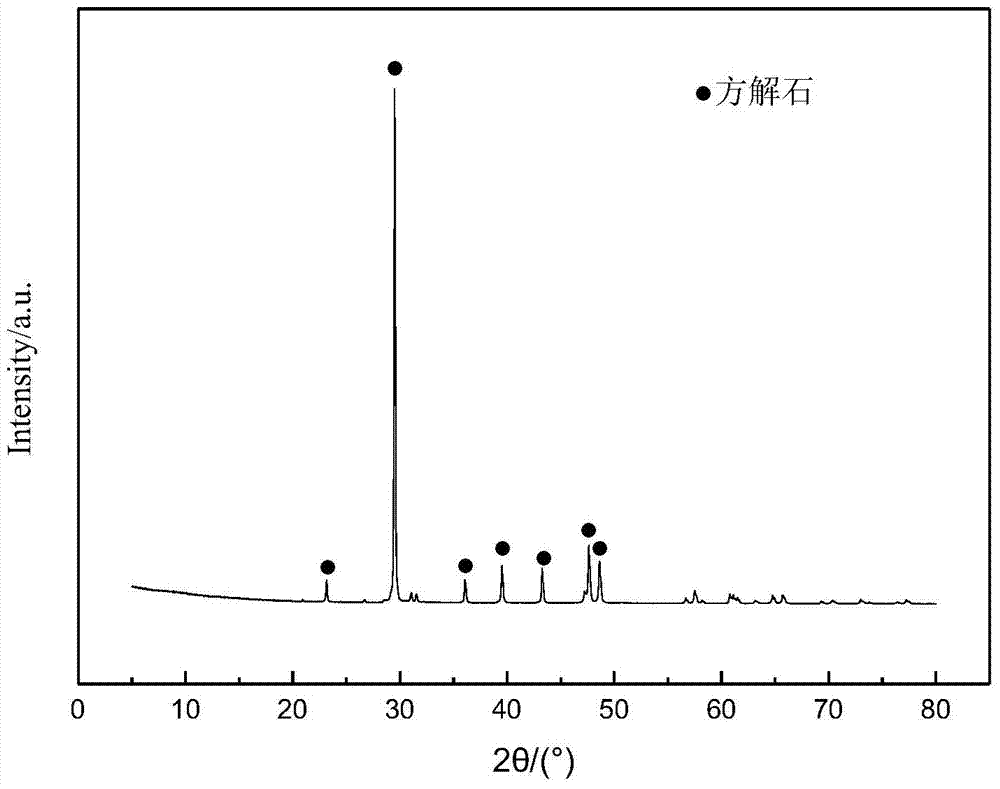

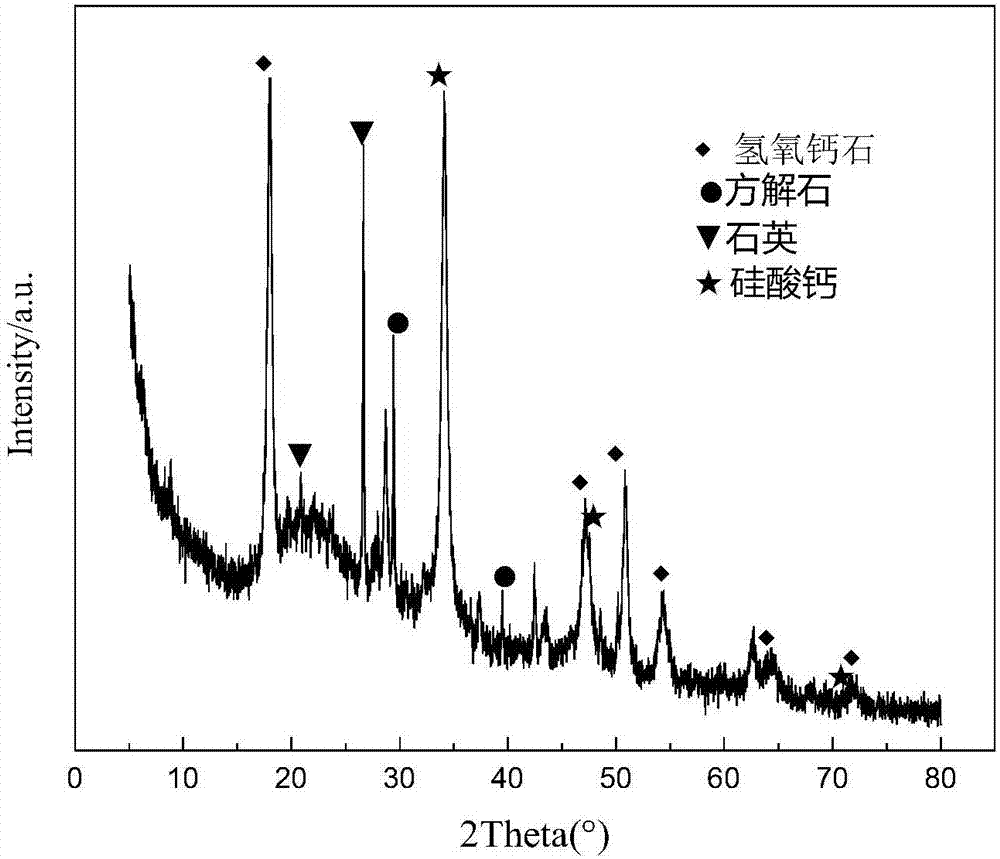

The invention relates to a diatomite / ground limestone composite humidity controlling material and a preparation method thereof. The preparation method comprises the following steps: by taking diatomite and ground limestone as raw materials, adopting a uniform mixing-roasting method, batching and uniformly mixing the diatomite and ground limestone according to a mass ratio of 1:(0.5-1.5), feeding the mixture into a rotary furnace, roasting at 600-850 DEG C for 1.0-3.0 hours, thereby obtaining the product. According to the composite humidity controlling material, main mineral components of the composite humidity controlling material are calcium silicate, portlandite, calcite and dehydrated diatomite, the nitrogen adsorption specific surface area is more than or equal to 8m<2> / g, the pore volume is more than or equal to 0.02cm<3> / g, and the mean pore size is 8-15nm. According to the composite humidity controlling material prepared by the method disclosed by the invention, the moisture absorption performance is obviously improved compared with the moisture absorption performance of a pure diatomite humidity controlling material, the ambient temperature is 30 DEG C, and the maximum moisture absorption content reaches 13 percent and 10 percent or more under the relative humidity of 90 percent and 80 percent; and moreover, the balanced moisture content reaches 13 percent and 9 percent or more and is improved by more than two times compared with that of pure diatomite, and the composite humidity controlling material adopts a simple preparation process, is low in production cost and has good application prospects.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

Molding material mixtures containing metal oxides of aluminum and zirconium in particulate form

ActiveUS20150306658A1High strengthImprove surface qualityFoundry mouldsFoundry coresMixed oxideShell molding

The invention relates to mold material mixtures containing at least one aluminum oxide in the alpha phase and / or at least one aluminum / silicon mixed oxide, except for aluminum / silicon mixed oxides having a layered silicate structure, as a particulate metal oxide, in combination with refractory mold base materials and a water glass-based binder system. The mold material mixtures are used for the production of molds and cores for the foundry industry.

Owner:ASK CHEM LP

Preparation method of gypsum mine slag cement-based thick-type steel structure fireproof, anticorrosive, thermal-insulation integrated coating

InactiveCN106867345AHigh strengthHigh bonding strengthFireproof paintsChemical industrySlagThermal insulation

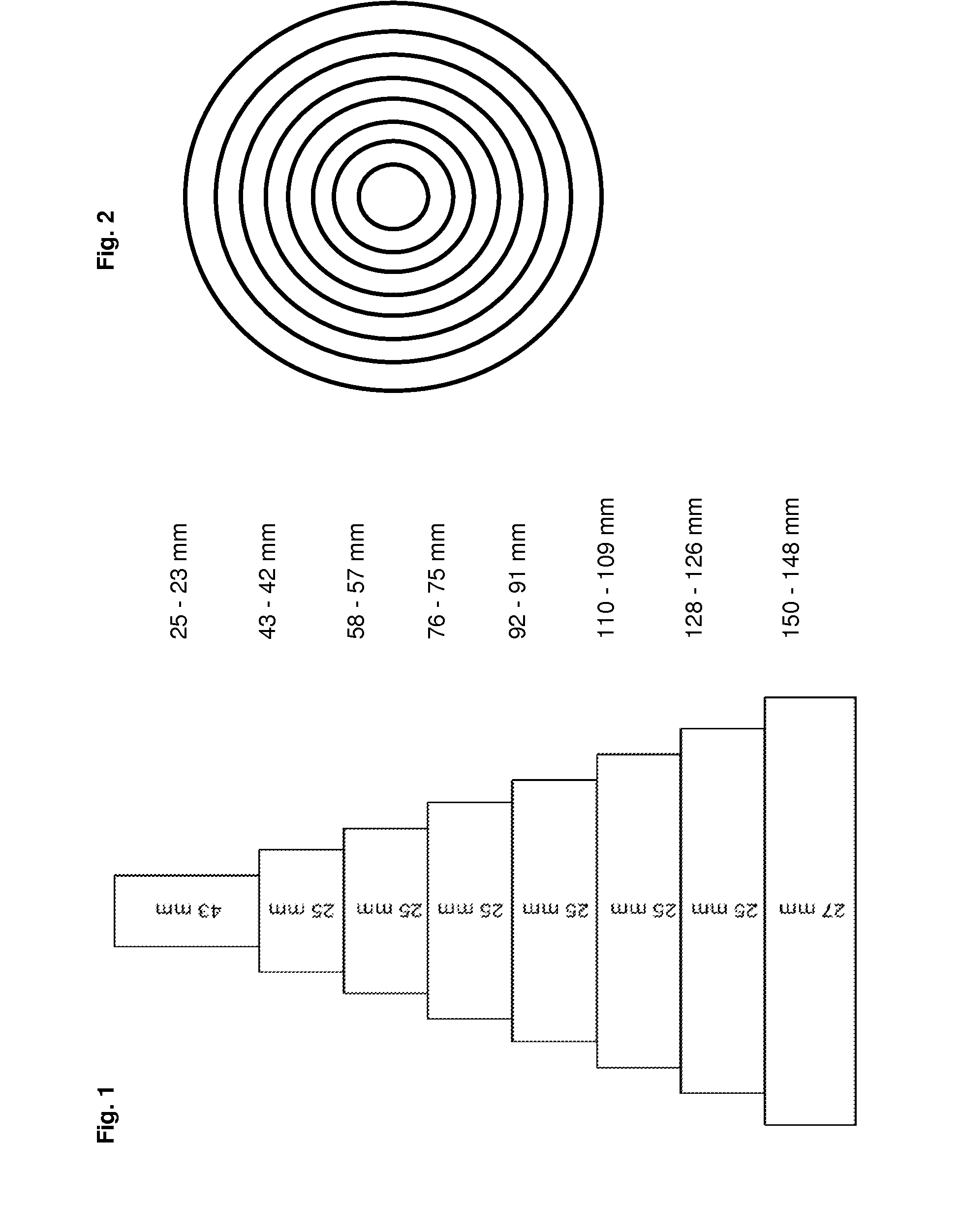

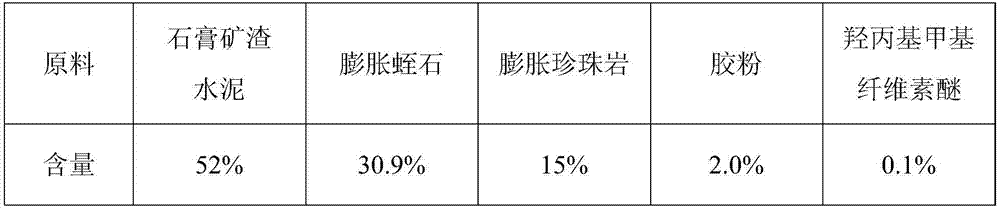

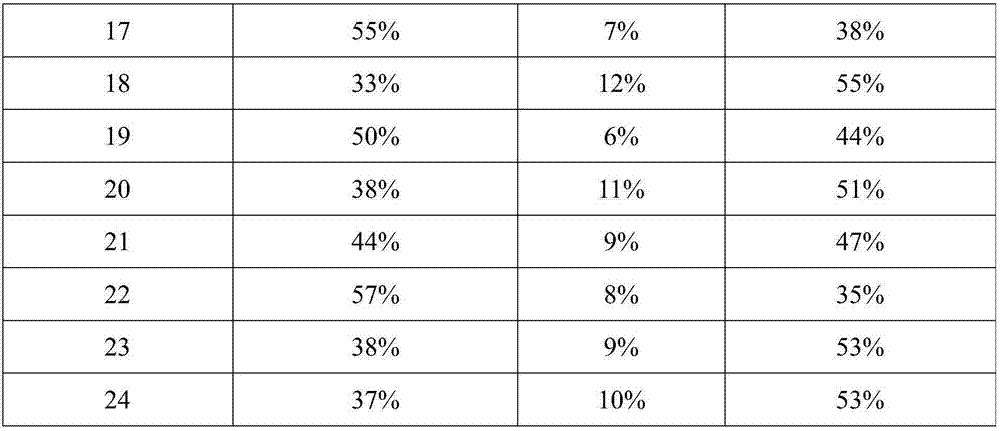

The invention discloses a preparation method of a gypsum mine slag cement-based thick-type steel structure fireproof, anticorrosive, thermal-insulation integrated coating. According to the preparation method, gypsum mine slag cement is obtained via mixing of gypsum, blast furnace slag, and Portland cement clinker; an ingredient A is obtained via mixing of acrylic acid waterproof elastic emulsion, styrene-acrylic emulsion, vinyl chloride-vinylidene chloride copolymer emulsion, mica powder, titanium dioxide powder, iron red powder, ammoniacal liquor, hydroxyethyl cellulose ether, a dispersant, an antifoaming agent, an antiseptic, a film forming auxiliary agent, and water; a fireproof steel structure anticorrosive primer is composed of the ingredient A and the gypsum mine slag cement; a thick-type steel structure fireproof thermal-insulation coating is obtained via mixing of expanded vermiculite, expanded perlite, rubber powder, hydroxyethyl cellulose ether, and the gypsum mine slag cement; and a finished product is obtained via steel structure surface cleaning treatment, coating of the fireproof steel structure anticorrosive primer, polishing, and coating of the thick-type steel structure fireproof thermal-insulation coating. The comprehensive cost is low; the preparation method is friendly to the environment, can be widely used for fire protection, corrosion protection, thermal insulation, and energy reduction of different kinds of steel structures.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

Glassy calcium phosphate particulates, coatings and related bone graft materials

ActiveUS20110300188A1High coating strengthImprove substrate adhesionBiocidePowder deliveryActive agentAntibiotic Y

Calcium phosphate and related coating powder particles comprising a surface component comprising a silicate content, plasma sprayed coatings thereof on implantable medical / dental devices, and bone grafting materials of such coated particles. Optionally, biologically active agents such as bone morphogenetic proteins, growth factors, analgesics, and antibiotics can be incorporated therein.

Owner:CAP BIOMATERIALS

A kind of resin type silicate wood modifier and preparation method of modified material thereof

ActiveCN104044193BImproves loss resistanceGood dimensional stabilityWood impregnation detailsTougheningPollution

The invention belongs to a resin type silicate wood modifier and a preparation method of a modified material of the modifier. According to the preparation method, the resin type silicate wood modifier is prepared by taking melamine, formaldehyde, urea and soluble sodium silicate as main raw materials as well as respectively taking polyvinyl alcohol and diethylene glycol as a toughening agent and a stabilizer; the resin type silicate wood modifier can be stably stored for a long time and can be repeatedly recycled. The modifier has the advantages that the dimensional stability, the density, the surface hardness, the anti-bending strength, the anti-bending elastic modulus, the impact toughness and the wear resistance of artificial forest wood processed by virtue of the modifier are substantially improved, the modifier has the advantages that the flame retardance and environment-friendly effect are achieved, no pollution is caused to a human body and the environment, the leachability resistance of the modifier in the processed wood is improved, and the application value of the artificial forest wood is improved.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

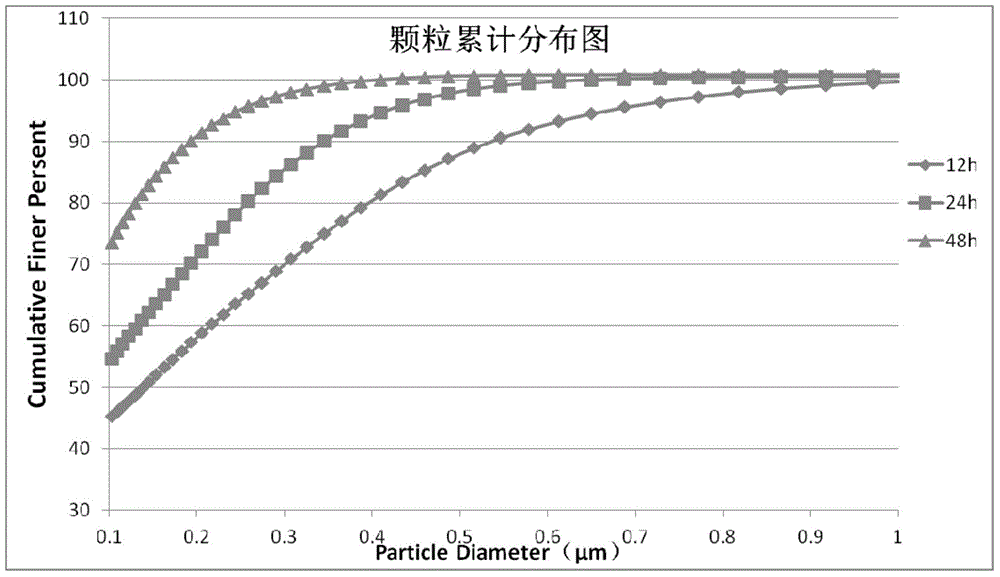

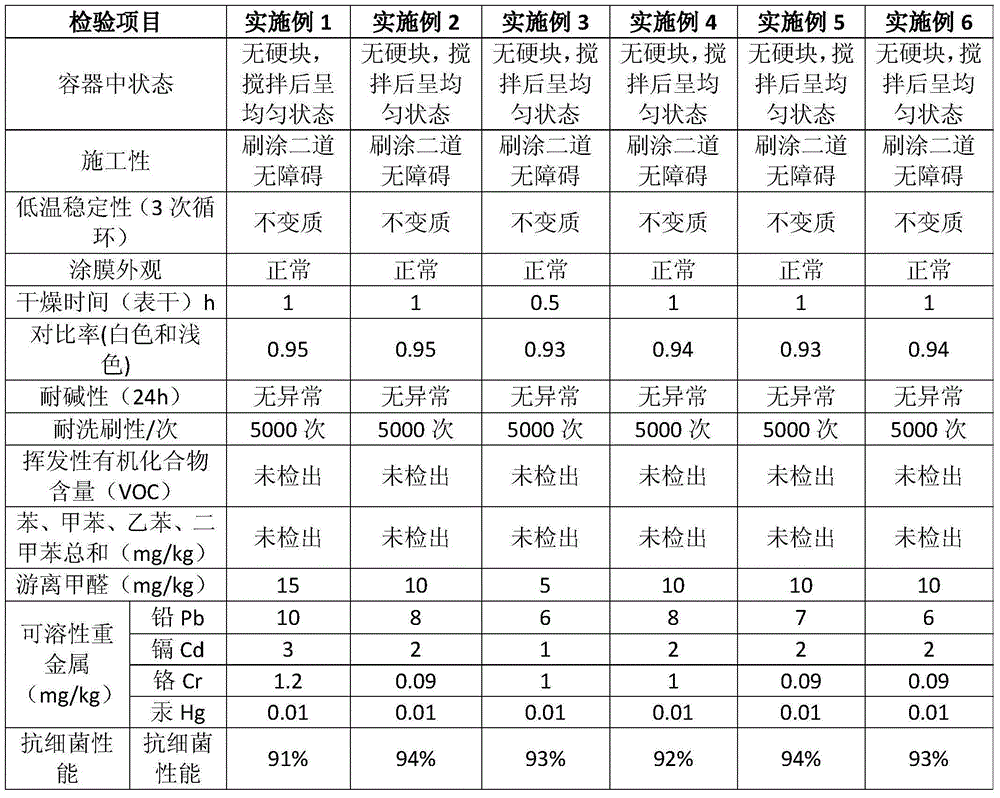

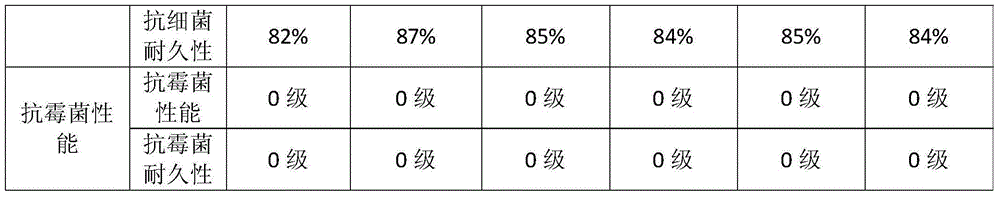

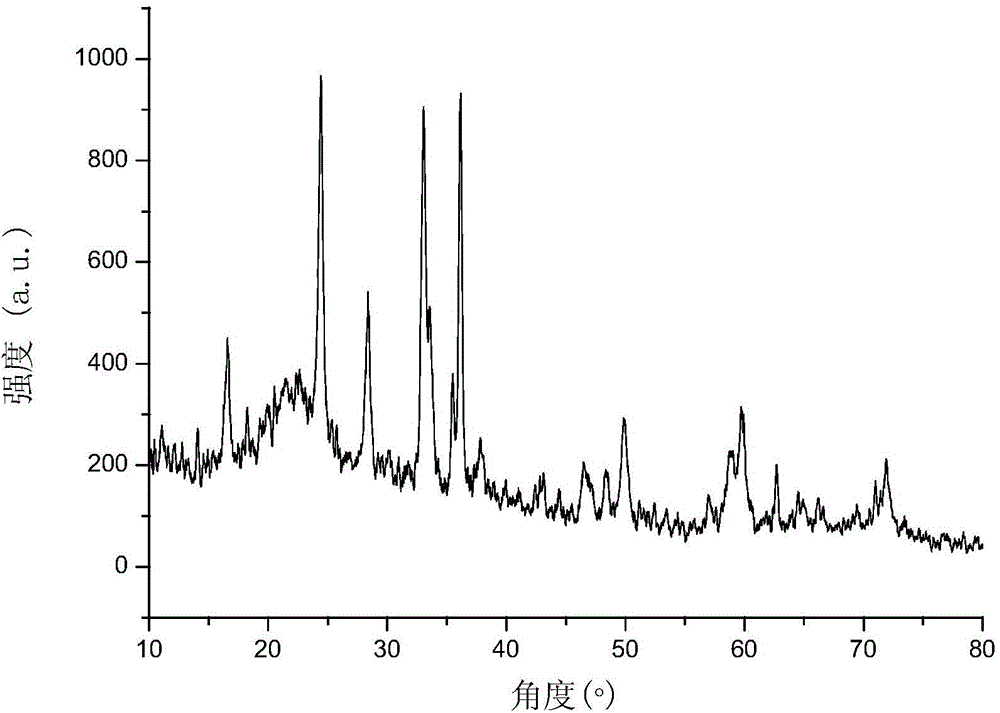

Nano antimicrobial internal wall paint containing illite-montmorillonite clay and preparation method thereof

InactiveCN105111859AGood compatibilityDoes not affect physical and chemical propertiesAntifouling/underwater paintsPaints with biocidesWater basedHigh energy

The invention discloses a nano antimicrobial internal wall paint containing illite-montmorillonite clay and a preparation method thereof, belonging to the field of phyllosilicate clay minerals. The nano antimicrobial internal wall paint is composed of an illite-montmorillonite clay nano slurry and a water-based internal wall latex paint, wherein the illite-montmorillonite clay nano slurry accounts for 10-20 wt% of the total nano antimicrobial internal wall paint. The preparation method comprises the following steps: (1) crushing natural illite-montmorillonite clay mineral, and adding water to obtain a slurry; (2) regulating the pH value of the slurry, and dispersing; (3) carrying out screening, iron removal and bleaching on the slurry; (4) grinding the bleached slurry by a high-energy density stirring grinder to obtain a nano slurry; and (5) mixing the nano slurry with the water-based internal wall latex paint, and sufficiently stirring uniformly to obtain the nano antimicrobial internal wall paint containing illite-montmorillonite clay. The nano antimicrobial internal wall paint has excellent anti-mildew and antimicrobial effects, and can obviously lower formaldehyde, methylbenzene, dimethylbenzene and other toxic harmful substances in the paint.

Owner:SINO NANOTECH HLDG

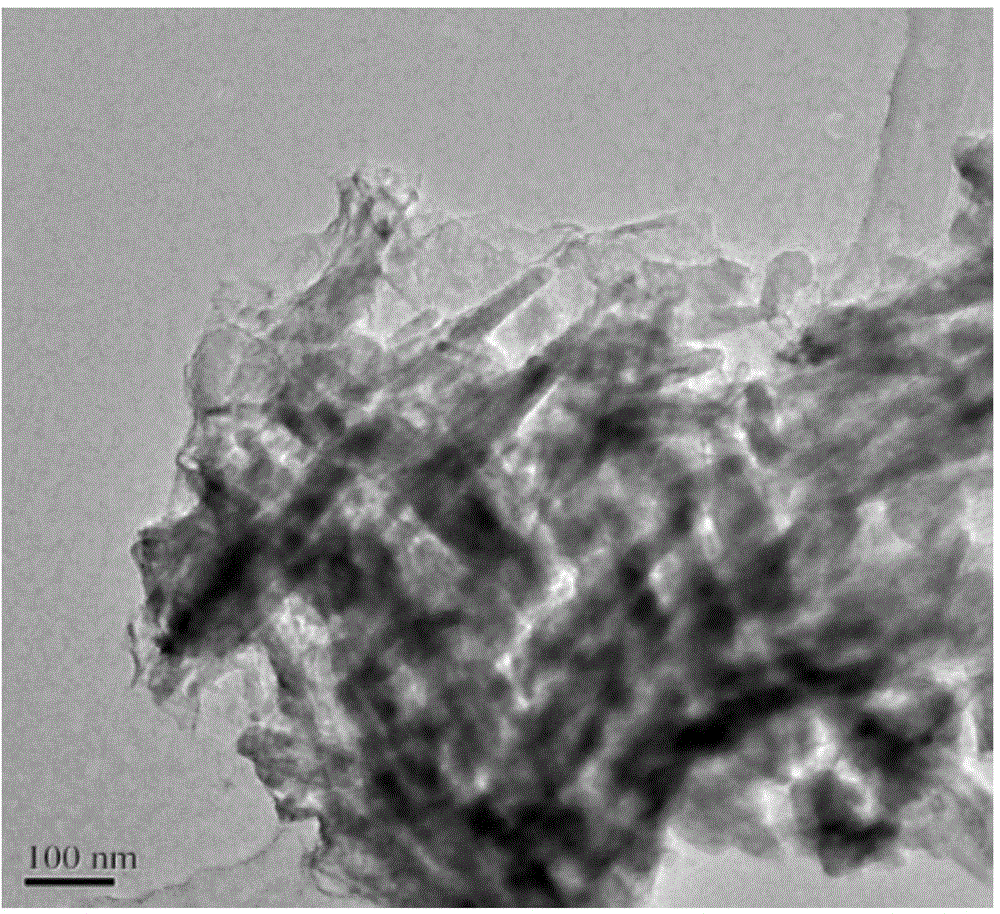

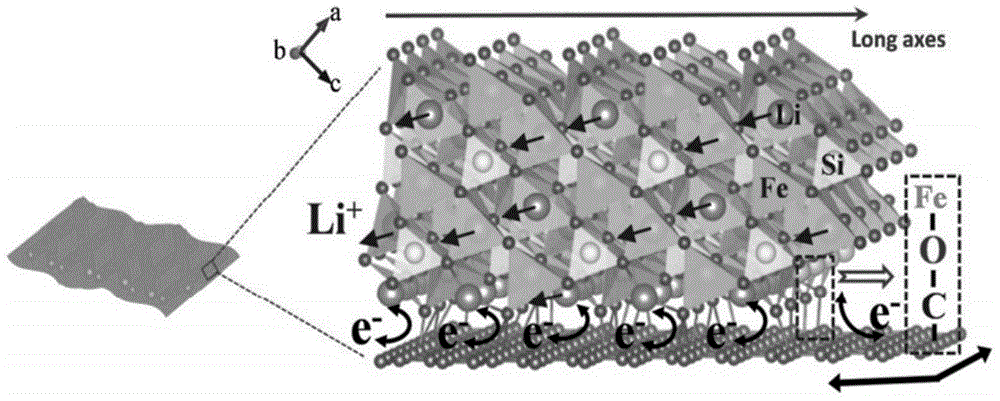

Silicate electrode material and preparation method thereof

ActiveCN106159203AImprove electrochemical activityImprove conductivityCell electrodesHigh rateComposite electrode

The present invention discloses a silicate composite electrode material and a preparation method thereof. According to the silicate composite electrode material provided by the present invention, a silicate Li2MSiO4 material and a high-conductivity carbon material are connected through chemical bonding to form a high-activity composite electrode material, wherein M is Fe, Co, Mn or Ni. According to the silicate electrode material provided by the present invention, the lithium ion / electron transmission performance of the silicate electrode material is enhanced through a chemical bonding function, so that the silicate electrode material has excellent electrochemical activity when serving as a positive pole or negative pole of a lithium ion battery; meanwhile, use of a carbon material further enhances the conductivity of the silicate electrode material; and therefore, a foundation is laid for preparation of a lithium ion battery with high rate performance. The silicate electrode material provided by the present invention is simple in preparation method and low in production cost and therefore is very suitable for large-scale industrial production.

Owner:未名电池科技(深圳)有限公司

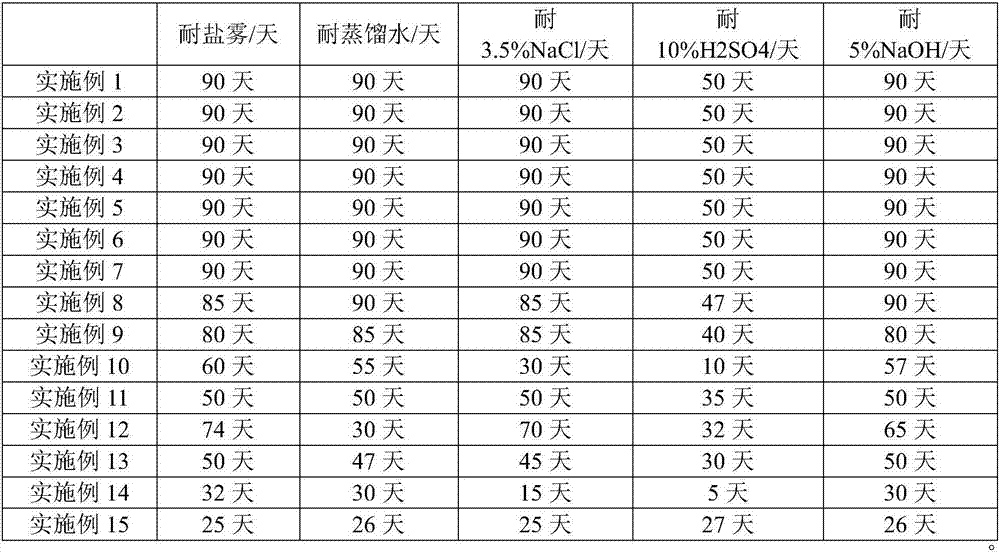

Preparation method of silicate-mineral-modified reduced graphene oxide, application of silicate-mineral-modified reduced graphene oxide

ActiveCN107266951AImprove the shortcomings of incompatibilityGood dispersionInorganic pigment treatmentGrapheneSilicate mineralsMaterials science

The invention discloses a preparation method of reduced silicate-mineral-modified reduced graphene oxide, application of the silicate-mineral-modified reduced graphene oxide, and belongs to the technical field of new materials. Stable silicate-mineral-modified reduced graphene oxide compound powder is prepared by adding a reducing agent and silicate mineral modifier into graphene oxide (GO) dispersion liquid, and compounding the silicate mineral modifier and reduced graphene oxide (rGO) under the action of a hydrogen bond according to a reduction-condensation method. The compound powder can be dispersed in water again, and is mixed with polymer emulsion through a direct blending manner to obtain stable compound emulsion which is used for preparing a waterborne anti-corrosion coating. The silicate-mineral-modified reduced graphene oxide is added, so that the anti-corrosion performance of the coating can be improved greatly, and the coating is free from falling, bubbles, rust and corrosion after soaked in the distilled water, sodium chloride solution, sulfuric acid solution and sodium hydroxide solution for 90 days.

Owner:BEIJING UNIV OF CHEM TECH

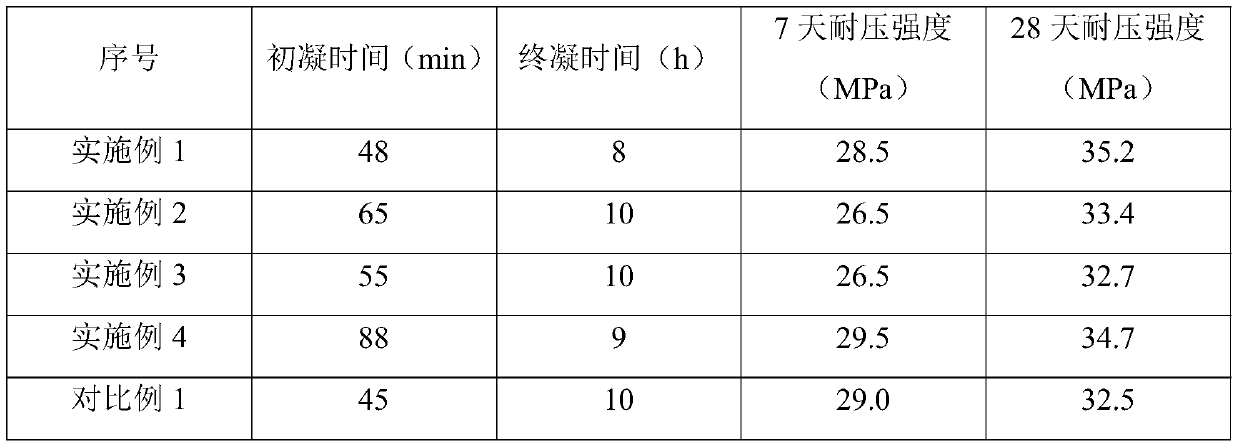

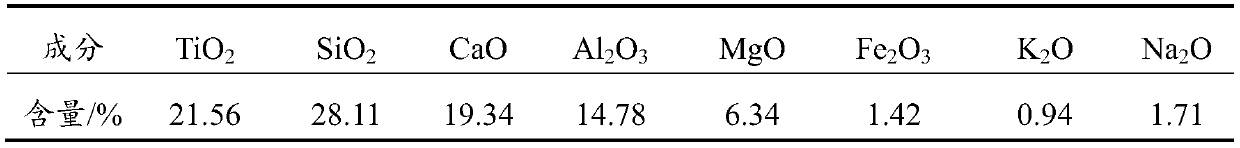

Titanium slag cement, preparation method and application thereof

Relating to the technical field of inorganic non-metallic materials, the invention discloses titanium slag cement, a preparation method and application thereof. The titanium slag cement contains titanium extraction tailings, an activator, a reinforcing agent, an auxiliary reinforcing agent and an early strength agent; wherein the titanium extraction tailings contain 25-30wt% of calcium oxide, 20-25wt% of silicon dioxide, 5-10wt% of titanium dioxide, 5-7wt% of fixed carbon, 7-8wt% of calcium chloride and magnesium chloride, 10-20wt% of aluminum oxide and 5-10wt% of magnesium oxide. The titaniumextraction tailings are adopted as the main raw material to prepare titanium slag cement, while the titanium slag cement production cost is reduced, and the resource utilization rate is increased, the titanium slag cement also has the characteristics of high strength and quick setting and hardening, and the performance indexes meet the 325R grade index requirements of ordinary Portland cement, therefore the titanium slag cement can be applied to cement blocks, cement pavement bricks, mortar, roadbed water stable layers, soil body curing materials and temporary engineering.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

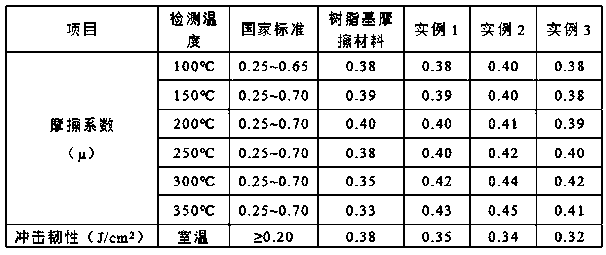

Composite salt binder composite friction material and preparation method thereof

ActiveCN109737159AImprove flame retardant performanceCuring shrinkage is smallOther chemical processesFriction liningFiberNon toxicity

The invention discloses a composite salt binder composite friction material and a preparation method thereof. Main components of the composite friction material are composed of a silicate binder, a phosphate binder, additive, a curing agent, a toughness adjusting agent, reinforced fiber, a friction performance adjuster and filler. The silicate binder mainly takes sodium water glass and potash water glass as raw materials. The phosphate binder mainly takes liquid aluminum dihydrogen phosphate as a raw material, and is mixed with calcium fluoride additive to prepare composite type composite saltbinder serving as a friction material binder. According to the composite friction material, a composite inorganic salt solution mixture serves as a binder, the characteristics of good fire resistance, environmentally friendliness, non-toxicity, simple preparation technology and high temperature resistance of the inorganic salt binder are utilized, and a resin binder is replaced. A silicate and phosphate compound has excellent bonding performance to carbon fiber and powdery materials such as barite and aluminum oxide, the stability of friction coefficients of medium-temperature and high-temperature areas is effectively improved, the problem of heat fading of a common resin-based friction material is solved, and the safety of the friction material in actual use is improved.

Owner:大连理工(营口)新材料工程中心有限公司

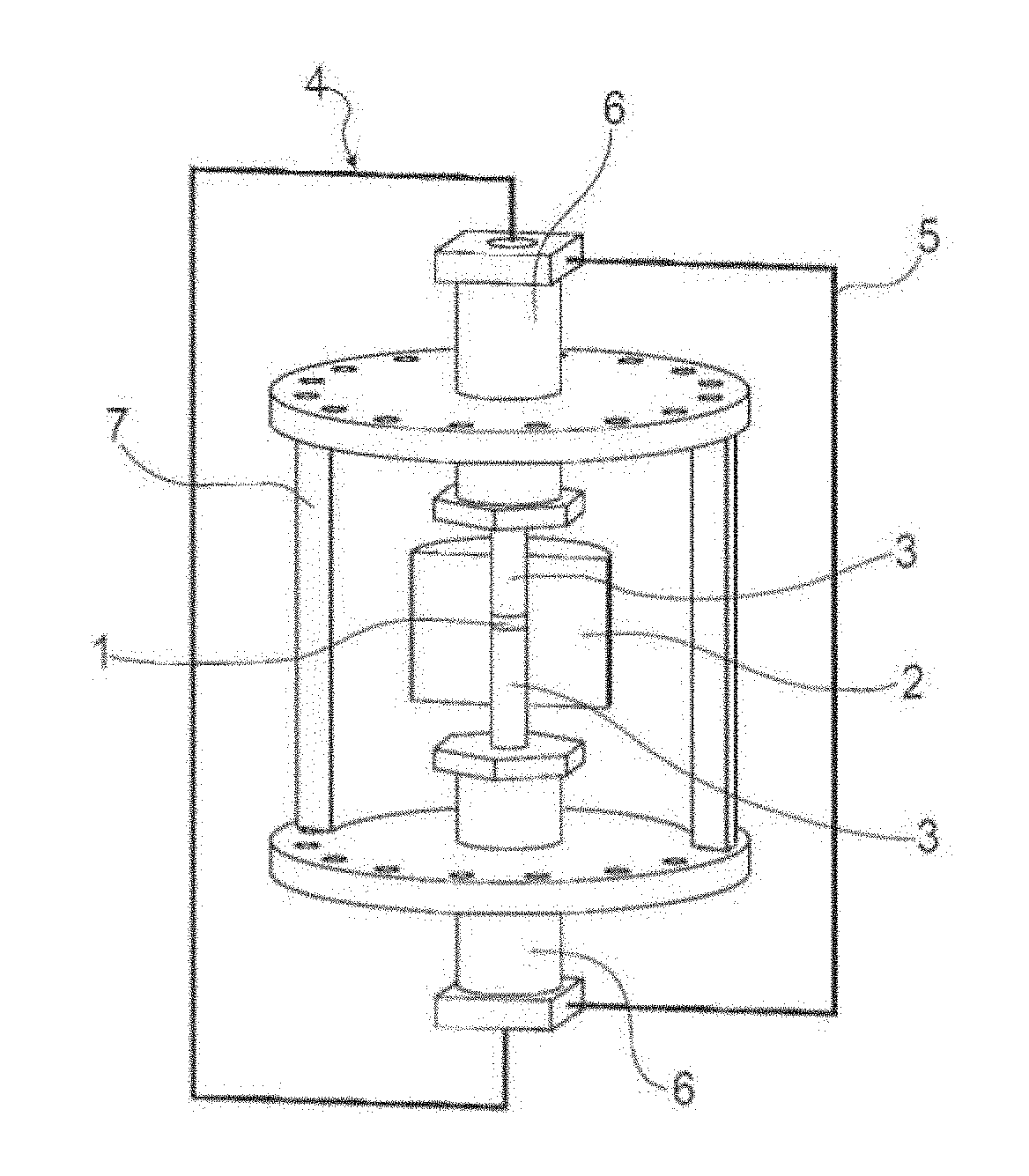

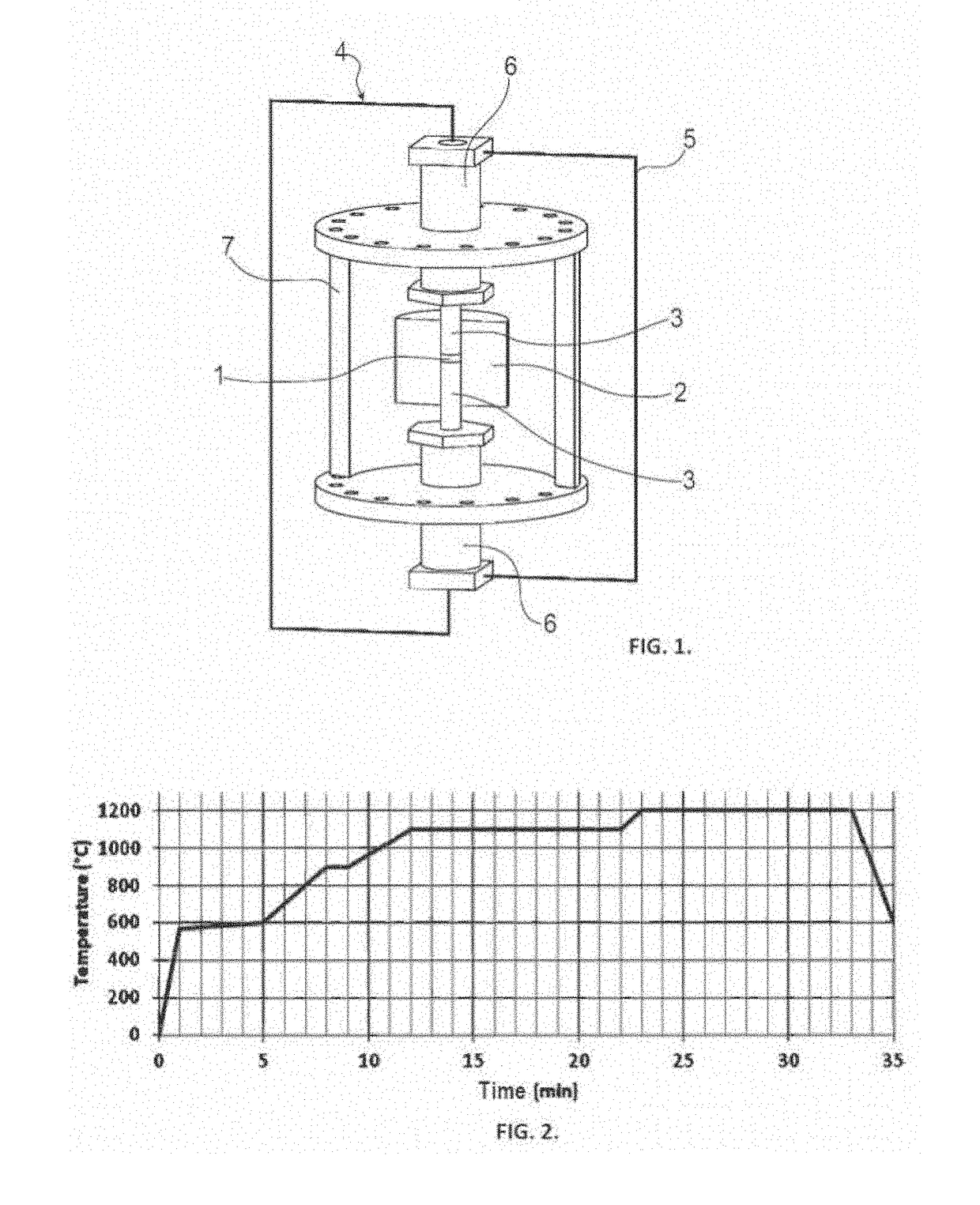

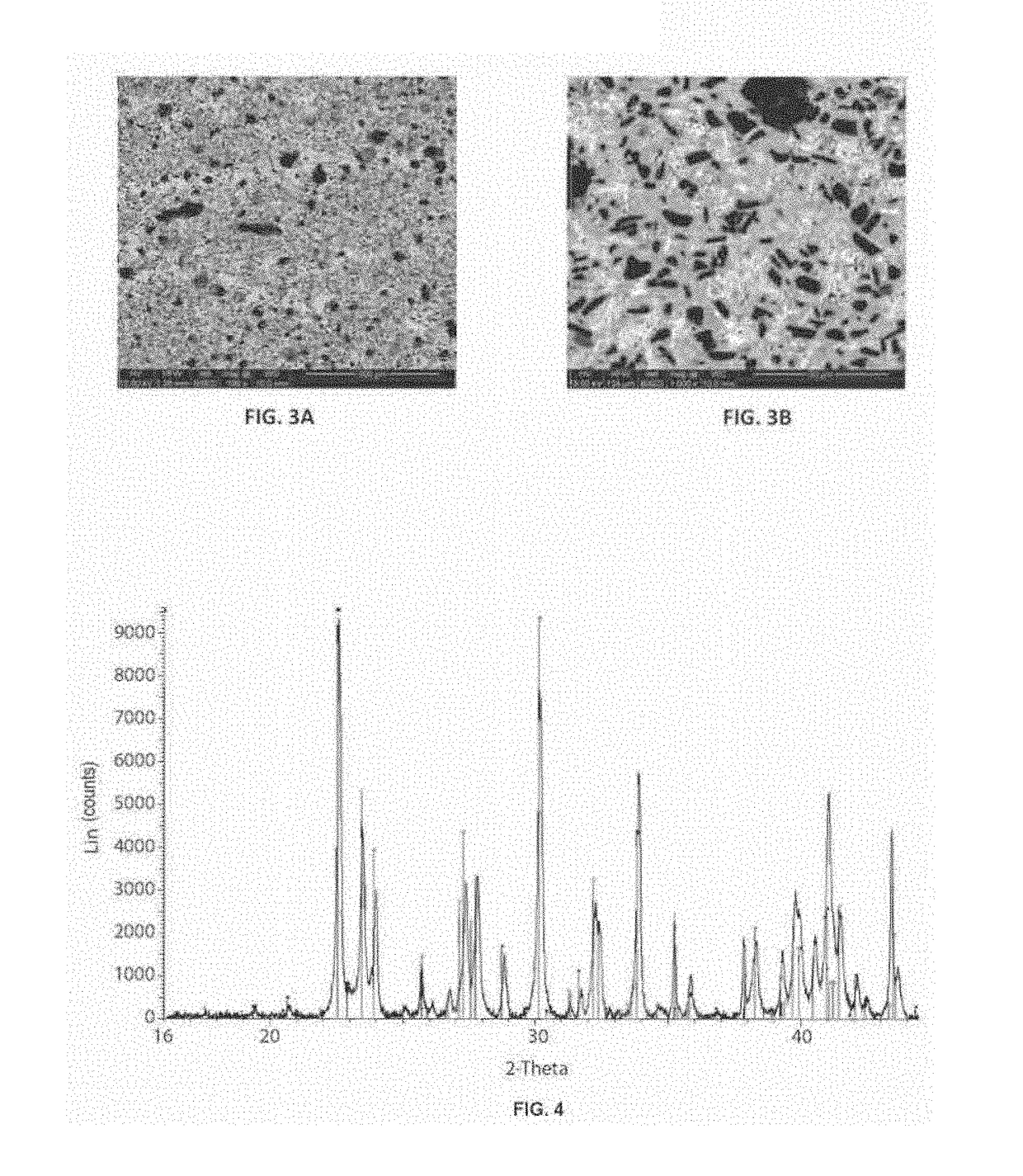

Method for preparing a material made from aluminosilicate and method for preparing a composite material having an aluminosilicate matrix

ActiveUS20180009669A1Uniform microstructureAluminium silicatesRadiating element housingsPolymer scienceAluminium hydroxide

The invention relates to a method for preparing a material based on an aluminosilicate selected from barium aluminosilicate BAS, barium-strontium aluminosilicate BSAS, and strontium aluminosilicate SAS, said aluminosilicate consisting of aluminosilicate with a hexagonal structure, characterised in that it includes a single sintering step in which a mixture of powders of precursors of said aluminosilicate, including an aluminium hydroxide Al(OH)3 powder, are sintered by a hot-sintering technique with a pulsed electric field SPS; whereby a material based on an aluminosilicate, said aluminosilicate consisting of an aluminosilicate with a hexagonal structure is obtained. The material based on an aluminosilicate prepared by said method can be used in a method for preparing a composite material consisting of an aluminosilicate matrix reinforced by reinforcements made of metalloid or metal oxide.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

Method for preparing continuous SiO2/nanocrystalline metal aerogel fiber with catalytic performance by adding nanocrystalline metal in situ

ActiveCN105603577AHas catalytic propertiesAdjust the size of the specific surface areaInorganic material artificial filamentsWet spinning methodsFiberSolvent

The invention relates to a method for preparing continuous SiO2 / nanocrystalline metal aerogel fiber with catalytic performance by adding nanocrystalline metal in situ. The method comprises the steps that salicate is prepared into a spinning solution, then, a nanocrystalline metal catalyst is added into the spinning solution, the spinning solution is added into coagulating bath, reaction wet spinning is conducted, orthosilicic acid / silicate fiber containing the nanocrystalline metal catalyst is obtained, winding and room temperature ageing are conducted, the orthosilicic acid / silicate fiber is washed to be neutral through deionized water, solvent replacement is conducted through deionized water or ethyl alcohol, drying is conducted, and the continuous SiO2 / nanocrystalline metal aerogel fiber is obtained. The method has the advantages that raw materials are low in price and easy to obtain, the reaction process is simple, and spinnability is good. The continuous SiO2 / nanocrystalline metal aerogel fiber with catalytic performance prepared through the method has abundant holes, and is high in specific surface area, and resistant to high temperature and chemical corrosion; the specific surface area of the fiber and the content of nanocrystalline metal in the fiber are adjustable, and the method has application prospects in catalysis and other fields.

Owner:DONGHUA UNIV

A kind of carbon fiber mat reinforced inorganic polymer matrix composite material and preparation method thereof

The invention provides a carbon fiber felt reinforcement inorganic polymer matrix composite and a preparation method of the carbon fiber felt reinforcement inorganic polymer matrix composite, and relates to an inorganic polymer matrix composite and a preparation method of the inorganic polymer matrix composite, in particular to the carbon fiber felt reinforcement inorganic polymer matrix composite and a preparation method of the carbon fiber felt reinforcement inorganic polymer matrix composite. The problems that an existing inorganic polymer material is poor in mechanical performance and low in toughness and the operation for adding short carbon fiber is complex are solved. The product is prepared through inorganic polymer material pulp and carbon fiber felt. The inorganic polymer material pulp is prepared through potassium hydroxide, silica sol and aluminosilicate powder. The method includes the steps of firstly, preparing the inorganic polymer material pulp; secondly, washing the carbon fiber felt; thirdly, preparing a prefabricated material blank; fourthly, preparing the carbon fiber felt reinforcement inorganic polymer matrix composite. The method is simple in process, low in cost, environmentally friendly and capable of being use for large-area preparation, and the prepared composite is good in mechanical property and wider in application range.

Owner:HARBIN INST OF TECH

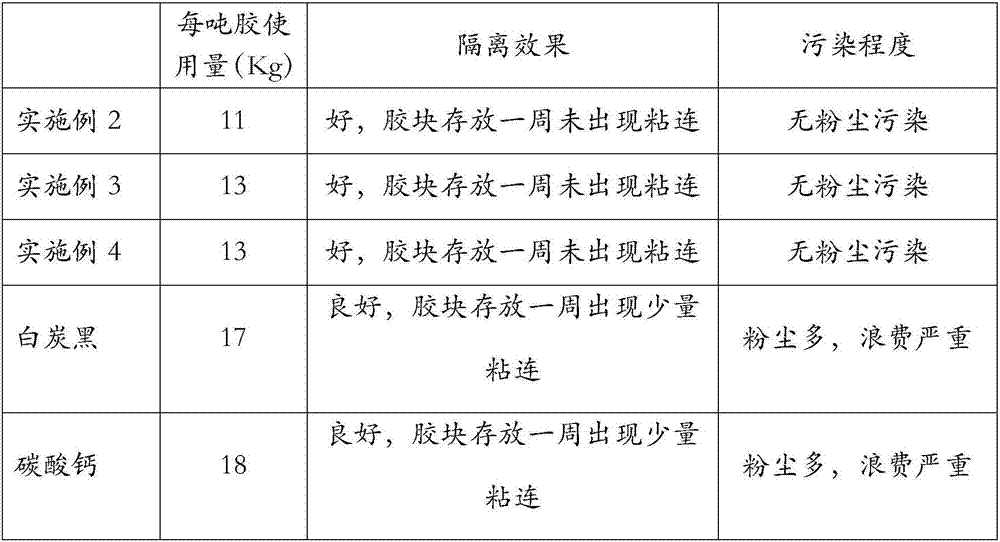

Rubber block isolating agent for breaking natural rubber, and preparation method thereof

The invention discloses a rubber block isolating agent for breaking natural rubber, and a preparation method thereof. The rubber block isolating agent comprises the following components in parts by weight: 10 to 20 parts of fatty acid ester, 10 to 20 parts of fatty acid, 1 to 10 parts of organic filler, and 60 to 75 parts of an inorganic carrier, wherein the fatty acid ester is one or more of pentaerythritol tetrastearate, glyceryl stearate and propylene glycol stearate; the fatty acid is one or more of stearic acid, palmitic acid and lauric acid; the organic filler is one or combination of fatty acid calcium and fatty acid zinc; the inorganic carrier is one or combination of silicate filler and calcium carbonate filler. The rubber block isolating agent can be combined with a broken rubber block quickly to isolate the rubber block so as to prevent adhesion again, dust cannot be generated during spraying, the usage of the isolating agent is reduced, and the working environment is improved.

Owner:青岛福凯橡塑新材料有限公司

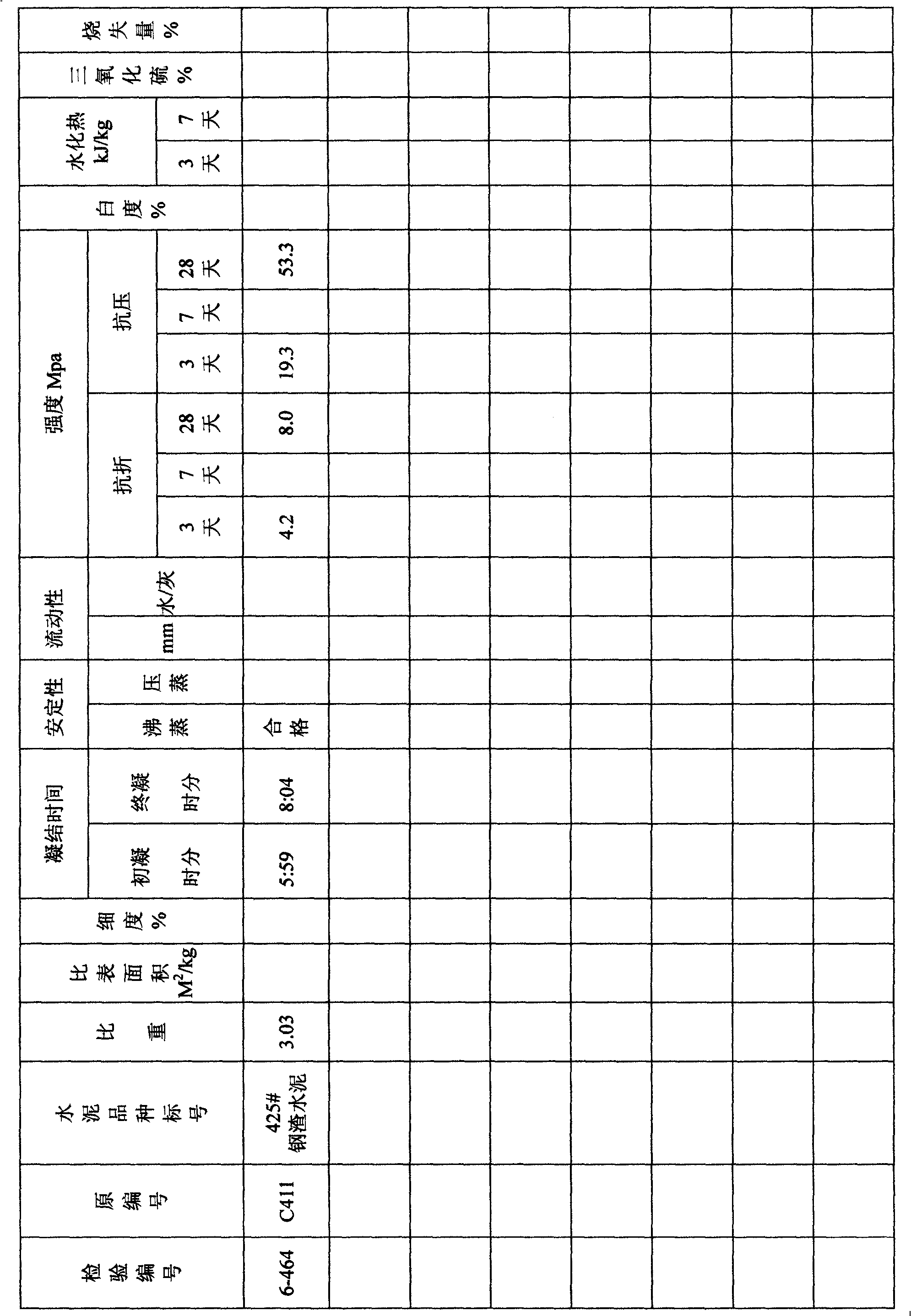

Production process of special low-carbon steel slag cement

InactiveCN102070306AAddress encroachment on agricultural landSolve environmental problemsCement productionSlagMagnetic separation

The invention relates to a production process of special low-carbon steel slag cement. The special low-carbon slag cement uses steel slag, mineral slag and portland cement clinker as main raw materials. Because the steel slag has low activity, large hardness, crushing difficulty and lower utilization rate further lower than the mineral slag, by adopting new processes of three-time crushing, three-time magnetic separation, closed-path pre-grinding and independent material grinding, the production process reduces the grinding particle size and the metal content of the steel slag, excites the activity of the steel slag to overcome the defects of low early-stage strength and long setting time of the steel slag cement, thereby stably producing 425 steel slag cement for a long term, wherein the 425 steel slag cement is used for various industrial and civil large-size buildings.

Owner:赵明友

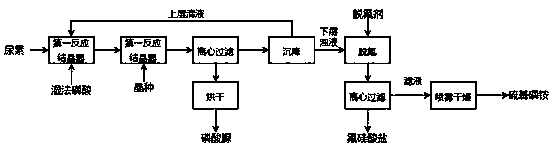

Method for preparing large-granule industrial-grade urea phosphate product through continuous reaction crystallization of wet-process phosphoric acid

ActiveCN110451513ALow viscosityLow impurity contentUrea derivatives preparationOrganic compound preparationPhosphoric acidSlurry

The invention discloses a method for preparing a large-granule industrial-grade urea phosphate product and a byproduct thereof through continuous reaction crystallization of wet-process phosphoric acid. The method comprises the steps: adding the wet-process phosphoric acid, urea and circulating mother liquor into a first reaction crystallizer; feeding a reacted solution to a second-stage crystallizer, adding a urea phosphate seed crystal, continuously outputting reaction obtained slurry, carrying out centrifugation and filtering, carrying out drying so as to obtain industrial-grade urea phosphate, and feeding filter liquor to a circulating mother liquor tank for thorough precipitation; cyclically outputting supernatant obtained through precipitation to the first reaction crystallizer for acyclic reaction, and subjecting a suspension of solid impurities to centrifugation and filtering, so as to obtain second filter liquor and a second filtered solid matter; adding potassium sulfate into the second filter liquor, carrying out a reaction, and carrying out filtering, so as to obtain third filter liquor and a byproduct, i.e., potassium fluorosilicate; and mixing the third filter liquorand the second filtered solid matter, carrying out concentrating, then, carrying out spray drying so as to obtain a sulfenyl nitrogen, phosphorus and potassium compounded fertilizer, and carrying outcyclic continuous production, thereby obtaining a urea phosphate crystal. According to the method, the purity is high, the grain size is large, the distribution is uniform, the crystal form is neat;and meanwhile, fluorosilicate and the sulfenyl nitrogen, phosphorus and potassium compounded fertilizer can be obtained, and no waste gases, waste water and waste residues is discharged.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

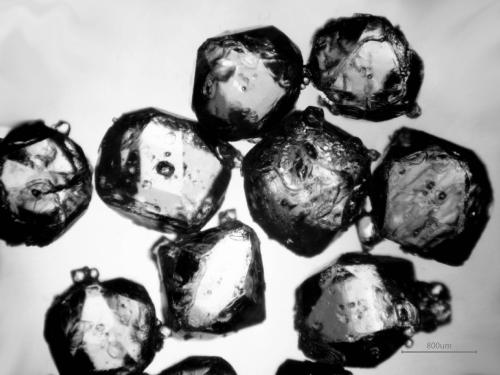

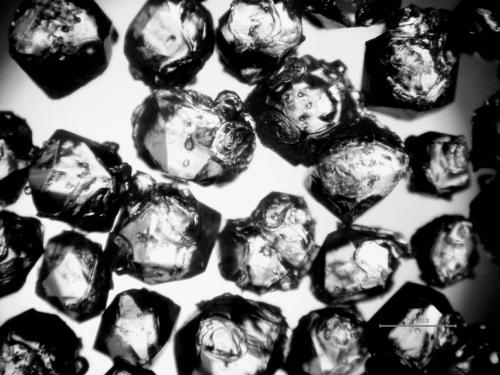

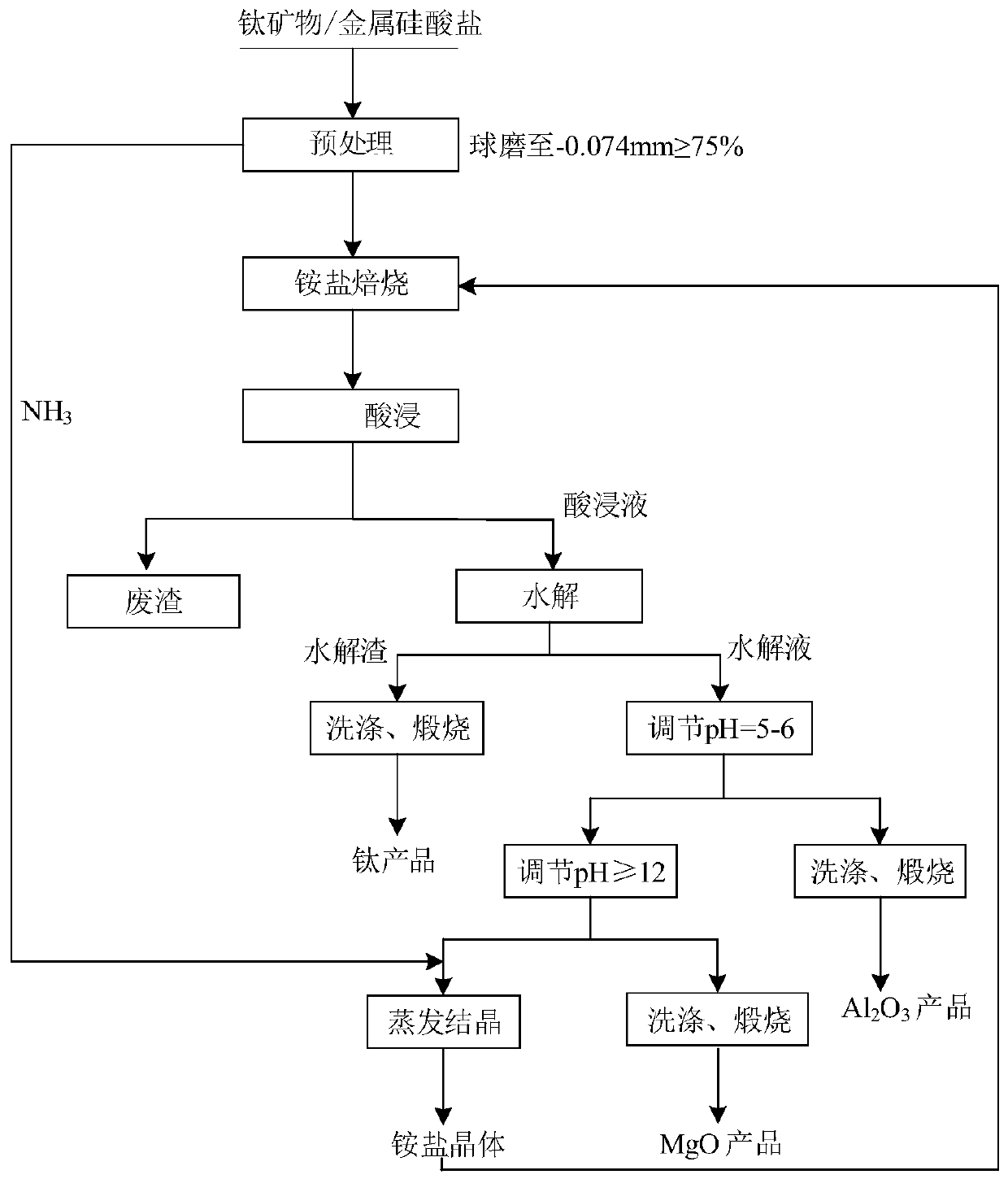

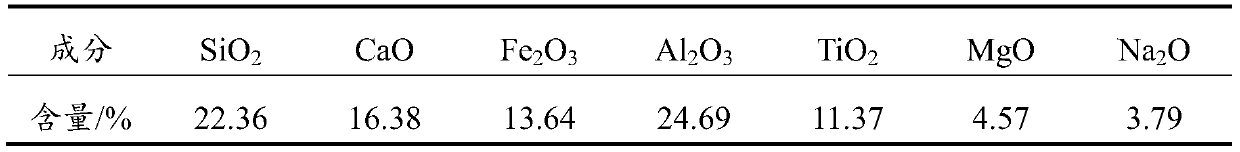

Treatment method of titanium mineral and metal silicate mineral through ammonium salt pressurized pyrolysis

InactiveCN110396610AImprove leaching rateImprove resource utilizationAluminium compoundsTitanium dioxideHigh concentrationSlag

The invention discloses a treatment method of titanium mineral and metal silicate mineral through ammonium salt pressurized pyrolysis. The method comprises the following steps of uniformly mixing thepre-treated titanium mineral and metal silicate mineral with ammonium salt based on a certain proportion and then conducting low-temperature pyrolysis on the mixer in high pressure kettle; performinghermetic roasting when the pH of sampling opening gas is acidic, so that under the hermetic condition, the ammonium salt can effectively salinize valuable metal in minerals and release valuable elements which are inset in the lattice, and then leaching roasting slag in dilute acid to obtain acid leaching solution containing high-concentration titanium-aluminum-magnesium; and performing fractionalhydrolysis on the titanium-aluminum-magnesium in acid leaching solution for step recycling so as to obtain a high purity product. Meanwhile, ammonia water is recycled, and then subjected to evaporation and crystallization, so that cyclic utilization of the ammonium salt can be realized. According to the method, the step recycling of the titanium-aluminum-magnesium in the titanium mineral and the metal silicate mineral is realized, and the ammonium salt is recycled, thus achieving the purpose of waste resource recovery.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

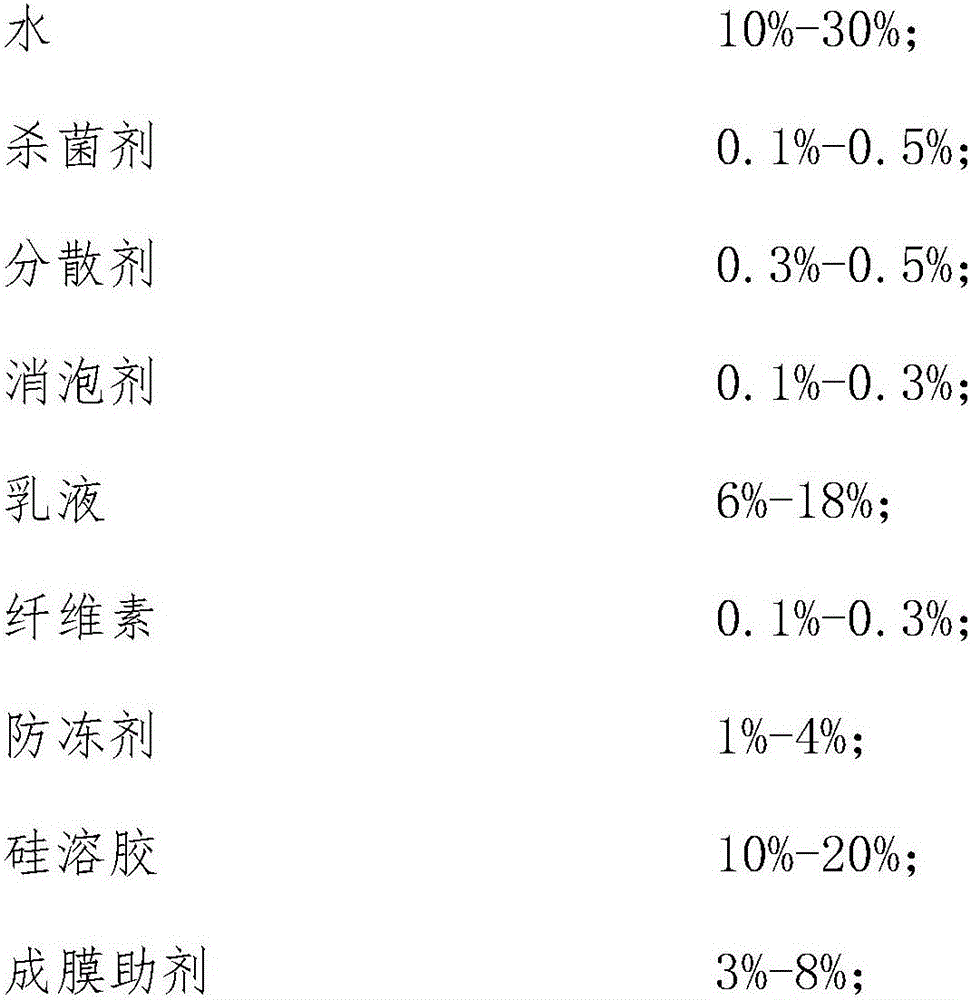

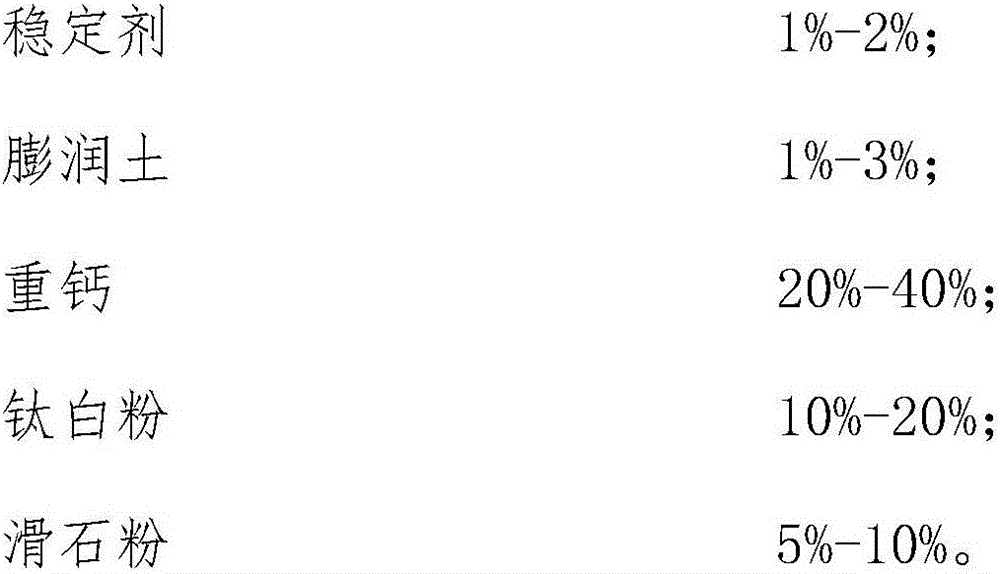

Inorganic silicate paint and preparation method thereof

InactiveCN106280589AGood flexibilityImprove adhesionFireproof paintsAntifouling/underwater paintsCelluloseEmulsion

The invention relates to the technical field of paint application, in particular to inorganic silicate paint and a preparation method thereof. The inorganic silicate paint is prepared from the raw materials of water, bactericide, a dispersing agent, a defoaming agent, emulsion, cellulose, an anti-freezing agent, silica sol, film coalescing aid, a stabilizer, bentonite, triple superphosphate, titanium dioxide and talcum powder. The inorganic silicate paint has the advantages that by selecting the emulsion with excellent ion stability, the flexibility and bonding force of a coating can be improved, and meanwhile flocculating can be prevented; by selecting a corresponding thickening system, the storage stability of the finished product is improved; by selecting the stabilizer, the flocculating problem is thoroughly solved. The prepared paint has excellent breathability, is resistant to growing of bacteria and moss, noncombustible, excellent in acid and alkaline resistance and environmentally friendly and emits heat radiation.

Owner:SUZUKA INTERNATIONAL (SHANGHAI) CO LTD

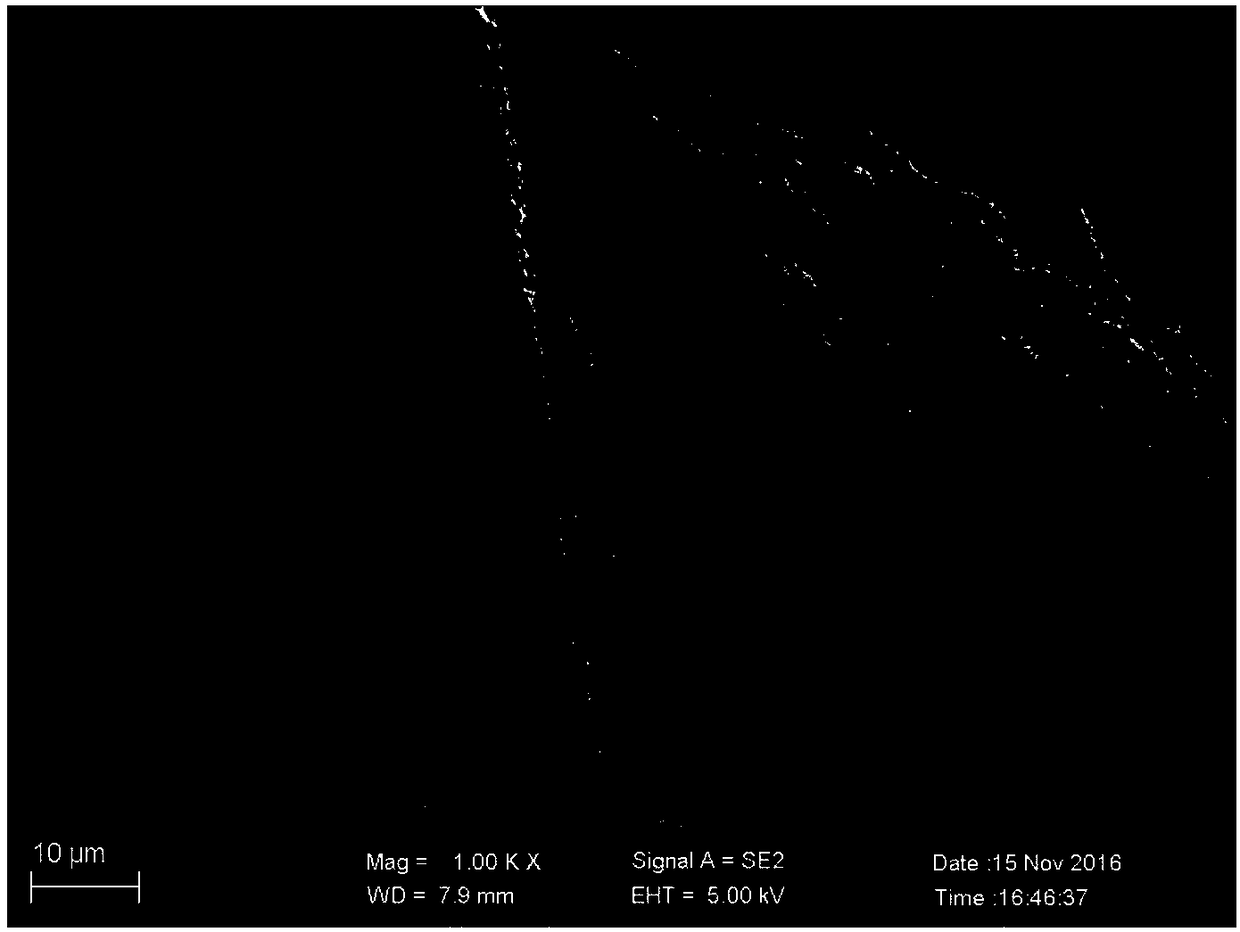

A kind of calcium-aluminosilicate glass-based low-temperature co-fired ceramic material and preparation method thereof

The invention provides a calcium aluminum silicon glass base low-temperature cofiring ceramic material and a preparation method thereof. The ceramic material comprises the following components in parts by weight: 40-60 parts of calcium aluminum silicon glass, 2-5 parts of silicon carbide, 10-20 parts of forsterite, and 5-10 parts of carbon nano tube. According to the invention, the calcium aluminum silicon glass is adopted as basic glass; the principal crystalline phase is silicate p-wollostonite adopting a chain structure, and is crossed and arrayed to net in a needle-shaped manner in the glass body; the material is enabled to have characteristics of being abrasion resistant, corrosion-resistant and shock resistant; the silicon carbide, the forsterite and the carbon nano tube are added in the calcium aluminum silicon glass, and the synergistic effect among the materials is utilized, so that the thermal conductivity of the prepared ceramic material is improved; the melting point of the calcium aluminum silicon glass is further reduced; experimental result shows that the coefficient of thermal expansion of the prepared ceramic material is 6.0*10<-6> / K, the dielectric constant of the ceramic material is 5.2 (1 MHz), and the thermal conductivity of the ceramic material is 32 W / mK.

Owner:梅州市溪山陶瓷有限公司

Resin-permeated silicate composite material and preparation and application thereof

InactiveCN108451773AEasy to prepareImprove production efficiencyImpression capsDentistry preparationsDouble networkPolyresin

The invention relates to a resin-permeated silicate composite material. The material is obtained through a curing reaction of components comprising resin and glass phase silicate under the presence ofa curing agent, wherein the mass ratio of the resin to glass phase silicate to the curing agent is 1:(1-3):(0.005-0.02). The invention also relates to a preparation method of the resin-permeated silicate composite material, grouting molding is adopted for preparing a porous ceramic block body, and after the resin is permeated into the porous ceramic block body, the composite material of a silicate / resin double network structure is obtained by means of curing. According to the preparation method, the preparation process of a porous silicate ceramic blank body is simplified, the resin-permeatedsilicate composite material prepared by the method effectively combines the advantages of the resin and ceramic and has high mechanical performance and aesthetic performance, great development potential and a broad market prospect in the aspect of dental restoration application.

Owner:TSINGHUA UNIV

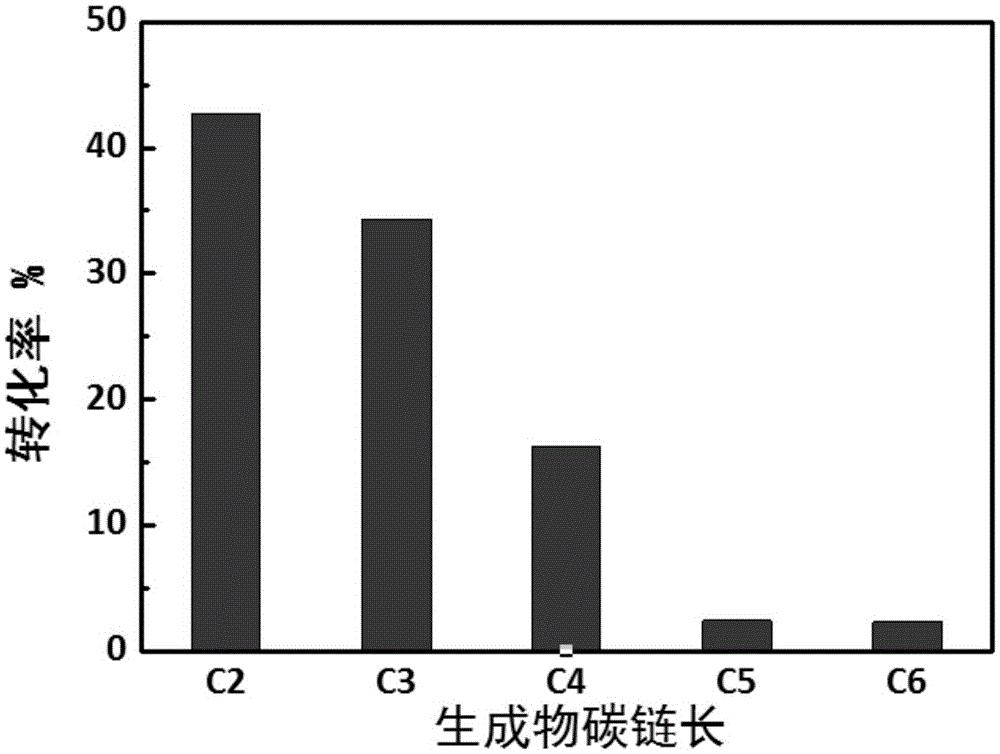

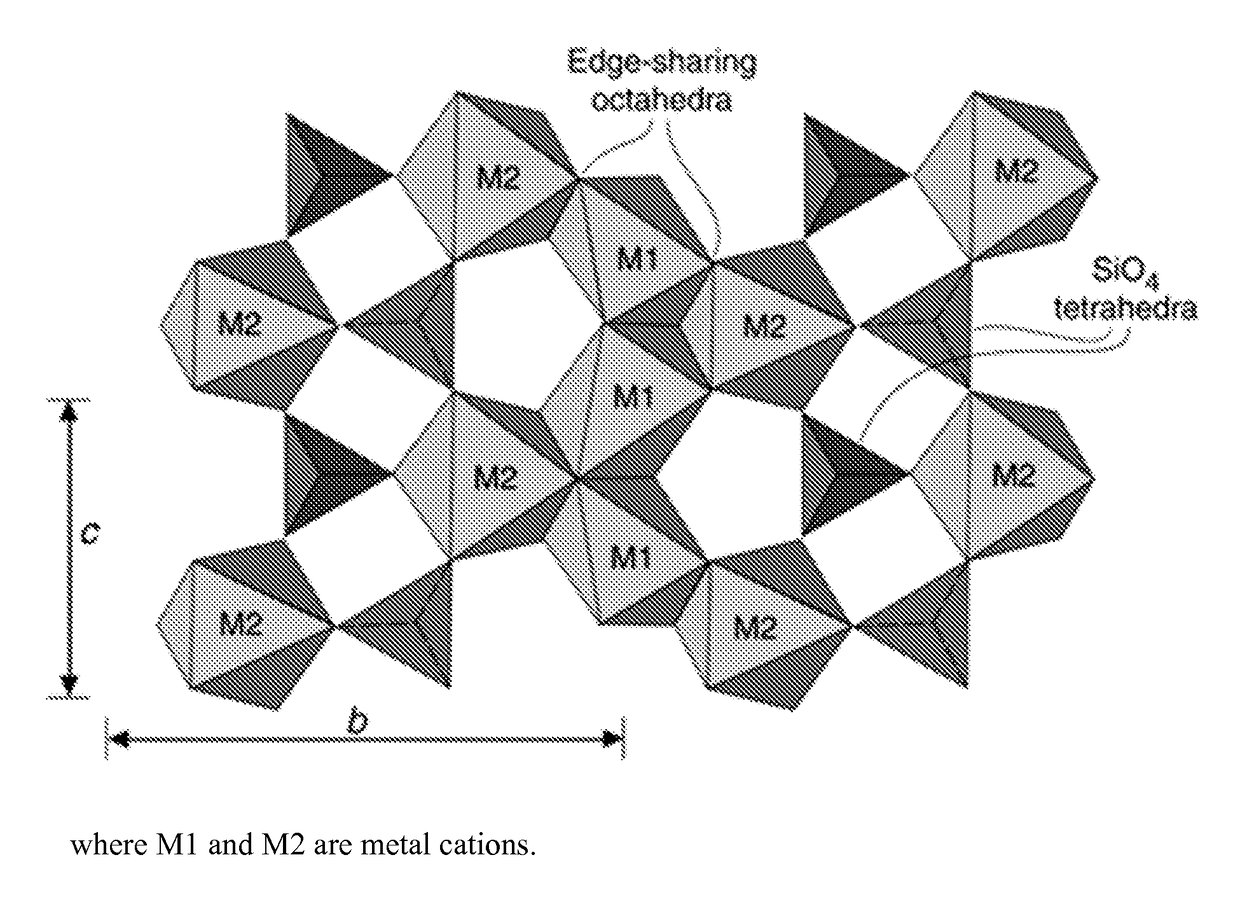

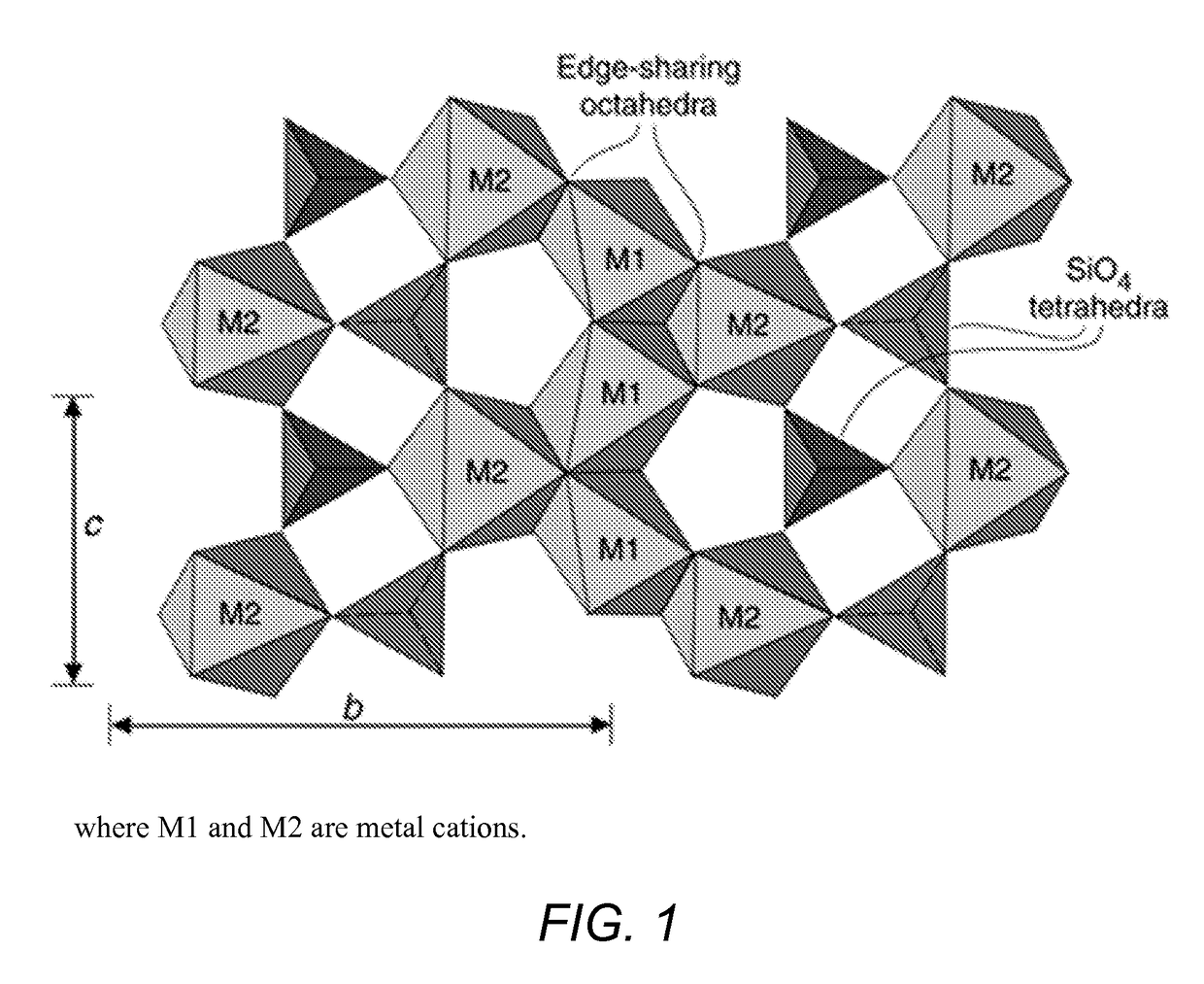

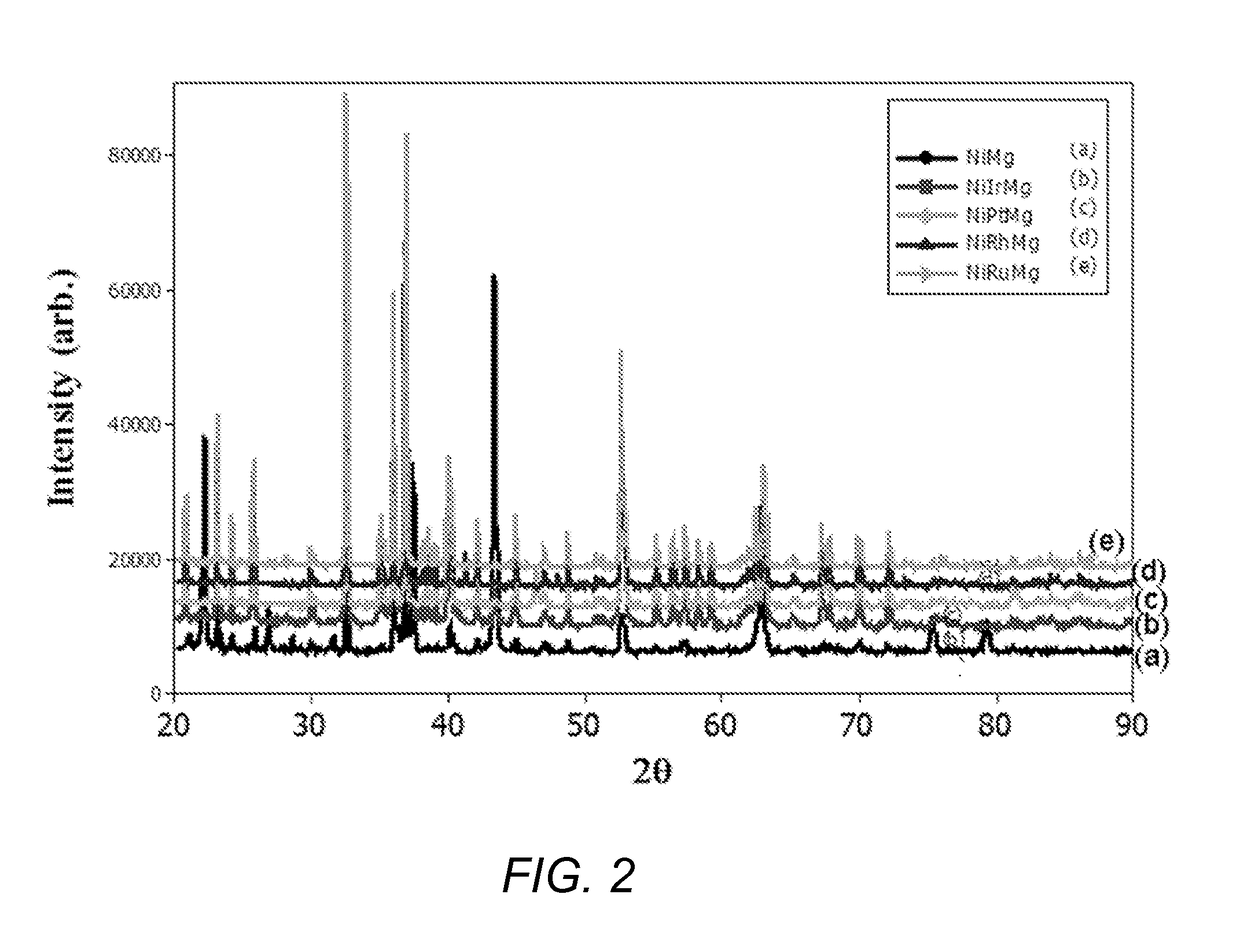

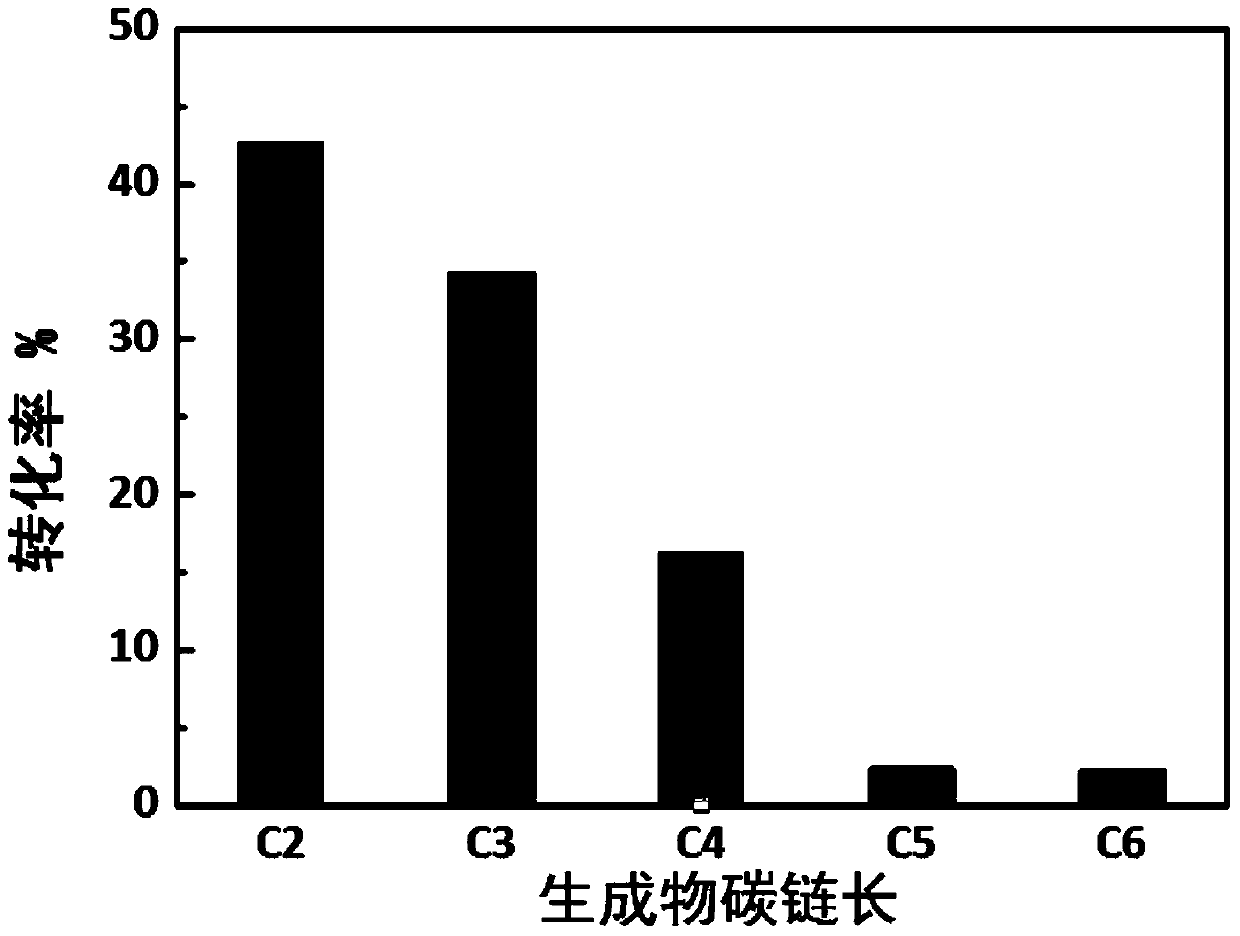

Use of olivine catalysts for carbon dioxide reforming of methane

InactiveUS20170120227A1High activityEnhanced coke resistanceHydrogenHeterogenous catalyst chemical elementsHydrogenOlivine

Disclosed are metal oxide catalysts, and methods for their use, that includes a bulk metal oxide catalyst composed of at least two metals and nesosilicate. The catalyst is capable of catalyzing the carbon dioxide reforming of methane to produce hydrogen and carbon monoxide.

Owner:SABIC GLOBAL TECH BV

A kind of preparation method of carbon-based wave-absorbing material prepared by aluminosilicate polymer

The invention discloses a carbon-based wave absorbing material prepared from aluminosilicate polymer and a preparation method of the carbon-based wave absorbing material. The carbon-based wave absorbing material is formed by using metakaolin, a carbon material and an alkali activating solution to synthesize the aluminosilicate polymer and curing, wherein a mole ratio of metakaolin and the carbon material is 1:(3-24), and a mole ratio of silicon and aluminum in the aluminosilicate polymer is (1-2):1. The preparation method includes: activating kaolin; preparing mixed powder; preparing the alkali activating solution; preparing the aluminosilicate polymer; curing for forming. The preparation method is simple in process, capable of realizing direct forming of complex or large parts at low temperature and wide in application range. The carbon-based wave absorbing material is low in cost and high in unit thickness absorptivity and meets requirements on thinness, lightness, width and strength.

Owner:智合(深圳)新材科技有限公司

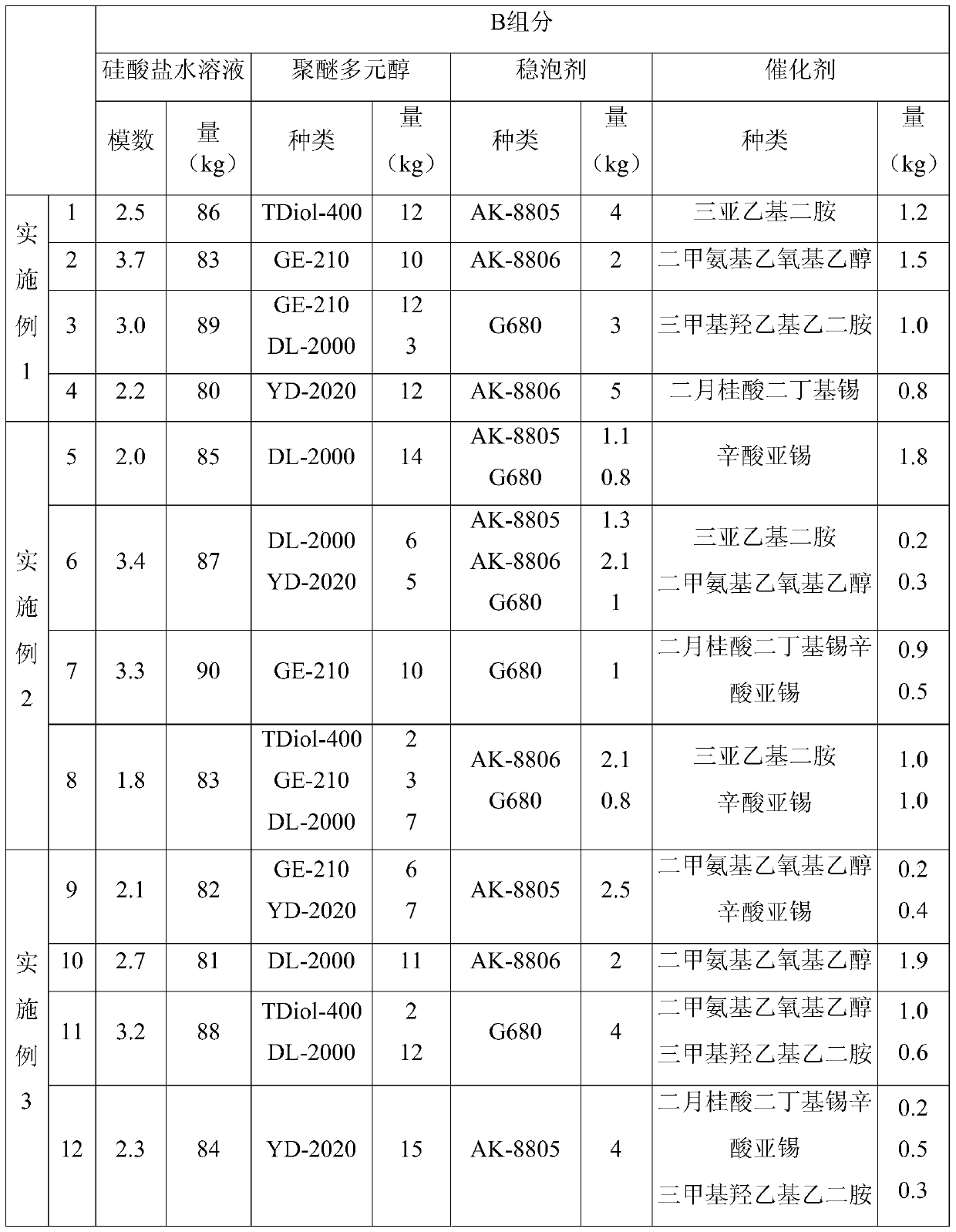

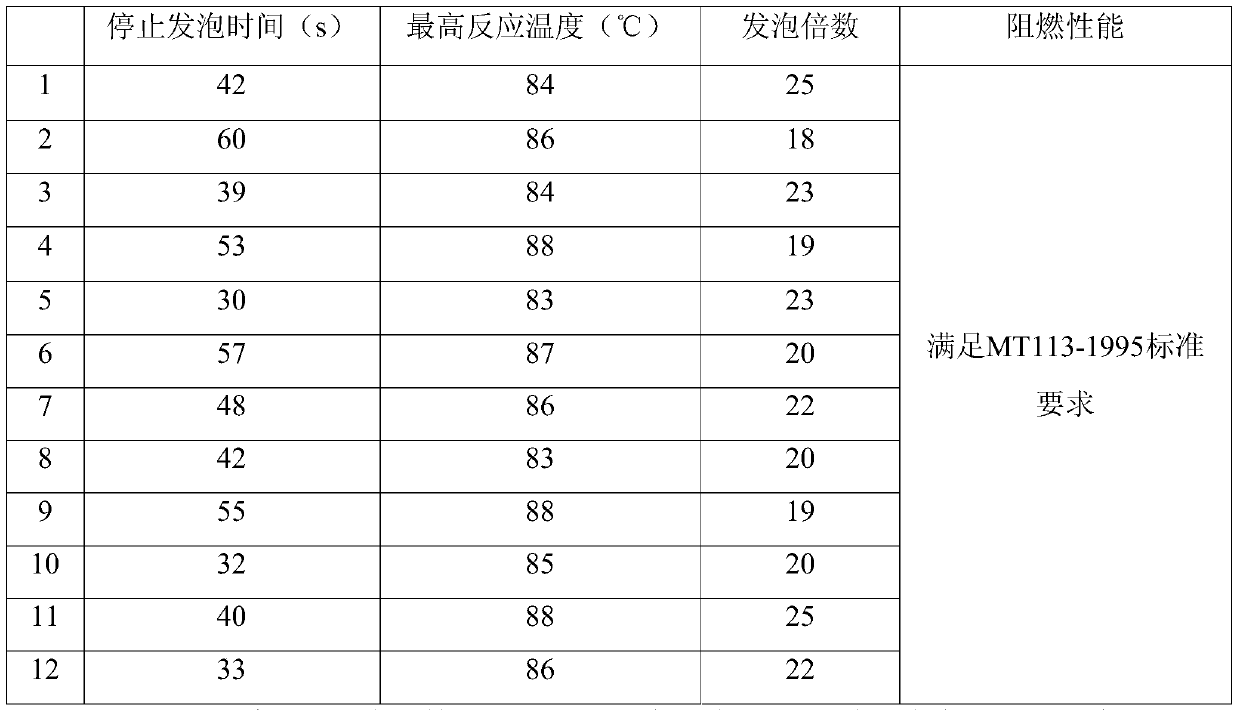

A silicate modified polyurethane foam material and its preparation method and use method

ActiveCN104558477BLow reaction temperatureComply with flame retardant performance requirementsFoaming agentReaction temperature

The invention provides a silicate modified polyurethane foam material, as well as a preparation method and an application method thereof, relates to a combination adopting an organic polymer compound as a base material, as well as a preparation method and an application method thereof, particularly relates to a combination adopting polyurethane as the base material, as well as a preparation method and an application method thereof, and aims to provide a silicate modified polyurethane foam material which is free from a foaming agent and an organic fire retardant, easy to get raw materials, low in reaction temperature, safe and stable, as well as a preparation method and an application method thereof. The foam material comprises a component A and a component B, wherein the component A comprises polyisocyanate and a toughening agent; the component B comprises a silicate aqueous solution, polyether glycol, a foam stabilizer and a catalyst. The foam material does not contain a foaming agent or an organic fire retardant, and is low in reaction temperature, safe and stable; the preparation method and the application method are simple and easy to operate; the foam material can be used in the fields of cavity filling of coal mine underground collapsed zones, gas prevention, air leakage prevention, airtightness, leakage stopping of water areas and the like.

Owner:BEIJING RUINUOANKE NEW ENERGY TECH

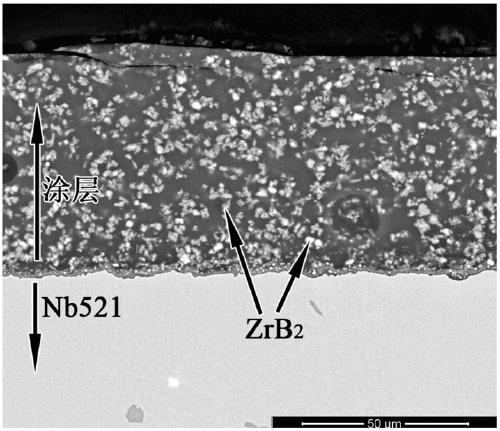

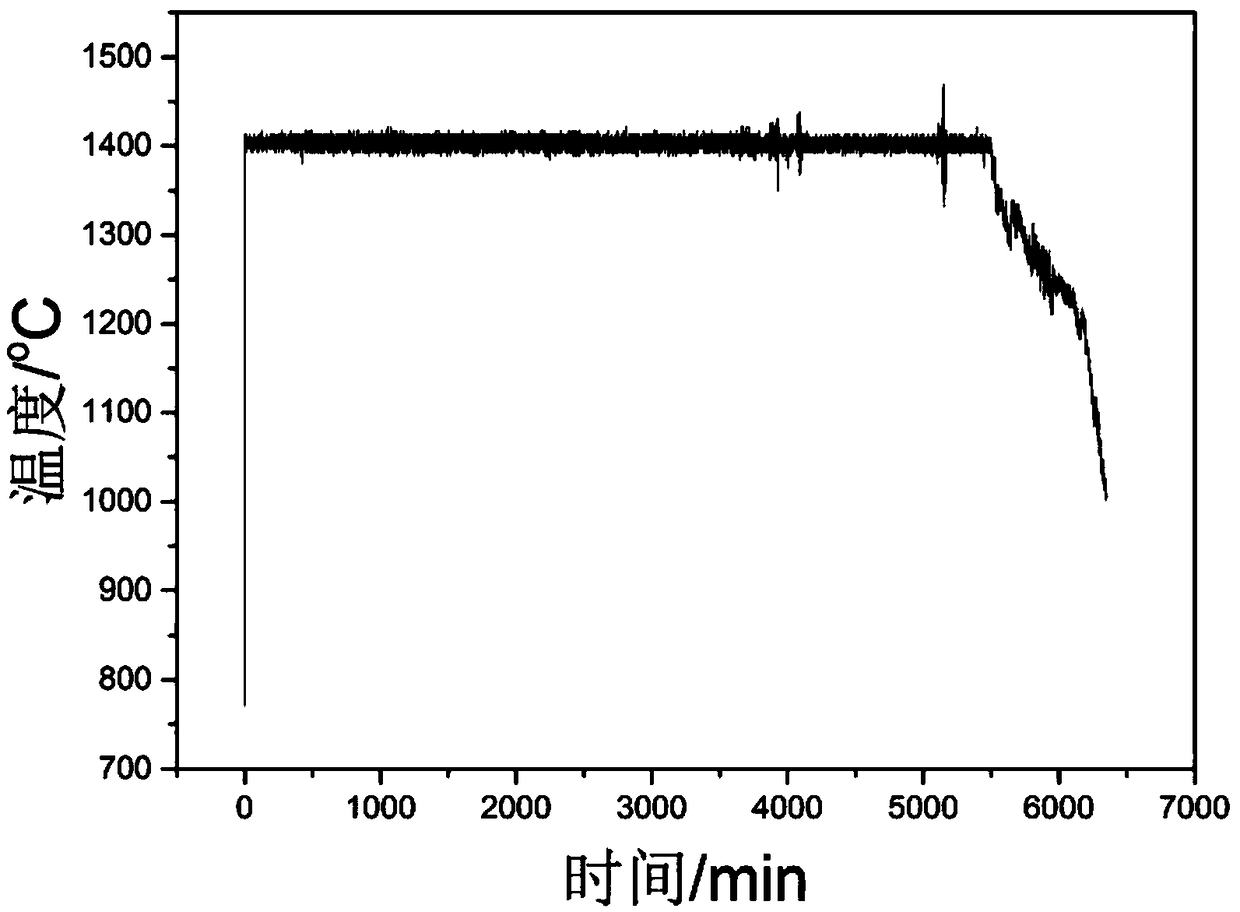

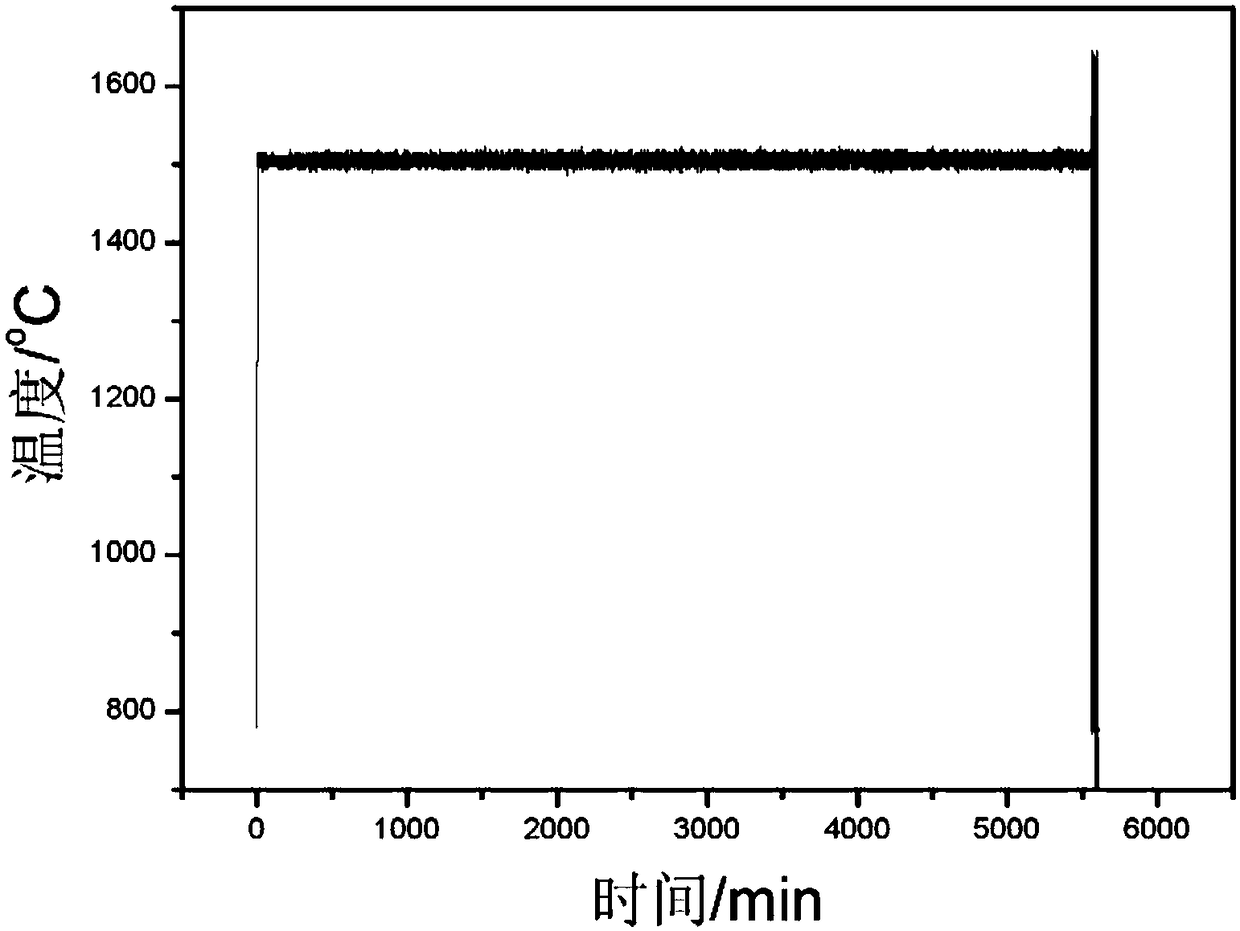

Boride-modified glass-ceramic matrix composite high-temperature anti-oxidation coating and preparation method thereof

The invention discloses a boride modified glass ceramic based composite high-temperature oxidation resisting coating. The composite high-temperature oxidation resisting coating fired on the surface of a refractory metal matrix is prepared from boride and silicate glass, wherein the boride is at least one or two of HfB2, ZrB2 and TiB2; besides, the invention further discloses a preparation method of the coating. The method comprises steps as follows: 1, the surface of the refractory metal matrix is treated; 2, boride particle modified glass ceramic composite slurry is prepared; 3, a preset layer is obtained by presetting the slurry on the surface of the refractory metal matrix, and the boride modified glass ceramic based composite high-temperature oxidation resisting coating is obtained vacuum high-temperature firing. The composite high-temperature oxidation resisting coating is used for high-temperature protection of the refractory metal matrix and can continuously protect the refractory metal matrix at the protection temperature of 400-1,600 DEG C for 5 h or longer.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

A method for in-situ addition of nanometals to prepare continuous SIO2/nanometal airgel fibers with catalytic properties

ActiveCN105603577BHas catalytic propertiesAdjust the size of the specific surface areaInorganic material artificial filamentsWet spinning methodsFiberSolvent

The invention relates to a method for preparing continuous SiO2 / nano-metal airgel fibers with catalytic properties by adding nano-metal in situ. The method includes: preparing silicate or silicate into a spinning stock solution, then adding a nanometal catalyst, and then adding it to a coagulation bath to perform reaction wet spinning to obtain orthosilicic acid / silicate fibers containing nanometal catalysts, and winding , aged at room temperature, washed with deionized water until neutral, solvent replaced with deionized water or ethanol, and dried. The method of the invention has the characteristics of cheap and easily available raw materials, simple reaction process and good spinnability. The continuous SiO2 / nano-metal aerogel fiber with catalytic performance prepared by the present invention has abundant pores, high specific surface area, high temperature resistance, and chemical corrosion resistance. At the same time, the specific surface area of the fiber and the nano-metal content in the fiber are adjustable. It is useful in catalysis, etc. The field has application prospects.

Owner:DONGHUA UNIV

A kind of diatomite/heavy calcium carbonate composite humidity control material and its preparation method

ActiveCN104841361BImproved humidity controlSimple preparation processOther chemical processesCalcium silicateCalcite

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com