Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43 results about "Porphyran" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Porphyran is a sulfated carbohydrate derived from red algae of the genus Porphyra.

Use of polysaccharose sulfate for preparing medicine against grippal virus

An application of the polyose sulfate (marinofloridpolyose sulfate, alpha-D-(1-6)-glucosan sulfate, or porphyran sulfate) in preparing the medicines for preventing and treating viral influenza A or B is disclosed.

Owner:FUZHOU UNIV

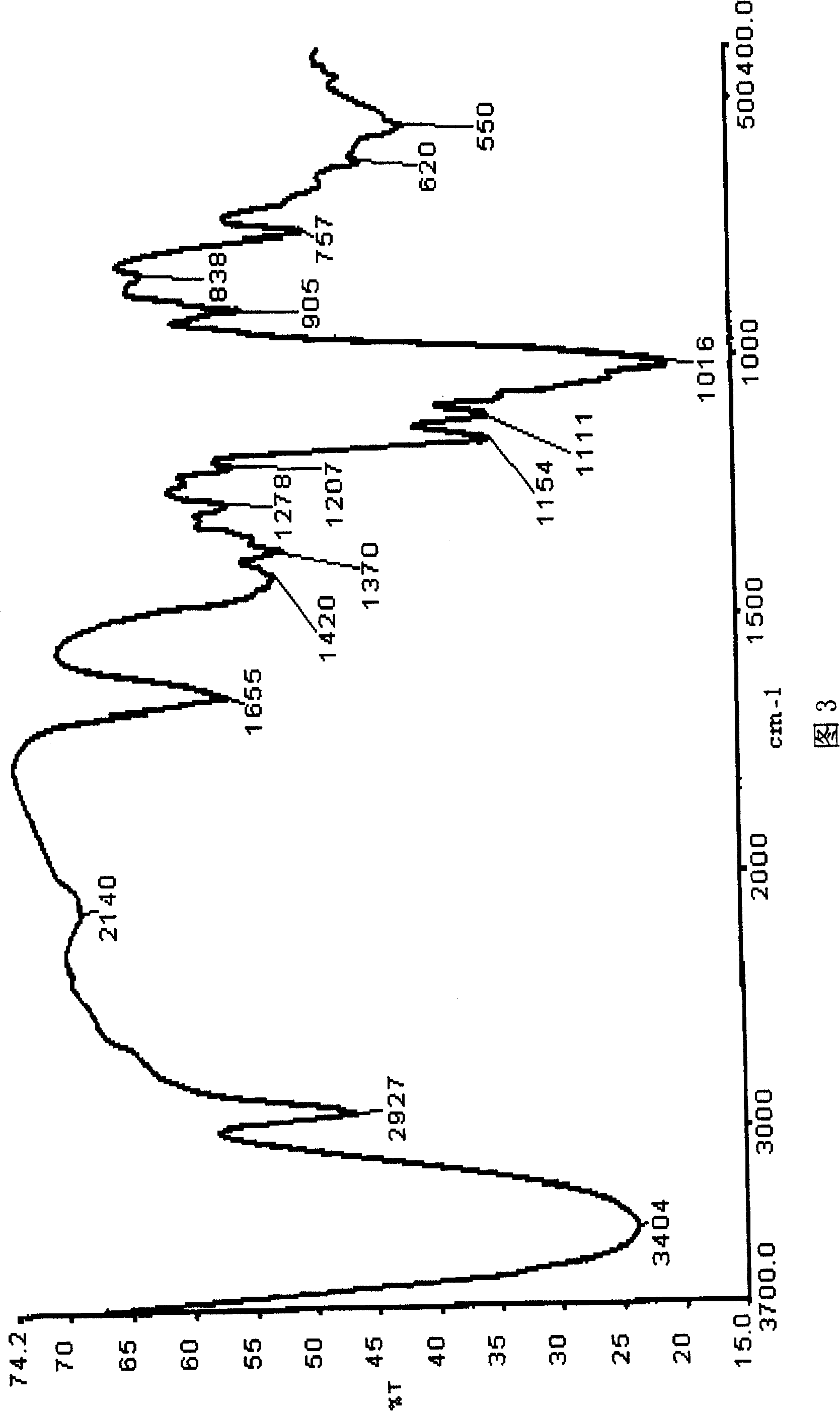

Preparation method and application of low-molecular porphyra haitanensis polyferose compound

ActiveCN103864950AImprove solubilityWide applicabilityOrganic active ingredientsBlood disorderCombinatorial chemistryIron chloride

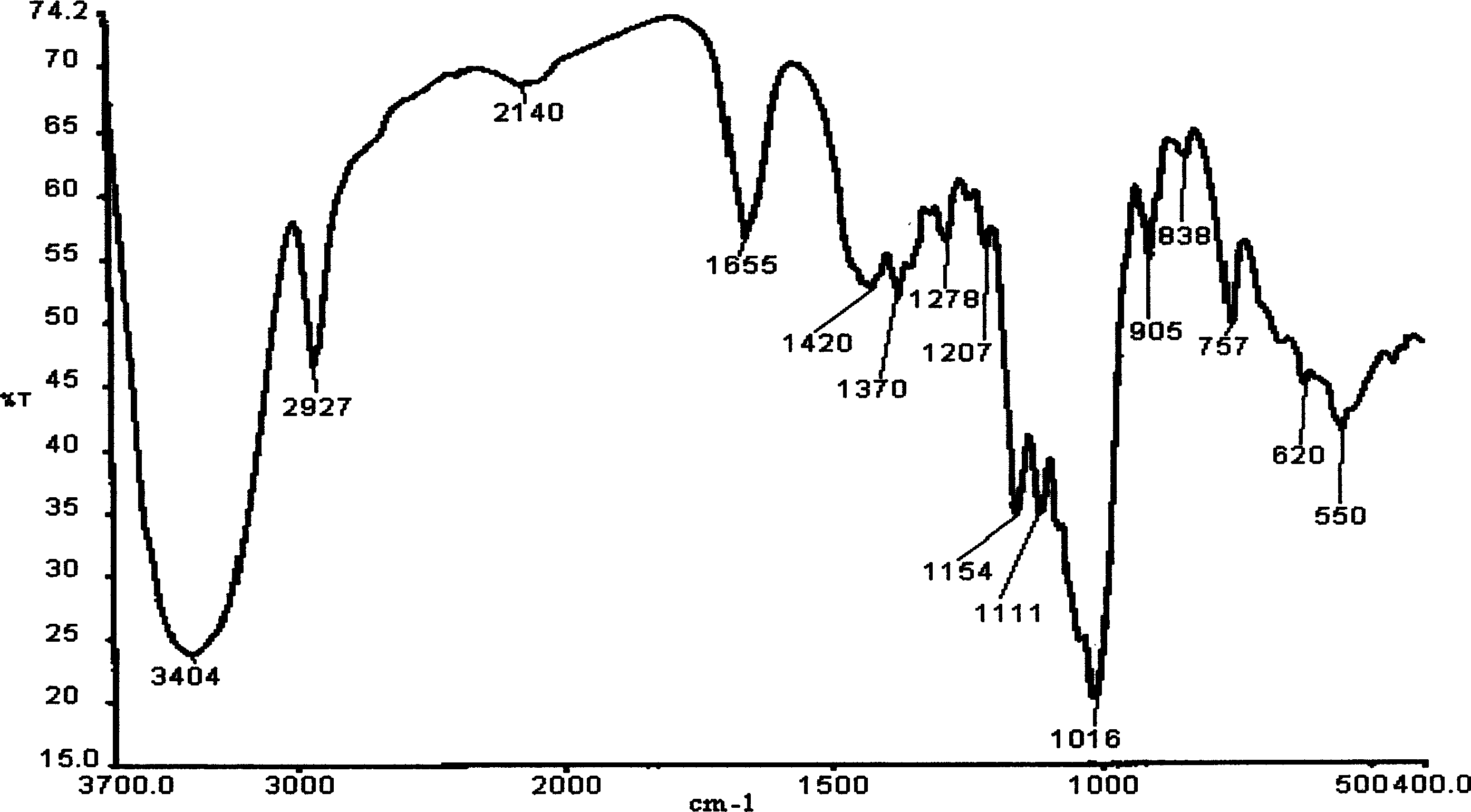

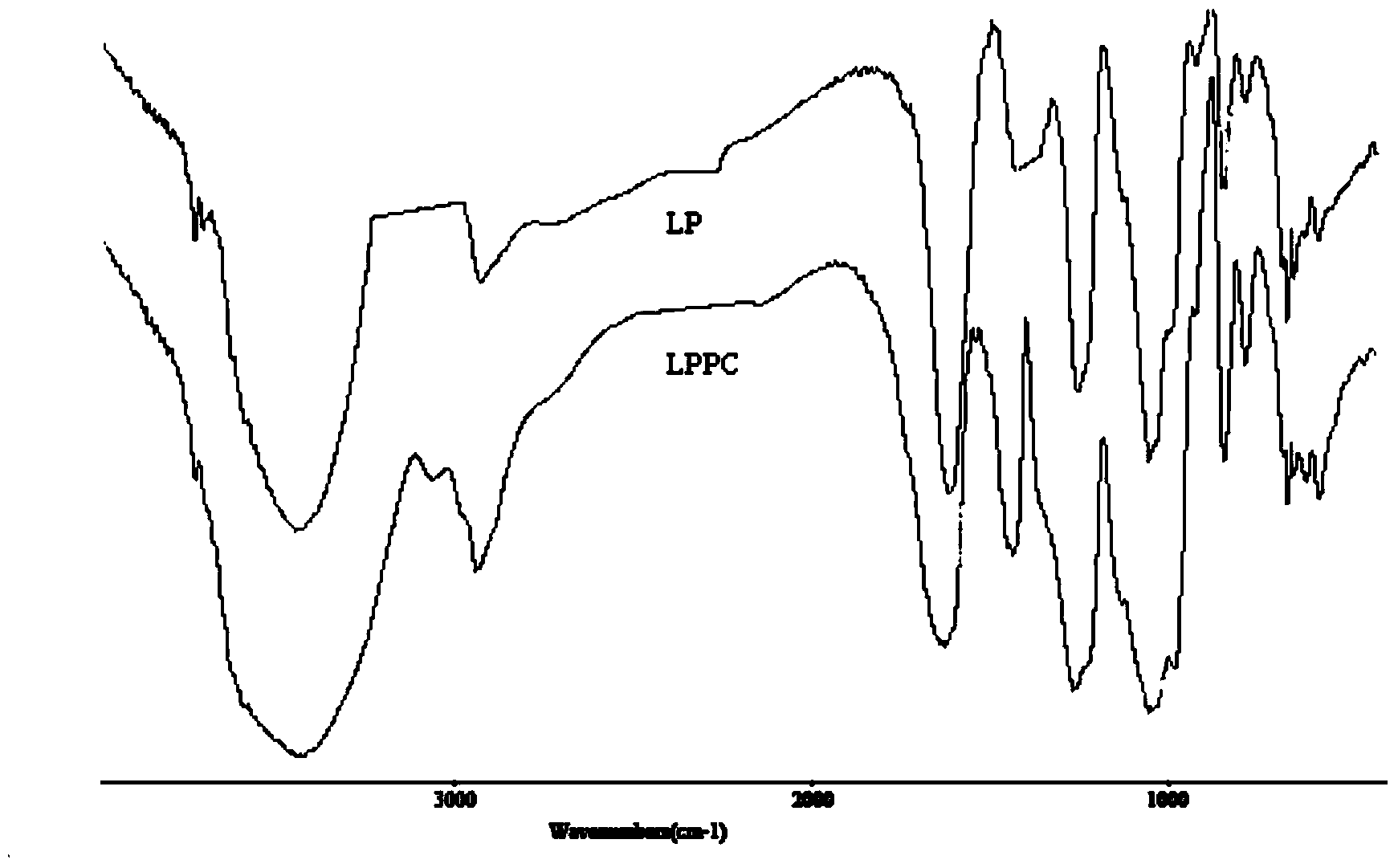

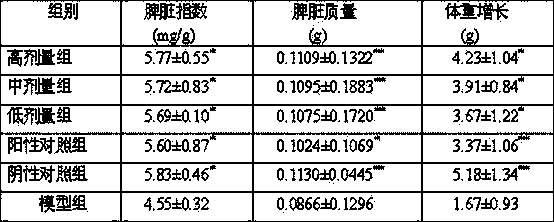

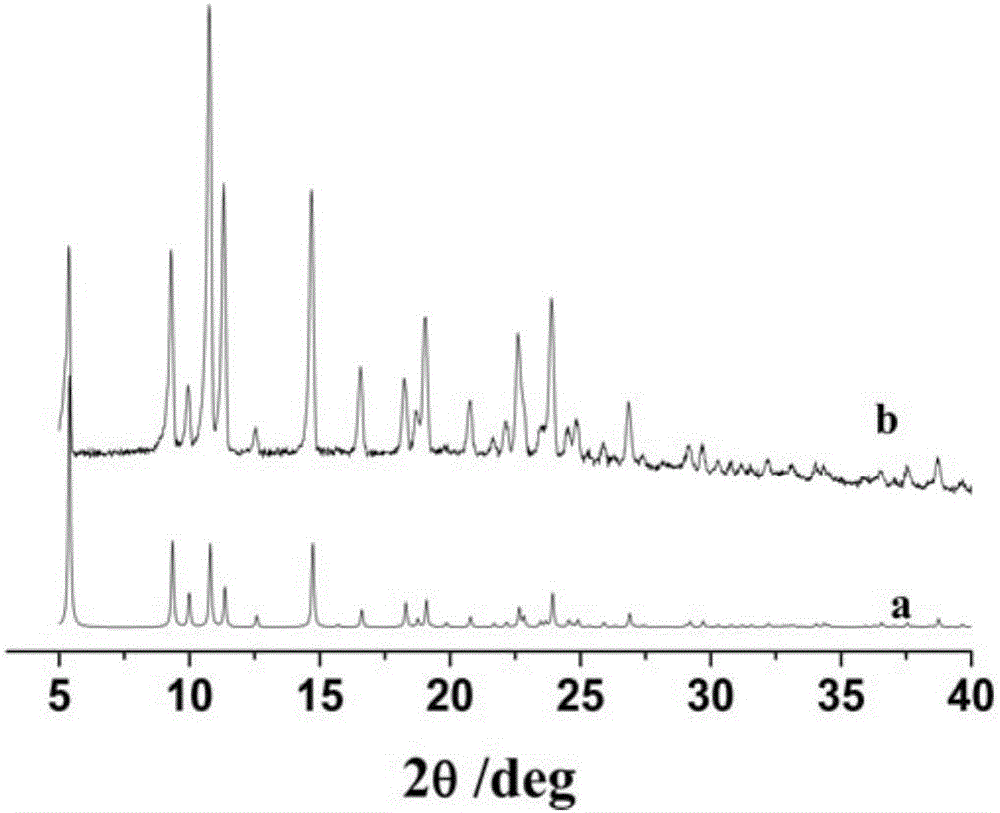

The invention provides a preparation method and application of a low-molecular porphyra haitanensis polyferose compound. The method is characterized in that low-molecular porphyran is used as a raw material and degraded by redox reaction to obtain low-molecular-weight porphyran with the molecular weight being less than 10000Da; and the polyferose compound synthesized by heating the porphyran and ferric chloride together can be dissolved well and exist stably under a physiological pH condition, and also shows a good effect in the iron-deficiency anemia mouse model experiment. The preparation method has the advantages of being simple and convenient in operation, stable in preparation process, low in preparation cost, etc.; and the preparation method also shows wide applicability to raw materials, namely, any polysaccharide with a proper molecular weight range is applicable to the preparation method.

Owner:HUZHOU TEACHERS COLLEGE

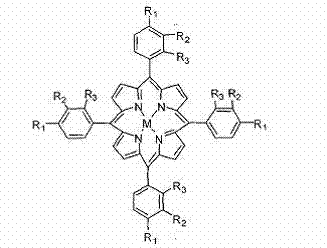

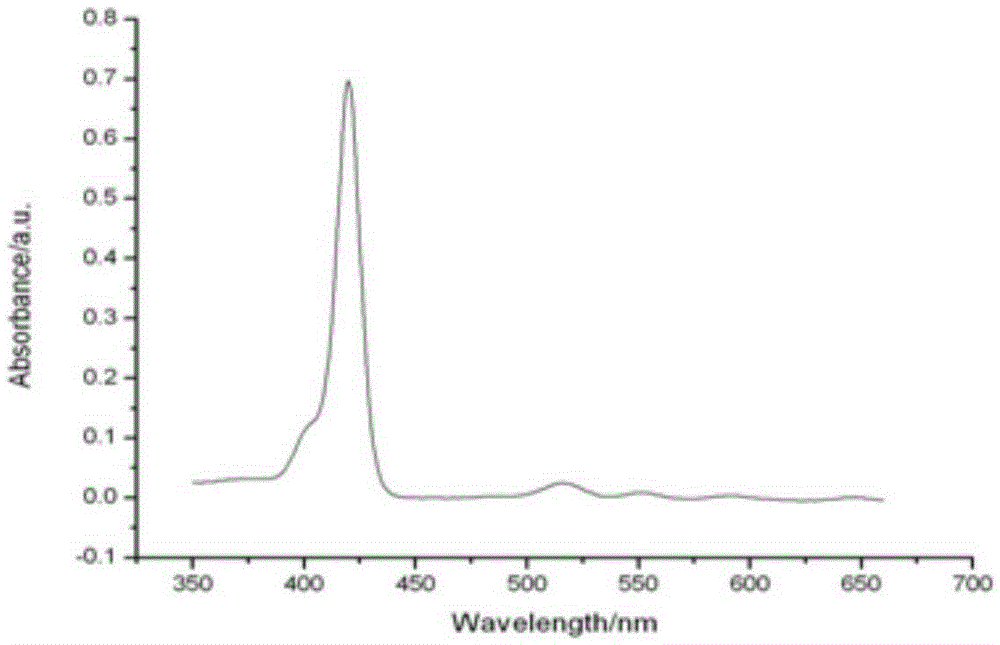

Application of CoTPyP porphyran coordination polymer materials

ActiveCN106324055ASmall particle sizeIncrease surface areaMaterial electrochemical variablesElectricityNitrite

The invention discloses application of CoTPyP porphyran coordination polymer materials. According to the application, CoTPyP porphyran coordination polymers are prepared into a carbon paste electrode; the carbon paste electrode is used as an electrochemical sensor to be applied to nitrite electrocatalysis, wherein the chemical formula of the CoTPyP porphyran coordination polymers is [Co(TPyP)]6 12CH3COOH 12 H2O. The electrocatalysis effect of the electrochemical sensor on nitrite is studied; the result shows that the sensor has better performance; the minimum detection limit is 2.0*10<8>M; the sensitivity is 743.3mA mol<-1> L cm<-2>; the linear range is 2.5*10<-6> to 5.5*10<-4>M, wherein R is 0.993; the surface has the characteristics of high sensitivity, short response time and the like; certain application values are realized in the aspect of electrochemical sensing.

Owner:NANJING NORMAL UNIVERSITY

Method for purification of uncatalyzed natural fuels from metal ions by means of at least one hemeprotein and use of the at least on hemeprotein

A method for purification of uncatalyzed natural fuels in liquid state from metal ions by removing at least one compound selected from the group consisting of natural occurring contaminating porphyrins, metalloporphyrins, chlorins and naturally occurring degradations products of these compounds, such as petroporphyrins, containing said metal ions from the fuels. At least one hemeprotein in apo-form selected from the group consisting of globins, peroxidases, pyrrolases and cytochromes having high affinity for porphyrins is added to the fuels. The hemeprotein is mixed with the fuels in such a way that the porphyrins is bounded to the hemeprotein. The hemeprotein with bound contaminating porphyrins is removed so as to obtain purified fuels. The invention relates also to the use of at least one hemeprotein selected from the group consisting of globins, peroxidases, pyrrolases and cytochromes having high affinity for porphyrins for the purification of uncatalyzed natural fuels in liquid state from metal ions.

Owner:PAUL JAN A K +1

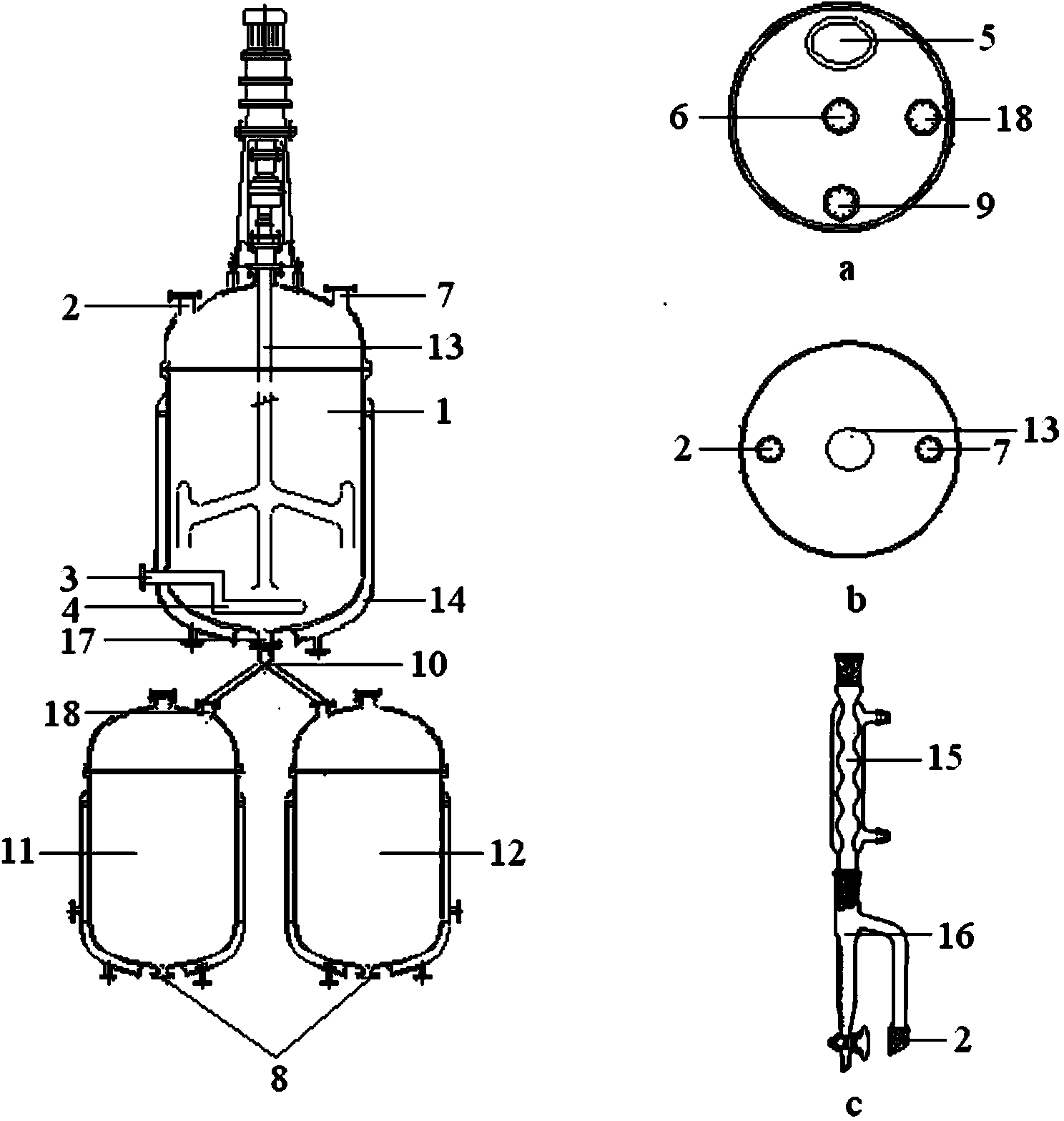

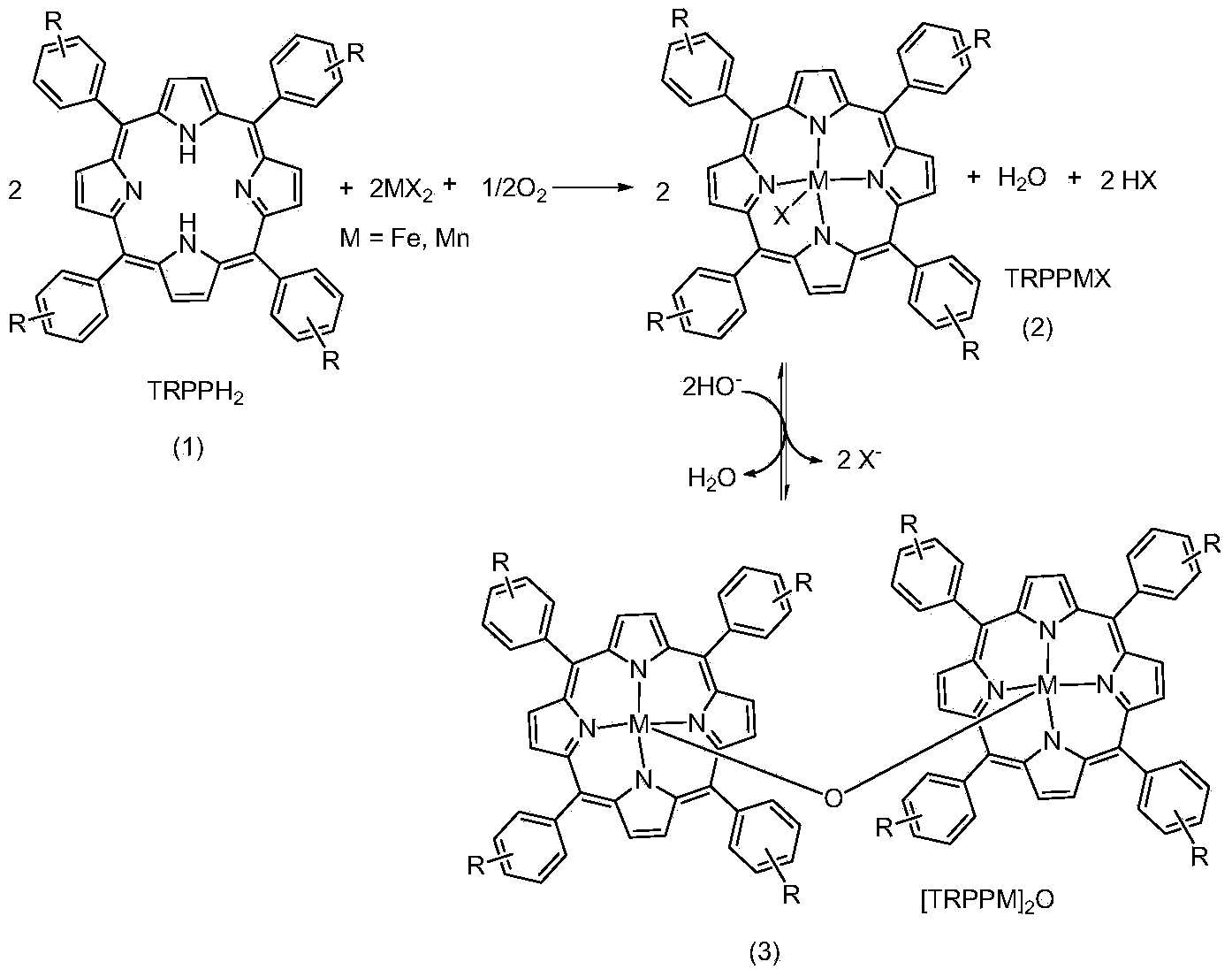

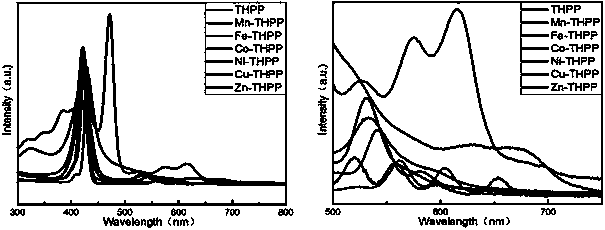

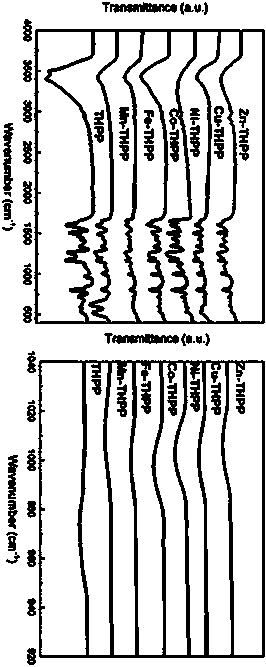

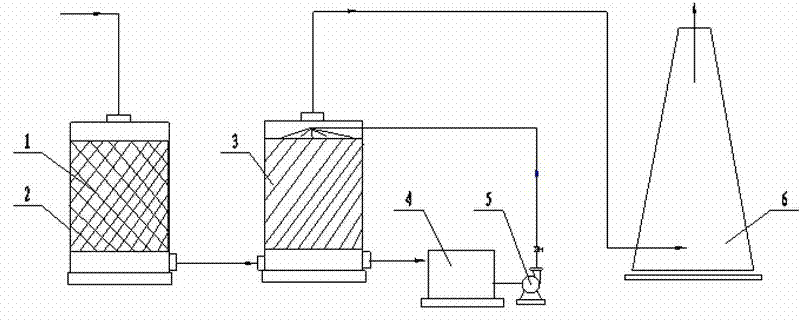

Continuous production technology for tetra-aryl-bi-metal porphyrin

The invention discloses a continuous production technology for tetra-aryl-bi-metal porphyrin. The continuous production technology is that a resolvent is fed into a heterogeneous reaction and separation synchronous reactor, wherein the reactor comprises a stirring reaction tower and at least two constant-temperature settling towers, the stirring reaction tower comprises a reflow device, the constant-temperature settling towers are communicated with the bottom of the stirring reaction tower, and the interior of the stirring reaction tower comprises a gas-phase area and a reaction area; during reaction, the reaction area and the constant-temperature settling towers are full of the resolvent, and reaction raw materials such as tetra-aryl-porphin and divalent metal salt are fed into the stirring reaction tower and react with air led into the stirring reaction tower when the reaction area and the constant-temperature settling towers are heated to the backflow temperature of the resolvent; the tetra-aryl-bi-metal porphyrin generated during the reaction settles directly under the actino of gravity and enters into a constant-temperature settling tower from the reaction area; when the constant-temperature settling tower is fully filled with the tetra-aryl-bi-metal porphyrin, the stirring reaction tower is switched to be communicated with the other constant-temperature settle tower fully filled with the resolvent; the steps are carried out alternately to ensure continuous production. The technology can be used for producing high-purity tetra-aryl-bi-metal porphyrin continuously with high yield and low cost.

Owner:YUANJIANG HUALONG CATALYST TECH

N, P double-doped graphitized carbon material based on self-assembled nanometer material of metalloporphyrin and phosphazene, preparation method and application thereof

ActiveCN109888309ARegular shapeUniform sizeMaterial nanotechnologyCell electrodesSolubilityPorphyrin

A N, P double-doped graphitize carbon material based on a self-assembled nanometer material of metalloporphyrin and phosphazene, a preparation method and application thereof are disclosed. At first, the self-assembled nano-material of metalloporphyrin and phosphazene are prepared by self-assembling, and the nano-material is calcined at high temperature and cooled to room temperature under the protection of Ar / H2 to obtain N, P double-doped graphitize carbon material. The phenylhydroxyl metalloporphyrin containing the specific C-N conjugated macrocyclic structure is used as the assembly block,the phosphazene with the unique N, P structure is used as the precursor, acetonitrile with good solubility of phenylhydroxyl metalloporphyrin is used as a solvent, and porphyrin-phosphazene composition is realized by self-assembly polymerization. By adjusting the molar ratio of TPP to HCCP, the porphyrin-phosphazene self-assembled nanomaterial with good thermal stability and controllable morphology could be obtained. The graphitized carbon material with controllable N and P doping content and uniform distribution can be obtained by adjusting the carbonization temperature and heating rate, which has an important application in electrocatalytic oxygen reduction.

Owner:HENAN UNIVERSITY

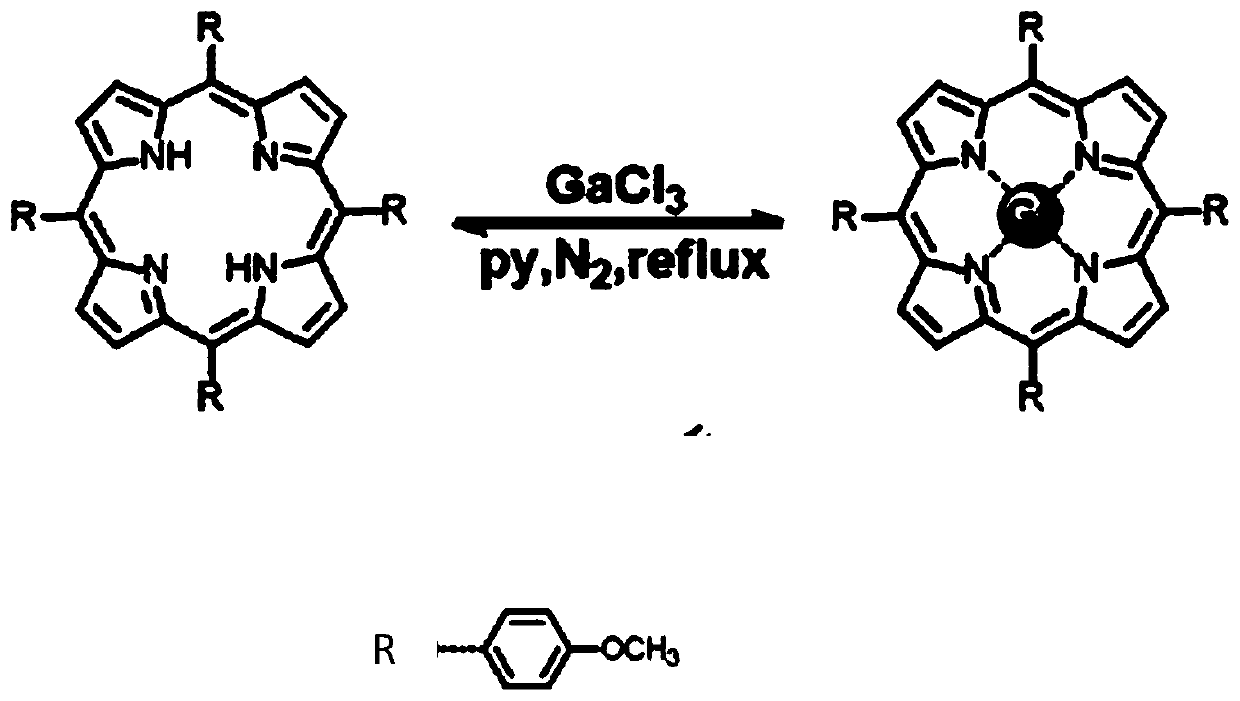

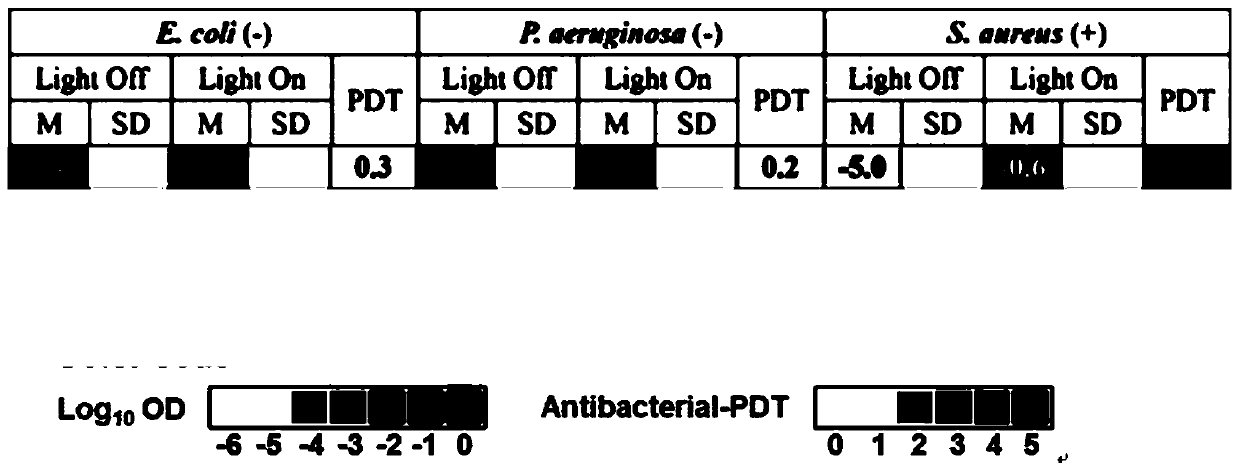

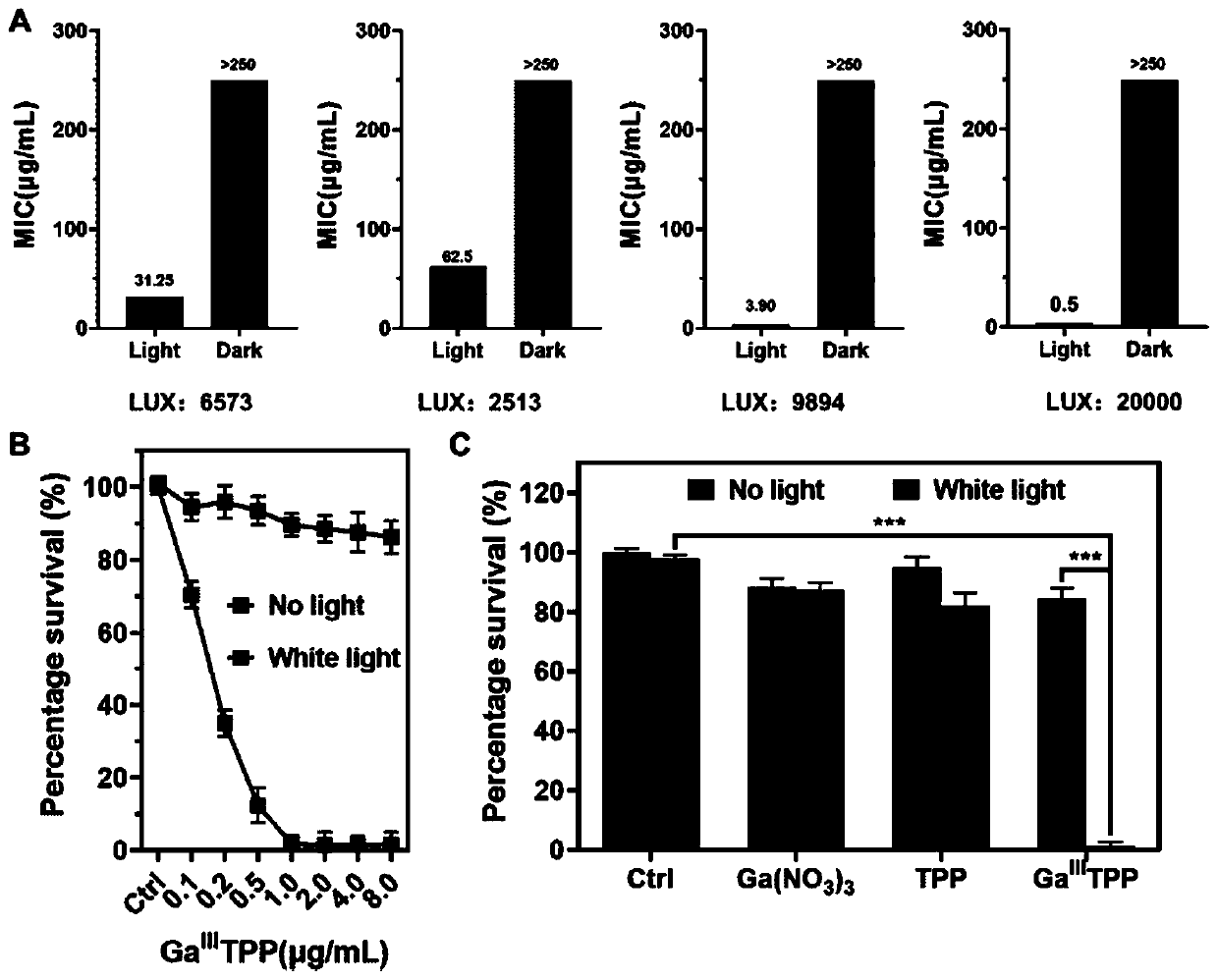

Metalloporphyrin complex and preparation method and application thereof

InactiveCN111574525AEnhanced inhibitory effectLow hemolyticAntibacterial agentsOrganic active ingredientsStaphylococcusPorphyrin

The invention discloses a metalloporphyrin complex and a preparation method and application thereof. With application of inhibiting the biological activity of staphylococcus aureus through a photodynamic mechanism, porphyrin small molecules are used as ligands to be coordinated with Ga to form a four-coordination metal complex according to the metal complex, the formed gallium porphyrin complex has a good antibacterial effect on staphylococcus aureus, the gallium porphyrin complex can effectively inhibit growth of bacteria, promote wound repair of mice and reduce drug resistance and toxicity of the bacteria under the action of photodynamics so that the gallium porphyrin complex has a good application prospect.

Owner:WENZHOU INST UNIV OF CHINESE ACAD OF SCI

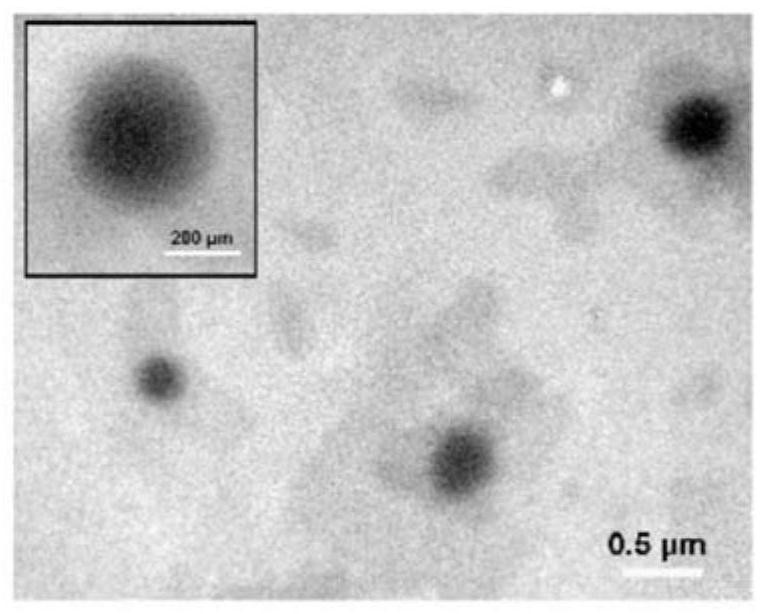

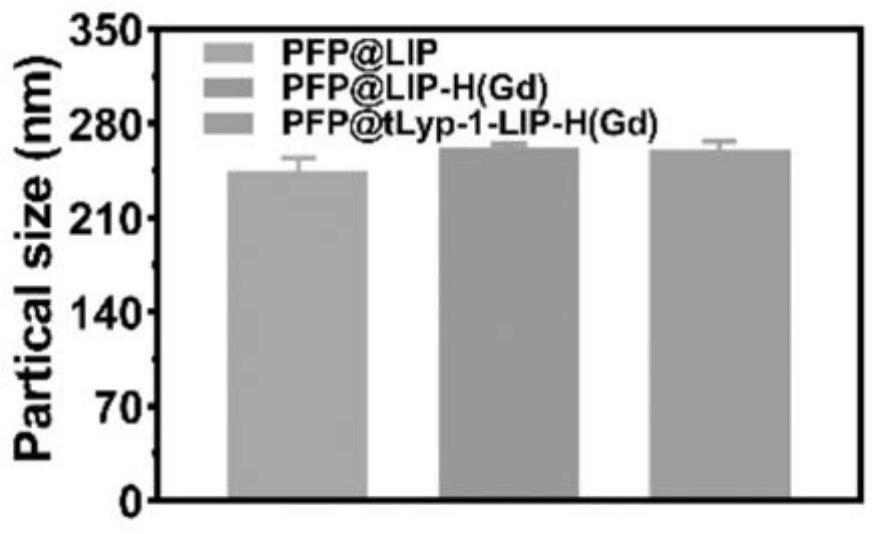

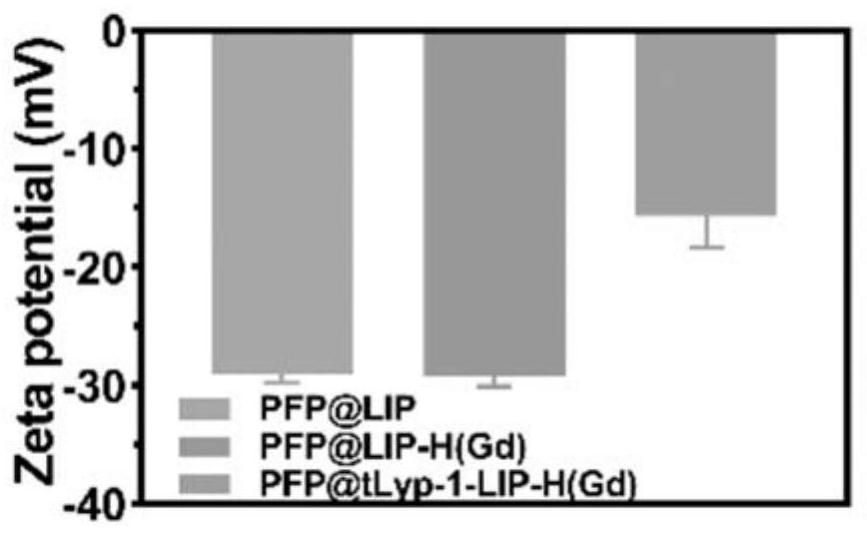

Peptide functionalized metal-loaded porphyrin phase-change nanoparticle and preparation method and application thereof

ActiveCN111671923ASolve the technical problem that it is difficult to break through the tumor tissue barrier and penetrate deep into the tumor tissueSolve technical problems deep inside tumor tissueDispersion deliveryGeneral/multifunctional contrast agentsPorphyrinLiposome

The invention belongs to the field of biomedicine, relates to a nanoparticle and a preparation method and application thereof, and in particular relates to a peptide functionalized metal-loaded porphyrin phase-change nanoparticle and a preparation method and application thereof. The nanoparticle comprises a shell membrane formed by liposome, and liquid fluorocarbon encapsulated in the shell membrane, wherein a tumor homing cell-penetrating peptide is covalently attached to the shell membrane, and the inside of the lipid bilayer of the liposome is encapsulated with a contrast agent. The nanoparticle has the function of penetrating the tumor blood vessel barrier and the tumor interstitial barrier, can penetrate deep into tumor tissues, and more effectively realizes the diagnosis and treatment of tumors. The nanoparticle of the scheme can be applied in the development and preparation of drugs for tumor diagnosis or treatment.

Owner:CHONGQING MEDICAL UNIVERSITY

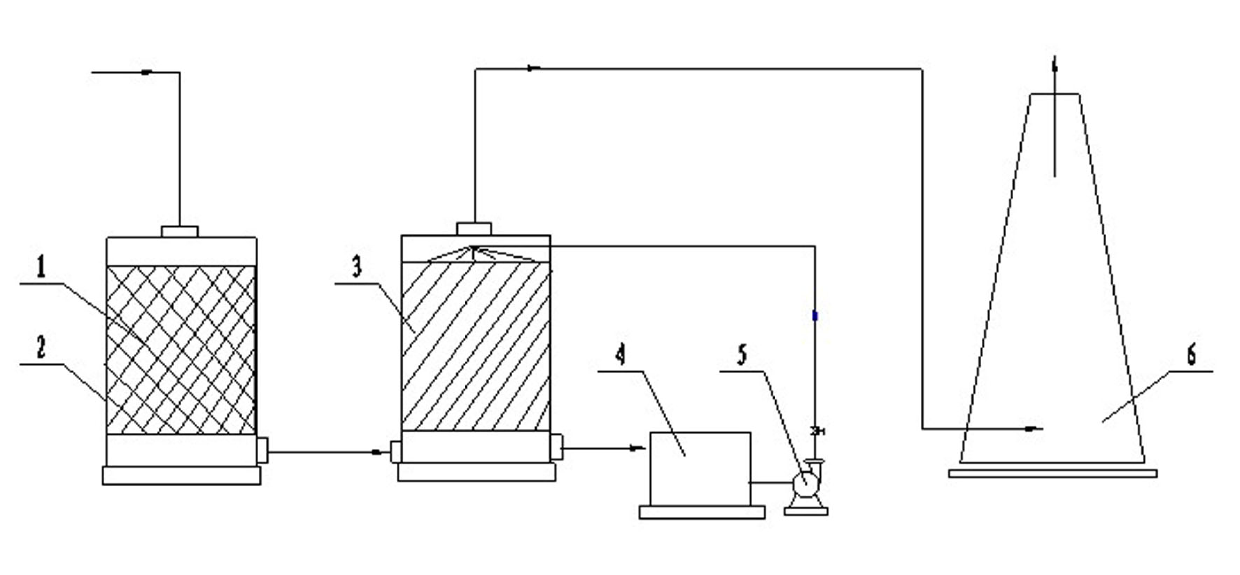

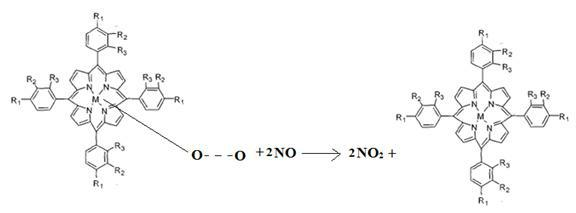

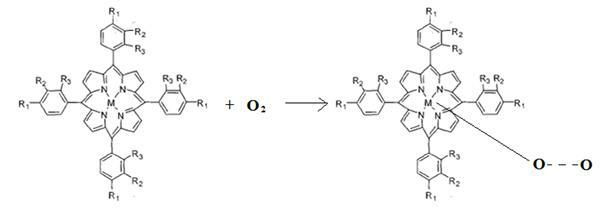

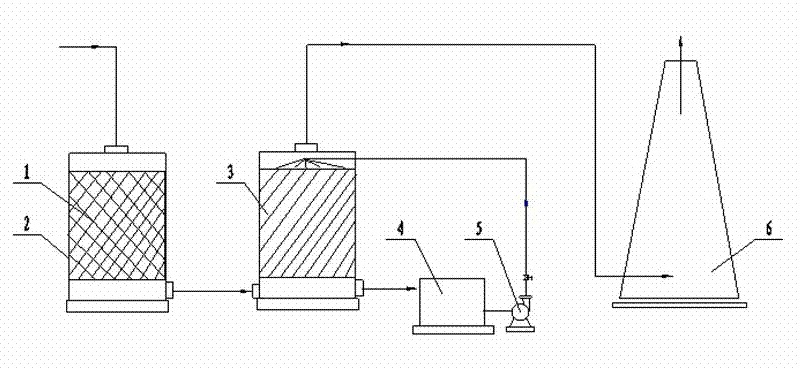

High purification method of industrial tail gas containing oxynitride

InactiveCN101905114ACompact designSimple and fast operationDispersed particle separationPtru catalystPhysical chemistry

The invention relates to a purification technique of an industrial tail gas, in particular to a high purification method of an industrial tail gas containing oxynitride, which solves the problem that the traditional dry methods or wet methods have different disadvantages respectively. The industrial tail gas containing oxynitride enters an oxidation reactor filled with an immobilized porphyran catalyst from the top of the oxidation reactor; dioxygen in the industrial tail gas is activated by the porphyran catalyst so that the nitric oxide gas is converted into a nitrogen dioxide gas; the industrial tail gas containing nitrogen dioxide gas enters the bottom of an absorber from the bottom of the oxidation reactor and comes into contact with dilute nitric acid which enters from the top of the absorber; the nitrogen dioxide is absorbed to generate nitric acid; and the industrial tail gas after being absorbed is discharged from the top of the absorber. The porphyran is used as an oxidation catalyst of the industrial tail gas containing oxynitride for the first time, the dioxygen in the industrial tail gas is activated to promote the nitrogen oxide to be converted into nitrogen dioxide, the oxidizability of the oxynitride is enhanced, and the size of an oxidation and absorption device of oxynitride is reduced by absorption with a wet method.

Owner:太原市恒远化工环保科技有限公司

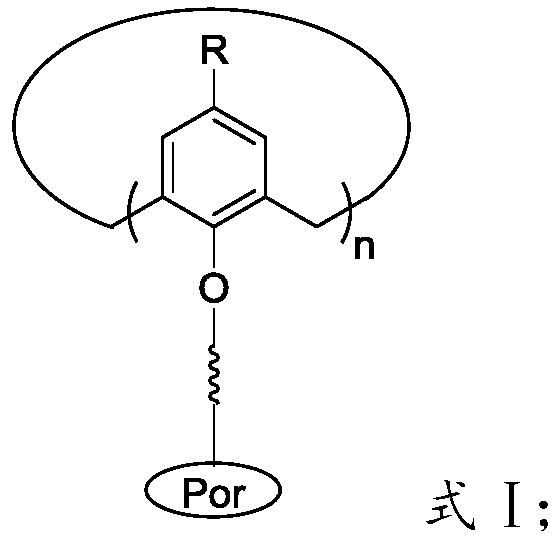

Macrocyclic carrier multi-center metalloporphyrin complex and preparation method of polycarbonate

ActiveCN111574548AFast preparationHigh catalytic activityGroup 3/13 element organic compoundsAlkanePolymer science

The invention provides a macrocyclic carrier multi-center metalloporphyrin complex. The macrocyclic carrier multi-center metalloporphyrin complex has a structure shown as a formula I. According to themulti-center metalloporphyrin complex, the porphyrin complex can be prepared by connecting porphyrin to calixarene with a specific group; the porphyrin complex containing a plurality of active centers can be rapidly prepared according to the scheme; compared with the prior art, the macrocyclic carrier multi-center metalloporphyrin complex has advantages that the number of the active centers is determined and can be adjusted through the size of a calixarene ring, and the spatial conformation can be adjusted and controlled by changing a calixarene substituent group. The catalyst shows high catalytic activity, product selectivity and high-temperature stability when catalyzing copolymerization of carbon dioxide and alkylene oxide.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

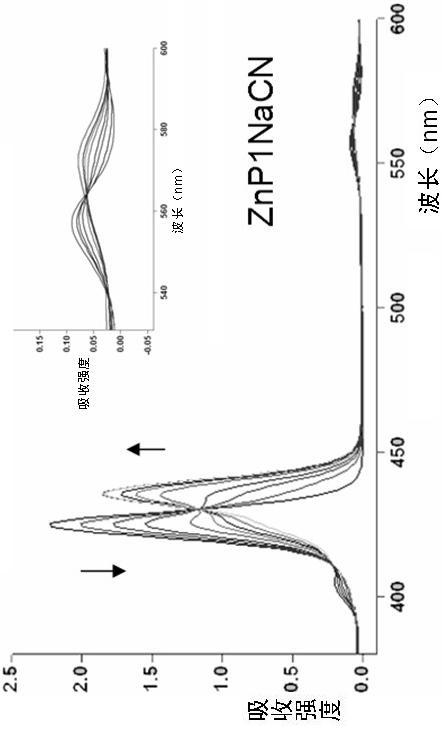

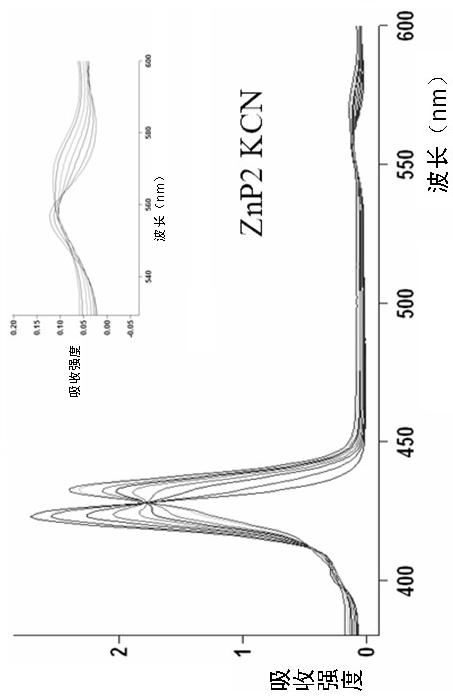

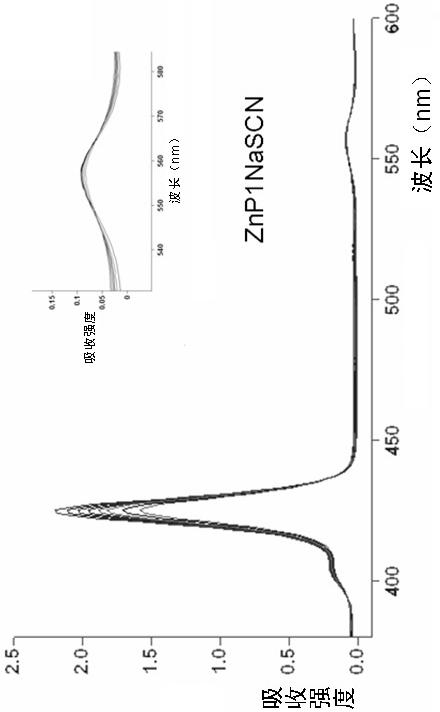

Porphyrin-crown ether compound, its synthesis and application

InactiveCN102408436AImprove solubilityHigh sensitivityOrganic chemistryMaterial analysis by observing effect on chemical indicatorPorphyrin moleculeFluorescence

The invention discloses a porphyrin-crown ether compound, which comprises a metallic porphyrin molecular skeleton and a crown ether complexation unit, as well as a linker connecting the two fragments in series. The compound has a general formula of: [Metallic porphyrin]-Linker-[Crown ether], the Metallic porphyrin represents metallic porphyrin, the Crown ether represents crown ether, and the Linker is an alkyl bond or an amide bond. In the invention, a metal ion on porphyrin can coordinate with different anions and cause optical signal changes of ultraviolet and fluorescence of a porphyrin chromophore, while the crown ether undergoes complexation with a counter cation (like Na<+>, K<+>, NH4<+>, etc.), preferably with a cation matching with the crown ether in size. For anions of different stereo configurations, the size of an intramolecular hole can be controlled by adjusting the length of a linking unit so as to make the intramolecular hole matching with an anion mutually. The obtained sensor molecule can detect inorganic anions with a concentration low to 0.1ppm (like C1<->, I<->, CN<->, SCN<->, and ClO4<->, etc.) in a water phase medium. The detection technology of high sensitivity in the invention is of great significance in environment analysis, biomedicine and other aspects.

Owner:WUHAN SYNCHALLENGE UNIPHARM INC

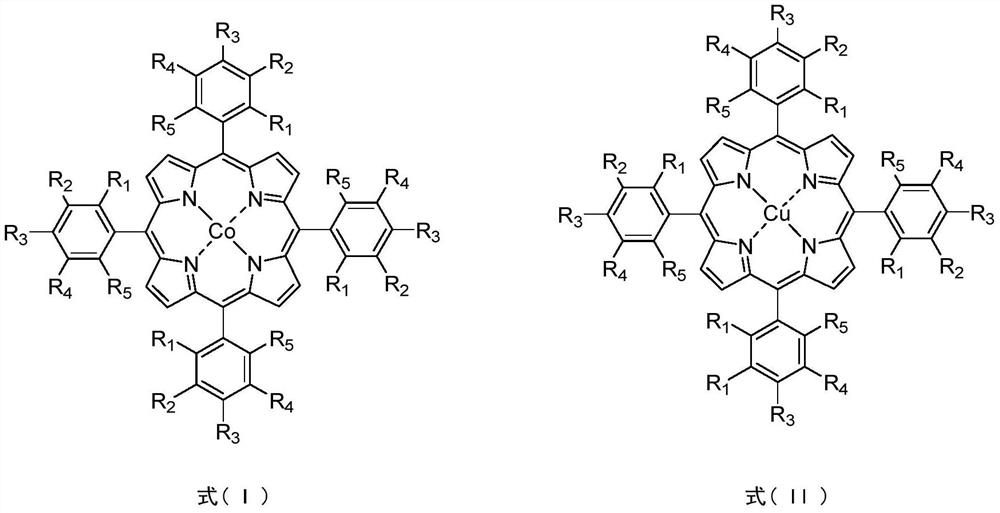

Method for catalytic oxidation of cycloalkane by bimetallic porphyrin MOFs PCN-224 (Co&Cu)

PendingCN112094179AInhibition of disordered diffusionAchieve catalytic conversionPreparation by oxidation reactionsOrganic compound preparationAlcoholPorphyrin

The invention relates to a method for catalytic oxidation of cycloalkane by bimetallic porphyrin MOFs PCN224 (Co&Cu), which comprises the following steps: dispersing bimetallic porphyrin MOFs PCN224 (Co&Cu) in cycloalkane, wherein the mass of the bimetallic porphyrin MOFs PCN224 (Co&Cu) is 1-10% of the molar mass of the cycloalkane, g / mol; and sealing the reaction system, heating to 90-150 DEG C while stirring, introducing an oxidant (0.10-2.0 MPa), keeping the set temperature and pressure, stirring to react for 2.0-24.0 hours, and carrying out after-treatment on the reaction solution to obtain the products naphthenic alcohol and naphthenic ketone. The method disclosed by the invention has the advantages of high naphthenic alcohol and naphthenic ketone selectivity, low reactiontemperature, few byproducts, small environmental influence and the like. In addition, the content of cycloalkyl hydroperoxide is low, and the safety coefficient is high. The invention provides an efficient, feasible and safe method for synthesizing naphthenic alcohol and naphthenic ketone through selective catalytic oxidation of cycloalkane.

Owner:ZHEJIANG UNIV OF TECH

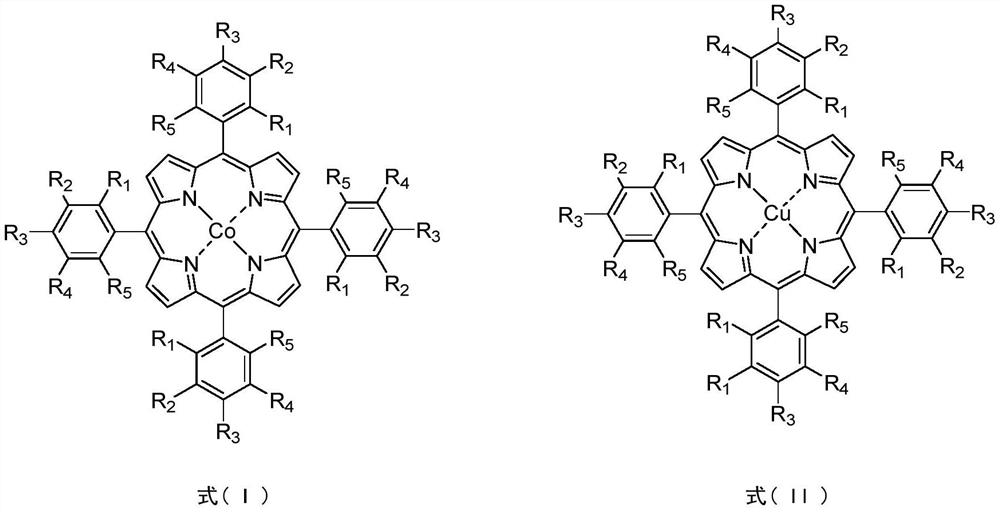

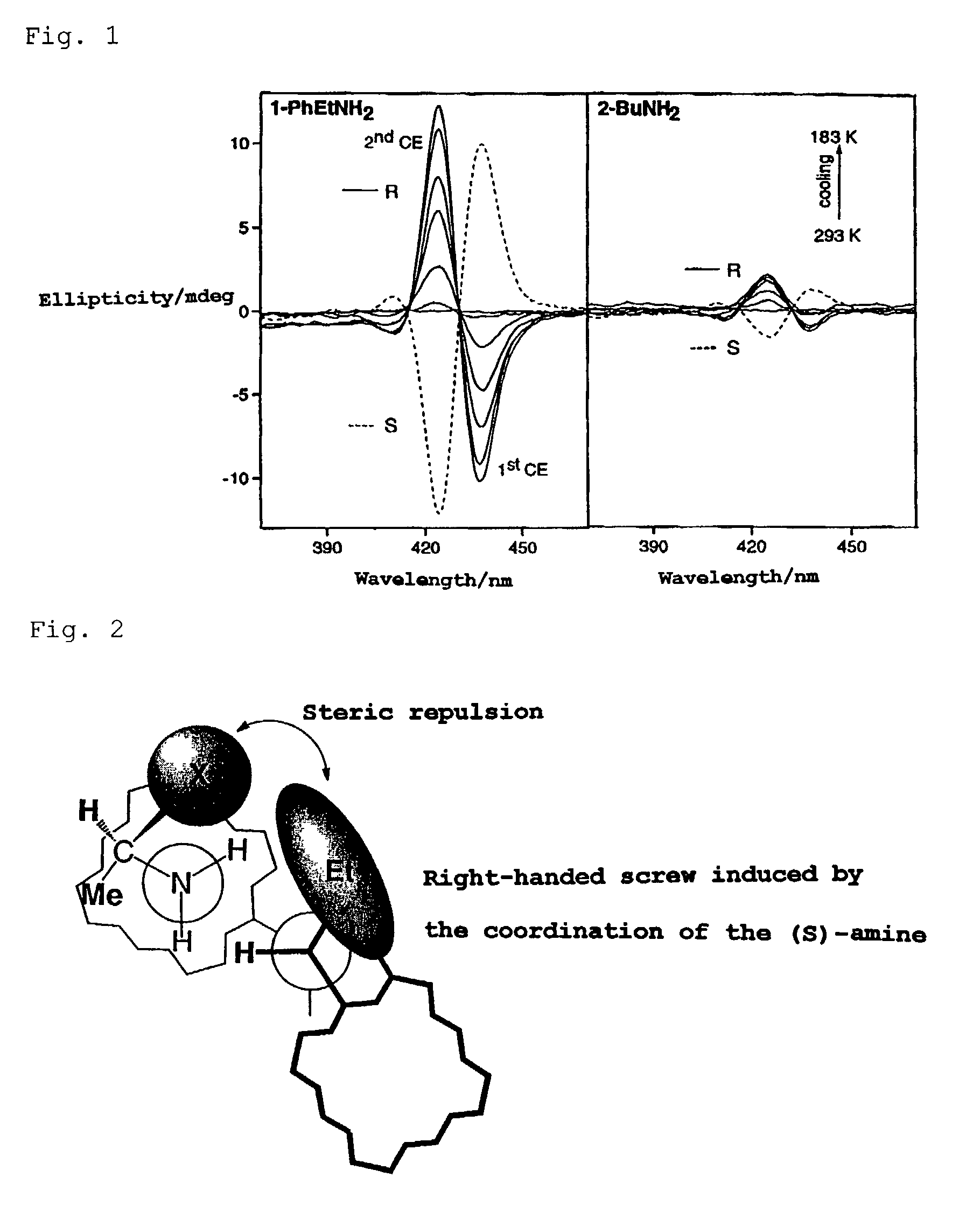

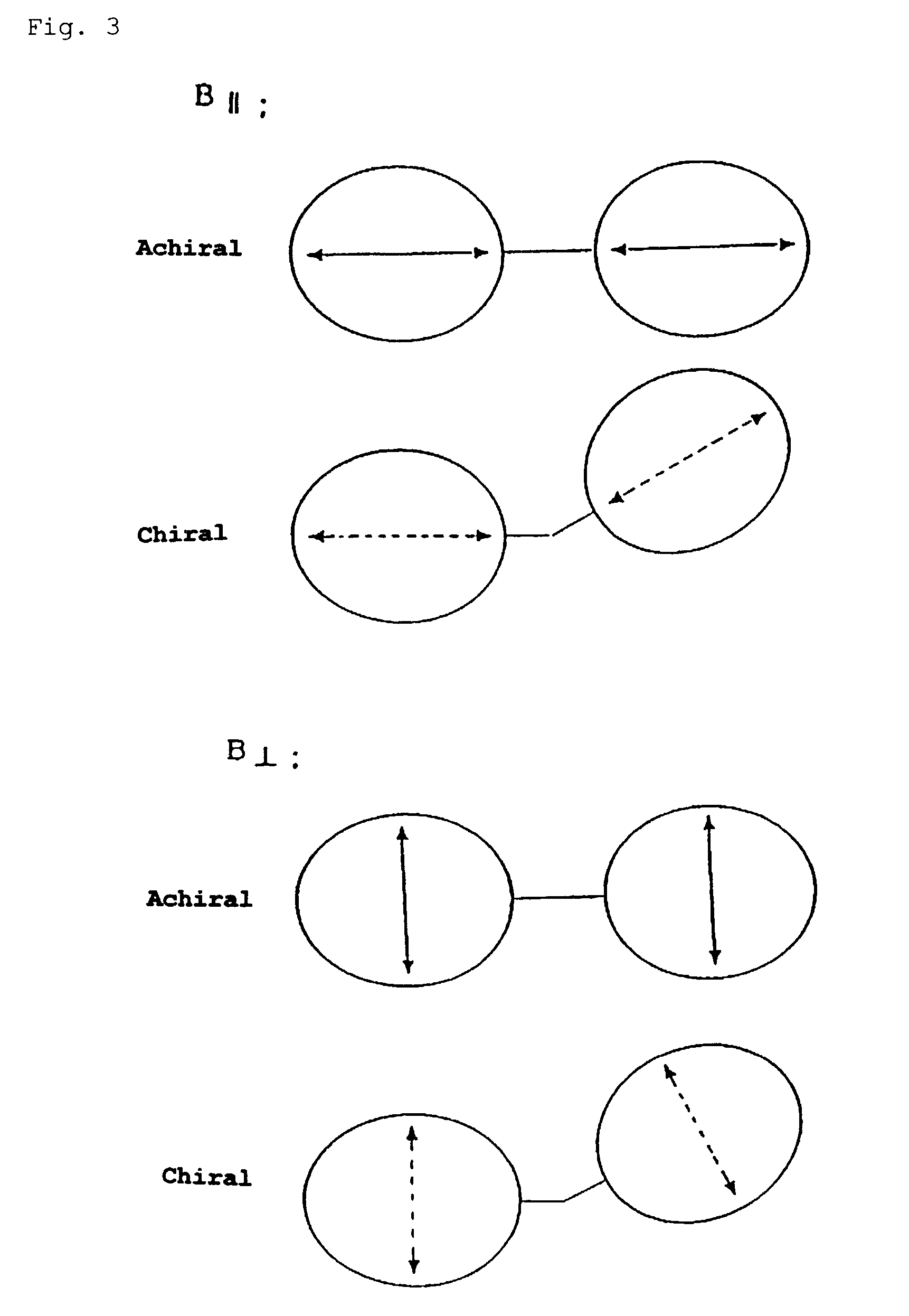

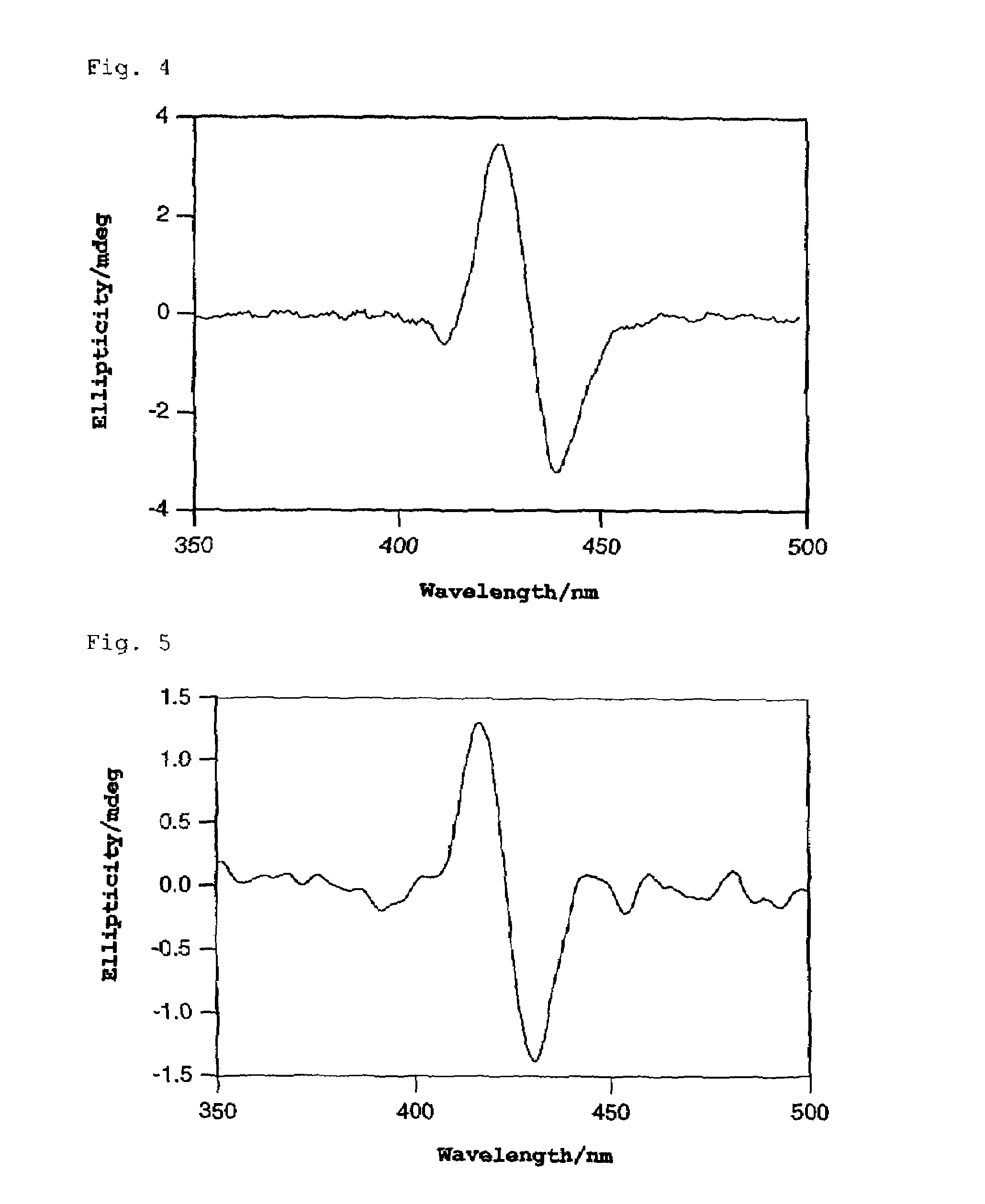

Method of determining absolute configuration of chiral compound

The absolute configuration of a chiral compound is determined by (i) coordinating the chiral compound to a metalloporphyrin having a carbon chain-crosslinked porphyrin dimer structure in which one of the two porphyrin rings has at least one ethyl or substituent bulkier than ethyl at at least one of the second peripheral carbon atoms from the carbon atom at the carbon chain crosslink site, and (ii) analyzing the resultant coordination compound by circular dichroism spectrophotometry to determine the absolute configuration of the asymmetric carbon based on the sign of the Cotton effect. The chiral compound has an asymmetric carbon bonded to a basic group capable of coordinating to the metal of the other porphyrin ring of the metalloporphyrin dimer or an asymmetric carbon atom adjacent to the carbon atom bonded to the basic group.

Owner:JAPAN SCI & TECH CORP

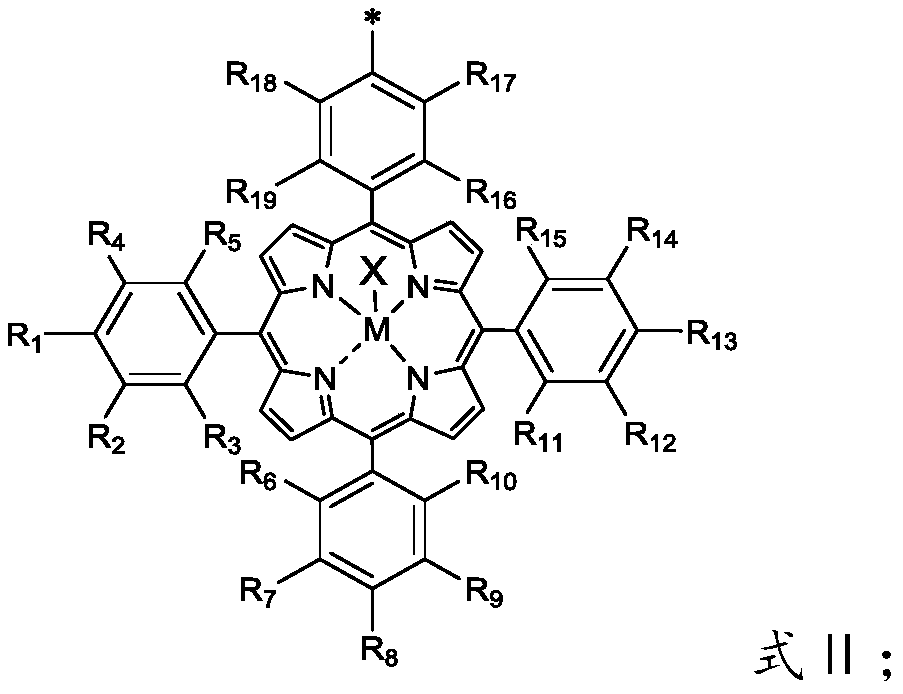

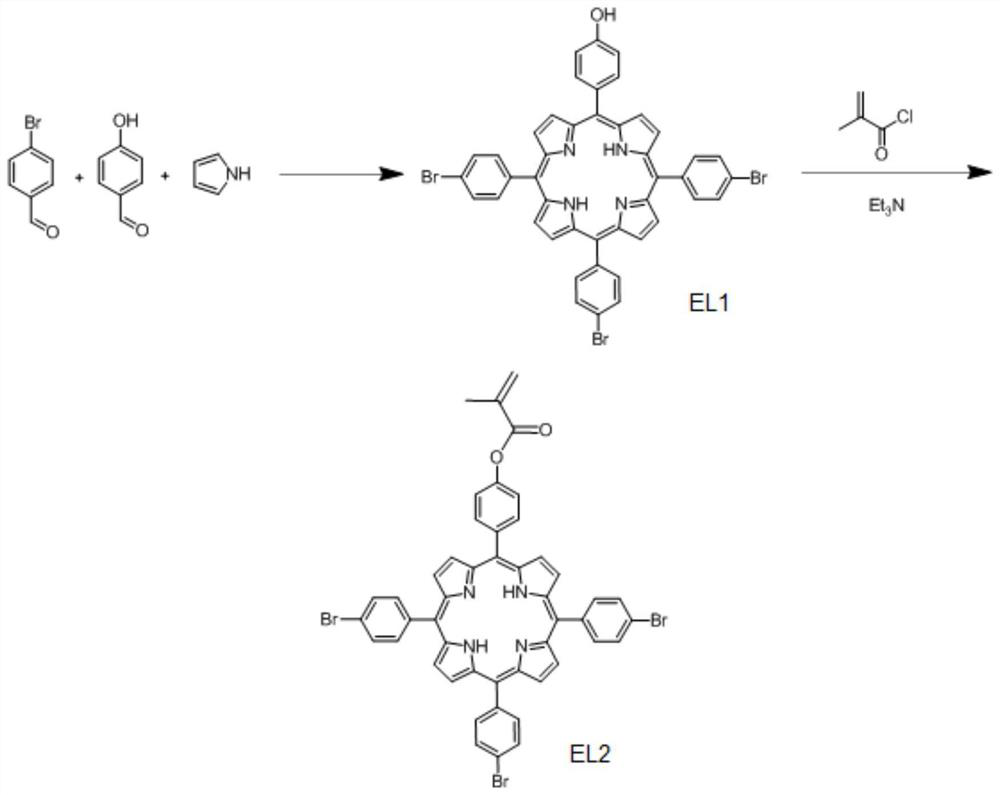

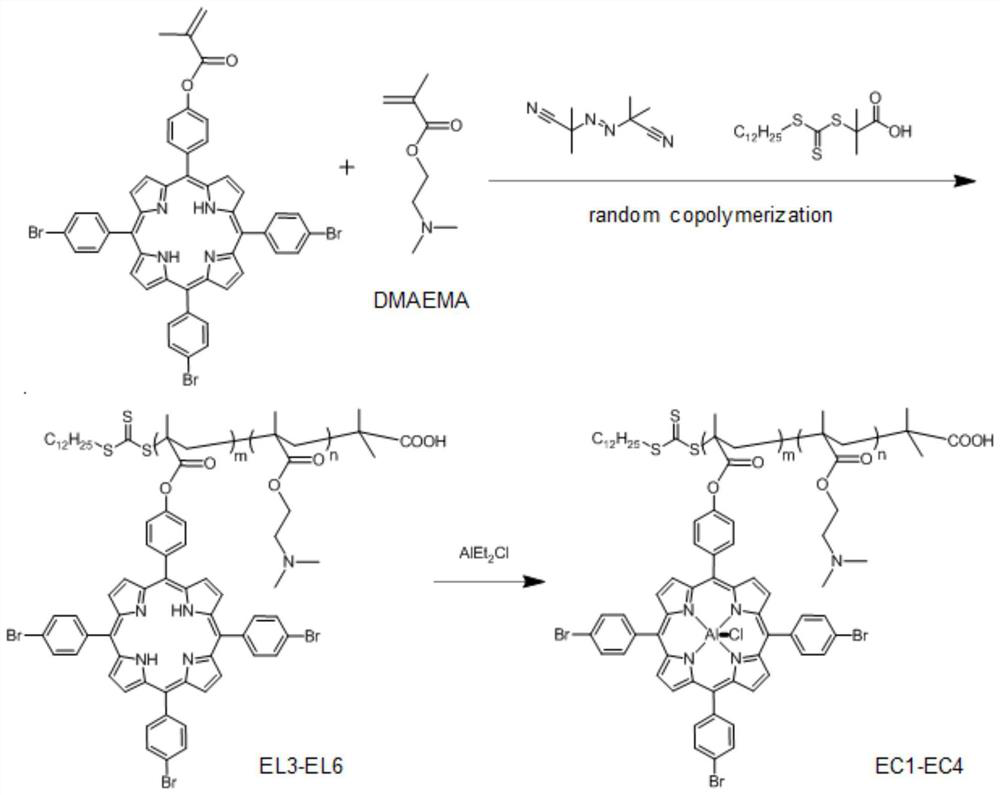

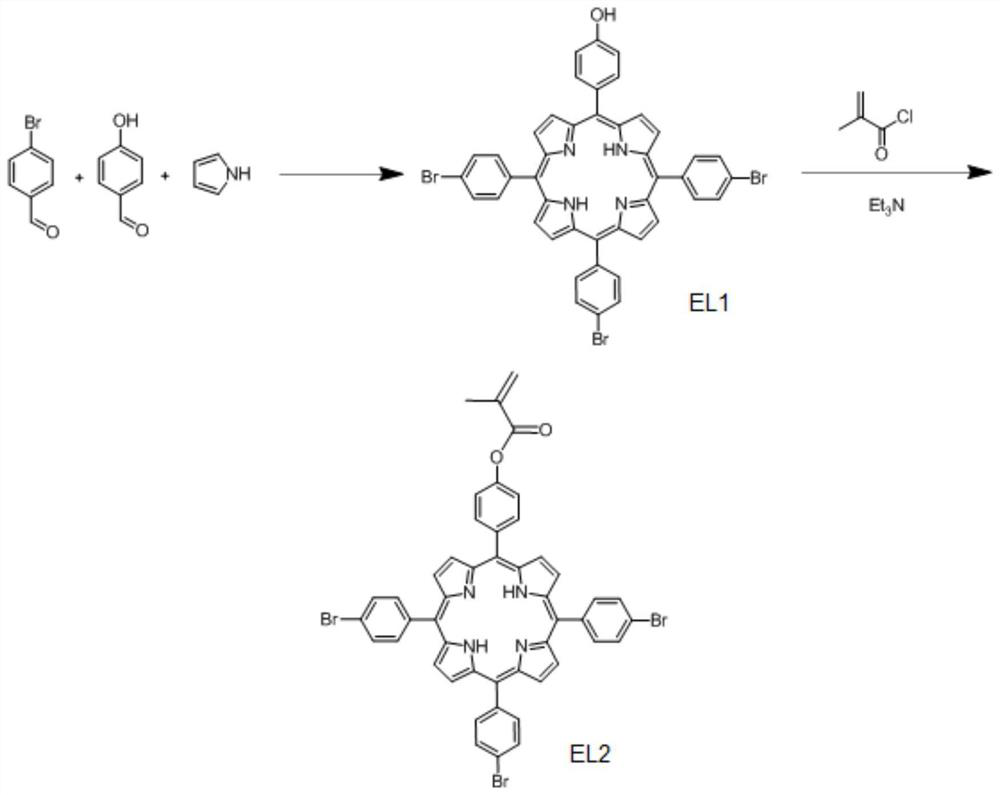

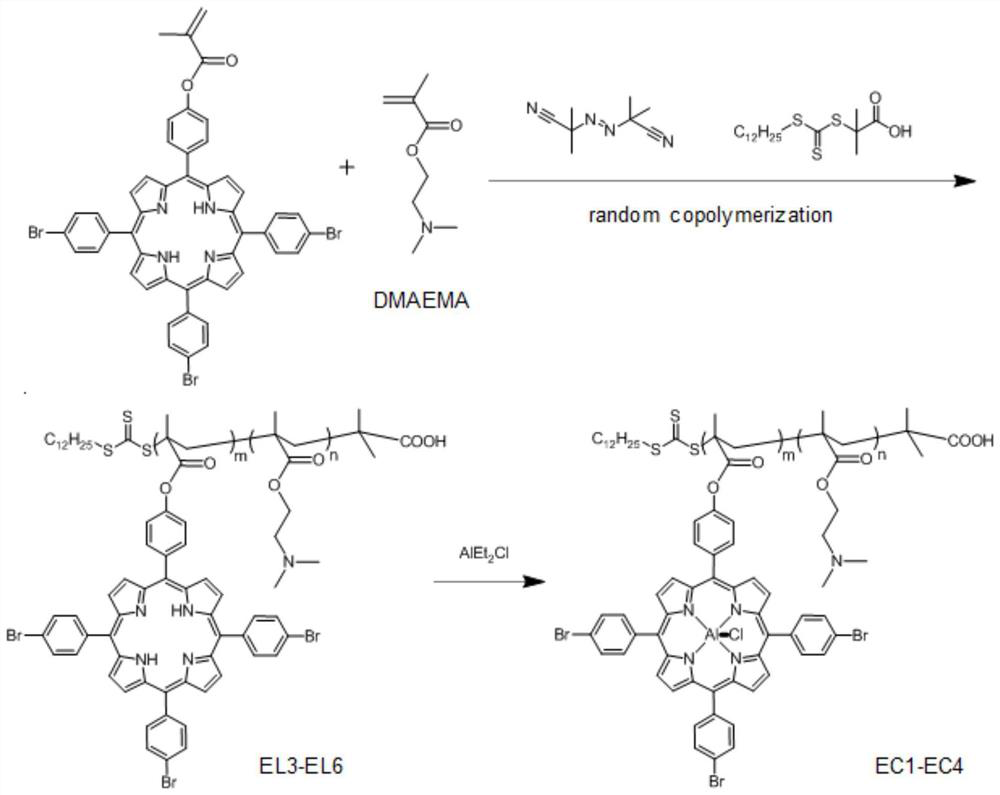

Multifunctional metalloporphyrin complex and preparation method thereof, and preparation method of polycarbonate

The invention provides a multifunctional metalloporphyrin complex and a preparation method thereof, and a preparation method of polycarbonate. The complex has a structure as shown in a formula I. According to the invention, the porphyrin complex is prepared by carrying out random copolymerization on a porphyrin monomer and a specific organic alkali monomer, and the scheme can be used for rapidly preparing the porphyrin complex containing a plurality of active centers. Compared with the prior art, interaction between the active centers and organic alkali and even the catalytic performance can be adjusted by changing the substituent group of the porphyrin monomer, a ratio of the porphyrin monomer to the organic alkali monomer and the type of the organic alkali. The produced catalyst shows very high catalytic activity, product selectivity and high-temperature stability when catalyzing copolymerization of carbon dioxide and alkylene oxide.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

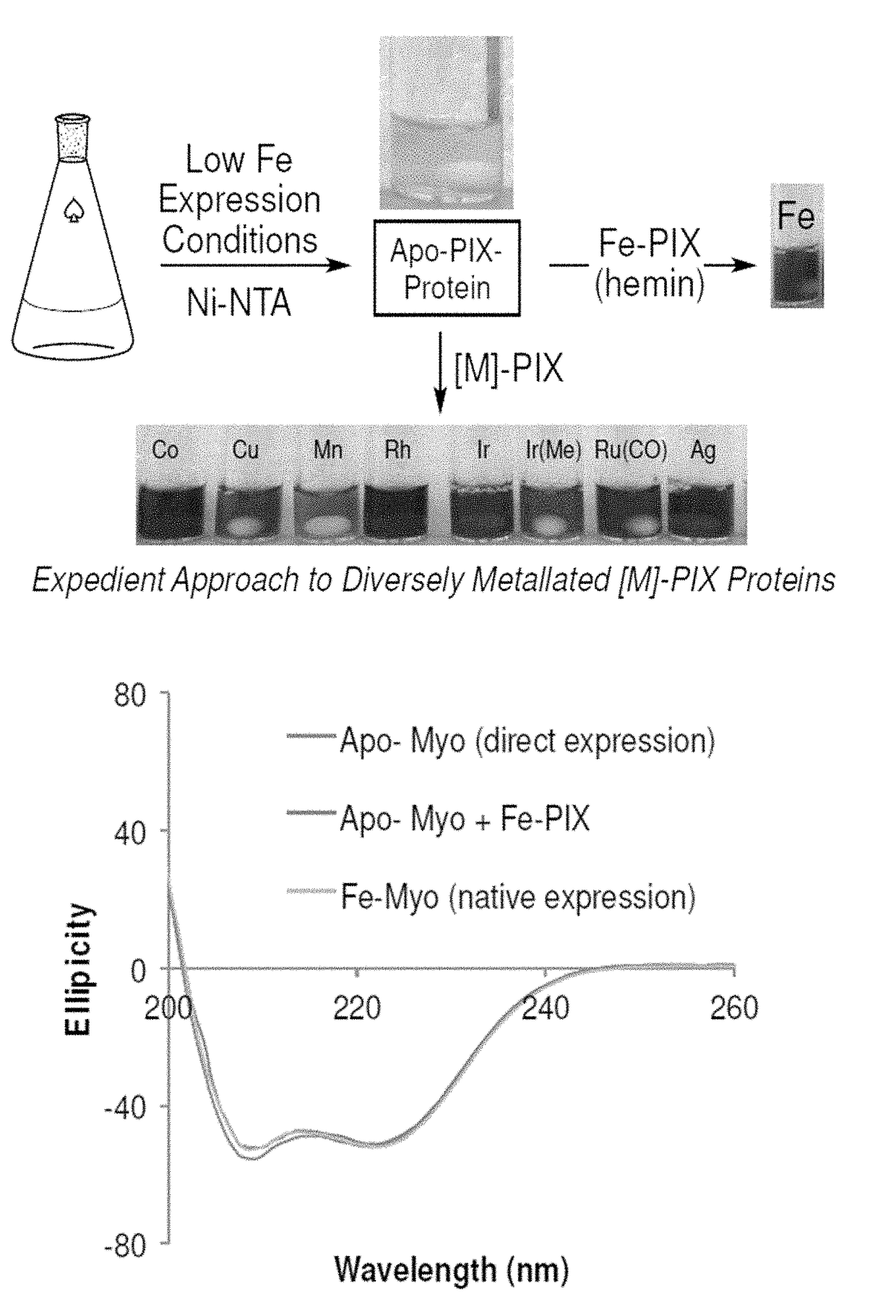

Artificial metalloenzymes containing noble metal-porphyrins

ActiveUS20180305368A1High activityHigh selectivityHaemoglobins/myoglobinsCytochromesPorphyrinCyclopropanation

The present invention is drawn to artificial metalloenzymes for use in cyclopropanation reactions, amination and C—H insertion.

Owner:RGT UNIV OF CALIFORNIA

Use of polysaccharose sulfate for preparing medicine against grippal virus

An application of the polyose sulfate (marinofloridpolyose sulfate, alpha-D-(1-6)-glucosan sulfate, or porphyran sulfate) in preparing the medicines for preventing and treating viral influenza A or B is disclosed.

Owner:FUZHOU UNIV

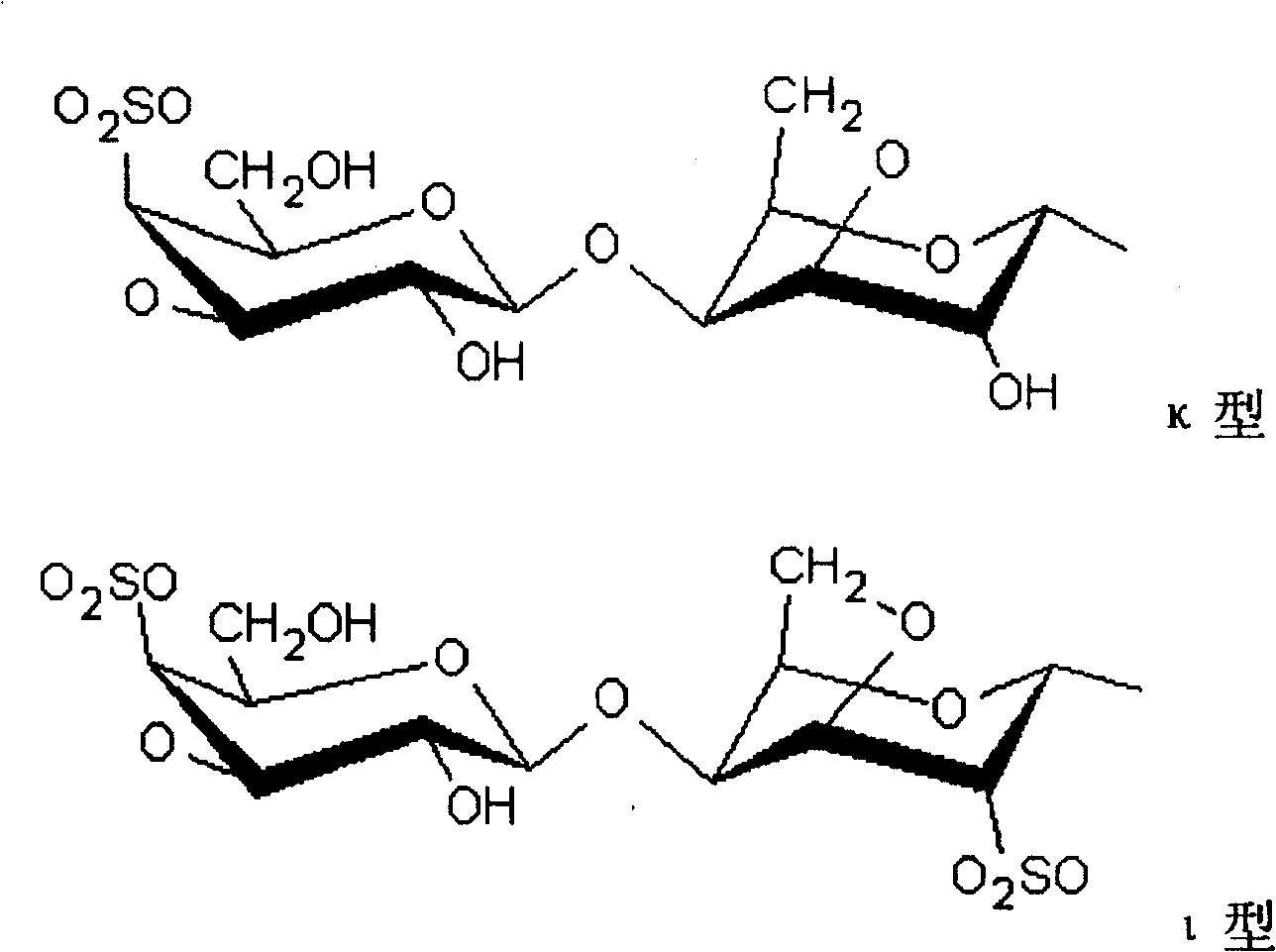

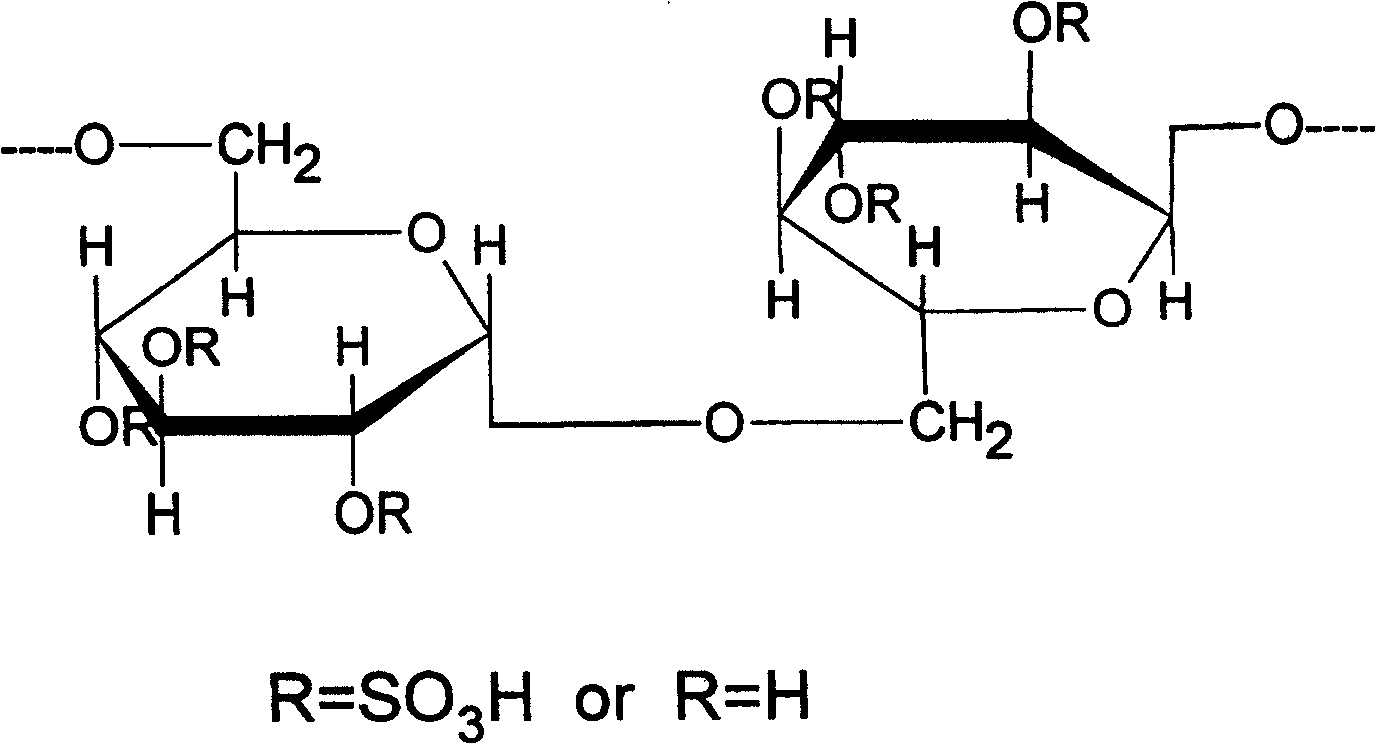

Modified Porphyran

InactiveUS20050201962A1Ensure stability of its physical propertyConveniently producedCosmetic preparationsOrganic active ingredientsSulfateSulphate Ion

Porphyran with modified bioactivity and physical property, method of making the modified Porphyran and use of modified Porphyran. Porphyran with modified bioactivity and physical property is produced by dissociating a salt from a sulphate group in Poryphran and removing it, making Porphyran having a free sulphate group wherein a salt is dissociated. Further, Porphyran with modified bioactivity and physical property is produced by dissociating a salt from sulphate group in Porphyran and removing it, and then altering the sulphate group, with the use of a given salt, into a sulphate salt of the given salt. The modified Porphyran also can be obtained by converting a salt of a sulphate group in Porphyran into a sulphate salt of a given salt by ion exchange. The modified Porphyran be added to cosmetics, food, and drink, and used as cosmetic, food and drink having inhibitory activity against hyaluronidase activity.

Owner:SHIRAKO CO LTD KK SHIRAKO

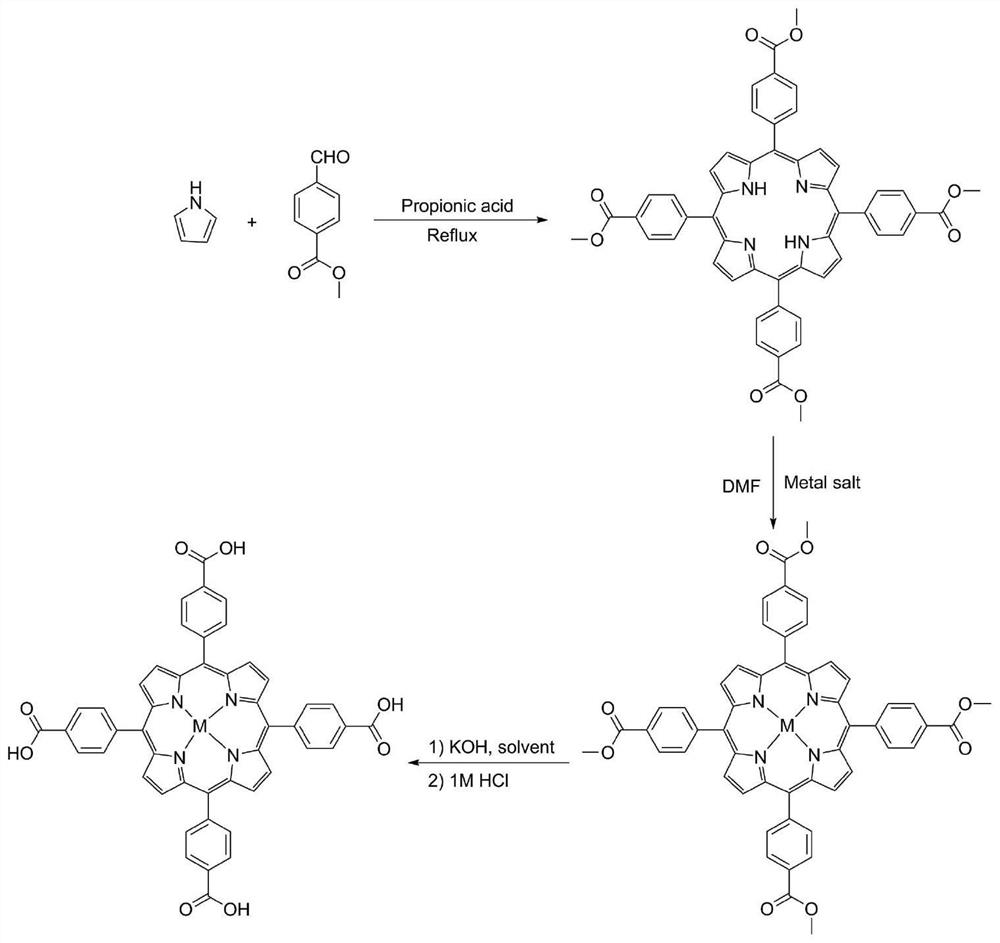

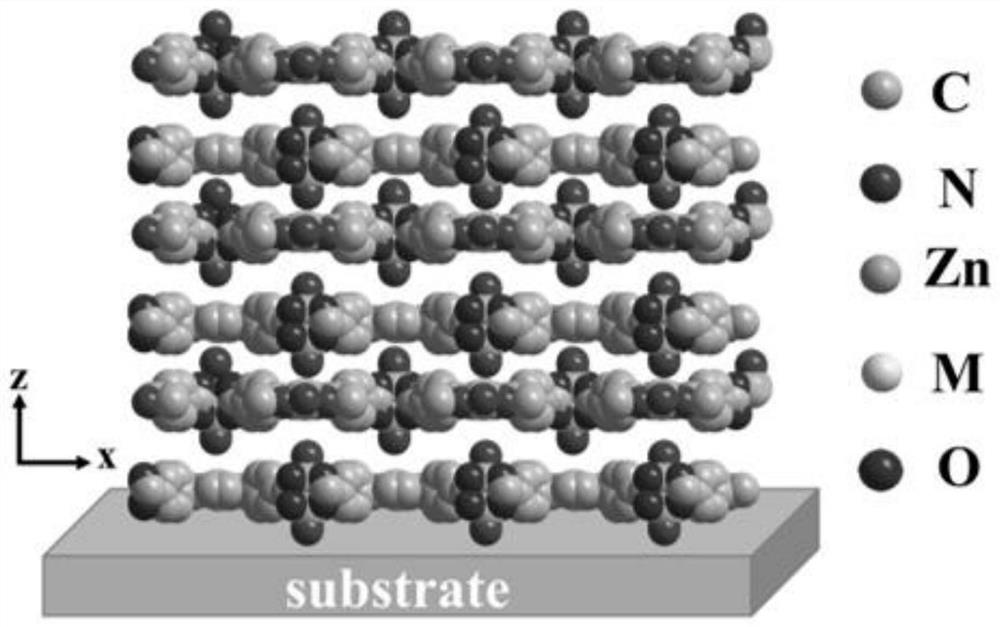

Preparation method and application of adjustable porphyrin MOFs film

ActiveCN114790336APrecisely Control ThicknessControl thicknessSolid-state devicesSemiconductor/solid-state device manufacturingPorphyrinFunctional modification

The invention discloses a preparation method and application of an adjustable porphyrin MOFs film. The preparation method comprises the following steps: preparing a metallized porphyrin ligand; the method comprises the following steps: performing functional modification on a growth substrate, alternately depositing droplets of a metal salt solution and a metallized porphyrin ligand solution on the surface of the growth substrate, and growing on the surface of the growth substrate through coordination to form the porphyrin MOFs film. According to the method, the thickness, the area and the roughness of the MOFs film can be accurately controlled in the preparation process, the preparation efficiency is high, and the operation is simple. The porphyrin MOFs thin film can be used as a photoelectric conversion layer in the preparation of an optical detector, the performance of the optical detector is regulated and controlled by changing the type of central metal of a porphyrin ligand, and the prepared porphyrin MOFs-based optical detector integrates the dual advantages of metalloporphyrin and MOFs structures; and a wide prospect is provided for the application of the material in the fields of optical detectors and other devices.

Owner:MINJIANG UNIV

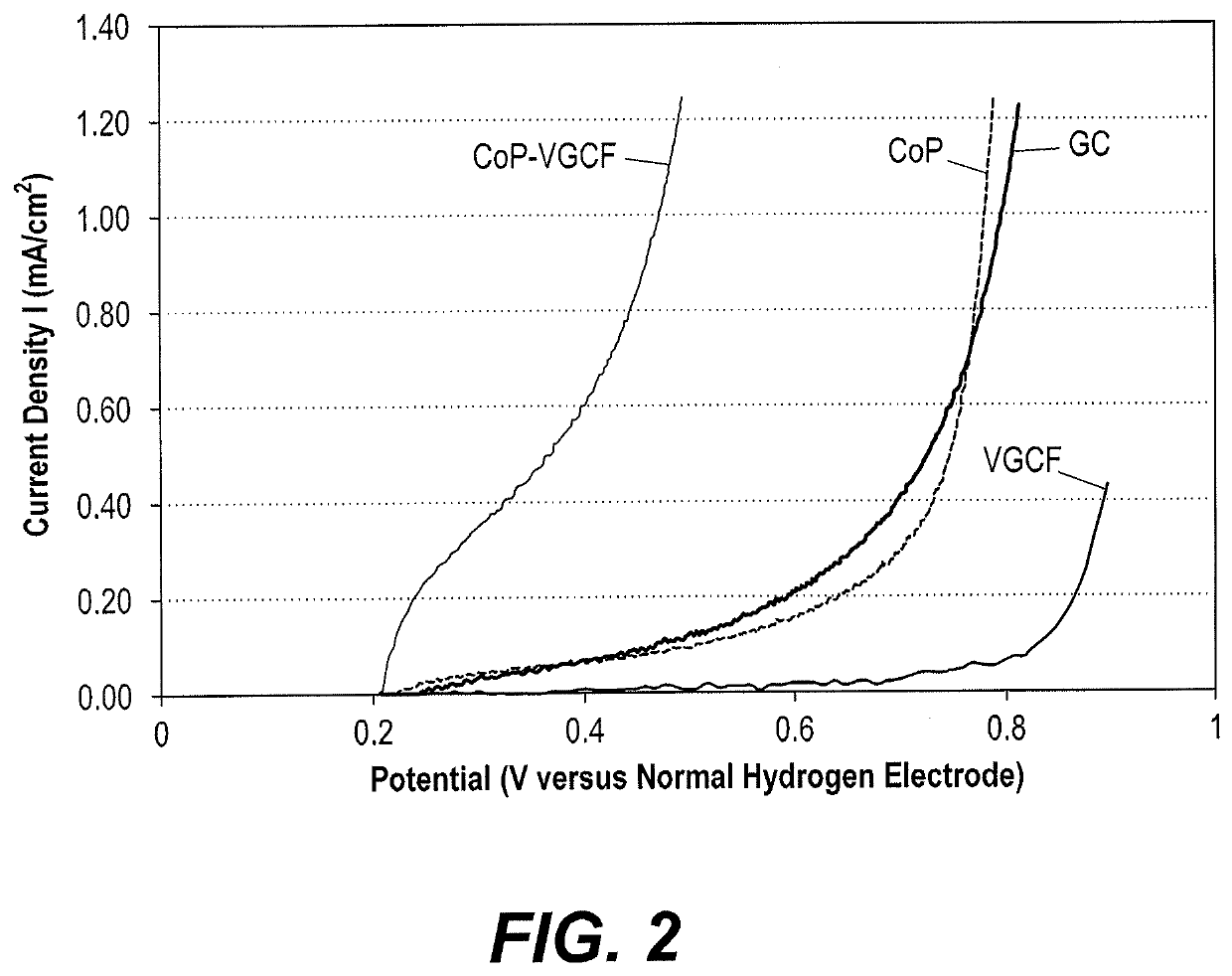

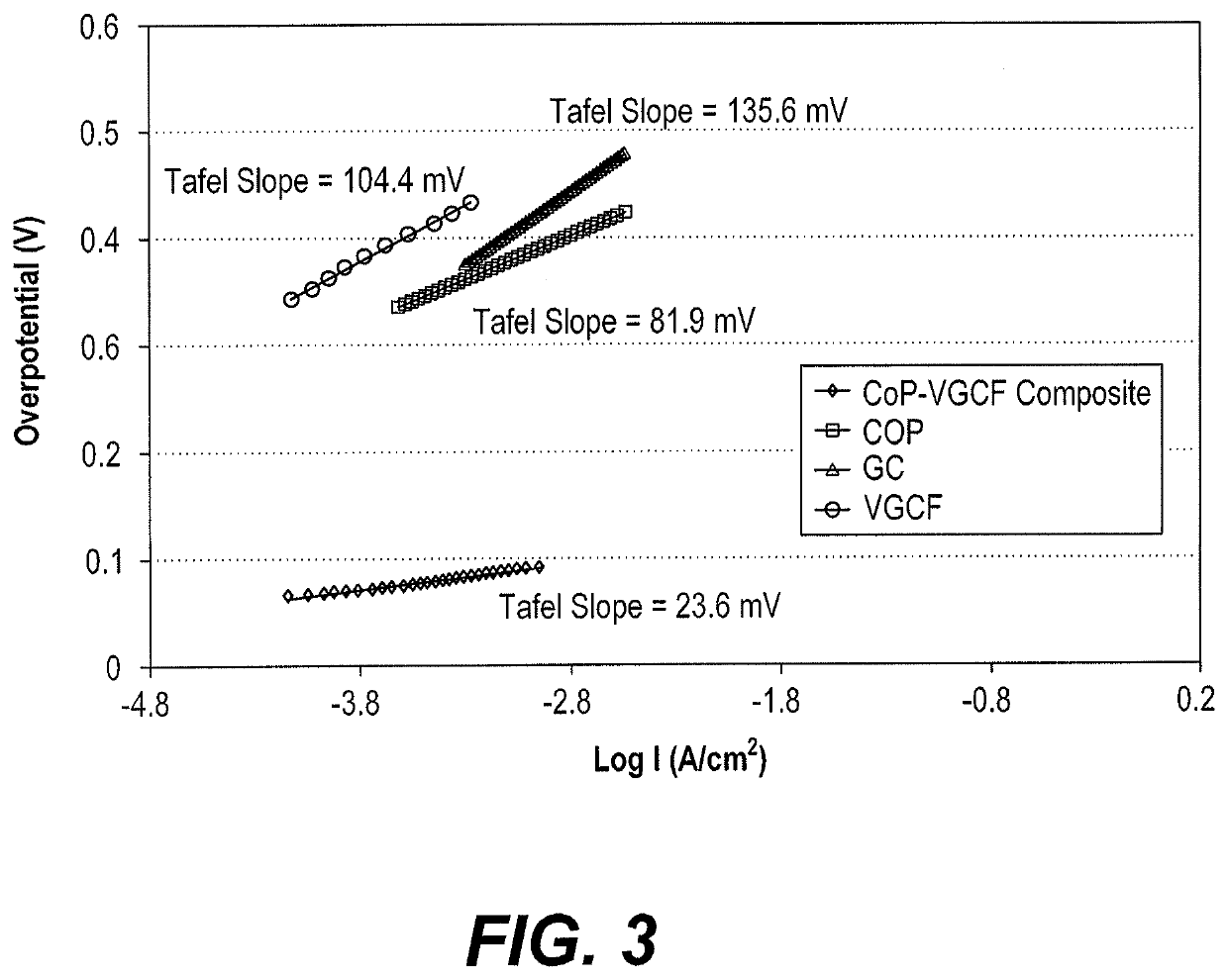

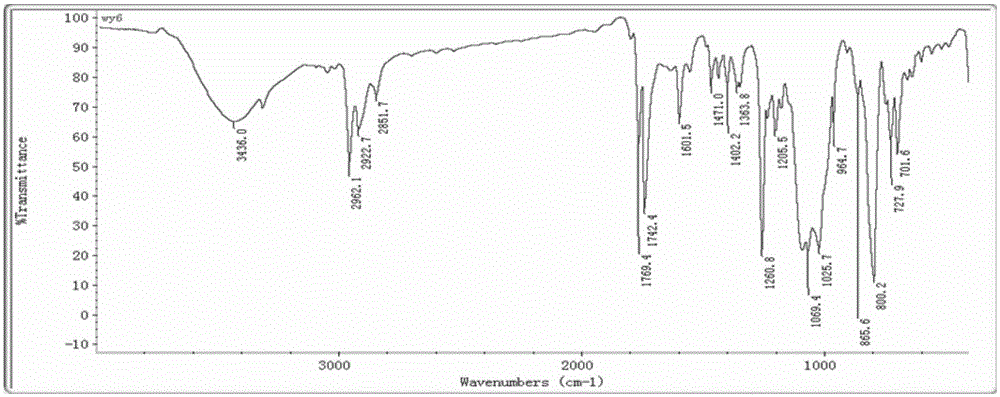

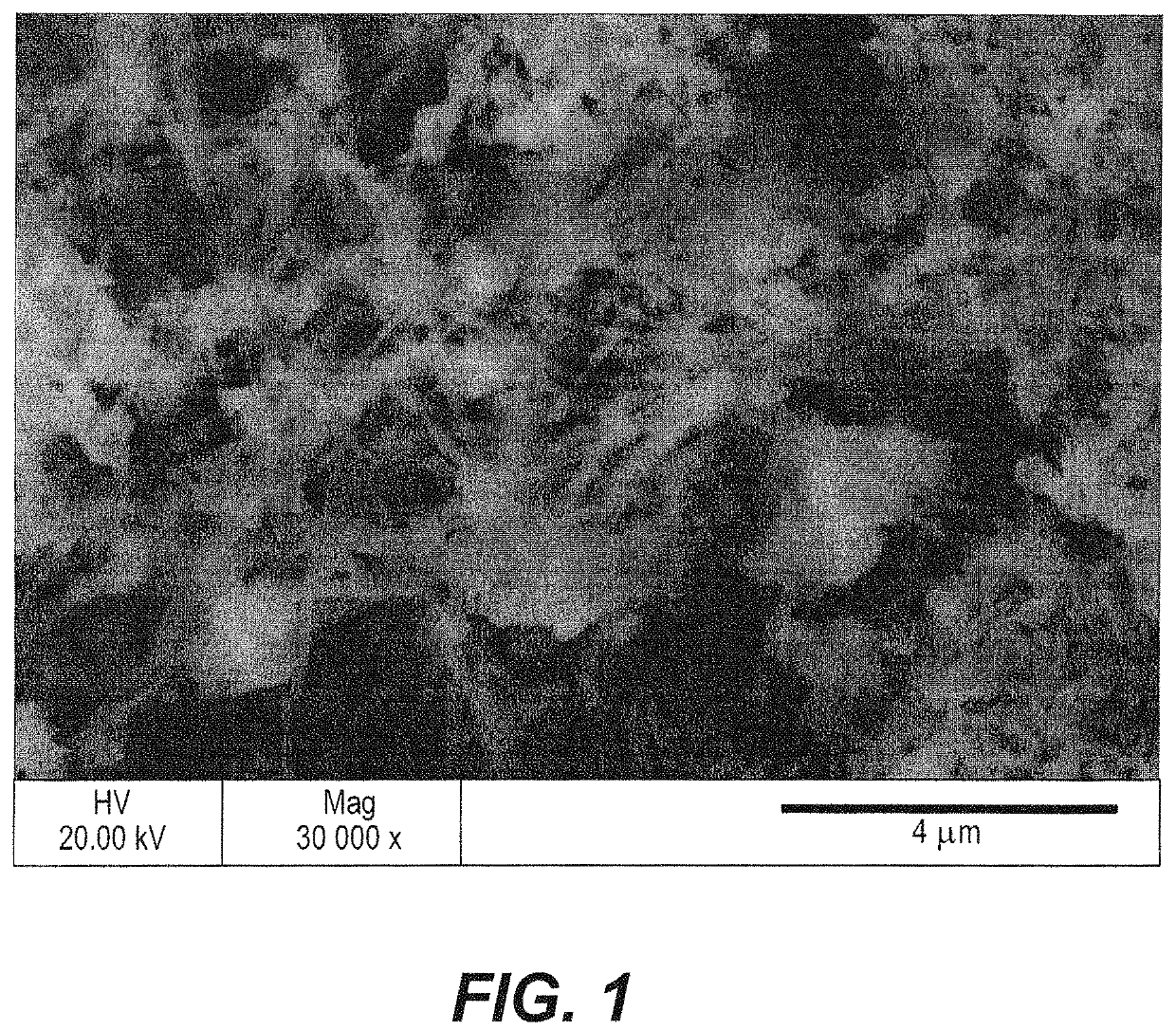

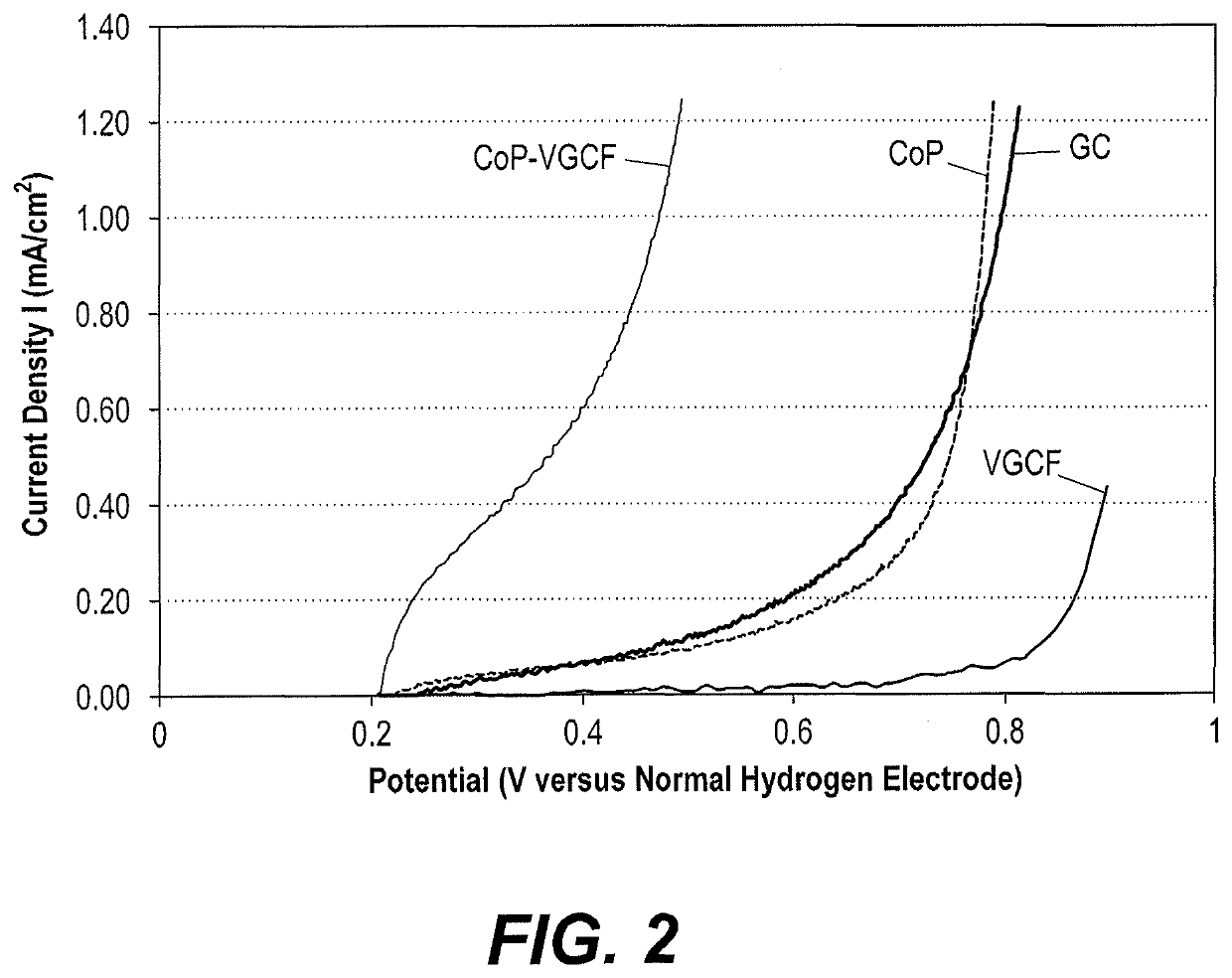

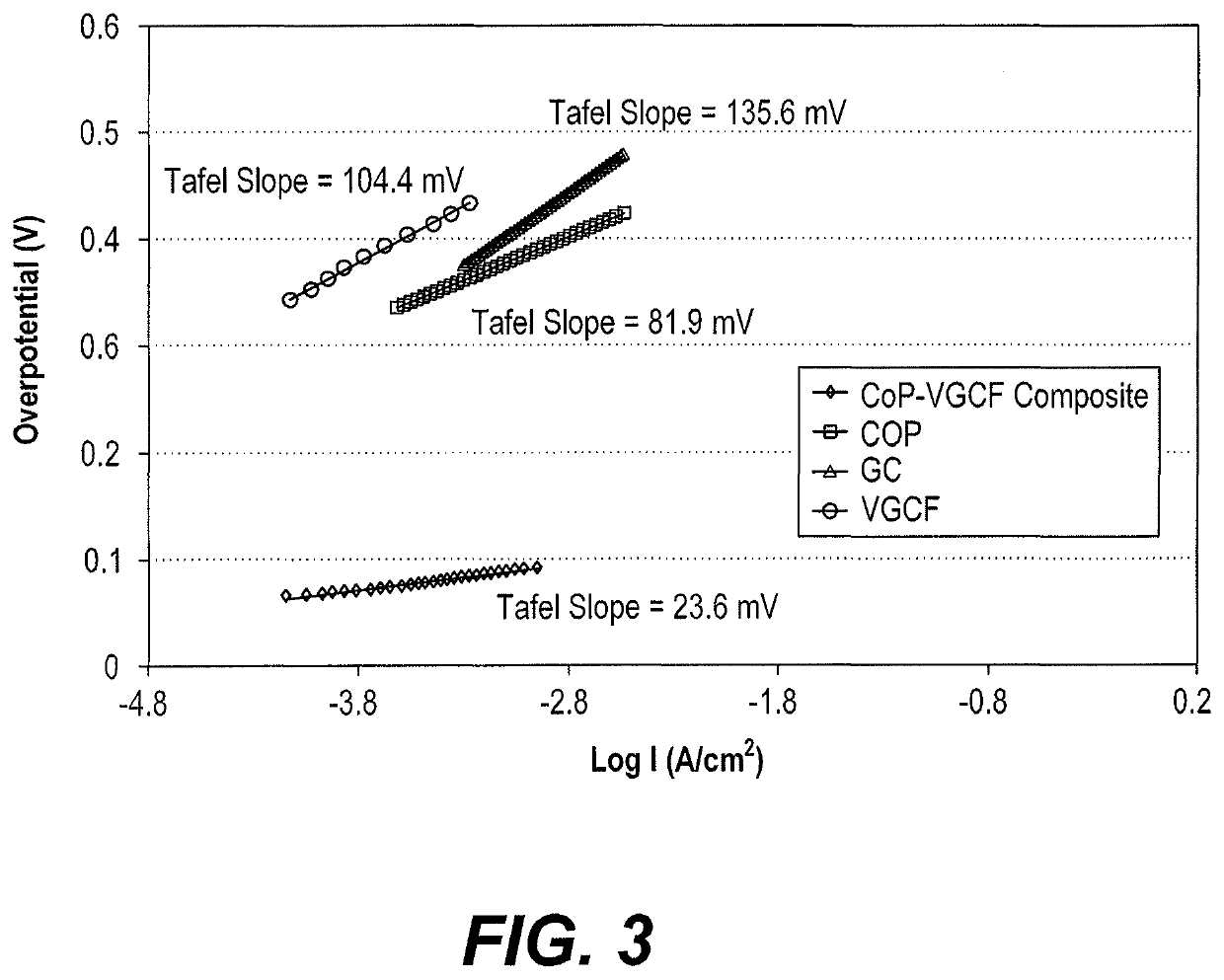

Porphyrin-based catalysts for water splitting

ActiveUS20200261897A1Improve electronic conductivityImprove electrocatalytic activityOrganic chemistryCell electrodesPtru catalystCarbon fibers

The porphyrin-based catalysts for water splitting are composites of porphyrin or metalloporphyrin active ingredients, conductive carbon (e.g., graphene sheets, vapor grown carbon fiber, carbon black, etc.), and a polymer or binder that may be coated on a glassy carbon electrode. The polymer or binder may be Nafion oil or polyvinylidine difluoride. The porphyrin may be a porphyrin having a transition metal or hydrogen at its center, and may be halogenated and / or have a thiophene substituent.

Owner:KING FAISAL UNIV

Zinc metalloporphyrin copolyimide and application thereof as photoelectric information storage material

ActiveCN111234216AAchieving Electric Storage BehaviorEasy to operateSolid-state devicesPhotovoltaic energy generationImideElectron donor

The invention discloses zinc metalloporphyrin copolyimide and an application thereof as a photoelectric information storage material, which belong to the field of organic information storage. A preparation method comprises the following steps: firstly, synthesizing zinc metalloporphyrin copolyimide with an electron donor-electron acceptor structure, and forming a nano-film on a treated substrate by using a prepared solution through a spin coating and vacuum evaporation method; the invention aims to solve the problem that the size of the line width and the size of a storage point of the existing storage device are close to the upper limit of application. A spin coating mode is adopted; wherein the size of a molecular functional unit is less than or equal to several nanometers; therefore, the size of a storage point of the equipment is reduced to a nanometer level; a aluminum / coPI / ITO SRAM memory device with a sandwich structure is prepared in a superposition mode; in addition, the porphyrin polyimide device is good in mechanical property, simple in processing technology and excellent in high and low temperature resistance, and has a wide application prospect in the field of information storage.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

Metal porphyrin polystyrene elastomer and preparation method and application thereof

ActiveCN110387020ASimple processing technologyReduce energy consumptionSolid-state devicesSemiconductor/solid-state device manufacturingElastomerPolymer science

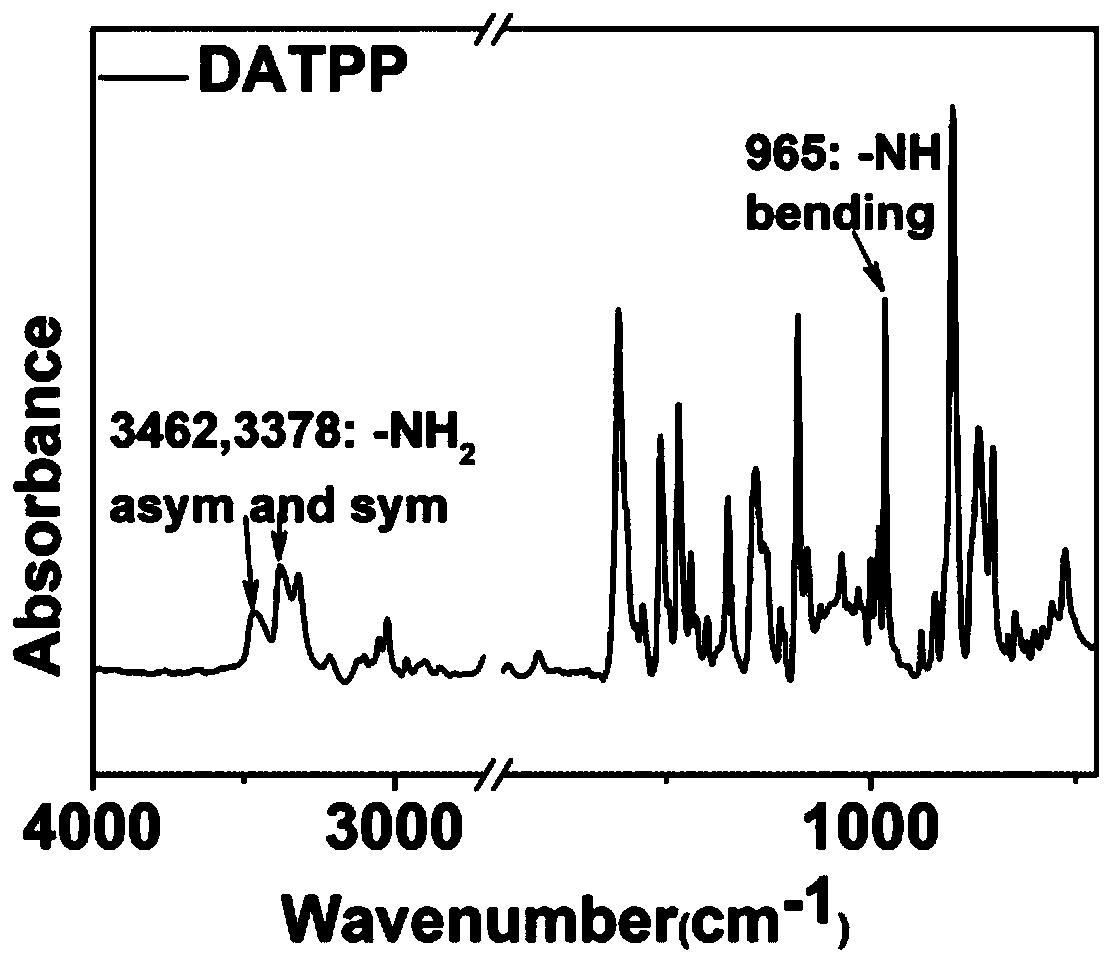

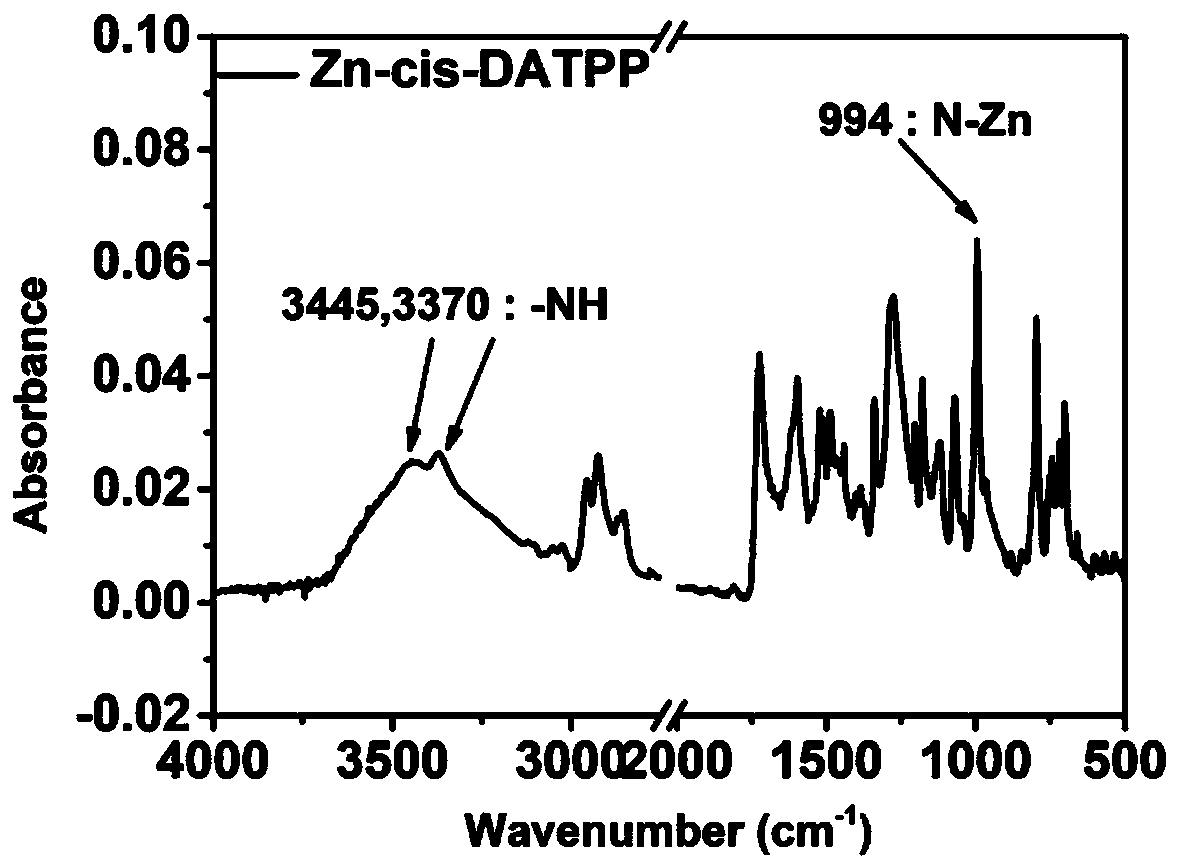

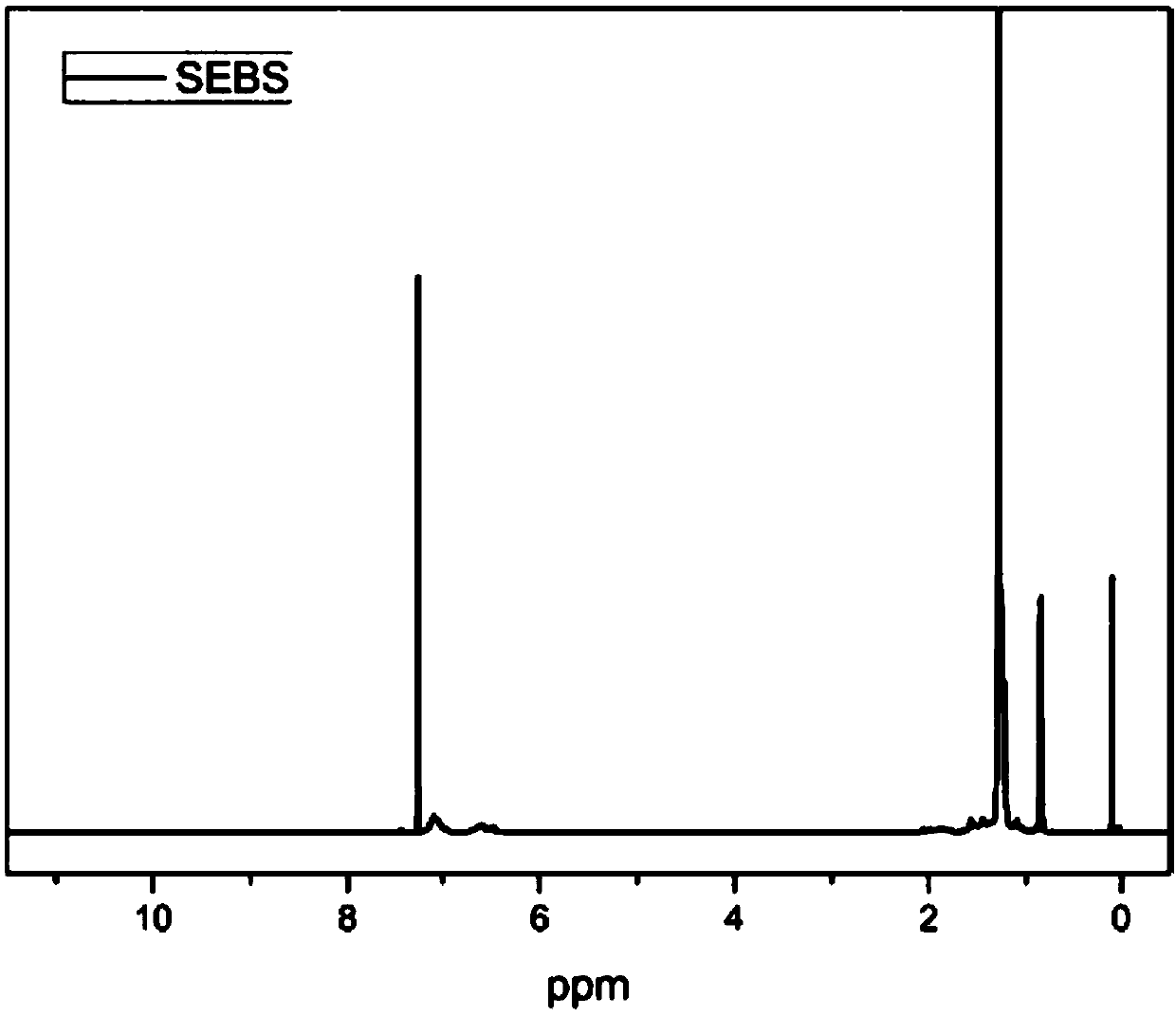

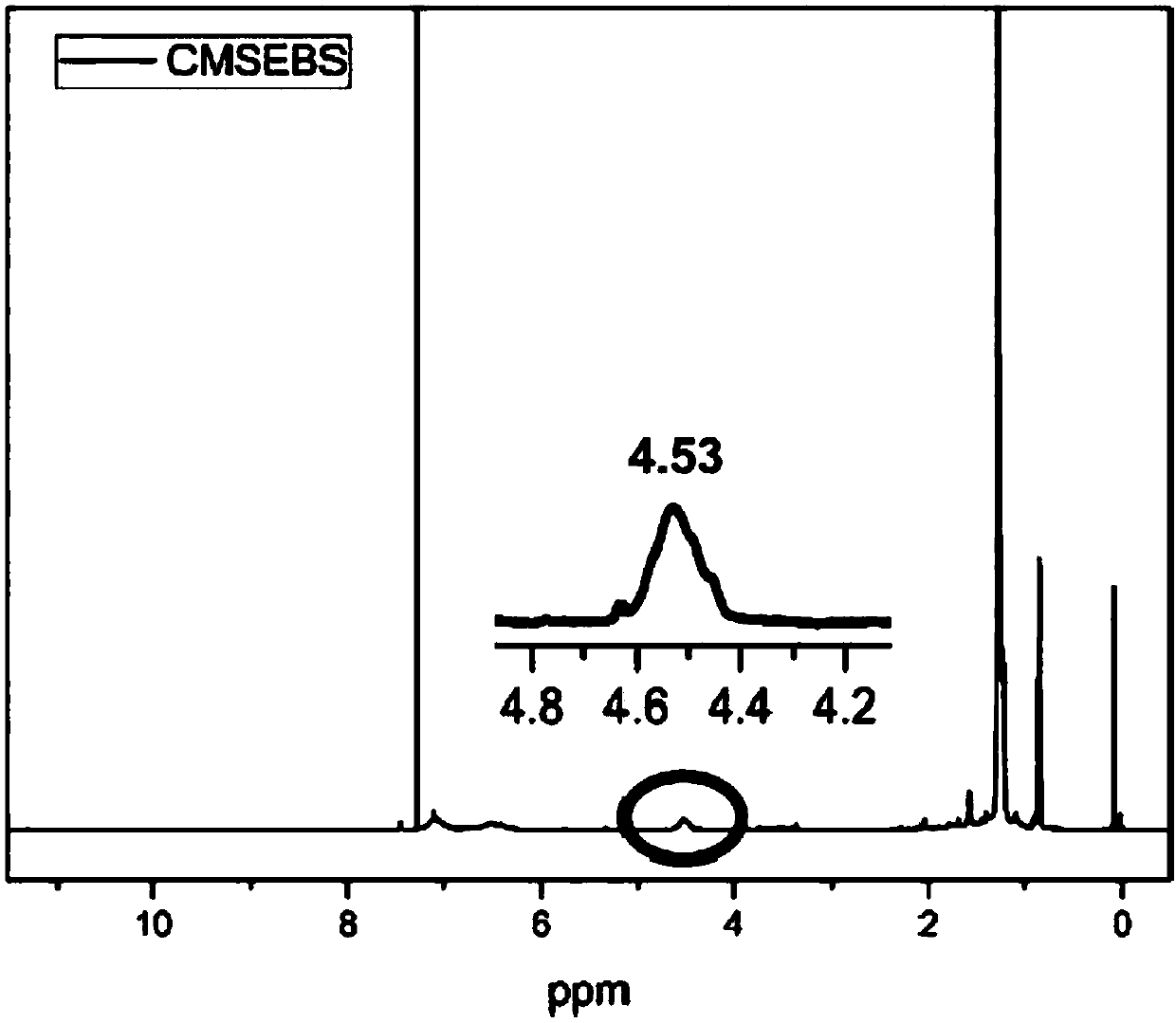

The invention discloses a metal porphyrin polystyrene elastomer and a preparation method and application thereof. A metal porphyrin polystyrene elastic composite material is an organic photoelectric conversion material and prepared by chloromethylation, aldehydes, porphyrin and metallization in sequence. The porphyrin graft rate can only be within 5%-55% of the specific range of the metal porphyrin polystyrene elastomer, the porphyrin polystyrene elastomer can have better photoelectric responsiveness while elasticity and flexibility of the porphyrin polystyrene elastomer are maintained, and particularly, according to the metal porphyrin polystyrene elastomer and the preparation method and application thereof, through the metallization of the porphyrin polystyrene elastomer and complexationof metal ions in the middle of porphyrin rings, the photoelectric responsiveness of the porphyrin polystyrene elastomer is further improved.

Owner:SICHUAN UNIV

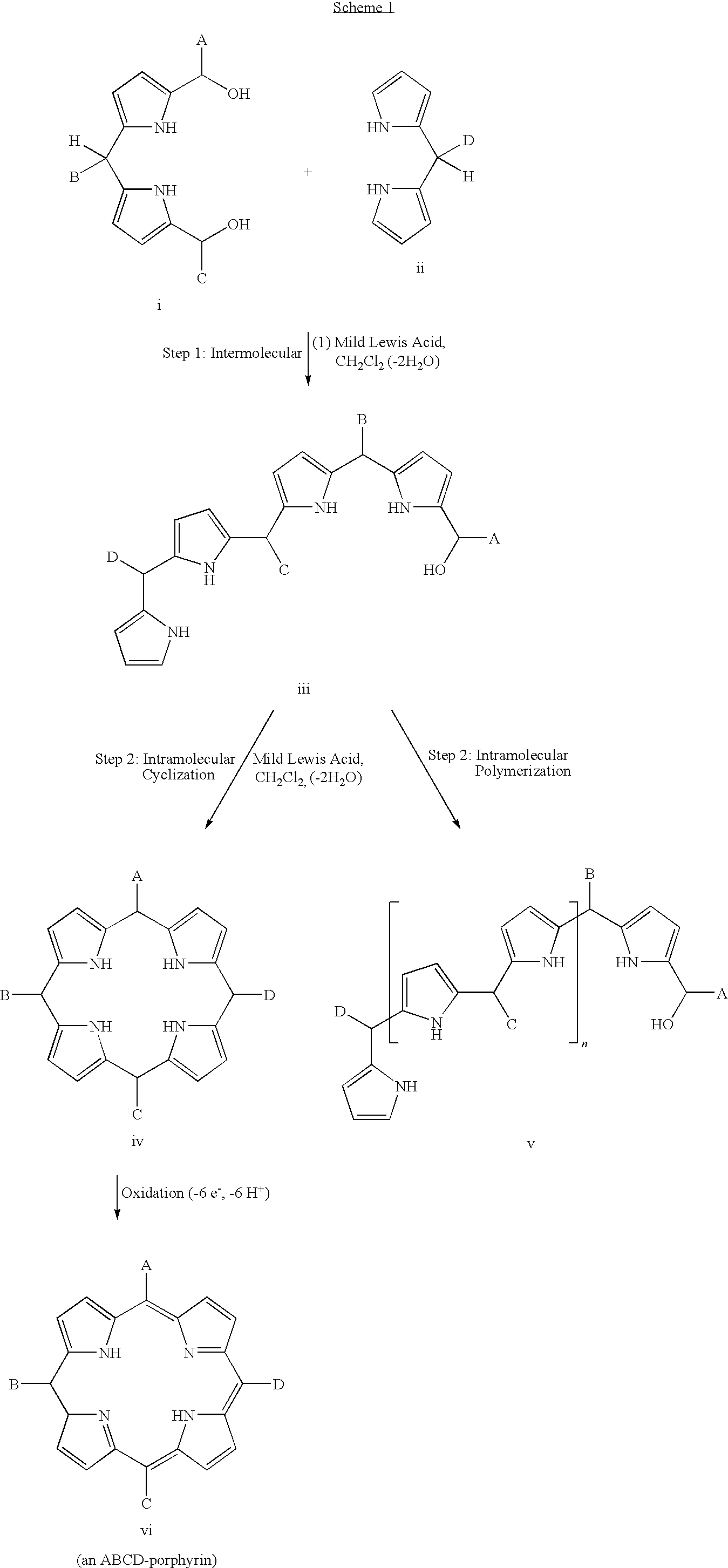

Synthetic route to abcd-porphyrins

InactiveUS20090082576A1Group 8/9/10/18 element organic compoundsFunctional group formation/introductionPorphyrin structureProtecting group

A method of making a metalloporphyrin is carried out by reacting (i) a linear tetrapyrrole, said linear tetrapyrrole having a 19-acyl group and a 1-protecting group, with (ii) a metal salt under basic conditions to produce the metalloporphyrin. Products produced by such methods and intermediates useful for carrying out such methods are also described.

Owner:NORTH CAROLINA STATE UNIV

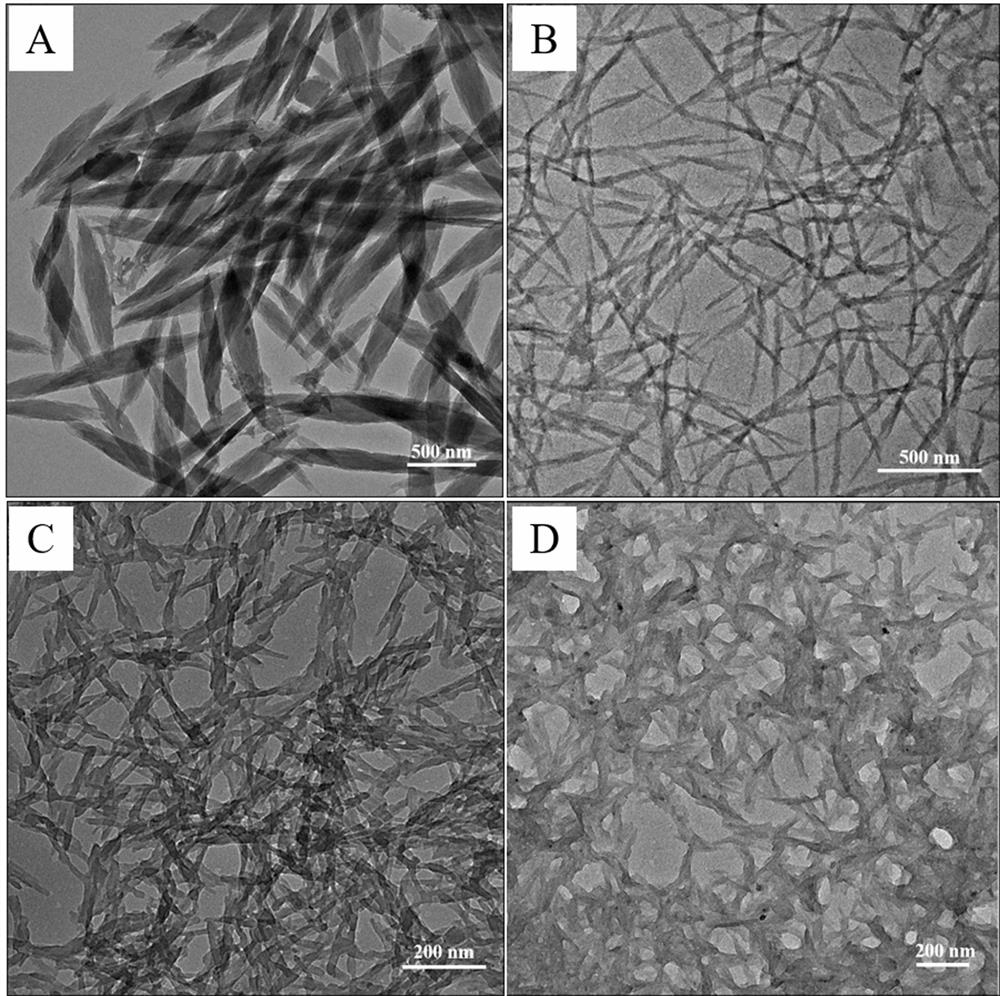

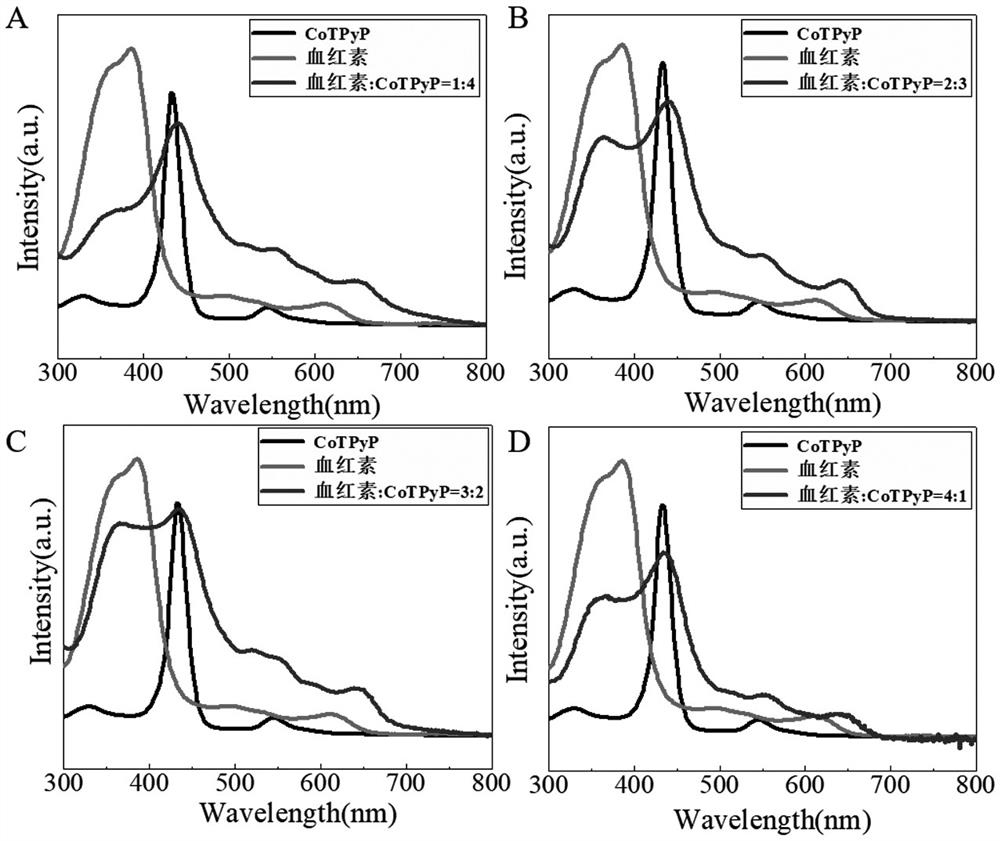

A kind of nanomaterial co-assembled with heme and pyridyl metalloporphyrin, its preparation method and application

ActiveCN110993970BEasy to prepareLow equipment requirementsMaterial nanotechnologyCell electrodesHemePorphyrin

The invention discloses a co-assembled nanomaterial of heme and pyridyl metalloporphyrin, its preparation method and application, and belongs to the technical field of material chemistry and electrochemical catalysis. Pyridyl metalloporphyrin co-assembled nanomaterials, by adjusting the feeding ratio of heme and pyridyl metalloporphyrin, the pH value of the reaction solution, the central metal of pyridyl porphyrin, and other conditions to obtain co-assemblies with different shapes, in a protective atmosphere calcination at high temperature and down to room temperature to obtain Fe / M doped graphitized carbon material. The present invention utilizes that heme contains two carboxyl groups, so that it can be dissolved in NaOH solution to generate anion. Since tetrapyridyl metalloporphyrin itself contains four pyridine groups, it can be dissolved in HCl and protonated to generate cation. The interaction force between the two porphyrins makes better assembly, which greatly increases the solubility of the reactants, thereby increasing the yield of the product.

Owner:HENAN UNIVERSITY

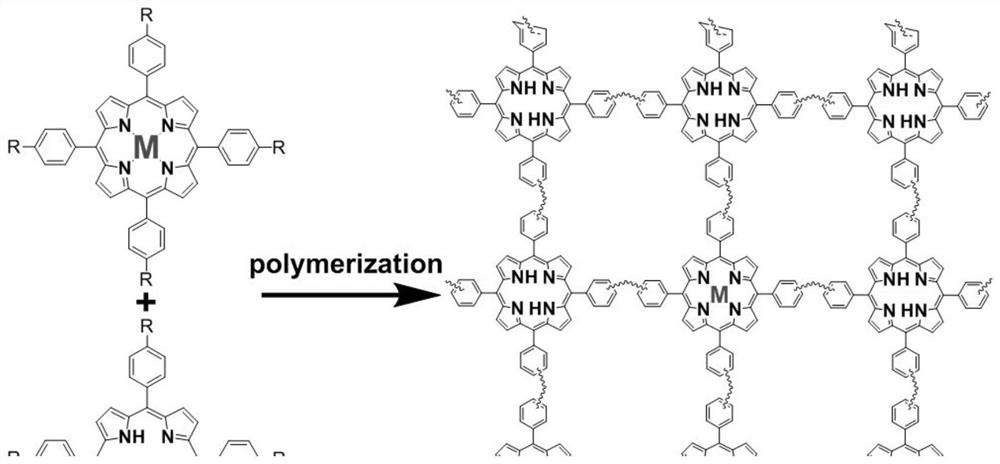

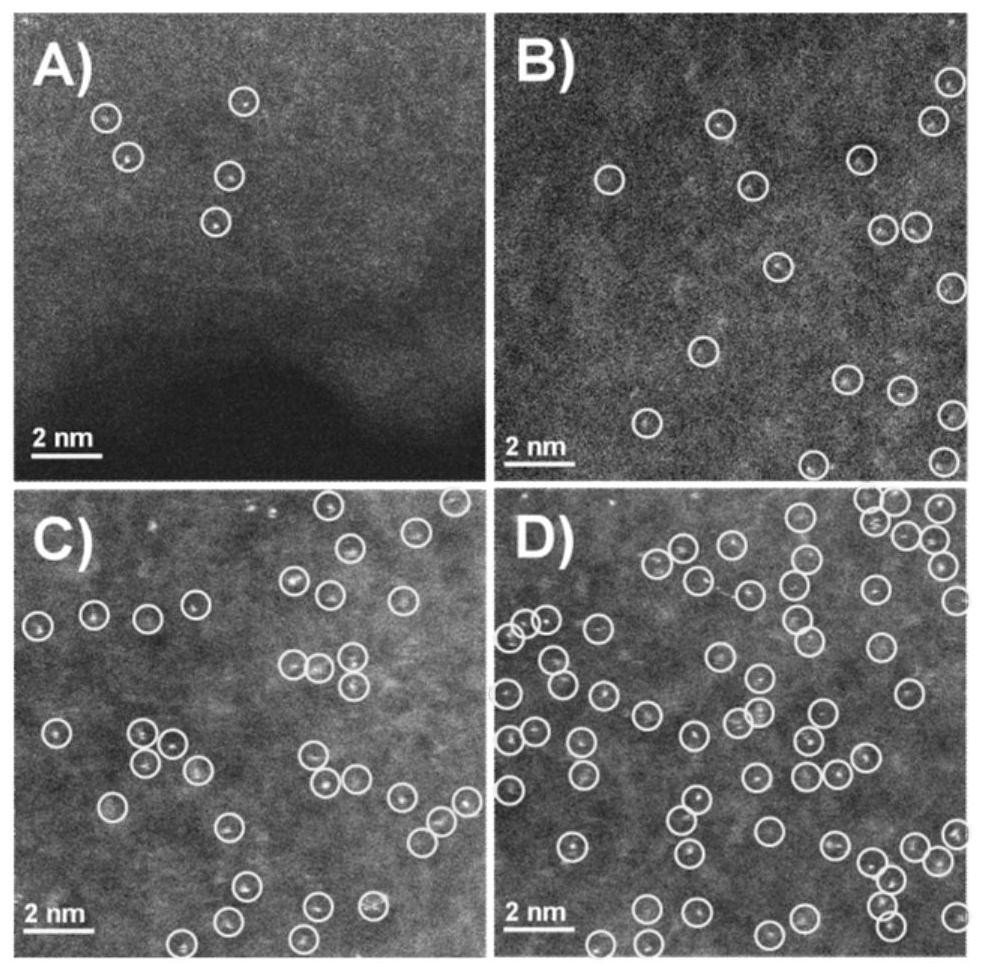

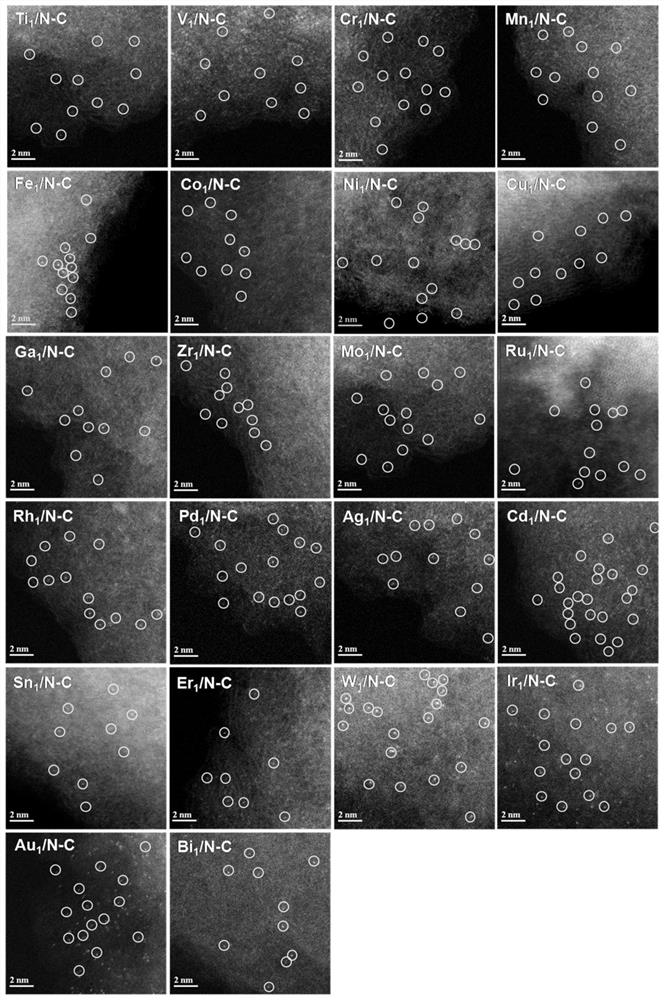

A preparation method of nitrogen-doped porous carbon-supported metal single-atom material

ActiveCN108579783BPrecise control ratioAchieving controllable equipmentCatalyst activation/preparationPorous carbonMaterial synthesis

The invention relates to a controllable preparation method of a nitrogen-doped porous carbon-supported metal single-atom material, which belongs to the technical field of material science and engineering. The present invention polymerizes porphyrin-metalloporphyrin through polymerization reaction, regulates the ratio of porphyrin-metalloporphyrin to regulate the metal content (0.06-4.00 wt%), regulates different metalloporphyrin types and regulates metal single atom types (A type, AB type , ABC type). The invention realizes the controllable preparation of metal single-atom materials, has good scalability and reproducibility, solves the problems of low metal content and few types in the prior art, and enriches the synthesis methodology of metal single-atom materials and other related fields Research.

Owner:SUN YAT SEN UNIV

High purification method of industrial tail gas containing oxynitride

InactiveCN101905114BCompact designSimple and fast operationDispersed particle separationPtru catalystPhysical chemistry

Owner:太原市恒远化工环保科技有限公司

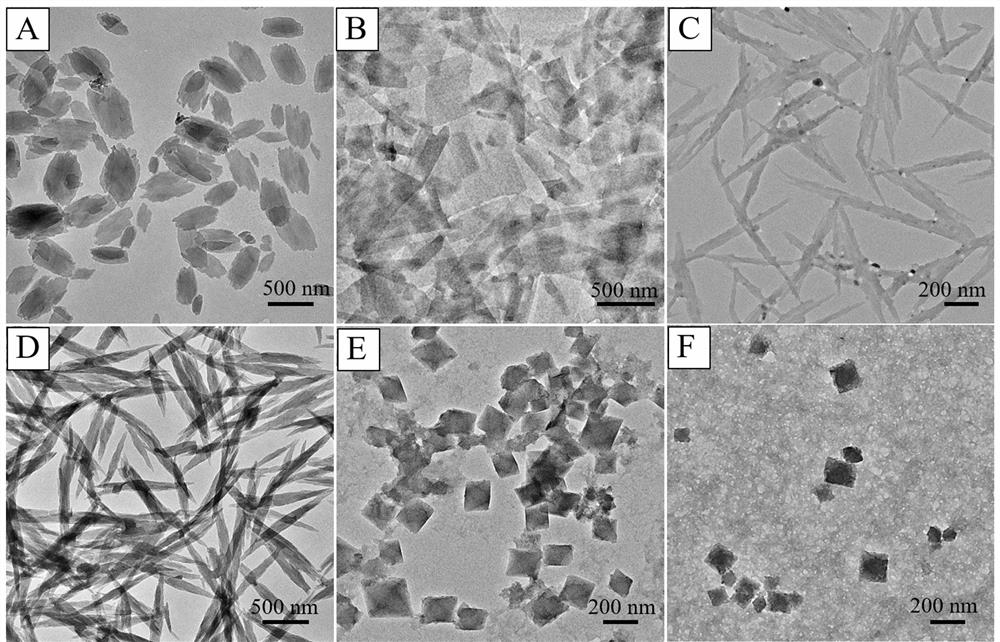

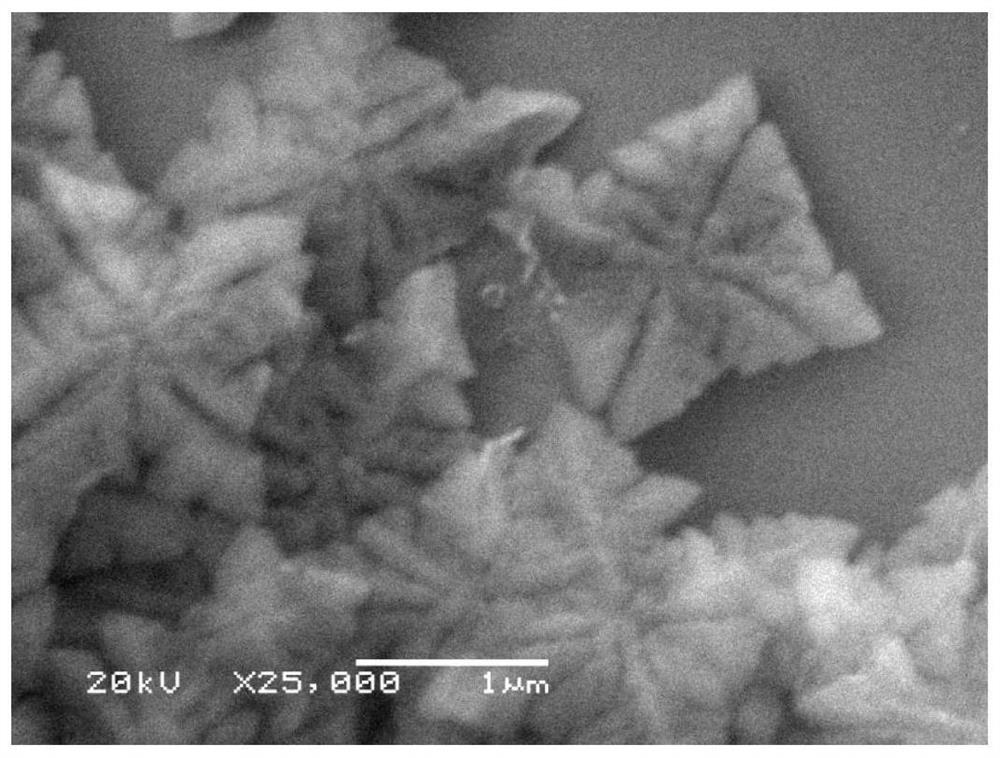

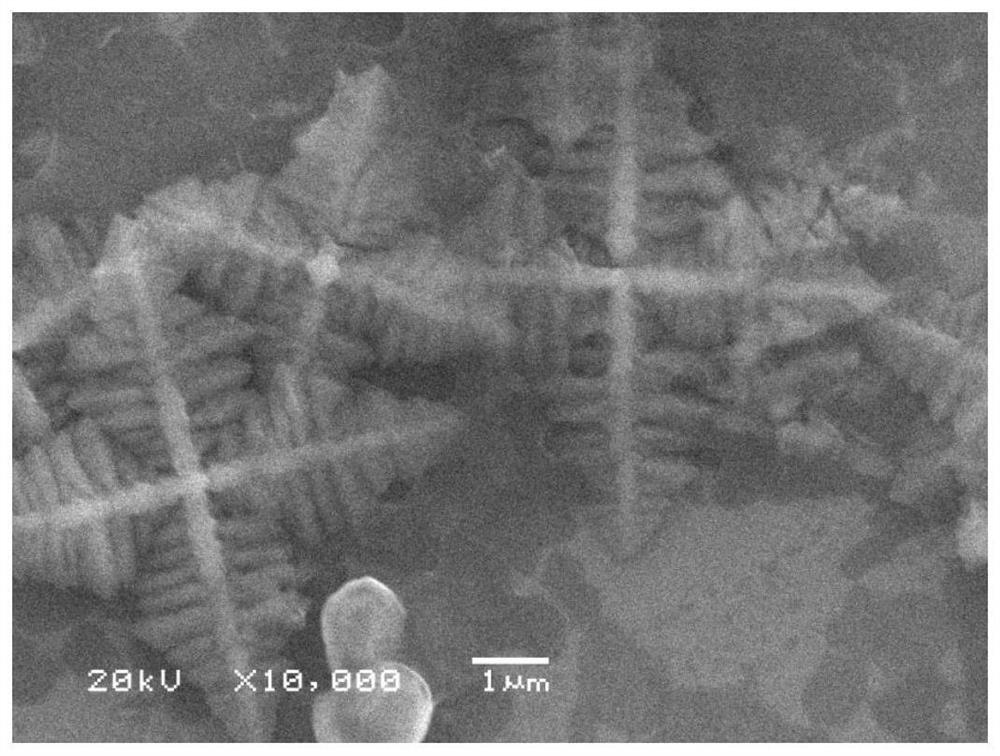

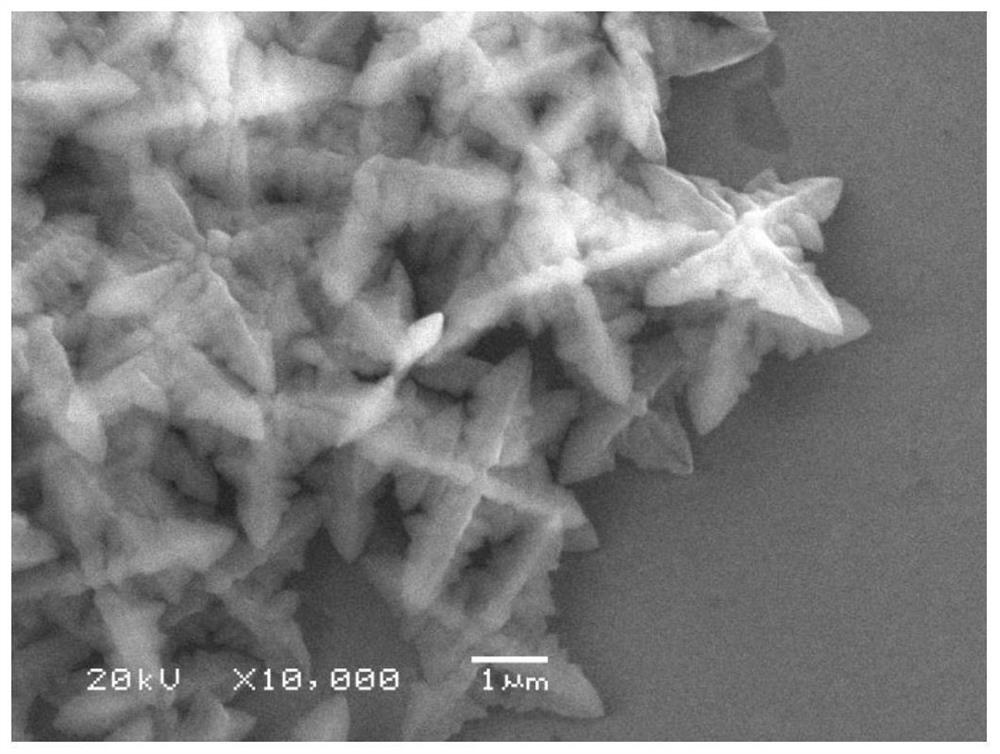

A method for preparing micron materials using surfactant-induced self-assembly metalloporphyrin

ActiveCN112920206BNovel structureThe synthesis process is simpleCobalt organic compoundsLuminescent compositionsActive agentPorphyrin

The invention discloses a method for preparing micron materials by adopting surfactant-induced self-assembly metalloporphyrin, and belongs to the field of micron material preparation. The preparation steps of the present invention are as follows: (1) dispose aqueous solutions of anionic and cationic surfactants with different concentrations; (2) carry out the aqueous solution of metalloporphyrin with positive / negative charge and the aqueous solution of cationic / anionic surfactants in (1). Mixing, the control solution temperature is 5-90 ℃; (3) will hold the mixed solution of the metalloporphyrin aqueous solution or metalloporphyrin aqueous solution of negative / positive charge and the anion / cationic surfactant aqueous solution in (1), control system The temperature is 5-90°C, and then added to the system (2) at one time; stirring for 5min-24h. In the present invention, the morphology and details of the microstructure are further regulated by adding anionic and cationic surfactants in the mixing process of oppositely charged porphyrins. The material with micron snowflake structure has clear branch structure, which is more conducive to the loading and dispersion of metal particles.

Owner:DALIAN NATIONALITIES UNIVERSITY

A preparation method of metalloporphyrin nanotube-cadmium sulfide composite photosensitive sensing material modified by graphene quantum dots

ActiveCN109254037BImprove transmission efficiencyHigh sensitivityOrganic-compounds/hydrides/coordination-complexes catalystsLuminescent compositionsThio-Cadmium acetate

The invention discloses a preparation method of a graphene quantum dot modified metalloporphyrin nanotube-cadmium sulfide composite photosensitive sensing material. The preparation method comprises the following steps: firstly preparing tetraphenylporphyrin, then preparing water soluble manganese tetrasulfophenyl porphyrin by taking fuming sulfuric acid as a sulfur source, and growing manganese tetrasulfophenyl porphyrin nanotubes on a porous alpha-alumina substrate; then by taking thioacetamide and cadmium acetate as sources, growing cadmium sulfide nanosheet blades on stems of the manganesetetrasulfophenyl porphyrin nanotubes by utilizing a hydrothermal method, and dropwise adding polydimethylsiloxane solution dissolved with graphene quantum dots on the surface of a composite material,and reserving a manganese tetrasulfophenyl porphyrin nanotube / cadmium sulfide composite material after the porous alpha-alumina substrate is removed, so that protective effect of a support material istaken, and then stability of the sensing material and electron conductivity are improved.

Owner:ZHEJIANG SCI-TECH UNIV

A kind of multifunctional metalloporphyrin complex, its preparation method and polycarbonate preparation method

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Porphyrin compound containing acid anhydride bond symmetrical molecular tweezers series and preparation method thereof

InactiveCN103724363BImplement featuresEasy to detectChemiluminescene/bioluminescenceLuminescent compositionsPorphyrin moleculeCarboxyl radical

The invention provides acid-anhydride-bond-containing symmetric molecular tweezer series porphyrin compounds and a preparation method thereof. The structural formula is disclosed in the specification, wherein M=H2, Zn, MnCl, Cu, Ni or Co. The molecular formulae of the porphyrin compounds are sequentially C90H58N8O3, C90H54N8O3Zn2, C90H54N8O3Cl2Mn2, C90H54N8O3Cu2, C90H54N8O3Ni2 and C90H54N8O3Co2. The free alkali porphyrin P is prepared by carrying out intermolecular removal of one water molecule on bimolecular 5-(4-carboxylphenyl)-10,15,20-triphenylporphyrin; and the synthesized protoporphyrin reacts with MnCl2.4H2O, ZnCl2, CuCl2, NiCl2.6H2O and CoCl2.6H2O to obtain the corresponding metalloporphyrin compounds. All the synthesized series porphyrins are molecular tweezer compounds with specific cavity size, and can be further developed into sensitive materials for detecting aldehyde ketones, amines and aromatics.

Owner:CHONGQING UNIV

Porphyrin-based catalysts for water splitting

ActiveUS11446648B2Improve electronic conductivityImprove electrocatalytic activityOrganic chemistryCell electrodesPtru catalystCarbon fibers

The porphyrin-based catalysts for water splitting are composites of porphyrin or metalloporphyrin active ingredients, conductive carbon (e.g., graphene sheets, vapor grown carbon fiber, carbon black, etc.), and a polymer or binder that may be coated on a glassy carbon electrode. The polymer or binder may be Nafion oil or polyvinylidine difluoride. The porphyrin may be a porphyrin having a transition metal or hydrogen at its center, and may be halogenated and / or have a thiophene substituent.

Owner:KING FAISAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com