Composite salt binder composite friction material and preparation method thereof

A composite friction material and binder technology, applied in friction linings, chemical instruments and methods, mechanical equipment, etc., can solve problems such as thermal recession, achieve good flame retardancy, improve safety, and solve the effects of thermal recession

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

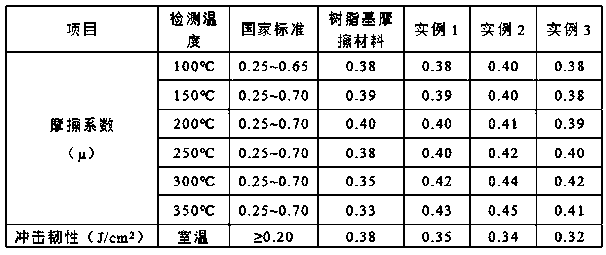

Examples

Embodiment 1

[0027] Add 10 parts of potassium water glass with the same modulus and Baume degree to 100 parts of sodium water glass with a modulus of 2.8 and a Baume degree of 45, mix and stir evenly to obtain silicic acid with a Na / K ratio of 10 / 1 salt binder.

[0028] Weigh 20 parts of silicate binder with a silicate Na / K ratio of 10 / 1, add 10 parts of liquid aluminum dihydrogen phosphate, 2.5 parts of calcium fluoride additive, mix and stir evenly, at 25~50℃ Heated and stirred for 10 minutes to obtain a compound salt binder.

[0029] Weigh 3 parts of sodium fluorosilicate, 2 parts of copper oxide, 12.5 parts of carbon fiber, 12.5 parts of barite, 5 parts of alumina, 3 parts of silicon carbide, 2 parts of copper powder, 2 parts of graphite, 2 parts of boron carbide and mix and stir for 2 Minutes, then weigh 12.5 parts of nitrile rubber as a toughness modifier, introduce and mix and stir for 1 minute; put the mixed powder in a blast drying oven and dry for 3 hours, and after drying, the ...

Embodiment 2

[0031] Add 30 parts of potassium water glass with the same modulus and Baume degree to 100 parts of sodium water glass with a modulus of 2.8 and a degree of Baume of 45, mix and stir evenly to obtain silicic acid with a Na / K of 10 / 3 salt binder.

[0032] Weigh 15 parts of silicate binder with a silicate Na / K ratio of 10 / 3, add 10 parts of liquid aluminum dihydrogen phosphate, and 4 parts of calcium fluoride additives, mix and stir evenly, at 25~50°C Heated and stirred for 10 minutes to obtain a compound salt binder.

[0033] Weigh 3 parts of sodium fluorosilicate, 1 part of copper oxide, 1 part of magnesium oxide, 12.5 parts of carbon fiber, 10 parts of barite, 10 parts of wollastonite, 5 parts of alumina, 3 parts of silicon carbide, 2 parts of copper powder, 2 parts of graphite and 2 parts of boron carbide were mixed and stirred for 2 minutes, then 7.5 parts of nitrile rubber was weighed and introduced as a toughness regulator and mixed and stirred for 1 minute; the mixed po...

Embodiment 3

[0035] Add 50 parts of potassium water glass with the same modulus and Baume degree to 100 parts of sodium water glass with a modulus of 2.8 and a degree of Baume of 45, mix and stir evenly to obtain silicic acid with a Na / K of 10 / 5 salt binder.

[0036] Weigh 15 parts of silicate binder with a silicate Na / K ratio of 10 / 5, add 15 parts of liquid aluminum dihydrogen phosphate, 5 parts of calcium fluoride additive, mix and stir evenly, at 25~50℃ Heated and stirred for 10 minutes to obtain a compound salt binder.

[0037] Weigh 2 parts of sodium fluorosilicate, 2 parts of copper oxide, 1 part of zinc oxide, 12.5 parts of carbon fiber, 10 parts of barite, 5 parts of wollastonite, 5 parts of alumina, 5 parts of silicon carbide, 2 parts of copper powder, 2 parts of graphite and 2 parts of boron carbide were mixed and stirred for 2 minutes, then 10 parts of nitrile rubber was weighed and introduced as a toughness regulator and mixed and stirred for 1 minute; the mixed powder was dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com