Magnesium-based powder metallurgy composite material and preparation method thereof

A composite material and magnesium-based powder technology, applied in the field of powder metallurgy composite materials and their preparation, can solve problems such as poor wear resistance, and achieve the effects of improving performance, low preparation cost and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

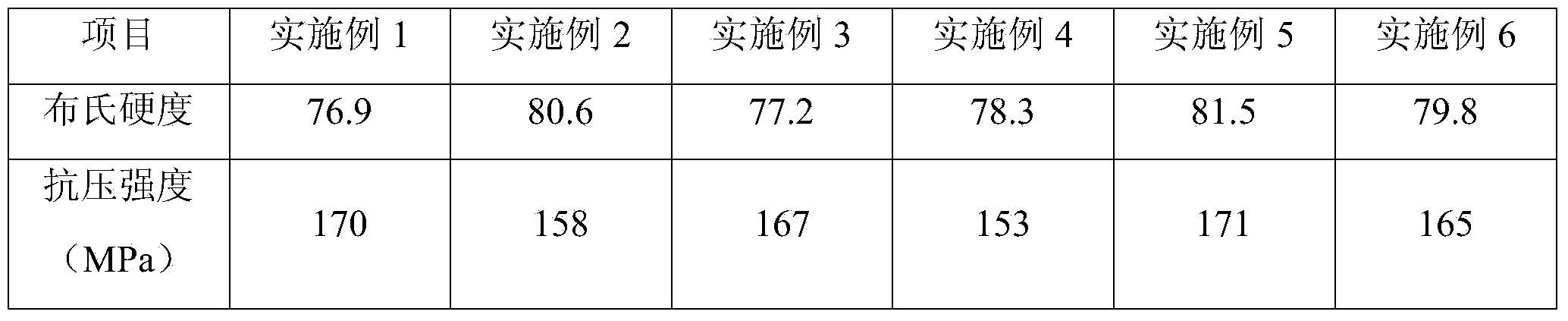

Examples

Embodiment 1

[0018] A magnesium-based powder metallurgy composite material is composed of the following substances in weight percentage: iron powder 2%, copper powder 1%, nickel powder 0.2%, chromium powder 2%, aluminum powder 10%, zinc powder 0.5%, SiC particles 16% , and the balance is magnesium powder, wherein the SiC particles have a particle size of 5-15 microns and a purity of ≥99.5%, and the magnesium powder has a particle size of 40-60 microns and a purity of ≥99.9%.

[0019] A preparation method of magnesium-based powder metallurgy composite material, comprising the following steps:

[0020] a: Mix the components evenly, then dry at 70°C for 5 hours;

[0021] b: Then sinter at 500°C for 1 hour, and after cooling, a magnesium-based powder metallurgy composite material can be obtained, wherein the heating rate is 150°C / min; the particle size of SiC particles is 5-15 microns, the purity is ≥99.5%, and magnesium powder The particle size is 40-60 microns, and the purity is ≥99.9%.

Embodiment 2

[0023] A magnesium-based powder metallurgy composite material is composed of the following substances in weight percentage: iron powder 5%, copper powder 3%, nickel powder 0.8%, chromium powder 3%, aluminum powder 15%, zinc powder 1%, SiC particles 20% , and the balance is magnesium powder, wherein the SiC particles have a particle size of 5-15 microns and a purity of ≥99.5%, and the magnesium powder has a particle size of 40-60 microns and a purity of ≥99.9%.

[0024] A preparation method of magnesium-based powder metallurgy composite material, comprising the following steps:

[0025] a: Mix the components evenly, and then dry at 75°C for 6 hours;

[0026] b: Then sinter at 550°C for 3 hours, and after cooling, a magnesium-based powder metallurgy composite material can be obtained, wherein the heating rate is 155°C / min; the particle size of SiC particles is 5-15 microns, the purity is ≥99.5%, and magnesium powder The particle size is 40-60 microns, and the purity is ≥99.9%. ...

Embodiment 3

[0028] A magnesium-based powder metallurgy composite material is composed of the following substances in weight percentage: iron powder 3%, copper powder 1.5%, nickel powder 0.4%, chromium powder 2.2%, aluminum powder 12%, zinc powder 0.6%, SiC particles 17% , and the balance is magnesium powder, wherein the SiC particles have a particle size of 5-15 microns and a purity of ≥99.5%, and the magnesium powder has a particle size of 40-60 microns and a purity of ≥99.9%.

[0029] A preparation method of magnesium-based powder metallurgy composite material, comprising the following steps:

[0030] a: Mix the components evenly, then dry at 80°C for 7 hours;

[0031] b: Then sinter at 600°C for 2 hours, and after cooling, a magnesium-based powder metallurgy composite material can be obtained, wherein the heating rate is 160°C / min; the particle size of SiC particles is 5-15 microns, the purity is ≥99.5%, and magnesium powder The particle size is 40-60 microns, and the purity is ≥99.9%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com