Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Improved coefficient of friction stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper-base powder metallurgical brake pad material for sea-base wind turbine generator system and preparation process thereof

InactiveCN102002609AMeet the performance requirementsIncrease coefficient of frictionFriction liningFerrochromeSeawater

The invention provides a copper-base powder metallurgical brake pad material for a sea-base wind turbine generator system, which comprises the following components in percentage by weight: copper, FWCuZn30 brass, graphite, sea sand, silicon carbide, ferrochrome and tin. The preparation process of the brake pad material comprises the following five steps: blending materials, pressing blank, making support steel backing, pressurizing and sintering in sections, and machining for molding. In the invention, by adopting the seawater corrosion resistant brass as a material matrix and high-content nonmetal components the weight ratio of which is more than 30%, excellent corrosion resistance, high friction coefficient and high brake moment can be obtained, and the stability of friction coefficient is good; the obtained powder metallurgical brake pad material conforms to the service performance requirements for a high-speed shaft braking device of the sea-base high-power wind turbine generator system; the material has the advantages of rational component proportion, simple machining process, good corrosion resistance, high friction coefficient, good friction coefficient stability and high strength, and is suitable for industrialized production; and the copper-base powder metallurgical brake pad material can be taken as a high-speed shaft braking material for the sea-base high-power wind turbine generator system with the power of more than 3.5MW.

Owner:CENT SOUTH UNIV

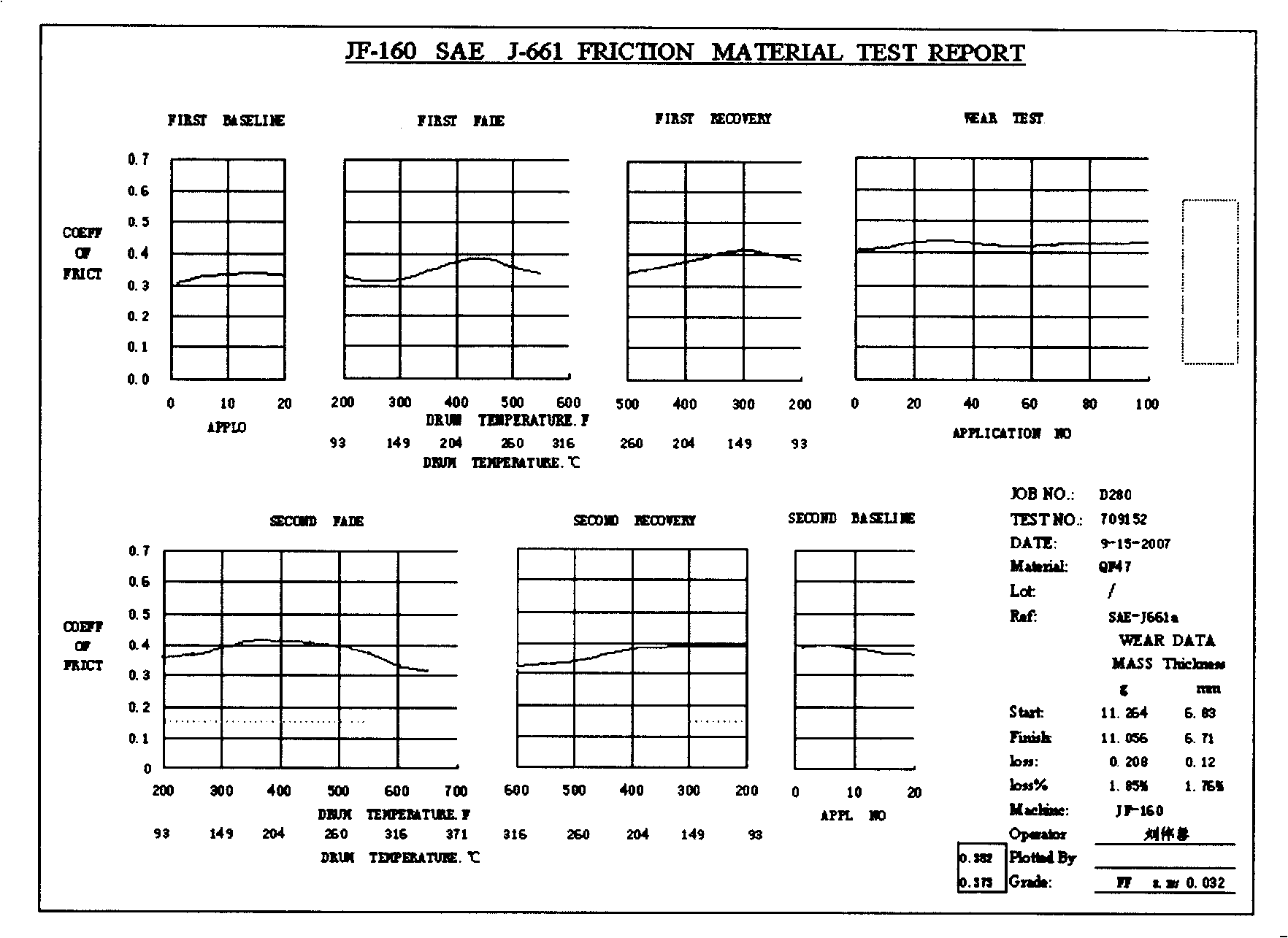

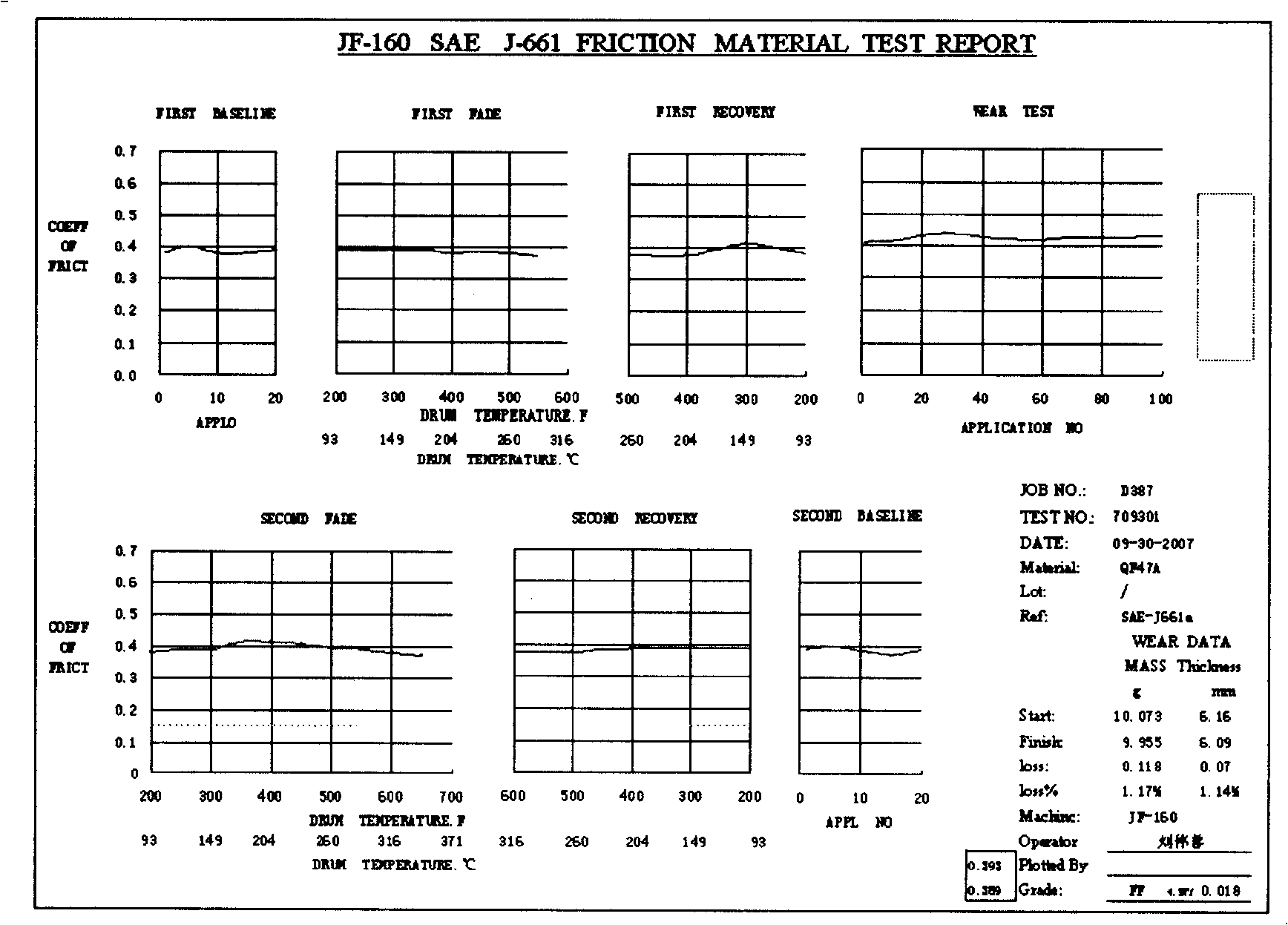

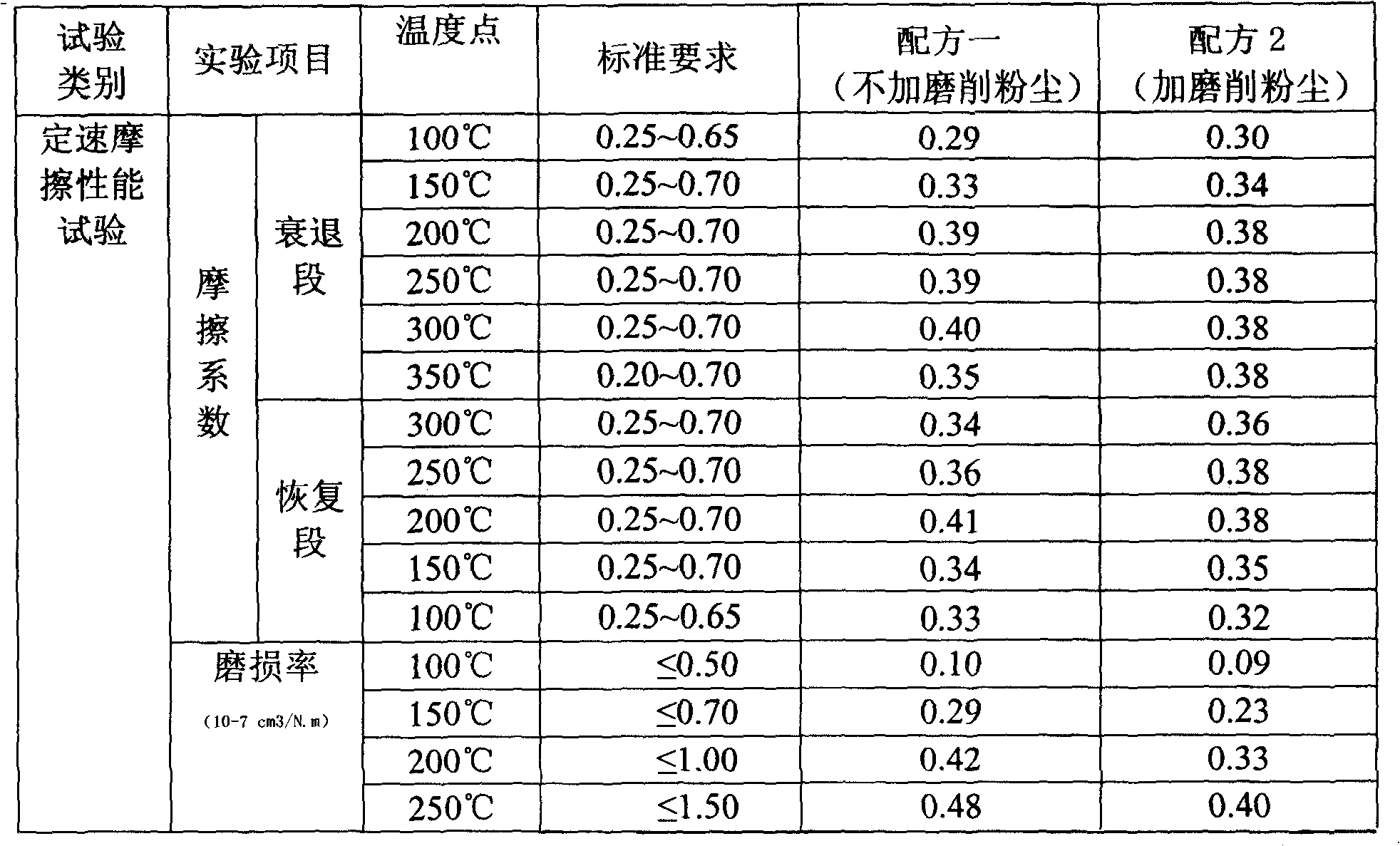

Abrasive dust recycling method in brake disc production

InactiveCN101270791AAvoid environmental pollutionImprove consistencyFriction liningScrapMachining process

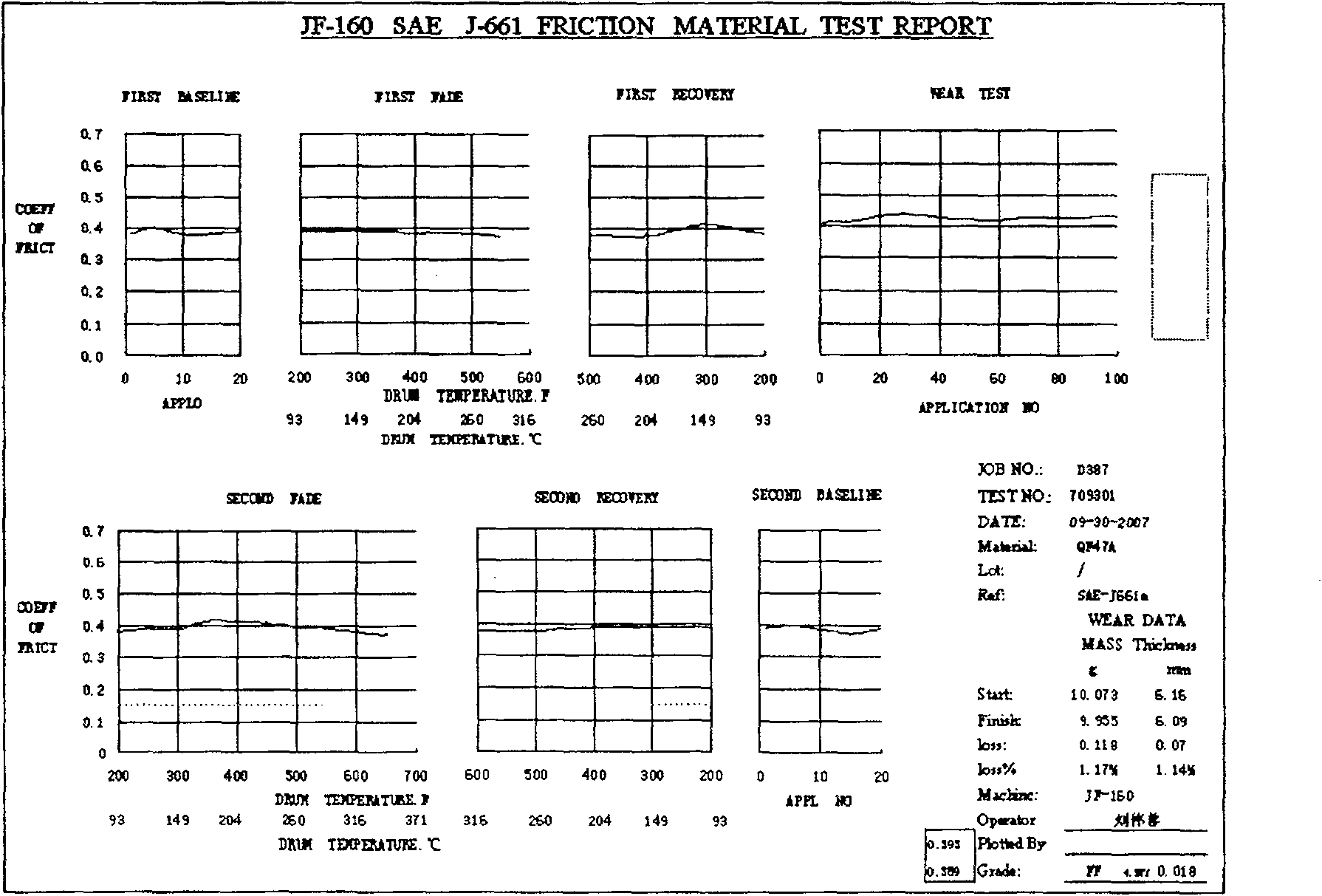

A recycling method of abrasive dust in the brake plate preparation process is provided. The brake plate is compounded by 5 percent to 10 percent of adhesives, 10 percent to 30 percent of reinforced material, 10 percent to 35 percent of friction performance regulator, 8 percent to 25 percent of stuffing and 25 percent to 65 percent of grinding dust material on quality. Under the unit pressure of 15 to 20MPa, the prepared and weighed friction material is poured into a plow harrow mixer to be evenly stirred for 5 minutes and then put into a mould to be suppressed for 8 to 10 minutes. The method has the following heat treatment procedures: keeping for 1 hour at 140 degrees centigrade, keeping for 2 hours at 165 degrees centigrade, keeping for 2 hours at 180 degrees centigrade, keeping for 1 hour at 195 degrees centigrade and then cooling to normal temperature. The invention recycles the waste reasonably, avoiding environmental pollution and obviously improving the friction coefficient stability and consistency of the product. The friction coefficient fluctuation is reduced 15 percent and the heat fading is small. The stability of the friction performance is improved more than 15 percent and the abrasion wear is reduced more than 20 percent. At the same time, the manufacture cost is reduced 15 percent and the economic benefit is also improved.

Owner:曲阜天博汽车零部件制造有限公司

Multielement silane coupling agent-modified phenolic resin base combined disc brake pad and preparation method thereof

ActiveCN105801014AImprove physical propertiesGood chemical propertiesFriction liningCarbon fibersSilanes

The invention provides a multielement silane coupling agent-modified phenolic resin base combined disc brake pad and a preparation method thereof, and relates to the technical field of automobile parts.The brake pad is prepared from, by mass, 4-7% of organosilicone-modified phenolic resin, 2-4% of polyacrylonitrile carbon fibers, 2-4% of aramid pulp, 10-34% of potassium titanate lamellae, 5-18% of steel fibers, 2-6% of glass fibers, 3-10% of natural flake graphite, 3-10% of granulated coke, 0.5-1.5% of silicon dioxide, 25-40% of barite and 2.5-10% of a multielement silane coupling agent.The disc brake pad has the advantages of being good in interfacial compatibility, stable in friction coefficient and product quality, excellent in wear resistance and anti-noise performance and the like; besides, a material modification process and a mixing process are integrated in the preparation method of the disc brake pad, so that production efficiency is high, modification cost is lowered, and the process is simple.

Owner:SHANDONG GOLD PHOENIX

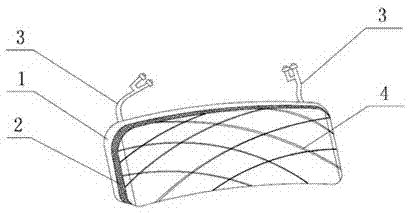

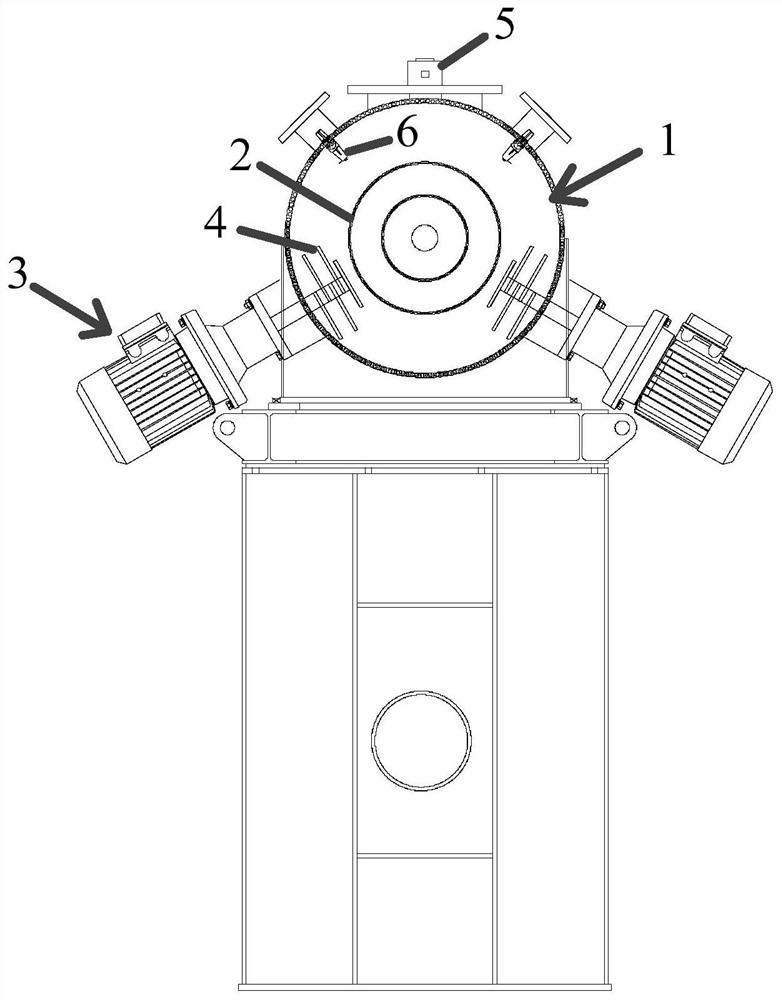

Vibration-damping, denoising and yaw low-speed braking pad and fabrication method thereof

ActiveCN103256325AStable coefficient of frictionGood high temperature friction performanceFriction liningLow speedCarbon fibers

The invention relates to a braking pad, in particular to a vibration-damping, denoising and yaw low-speed braking pad for a yaw braking device of a wind generating set and a fabrication method of the braking pad. The vibration-damping, denoising and yaw low-speed braking pad comprises a steel backing and an abrasive layer attached to the steel backing, wherein the abrasive layer is fabricated by taking PTS (Phenolic Thermospheres) suspension method phenolic resin as a gluing agent, taking graphite, tin sulfide and copper sulfide as a lubricant, taking antimony trisulfide, zirconium silicate, silicon carbide and silicon dioxide as an abradant, taking potassium titanate whiskers, ceramic fibers, aramid fibers, carbon fibers, steel fibers and copper fibers as reinforced fibers, taking calcium carbonate, mica, vermiculite and foam ferrous powder as an inorganic filler, and taking cashew nut shell oil friction powder and rubber powder as an organic filler according to a wet method pressing technology. The braking pad has the advantages that component percentages of a friction material and a processing technology are reasonable; the braking sensitivity is high; the braking vibration is small; the friction noise is low; and the braking pad is provided with a pad abrasion alarm line.

Owner:JIAOZUO LICHUANG BRAKE

Copper-free friction material and brake pad

ActiveCN105670564AImprove stabilityReduce wearOther chemical processesFriction liningButadiene-styrene rubberMagnesium

The invention discloses a copper-free friction material and a brake pad. The copper-free friction material comprises the following raw materials by weight: 30-40 parts of steel fiber, 5-15 parts of modified phenolic resin, 5-10 parts of nitrile butadiene rubber, 10-15 parts of styrene butadiene rubber, 10-15 parts of graphite, 3-4 parts of molybdenum disulfide, 5-10 parts of cryolite, 5-8 parts of barium sulfate, 1-5 parts of aramid fiber, 1-5 parts of heavy calcium carbonate, 1-5 parts of heavy magnesium oxide, 1-3 parts of aramid fiber, and 3-4 parts of silicon carbide. The brake pad made of the copper-free friction material provided by the invention has good hot cracking resistance and wear resistance, and low wear rate, thereby prolonging the service life. And reasonable control of the friction material composition proportion can ensure no abnormal wear to a brake disc.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

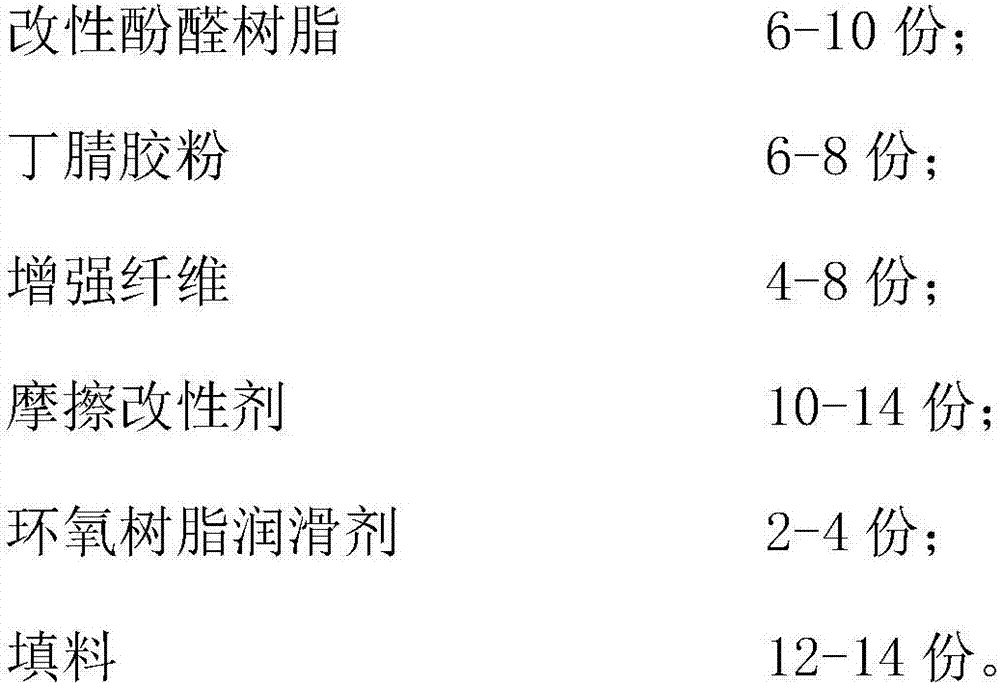

High temperature resistant resin-based friction material

InactiveCN107606005AImprove performanceImprove wear resistanceOther chemical processesFriction liningSocial benefitsFiber

The invention discloses a high temperature resistant resin-based friction material. The material is composed of the following raw materials of, by weight, 6-10 parts of modified phenolic resin, 6-8 parts of butadiene-acrylonitrile rubber powder, 4-8 parts of reinforced fibers, 10-14 parts of a friction modifier, 2-4 parts of an epoxy resin lubricant, and 12-14 parts of a filler. According to the high temperature resistant resin-based friction material provided by the invention, phenolic resin is modified through a cashew nut shell oil modifier, and the modified phenolic resin is more excellentin performance and applied to preparation of the resin-based friction material; the abrasion resistance, the high temperature resistance and the friction coefficient stability of the prepared resin-based friction material are improved; and sources of the raw materials are extensive, and the high temperature resistant resin-based friction material is applicable to industrial production and has good economical and social benefits.

Owner:SUZHOU CUINAN ELECTRONICS TECH CO LTD

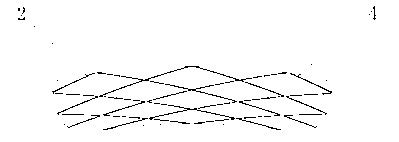

Curved shallow-crossing linking structure carbon fiber/copper fiber carbon-based friction material and preparation method thereof

InactiveCN105803637AOvercoming Delamination ProblemsIncreased interlaminar shear strengthCarbon fibresWoven fabricsWeft yarnCopper

The invention discloses a curved shallow-crossing linking structure carbon fiber / copper fiber carbon-based friction material and a preparation method thereof.The preparation method of the friction material comprises the following steps that 1, preparation of a curved shallow-crossing linking structure carbon fiber / copper fiber preform is conducted and includes (1) warp yarn preparation, (2) weft yarn preparation, (3) warping, (4) drafting and denting, (5) weaving and (6) take-up and let-off; 2, CVI deposition is performed: the carbon fiber / copper fiber perform is arranged in a CVI system for deposition to prepare the friction material.Long carbon fibers and copper fibers are mixed and woven for preparation of the friction material, the advantages of the two types of fibers are fully played and the shortcomings of the fibers are overcome to achieve the effect of overcoming their own shortcomings by learning from their strong points.

Owner:JIANGNAN UNIV

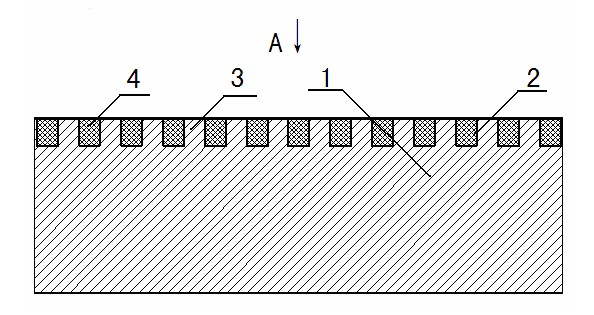

Special composite analog pavement for testing mechanical characteristics of tire

InactiveCN102426132AControllable Coefficient of FrictionImproved coefficient of friction stabilityInvestigating abrasion/wear resistanceEngineeringRoad surface

The invention belongs to the technical field of test of mechanical characteristics of a vehicle tire, and in particular relates to a special composite analog pavement for testing mechanical characteristics of a tire, which is used in mechanical test of a tire. The composite pavement comprises a steel plate matrix, a groove and a boss which are machined on the steel plate matrix, and a mixture layer of resin and carborundum which is filled in the groove. The special composite analog pavement overcomes various disadvantages of the current analog pavement for tire test, and has the advantages of high tire test accuracy, high cycle frequency, small external interference and controllable friction coefficient.

Owner:JILIN UNIV +1

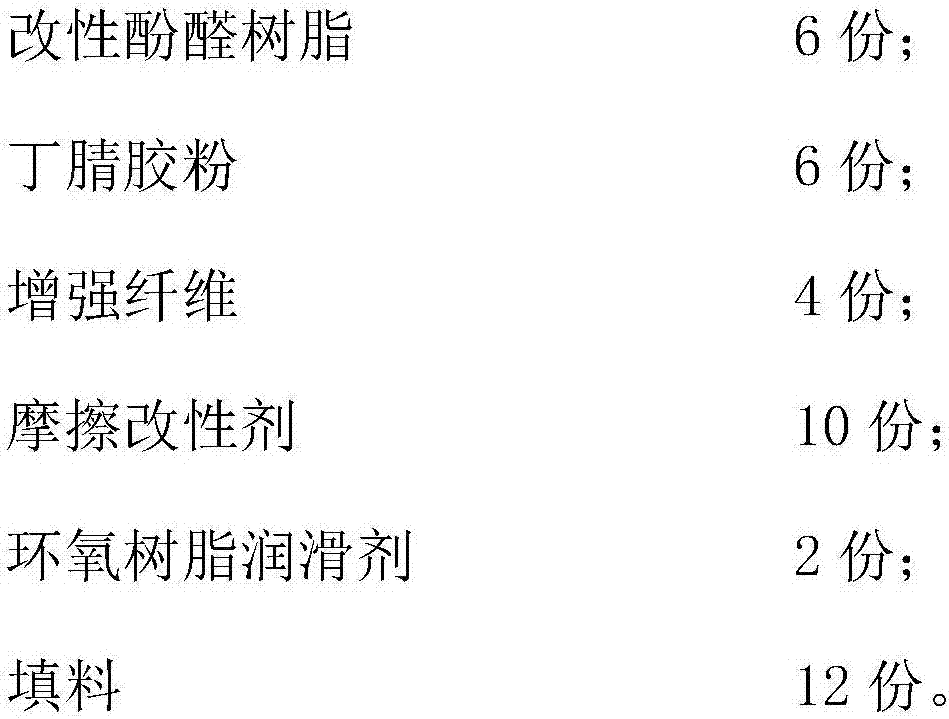

High-temperature-resistant resin-based friction material

InactiveCN107446547AImprove wear resistanceImprove high temperature resistanceOther chemical processesFriction liningSocial benefitsFiber

The invention discloses a high-temperature-resistant resin-based friction material. The high-temperature-resistant resin-based friction material is composed of, by weight, 6 to 10 parts of modified phenolic resin, 6 to 8 parts of nitrile rubber powder, 4 to 8 parts of reinforcing fiber, 10 to 14 parts of a friction modifier, 2 to 4 parts of an epoxy resin lubricant, and 12 to 14 parts of a filling material. According to a preparation method, a cashew nut shell oil modifier is adopted for modification of phenolic resin, so that the performance of the modified phenolic resin is better; the modified phenolic resin is used for preparing the high-temperature-resistant resin-based friction material, so that the friction resistance, the high temperature resistance, and the friction coefficient stability of the high-temperature-resistant resin-based friction material are improved; the raw materials are widely available; the high-temperature-resistant resin-based friction material is suitable for industrialized production; and excellent economical and social benefits are achieved.

Owner:苏州飞伦利斯金属科技有限公司

Composite salt binder composite friction material and preparation method thereof

ActiveCN109737159AImprove flame retardant performanceCuring shrinkage is smallOther chemical processesFriction liningFiberNon toxicity

The invention discloses a composite salt binder composite friction material and a preparation method thereof. Main components of the composite friction material are composed of a silicate binder, a phosphate binder, additive, a curing agent, a toughness adjusting agent, reinforced fiber, a friction performance adjuster and filler. The silicate binder mainly takes sodium water glass and potash water glass as raw materials. The phosphate binder mainly takes liquid aluminum dihydrogen phosphate as a raw material, and is mixed with calcium fluoride additive to prepare composite type composite saltbinder serving as a friction material binder. According to the composite friction material, a composite inorganic salt solution mixture serves as a binder, the characteristics of good fire resistance, environmentally friendliness, non-toxicity, simple preparation technology and high temperature resistance of the inorganic salt binder are utilized, and a resin binder is replaced. A silicate and phosphate compound has excellent bonding performance to carbon fiber and powdery materials such as barite and aluminum oxide, the stability of friction coefficients of medium-temperature and high-temperature areas is effectively improved, the problem of heat fading of a common resin-based friction material is solved, and the safety of the friction material in actual use is improved.

Owner:大连理工(营口)新材料工程中心有限公司

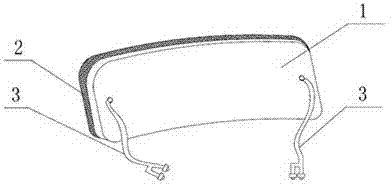

Brake lining for disc brake and brake lining system

ActiveCN103398120APrevent rotationAvoid vibrationBraking elementsFriction liningBrake liningBiomedical engineering

The invention relates to a brake lining (2) for a disc brake, particularly for rail vehicles, comprising at least one carrier metal (3) having a plurality of friction segments (4) attached in a releasable manner to the carrier metal (3) and comprising a back part (1), wherein the carrier metal (3) is held via at least one holding element (6) on the back part (1). According to the invention, the back part (1) is a casting piece.

Owner:BECORIT

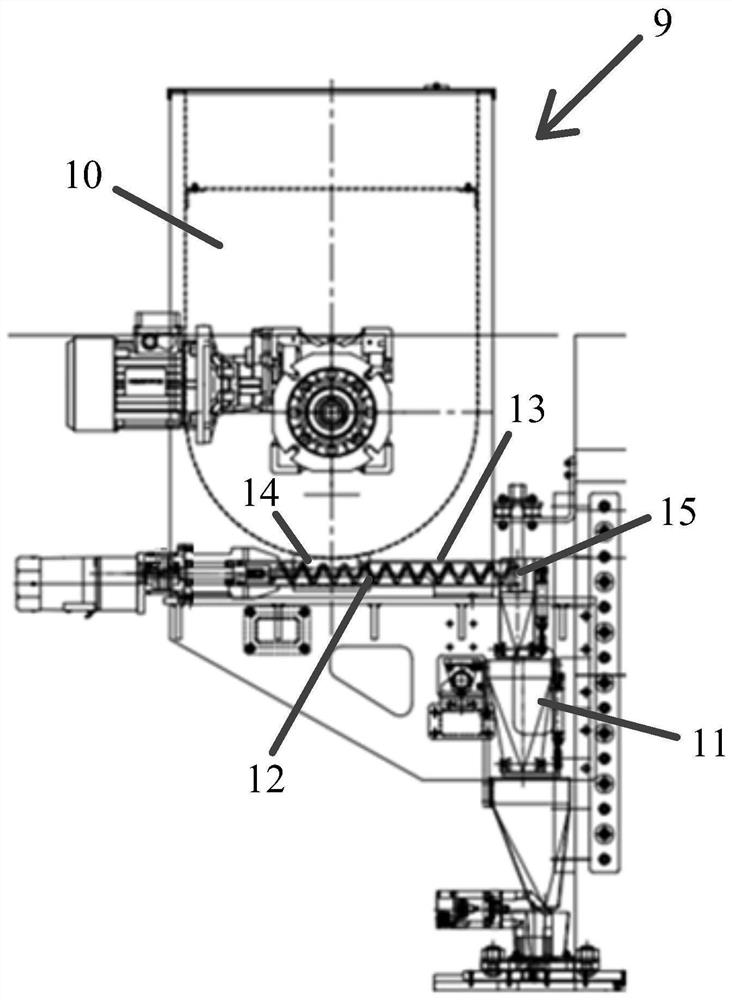

Resin-based friction body, resin-based synthetic brake pad and preparation method thereof

ActiveCN112029227AImprove wear resistanceIncrease coefficient of frictionFriction liningActuatorsVulcanizationAramid

The invention provides a resin-based friction body, a resin-based synthetic brake pad and a preparation method thereof, and belongs to the technical field of friction braking. The resin-based frictionbody comprises the following components in percentage by mass: 8-12wt% of phenolic resin, 5-10wt% of liquid latex, 3-6wt% of nitrile rubber powder, 20-28wt% of steel fibers, 2-5wt% of mineral fibers,0.1-2wt% of aramid pulp, 0.1-5wt% of graphene nanosheets, 8-12wt% of calcined petroleum coke, 1-5wt% of molybdenum disulfide, 3-8wt% of ferrochromium powder, 10-15wt% of cast iron powder, 1-5wt% of expanded vermiculite, 5-10wt% of barium sulfate, 5-10 wt% of calcium carbonate and 0.1-2 wt% of a vulcanization accelerator. According to the resin-based friction body, the stability of the friction coefficient in the braking process is effectively improved, particularly the stability of the friction coefficient under different braking pressures is reflected, and the braking process is more stableand comfortable. The invention further provides a resin-based synthetic brake pad which comprises a steel backing and the friction body, and the friction body is fixed to the steel backing.

Owner:北京浦然轨道交通科技股份有限公司 +1

Multi-fiber hybrid automobile friction material and preparation method thereof

InactiveCN105567160AImprove the mixing effectAchieve lightweightOther chemical processesCarbon fibersTemperature resistance

Owner:西安艾菲尔德复合材料科技有限公司

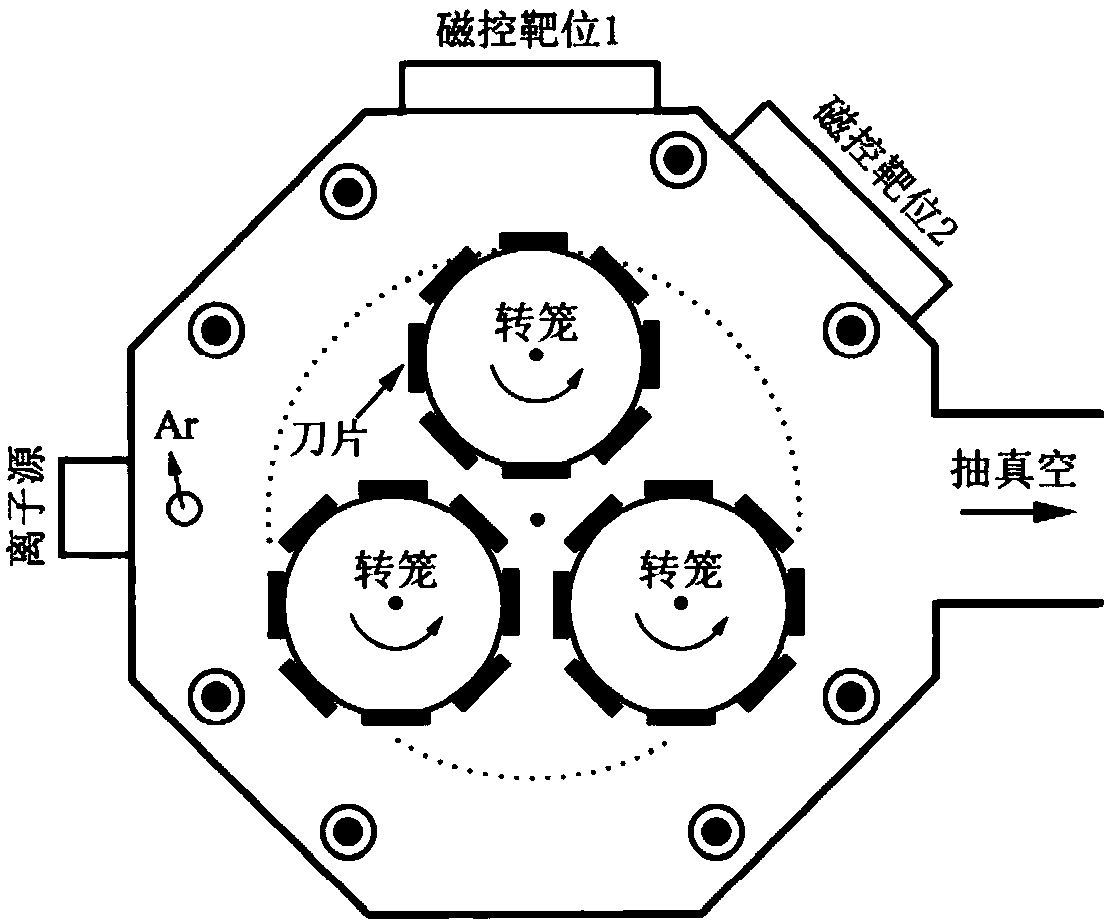

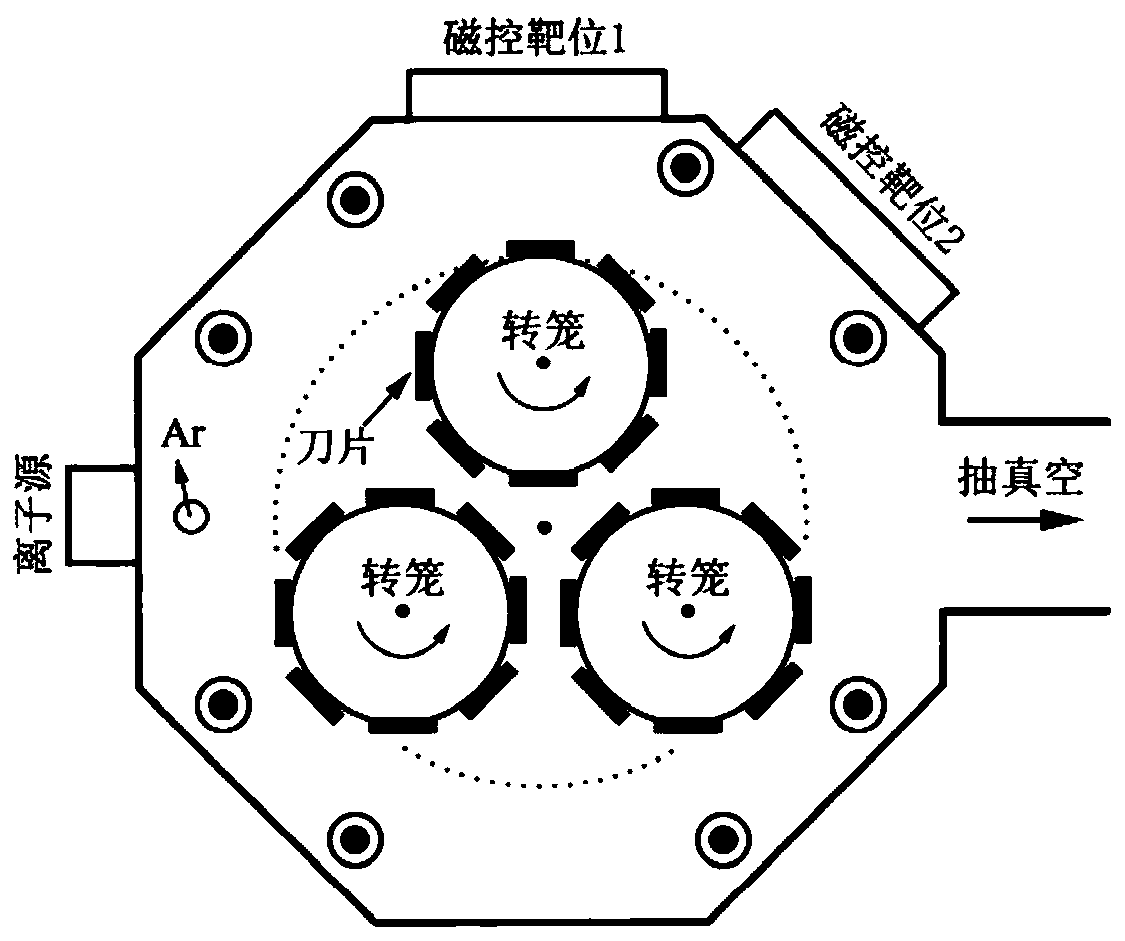

TiB2 self-lubricating coating, preparation method thereof and abrasion-resistant component

ActiveCN108251803AHigh hardnessImprove wear resistanceVacuum evaporation coatingSputtering coatingFriction reductionCutting force

The invention discloses a TiB2 self-lubricating coating, a preparation method thereof and an abrasion-resistant component. The TiB2 self-lubricating coating comprises a hard phase TiB2 and a vanadiumelement doped in the TiB2. The TiB2 self-lubricating coating has a low friction coefficient and achieves a friction reduction effect, the usage temperature range is wide, and the friction coefficientstability of the coating is good; and as for the preparation method of the coating, target conductivity is high, the deposition efficiency is high, the technical conditions are easily controlled, maneuverability is high, controllability is good, industrial production is easily achieved, and the prepared TiB2 self-lubricating coating has stable performance. The surface of the abrasion-resistant component is provided with the TiB2 self-lubricating coating, and thus the abrasion-resistant component is low in cutting force and cutting temperature, high in processing precision and long in service life.

Owner:SHENZHEN INST OF ADVANCED TECH

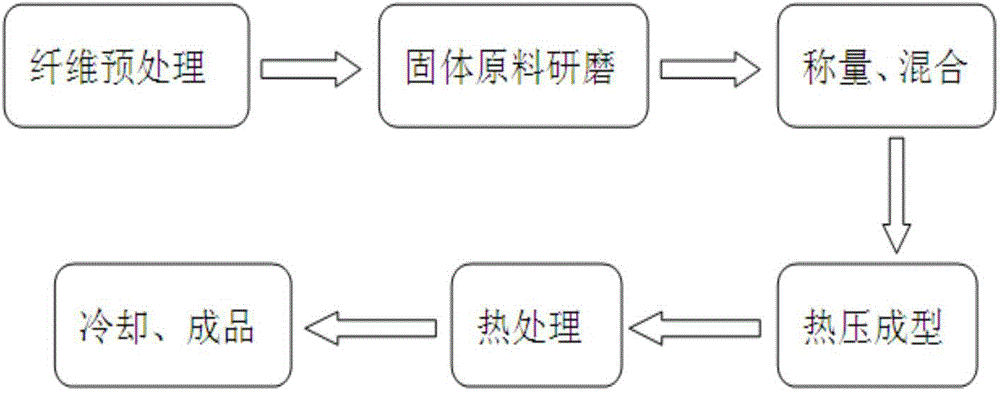

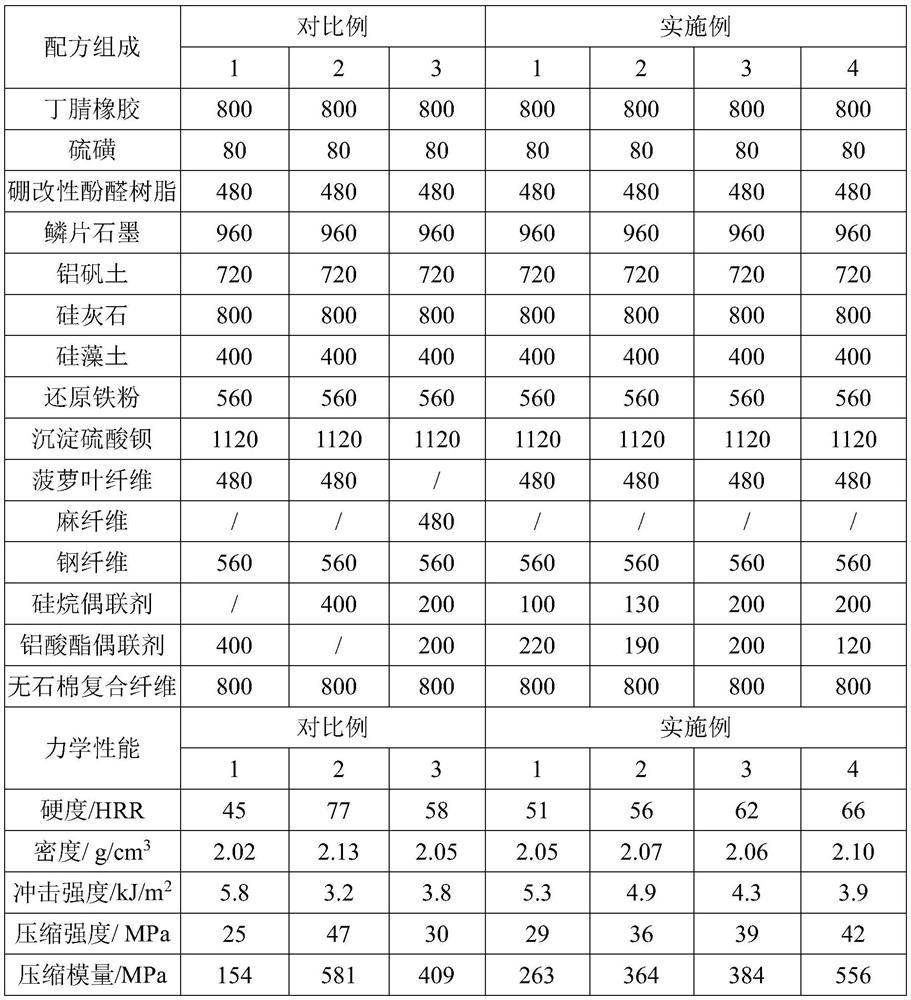

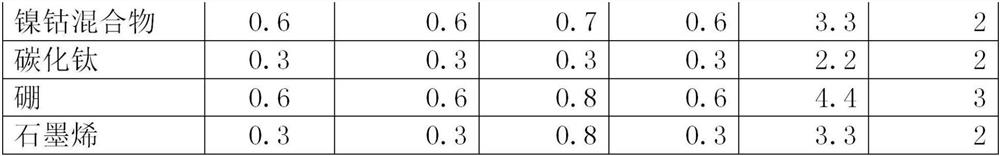

Synthetic friction material and preparation method and application thereof

ActiveCN113388173AImprove mechanical propertiesReduce coefficient of frictionNitrile rubberPhysical chemistry

The invention provides a synthetic friction material and a preparation method and application thereof. The synthetic friction material comprises the following components in percentage by mass: 8-10% of nitrile rubber, 0.9-3% of sulfur, 5-7% of boron modified phenolic resin, 10-14% of crystalline flake graphite, 8-10% of bauxite, 8-10% of wollastonite, 3-5% of diatomite, 6-7% of reduced iron powder, 12-15% of precipitated barium sulphate, 5-7% of pineapple leaf fibers, 6-8% of steel fibers, 2-4% of a coupling agent combination agent and 7-10% of inorganic mineral fibers. The sum of the mass percentages of all the components is 100%. The coupling agent combination agent comprises a silane coupling agent and an aluminate coupling agent. The invention further provides application of the synthetic friction material in synthetic friction materials for urban rail vehicles. The synthetic friction material provided by the invention has the advantages of environmental protection, high mechanical strength, low compression modulus, small dual wear, low abrasion and the like.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +3

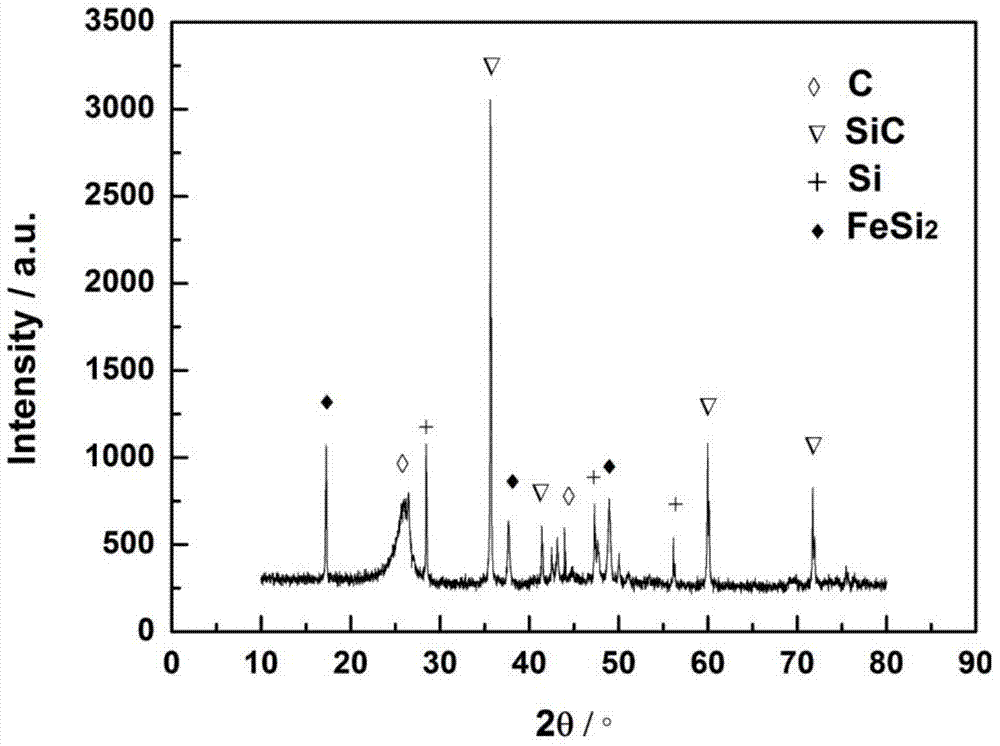

Preparation method of FeSi2 modified C/SiC braking material

InactiveCN104844243AImprove mechanical propertiesGood for heat dissipationRaw materialNanotechnology

The invention relates to a preparation method of a FeSi2 modified C / SiC braking material. A method combining CVI with RMI is adopted to prepare the FeSi2 modified three-dimensional needled C / SiC braking material. The preparation method includes: taking FeSi75 alloy powder as a RMI infiltration raw material; obtaining the FeSi2 modified C / SiC braking material through a reactive melt infiltration (RMI) process. By the preparation method, raw material cost is lowered remarkably, and RMI process temperature is lowered; a FeSi2 phase is introduced into a C / SiC composite material, so that strength and heat conductivity of the braking material are improved, friction stability is improved, and wear rate is lowered.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Magnesium-based powder metallurgy composite material and preparation method thereof

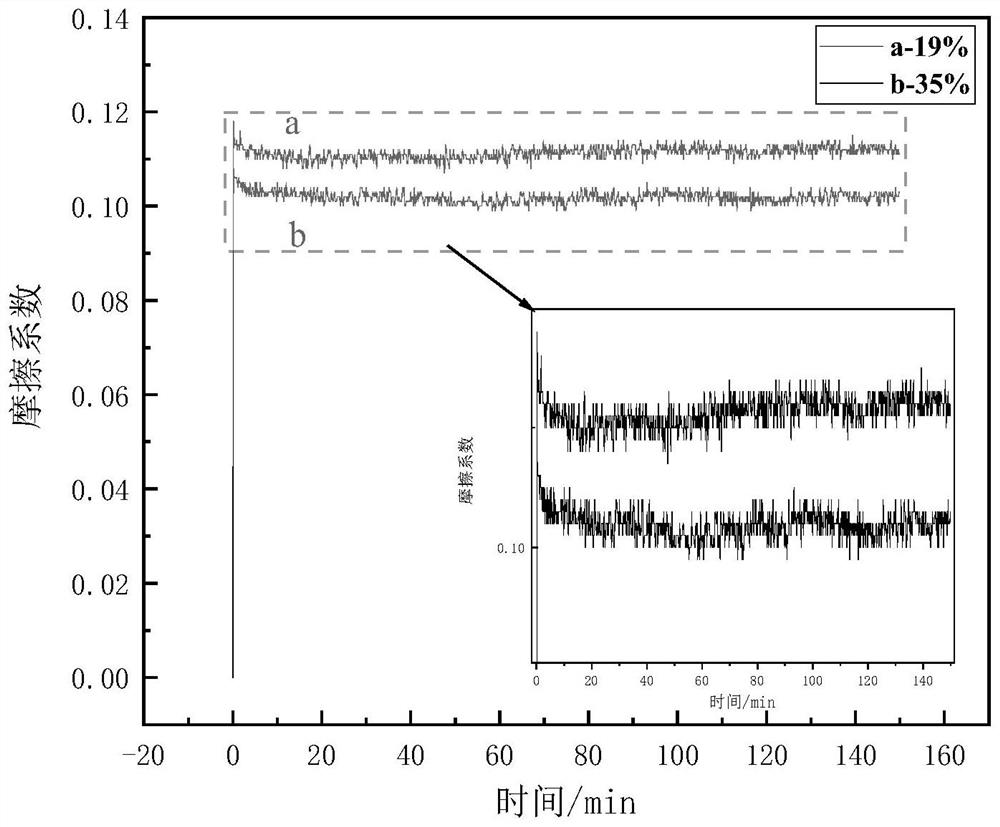

ActiveCN104384497AImprove performanceImproved coefficient of friction stabilityIron powderWear resistant

The invention discloses a magnesium-based powder metallurgy composite material and a preparation method thereof. The composite material is composed of the following materials according to the percentage by weight: 2% to 5% of iron powder, 1% to 3% of copper powder, 0.2% to 0.8% of nickel powder, 2% to 3% of chromium powder, 10% to 15% of aluminum powder, 0.5% to 1% of zinc powder, 16% to 20% of SiC particle and the balance of magnesium powder, wherein the granularity of the SiC particles is 5 to 15 micrometers, the purity of the SiC particles is greater than or equal to 99.5%, the granularity of the magnesium powder is 40 to 60 micrometers, and the purity of the magnesium powder is greater than or equal to 99.9%. The preparation method comprises the steps: a. drying at 70 to 90 DEG C for 5 to 8 hours; b. sintering at 500 to 750 DEG C for 1 to 3 hours. The magnesium-based powder metallurgy composite material prepared by the preparation method has the advantage of good wear resistant performance and can meet the requirement on the wear resistant performance of the magnesium-based powder metallurgy composite material in a practical application.

Owner:江阴金属材料创新研究院有限公司

tib 2 Self-lubricating coating and its preparation method and wear-resistant component

ActiveCN108251803BHigh hardnessImprove wear resistanceVacuum evaporation coatingSputtering coatingCutting forceCoating

Owner:SHENZHEN INST OF ADVANCED TECH

High-strength semimetal brake pad

InactiveCN107289050AReasonable formulaImproved coefficient of friction stabilityOther chemical processesFriction liningMetal fiberHigh intensity

The invention provides a high-strength semimetal brake pad. The high-strength semimetal brake pad is prepared from, by weight, 10-30 parts of hybrid fiber, 10-35 parts of metal fiber, 10-25 parts of nano-viscose, 5-10 parts of ceramic adhesive agent, 8-18 parts of friction performance regulator, 10-25 parts of filler and 1-3 parts of technological regulator. The high-strength semimetal brake pad is reasonable in formula, the prepared brake pad is high in friction coefficient stability, and the wear rate of the brake pad is effectively lowered; meanwhile, noise generated during work is drastically lowered, pollution to the environment is lowered, the strength of the brake pad is guaranteed, the work toughness of the brake pad is improved, the high temperature resistance is high, the brake pad is not prone to rusting, and the service life is prolonged.

Owner:苏州飞伦利斯金属科技有限公司

Low-noise high-metal friction plate for military vehicle and preparation method thereof

The invention belongs to the technical field of a friction plate for a vehicle, in particular to a low-noise high-metal friction plate for a military vehicle and a preparation method thereof. The rawmaterials of the low-noise high-metal friction plate comprise the following components in percentage by weight: 5-20% of Ni3Al powder with a carbon nano tube, 5-15% of sponge iron powder, 7-30% of metal fiber, 7-21% of nonmetal fiber, 5-15% of artificial graphite, 5-8% of resin, 2-5% of rubber and the rest of calcium carbonate. The preparation method comprises the steps of weighing and mixing thecomponents according to the designed proportion, conducting hot pressing molding, curing and machining, and thus obtaining the low-noise high-metal friction plate for the military vehicle. Under the premise that the density of the metal friction plate is not greatly reduced, the brake noise incidence is greatly reduced. When being used on the special military vehicle, the high-metal-content friction plate has good weather resistance and corrosion resistance and solves the technical bottleneck of the existing friction plate for the military vehicle in use.

Owner:CENT SOUTH UNIV +1

Low-noise high-strength semimetal brake pad

InactiveCN107120372AReasonable formulaImproved coefficient of friction stabilityFriction liningActuatorsLow noiseHigh intensity

The present invention proposes a low-noise high-strength semi-metallic brake pad, which comprises the following raw materials in parts by weight: 10-30 parts of hybrid fiber, 10-35 parts of metal fiber, 10-25 parts of nano-binder, ceramic binder 5~10 parts, 8~18 parts of friction modifier, 10~25 parts of filler, 1~3 parts of process regulator. The formula of the brake pad proposed by the present invention is reasonable, and the friction coefficient of the prepared brake pad has high stability, which effectively reduces its wear rate. At the same time, it greatly reduces the noise generated during work, reduces the pollution to the environment, and ensures the brake The strength of the sheet improves its working toughness, high temperature resistance, not easy to rust, and improves the service life.

Owner:TAICANG JIEGONG PRECISION METAL MATERIALS CO LTD

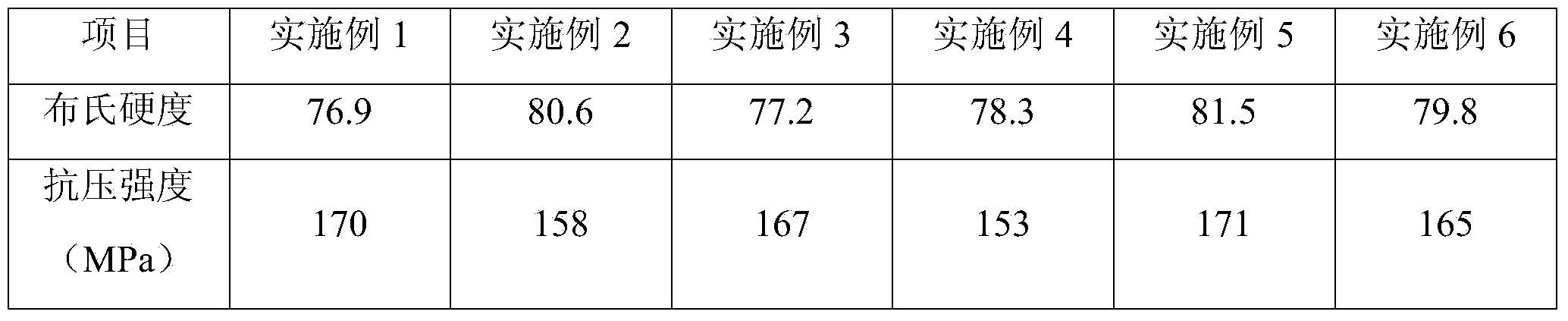

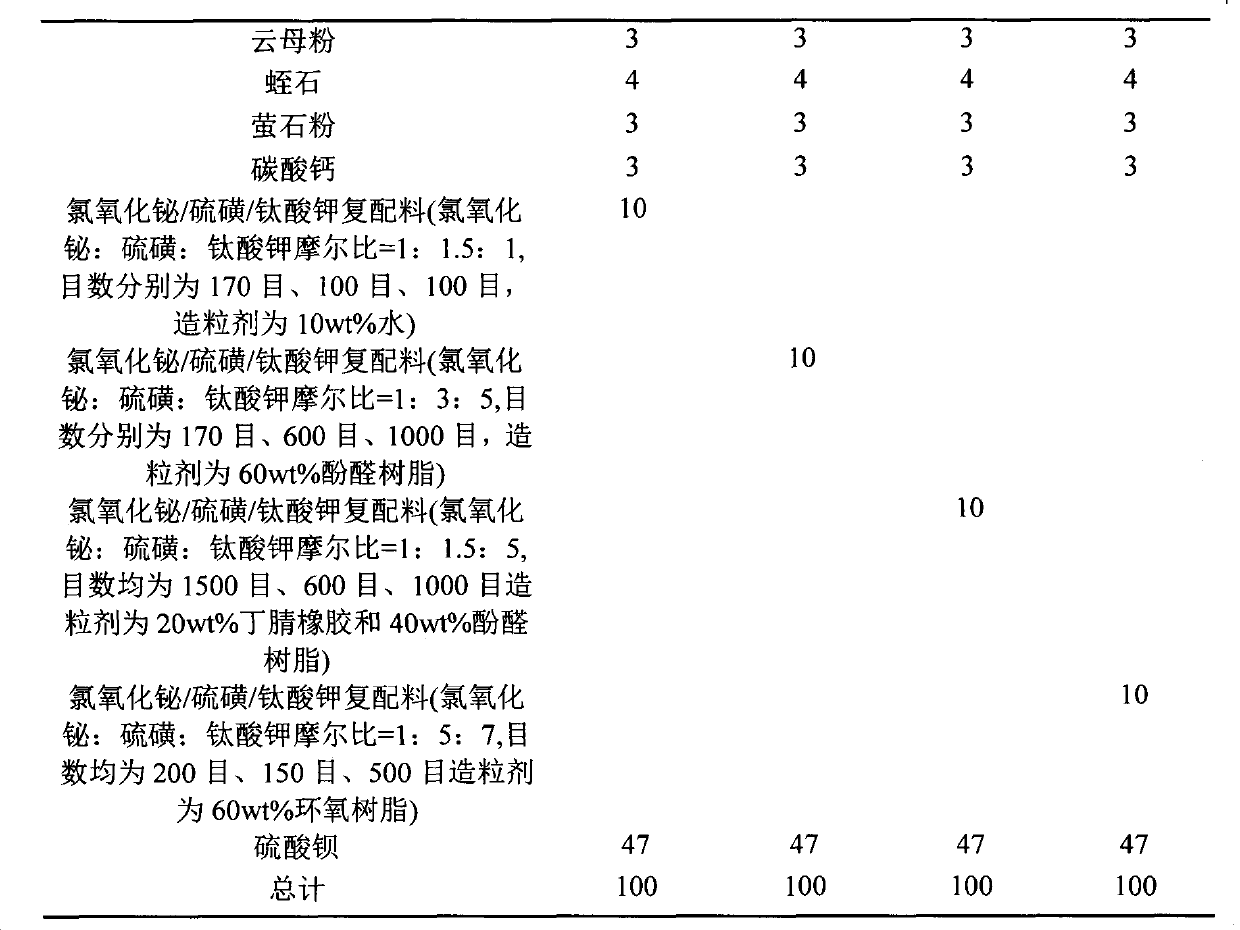

Friction material containing bismuth oxychloride/sulphur/potassium titanate compound ingredient

InactiveCN102994046AReduce pollutionImproved coefficient of friction stabilityOther chemical processesBismuth oxychloridePotassium titanate

The invention relates to application of a bismuth oxychloride / sulphur / potassium titanate compound ingredient to a phenolic-resin-based friction material. The compound ingredient is obtained through pelleting; the content of the compound ingredient in the phenolic-resin-based friction material is 5-40wt%; and the compound ingredient is capable of increasing the stability of the friction coefficient, reducing the wear rate and replacing poisonous and harmful sulfides.

Owner:CHANGSHU YUTYRONE ADVANCED WEAR MATERIALS TECH

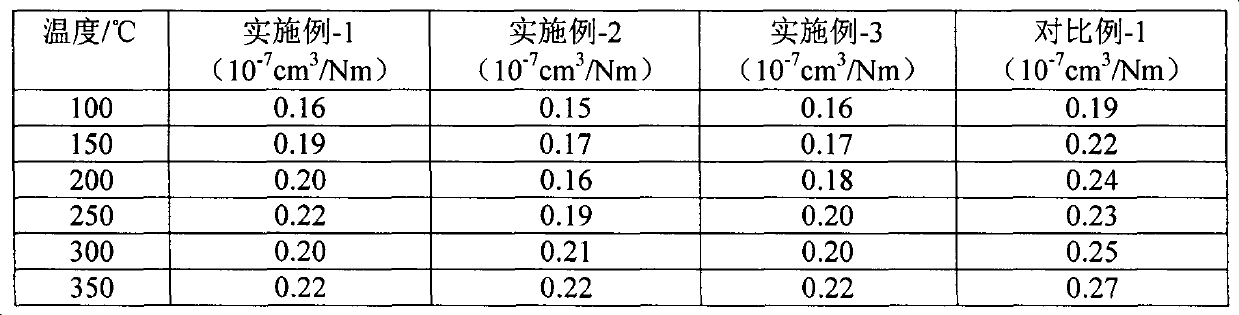

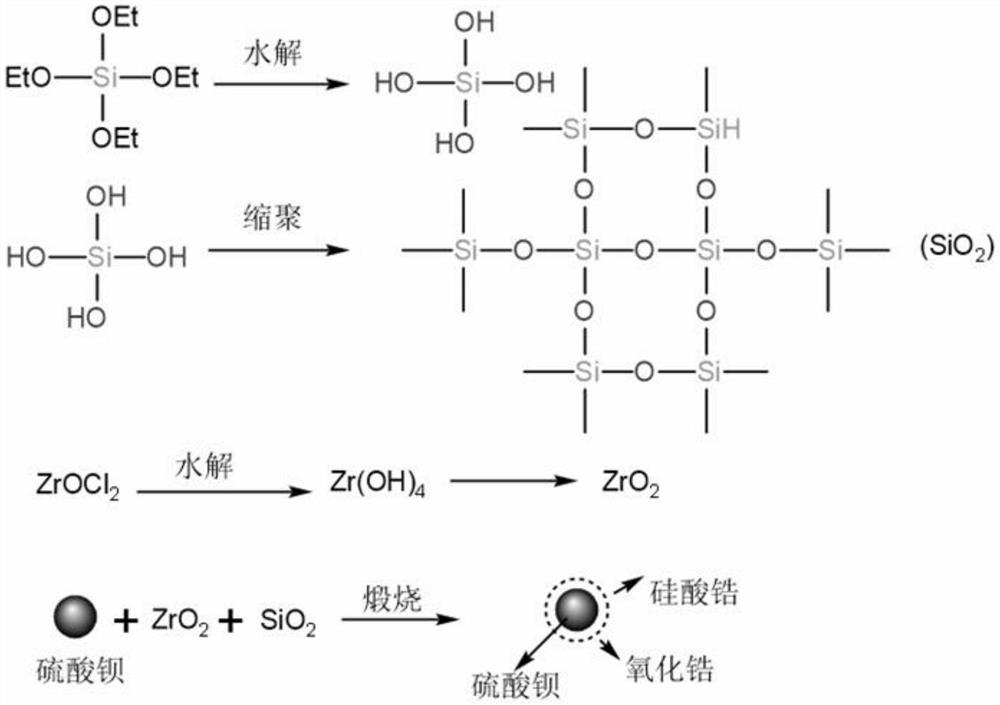

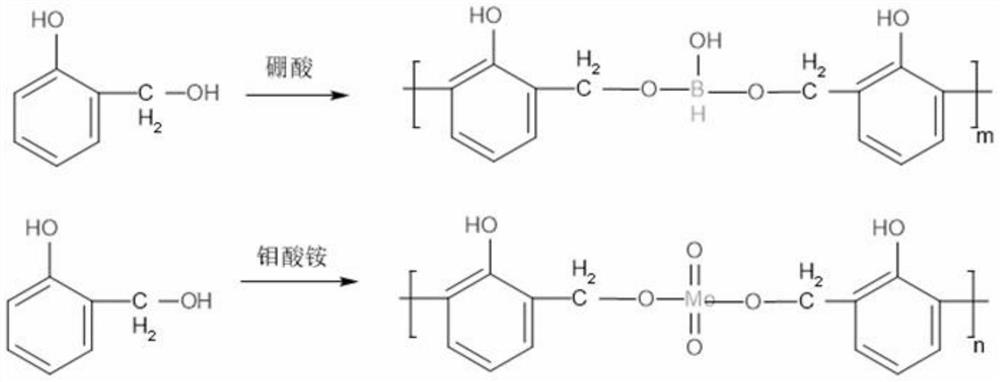

Passenger car friction material suitable for high speed of 200 kilometers and high deceleration speed of 0.8 G and preparation method of passenger car friction material

ActiveCN112855812AHigh decelerationReduce wearOther chemical processesFriction liningCalcium hydroxideHot pressing

The invention discloses a passenger car friction material suitable for a high speed of 200 kilometers and a high deceleration speed of 0.8 G and a preparation method of the passenger car friction material. The preparation method comprises the following steps that firstly, a steel backing is treated; secondly, friction materials are mixed, wherein by mass part, steel fibers, self-made friction powder, granular potassium hexatitanate, aramid fibers, mineral fibers, tin sulfide, graphite powder, coke powder, zirconium silicate / zirconium oxide / barium sulfate composite powder, calcium hydroxide and mica are added into a high-speed mixer, after mixing, modified resin is added, mixing is conducted for 30-60 min at the speed of 400-500 r / min, and a friction material mixture is obtained; and thirdly, a brake pad is prepared through hot pressing, wherein the obtained brake pad is machined, subjected to surface plastic spraying treatment, marked and assembled, and the passenger car friction material suitable for the high speed of 200 kilometers and the high deceleration speed of 0.8 G is obtained. The friction material has a high deceleration speed and excellent wear resistance.

Owner:浙江万赛汽车零部件股份有限公司

High-strength high-temperature-resistant clutch facing and method for preparing same

InactiveCN108623990AImprove burst strengthImproved coefficient of friction stabilityFriction clutchesActuatorsWater bathsFiber

The invention discloses a high-strength high-temperature-resistant clutch facing and a method for preparing the same. The high-strength high-temperature-resistant clutch facing is made from phenolic resin, preservatives, thickeners, nitrile rubber, wollastonite, inorganic silicate, inorganic phosphate, iron black, carbon black, zinc oxide, sodium chloride, aluminum oxide and distilled water. The high-strength high-temperature-resistant clutch facing and the method have the advantages that the proportions of various components of the high-strength high-temperature-resistant clutch facing are strictly controlled, the traditional clutch facing formulas are changed, accordingly, the comprehensive performance of the high-strength high-temperature-resistant clutch facing can be greatly improved,and processes for manufacturing the high-strength high-temperature-resistant clutch facing are simple; the water temperature is easy to control in water-bath heating modes, and accordingly the high-strength high-temperature-resistant clutch facing is stable in performance; styrene butadiene rubber in existing formulas is replaced by the nitrile rubber, and accordingly the high-temperature resistance of the high-strength high-temperature-resistant clutch facing can be greatly improved; framework core materials are reinforcement composite wires, each reinforcement composite wire comprises two wires and three expanded glass fibers, each wire comprises twelve 18-wire copper wires, a chemical fiber and three glass fibers which are combined with one another and are primarily twisted, and accordingly the bonding strength of framework materials and slurry can be greatly improved.

Owner:来安县隆华摩擦材料有限公司

A kind of non-heavy metal friction material and brake pad

ActiveCN105524316BImproved coefficient of friction stabilityIncrease coefficient of frictionOther chemical processesFriction liningCrack resistanceButadiene-styrene rubber

The invention discloses a heavy-metal-free friction material and a brake pad. The heavy-metal-free friction material comprises the following raw materials, by weight: 20-30 parts of steel fiber, 5-15 parts of mineral fiber, 5-15 parts modified phenolic resin, 10-15 parts of nitrile rubber, 10-15 parts of styrene-butadiene rubber parts, 2-3 parts of graphite, 3-4 parts of molybdenum disulfide, 5-8 parts of barium sulfate, 1-5 parts of aramid, 1-5 parts of heavy calcium carbonate, 1-5 parts of heavy magnesium oxide, 1-3 parts of white corundum, and 3-4 parts of silicon carbide. The heavy-metal-free friction material does not contain heavy metal, and has low copper content, such that pollution is reduced. The material has good thermal crack resistance, good wear resistance and low wear rate, such that the service life is further prolonged. The component ratio of the friction material is reasonably controlled, such that abnormal wear on a brake disk caused by the friction material is prevented.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

Vibration-reducing noise-reducing yaw low-speed brake pad and manufacturing method thereof

ActiveCN103256325BStable coefficient of frictionGood high temperature friction performanceFriction liningLow speedCarbon fibers

The invention relates to a braking pad, in particular to a vibration-damping, denoising and yaw low-speed braking pad for a yaw braking device of a wind generating set and a fabrication method of the braking pad. The vibration-damping, denoising and yaw low-speed braking pad comprises a steel backing and an abrasive layer attached to the steel backing, wherein the abrasive layer is fabricated by taking PTS (Phenolic Thermospheres) suspension method phenolic resin as a gluing agent, taking graphite, tin sulfide and copper sulfide as a lubricant, taking antimony trisulfide, zirconium silicate, silicon carbide and silicon dioxide as an abradant, taking potassium titanate whiskers, ceramic fibers, aramid fibers, carbon fibers, steel fibers and copper fibers as reinforced fibers, taking calcium carbonate, mica, vermiculite and foam ferrous powder as an inorganic filler, and taking cashew nut shell oil friction powder and rubber powder as an organic filler according to a wet method pressing technology. The braking pad has the advantages that component percentages of a friction material and a processing technology are reasonable; the braking sensitivity is high; the braking vibration is small; the friction noise is low; and the braking pad is provided with a pad abrasion alarm line.

Owner:JIAOZUO LICHUANG BRAKE

A kind of friction material and its preparation method and application

ActiveCN111014692BAvoid the problem of poor consistency of friction coefficientGuaranteed friction coefficient stabilityFriction liningActuatorsThermodynamicsEngineering

Owner:BEIJING TIANRENDAOHE NEW MATERIAL CO LTD

Friction material and product thereof

PendingCN114704571AImprove heat resistanceImproved coefficient of friction stabilityTransportation and packagingMetal-working apparatusMetallic materialsEmergency brake

The invention discloses a friction material which comprises a metal material, a bonding material, an abrasive material, a fiber reinforced material, a friction increasing material, a friction reducing material, a function reinforced material and other fillers. According to the invention, the powder metallurgy technology is utilized to combine the advantages of the iron-based friction material and the copper-based friction material, then the combination material, the abrasive material, the friction increasing material, the friction reducing material, the function reinforcing material, the fiber reinforcing material and other fillers are reasonably matched, and all the components are kept in the material in a mechanical combination manner, so that the whole friction material with certain mechanical properties is formed. The heat resistance of the friction material is improved, the components of low-melting-point metal are reduced, the content of metal with high heat conductivity is increased, the friction coefficient stability of the friction material can be improved, the heat fading phenomenon caused by sharp temperature rise of the friction material due to emergency braking or continuous downhill is improved, and the service life of the friction material is prolonged. Under the condition that the moderate and stable friction coefficient is ensured, the excellent characteristics of noise reduction, heat resistance and small dual damage are also realized.

Owner:晋江市凯燕新材料研究院股份有限公司

Aramid fiber fabric reinforced wet friction material and preparation method thereof

The invention relates to an aramid fiber fabric reinforced wet friction material and a preparation method thereof, the aramid fiber fabric and modified phenolic resin are used as raw materials, the pretreated aramid fiber fabric is alternately cleaned with deionized water and absolute ethyl alcohol and dried, then the aramid fiber fabric is immersed in a phenolic resin solution dissolved with absolute ethyl alcohol for a period of time, and the aramid fiber fabric reinforced wet friction material is obtained. Taking out, naturally airing, and carrying out hot-pressing curing by using a press vulcanizer to obtain the final aramid fiber fabric reinforced composite material. According to the invention, the problems of the existing carbon fiber fabric reinforced wet-type friction material in the preparation process and the application process are solved, so that the aramid fiber fabric reinforced wet-type friction material with more excellent comprehensive performance is obtained. The prepared friction material is tested by an HSR-2M type high-speed reciprocating friction-wear testing machine, the friction-wear performance (the friction coefficient is increased by about 10%) is excellent, the dynamic friction coefficient under the wet condition is high and stable, the cost is low, and the durability and the reliability are extremely good.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Abrasive dust recycling method in brake disc production

InactiveCN100585212CAvoid pollutionImproved coefficient of friction stabilityFriction liningAdhesiveEconomic benefits

A recycling method of abrasive dust in the brake plate preparation process is provided. The brake plate is compounded by 5 percent to 10 percent of adhesives, 10 percent to 30 percent of reinforced material, 10 percent to 35 percent of friction performance regulator, 8 percent to 25 percent of stuffing and 25 percent to 65 percent of grinding dust material on quality. Under the unit pressure of 15 to 20MPa, the prepared and weighed friction material is poured into a plow harrow mixer to be evenly stirred for 5 minutes and then put into a mould to be suppressed for 8 to 10 minutes. The method has the following heat treatment procedures: keeping for 1 hour at 140 degrees centigrade, keeping for 2 hours at 165 degrees centigrade, keeping for 2 hours at 180 degrees centigrade, keeping for 1 hour at 195 degrees centigrade and then cooling to normal temperature. The invention recycles the waste reasonably, avoiding environmental pollution and obviously improving the friction coefficient stability and consistency of the product. The friction coefficient fluctuation is reduced 15 percent and the heat fading is small. The stability of the friction performance is improved more than 15 percent and the abrasion wear is reduced more than 20 percent. At the same time, the manufacture cost is reduced 15 percent and the economic benefit is also improved.

Owner:曲阜天博汽车零部件制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com