Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

100 results about "Para-tertiary-butylphenol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

BADGE- and BPA-free can coating

ActiveUS7682674B2Suitable flexibilitySuitable resistanceSynthetic resin layered productsPretreated surfacesAcrylic resinPolyvinyl chloride

The present invention relates to a composition, which is useful for producing coatings for metal sheet substrates of metal cans for storing and / or transporting food or beverages or a lid thereof, and which comprises the following components:(a) 30 to 90 wt. % of a polyvinylchloride-(PVC)-polymer,(b) 7 to 25 wt. % of an acrylic resin,(c) 3 to 40 wt. % of a crosslinking agent, which is produced from phenol, para-tert.-butylphenol, xylenol or a mixture thereof, and formaldehyde,(d) 0 to 8 wt. % additive,(e) 0 to 50 wt. % pigment and(f) a solvent-component,where all weight percentages are on the basis of the total dry weight of the coating composition (without solvents) and the composition is substantially free of bisphenol-A-diglycidyl-ether (“BADGE”) and also substantially free of bisphenol-A-resins. The composition provides metal can coatings that have suitable flexibility, scratch resistance, adherence and sterilization resistance when processed in contact with food. The coatings are suitable for three-piece cans as well as deep-drawn metal cans. In particular they are, however, useful for lids that are to be torn open due to their extraordinary flexibility and sterilization resistance.

Owner:HENKEL KGAA

Preparation method and application of mercaptan fluorescence probe based on coumarin

The invention discloses a preparation method and application of a mercaptan fluorescence probe based on coumarin. The preparation method includes: coumarin and p-tert-butylphenol dialdehyde are used as raw materials to synthesize a bis-Schiff base coumarin derivative (compound I), the compound I has strong fluorescence, and the compound I is coordinated with copper ions to prepare coumarin-copper ion (II) complex, namely the mercaptan fluorescence probe I-Cu (II). Due to the influence of the paramagnetism of Cu2+ and photoinduction electron transfer effect, the fluorescence of the compound I is quenched; sulfur atoms in compounds such as mercapto-amino acid and derivatives such as glutathione thereof and Cu2+ have a strong coordination effect, the competitive coordination effect allows the copper ions in the coumarin-copper ion (II) complex to be taken away by the mercapto-amino acid and the derivatives thereof so as to regenerate the compound I, and the fluorescence of the compound I is restored. Accordingly, a method for fast and simply detecting mercaptan compounds is built.

Owner:XINXIANG MEDICAL UNIV

Toughening method of poly(3-hydrox butyrate) and poly(3-hydroxy butyrate-3-hydroxy pentanoate)

The present invention relates to a toughening method of poly(3-hydroxy butyrate) and poly(3-dydroxy butyrate-3-hydroxy pentanoate). The raw material includes the first component of poly(3-hydroxy butyrate) or poly(3-dydroxy butyrate-3-hydroxy pentanoate) with 3-hydroxy pentanoate monomer molar content less than 20%; the second copmonent of p-tert-butylphenol, bisphenol A, bisphenol S or 2,4,6-tri(2'-hydroxy-4'-butoxyphenyl)-1,3,5- triazine; and the optional component including plasticizer and stuffing. The weight ratio between the first component and the second component is 70-90 to 10-30 andthe optional component is 0-30 wt% of the first component. By means of solution blending or melting blending, modified material with excellent toughness may be obtained.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Preparation of polydicyclopentadiene/montmorillonite nano composite material

The invention discloses a preparation method of the poly-dicyclopentadiene / montmorillonite nanocomposites. The support catalysts is prepared through the complex compound compounded by the compound with hydroxide radical and the tungsten hexachloride attaching to the organic montmorillonite, and the complex compound comprises the paratert-butyl phenol, quadruple ((Beta-(3, 5-tert-butyl -4- hydroxy phenyl) monoprop) pentaerythritol ester or 2-hydroxy-4-n-octyloxybenzophenone, etc. The polymerization of the dicyclopentadiene is catalysed through the in situ polymerization model by the catalyst, the interlayer spacing is increased when the dicyclopentadiene monomer polymerizing in the interlayer of the montmorillonite, the interlayer of the montmorillonite is peeled by the heat produced in the reaction, the peeled interlayer of the montmorillonite is scattered in the poly-dicyclopentadiene, and the poly-dicyclopentadiene / montmorillonite Nanocomposites is produced, and then a model is prepared by the reaction injection molding method. The composites are showed with nanocomposites structure through the X-ray diffractogram.

Owner:HENAN UNIV OF SCI & TECH

BADGE- and BPA-Free Can Coating

ActiveUS20080299343A1Suitable flexibilitySuitable resistanceSynthetic resin layered productsPretreated surfacesAcrylic resinPolyvinyl chloride

The present invention relates to a composition, which is useful for producing coatings for metal sheet substrates of metal cans for storing and / or transporting food or beverages or a lid thereof, and which comprises the following components:(a) 30 to 90 wt. % of a polyvinylchloride-(PVC)-polymer,(b) 7 to 25 wt. % of an acrylic resin,(c) 3 to 40 wt. % of a crosslinking agent, which is produced from phenol, para-tert.-butylphenol, xylenol or a mixture thereof, and formaldehyde,(d) 0 to 8 wt. % additive,(e) 0 to 50 wt. % pigment and(f) a solvent-component,where all weight percentages are on the basis of the total dry weight of the coating composition (without solvents) and the composition is substantially free of bisphenol-A-diglycidyl-ether (“BADGE”) and also substantially free of bisphenol-A-resins. The composition provides metal can coatings that have suitable flexibility, scratch resistance, adherence and sterilization resistance when processed in contact with food. The coatings are suitable for three-piece cans as well as deep-drawn metal cans. In particular they are, however, useful for lids that are to be torn open due to their extraordinary flexibility and sterilization resistance.

Owner:HENKEL KGAA

Preparation method of high-cis vertenex

InactiveCN101830798AIncrease contentMild reaction conditionsOrganic compound preparationCarboxylic acid esters preparationChemical synthesisAcetic acid

The invention discloses a chemical synthesis method, in particular to a preparation method of high-cis vertenex. The vertenex is prepared from two steps of reactions: firstly, using p-tert-butyl phenol and hydrogen as raw materials to synthesize tert-butyl cyclohexanol under the condition of a catalyst; secondly, using tert-butyl cyclohexanol and acetic acid as raw materials to carry out a synthesis reaction under the condition of a catalyst III to obtain high-cis vertenex. The invention has the advantages of mild reaction conditions, safe and convenient operation, high cis body content in the product and thinner and stronger and fine product fragrance. The method can be widely applied to the preparation process of perfume.

Owner:杭州友邦香料香精有限公司

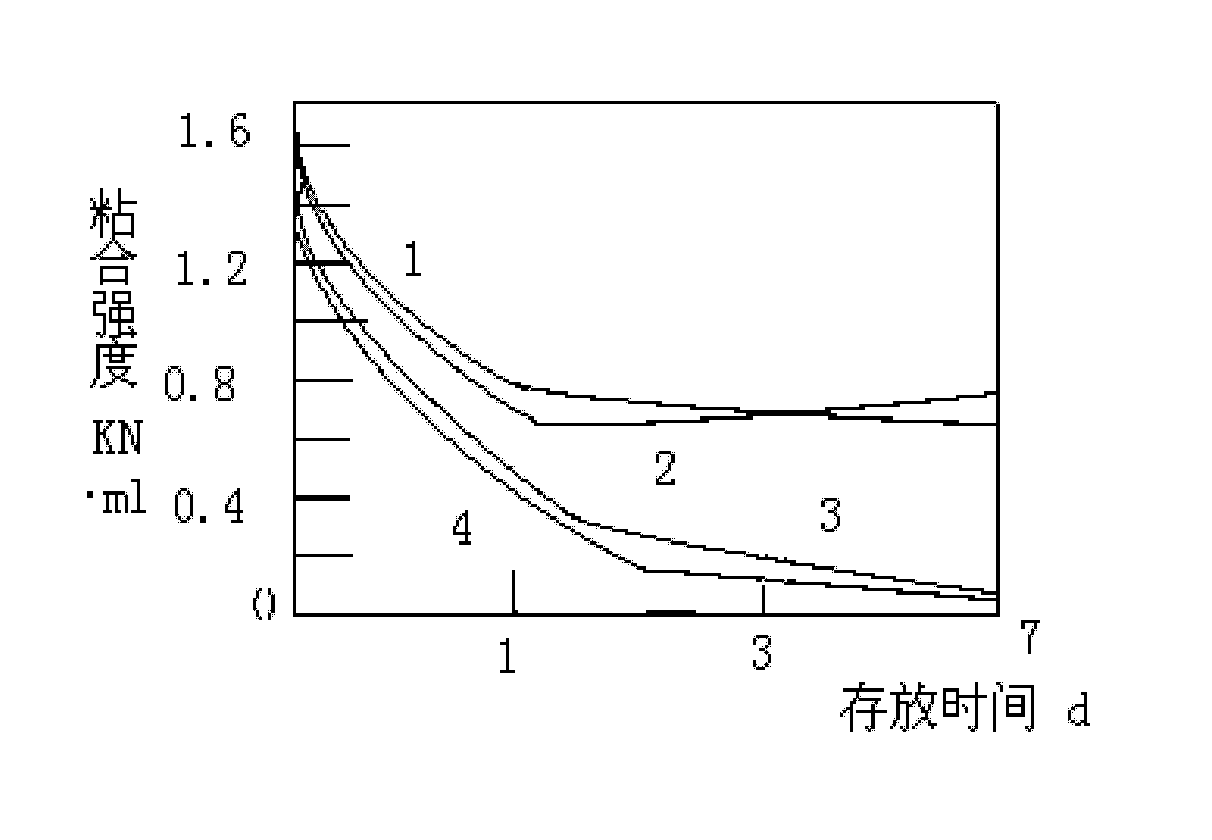

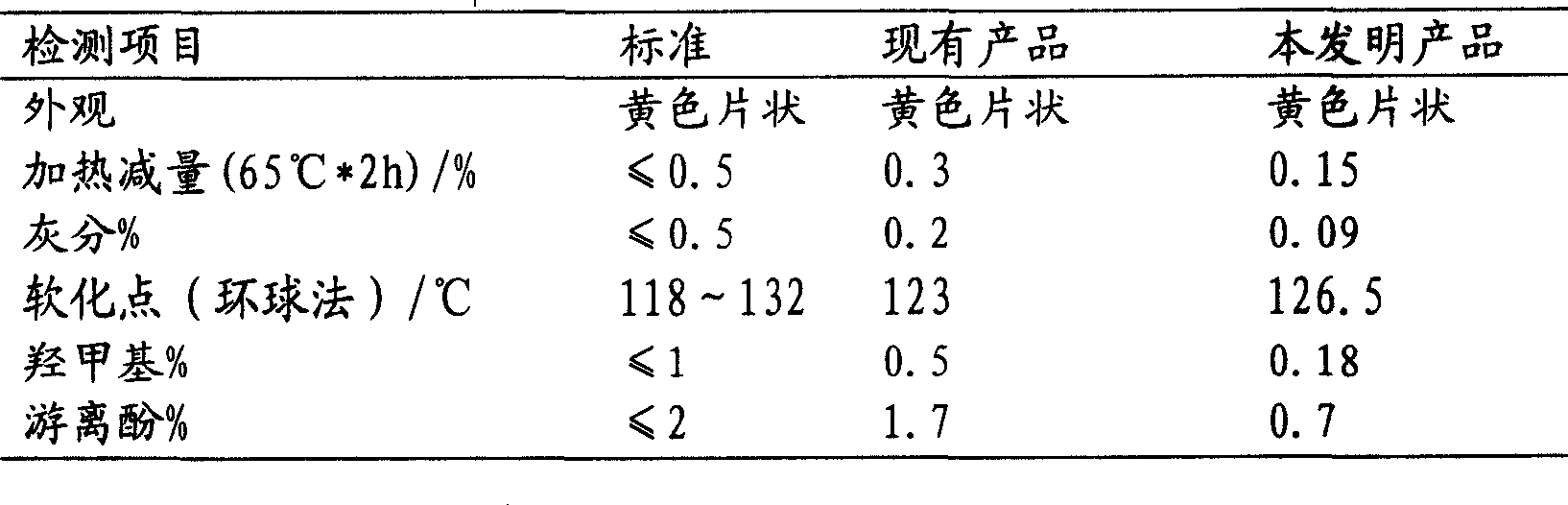

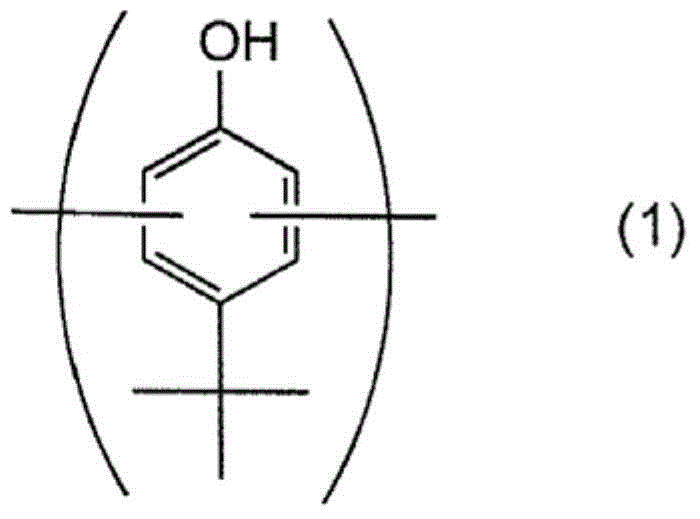

Morpholine modified p-tert-butylphenol-formaldehyde resin and preparation method thereof

ActiveCN102295621AGood viscosity increasing effectSimple processOrganic chemistryTert butyl phenolPolymer science

The invention relates to a morpholine modified para-tert-butyl phenolic resin and is characterized in that the structural formula of the morpholine modified para-tert-butyl phenolic resin is described in the specification, wherein R is morpholine, n can be 1,2,3,4 or 5, and the average molecule weight of the substance is 800-1000. According to the invention, the resin can improve the tackifying property of a product so that the tackifying property of the product meets the processing technology of automobile tyre and rubber; and the performance of the resin is equivalent to that of para-tert-butyl phenol-acetylene resin produced by BASF in German. The invention also discloses the preparation process of the morpholine modified para-tert-butyl phenolic resin.

Owner:WUHAN JINGHE CHEM

Green waterproof milk white polymer paint

InactiveCN1887990APromote environmental protectionHigh tensile strengthAntifouling/underwater paintsPaints with biocidesUltravioletSynthetic Polymeric Macromolecules

The present invention discloses one kind of waterproof milk white polymer paint. The green waterproof milk white polymer paint consists of 19 kinds of materials, including SEBS, SBS, coumarone resin, petroleum resin, terpene resin, etc. in certain weight proportion. It has good comprehensive mechanical performance, high waterproof performance, construction convenience and no environmental pollution.

Owner:河南省治海建材有限公司

High-speed rail turnout rust-preventative oil

ActiveCN104046420AApplicable useGood kinematic viscosityLubricant compositionTert butyl phenolBarium salt

The invention discloses high-speed rail turnout rust-preventative oil which is composed of the following raw materials, by weight, 52-60 parts of machine oil, 4-6 parts of p-tert-butylphenol formaldehyde resin, 1-2 parts of vaseline, 4-6 parts of dinonyl-naphthalenesulfonic acid barium salt, 2-4 parts of neutral dinonyl-naphthalenesulfonic acid barium salt, 3-4 parts of petroleum sodium sulfonate, 1-2 parts of lauric diethanolamide, 0.7-1 part of aluminium isopropoxide, 0.2-0.4 part of 2,2'-methylene-bis(4-methyl-6-tert-butyl phenol), and 4-6 parts of an antirust auxiliary agent. The rust-preventative oil has stable film, can completely cover a rust layer and a metal surface, can saturate the rust layer within a short time to form a hard film, has good kinematic viscosity and is especially suitable for outdoor steel rails and turnouts.

Owner:徐州邦贤信息科技有限公司

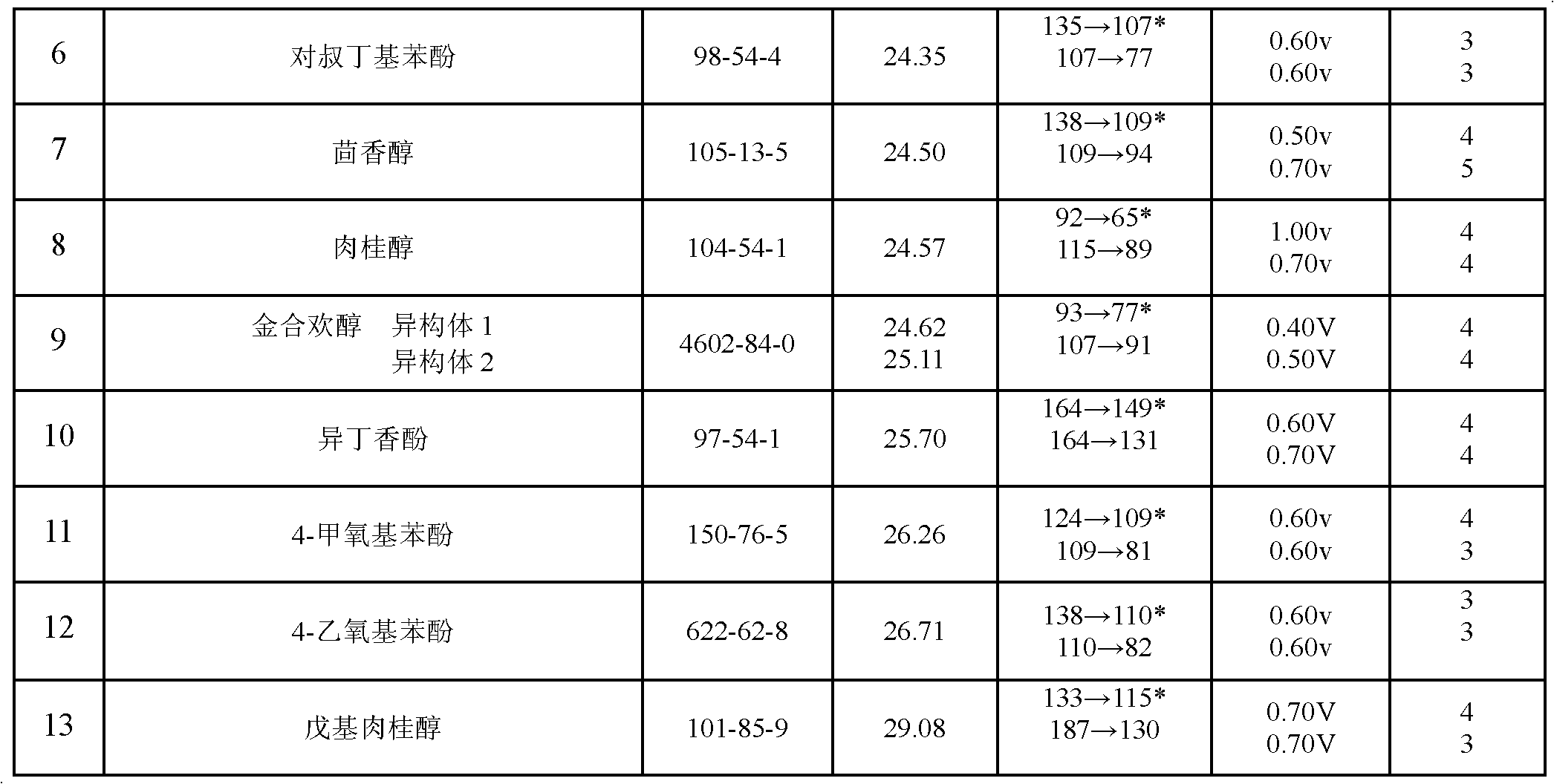

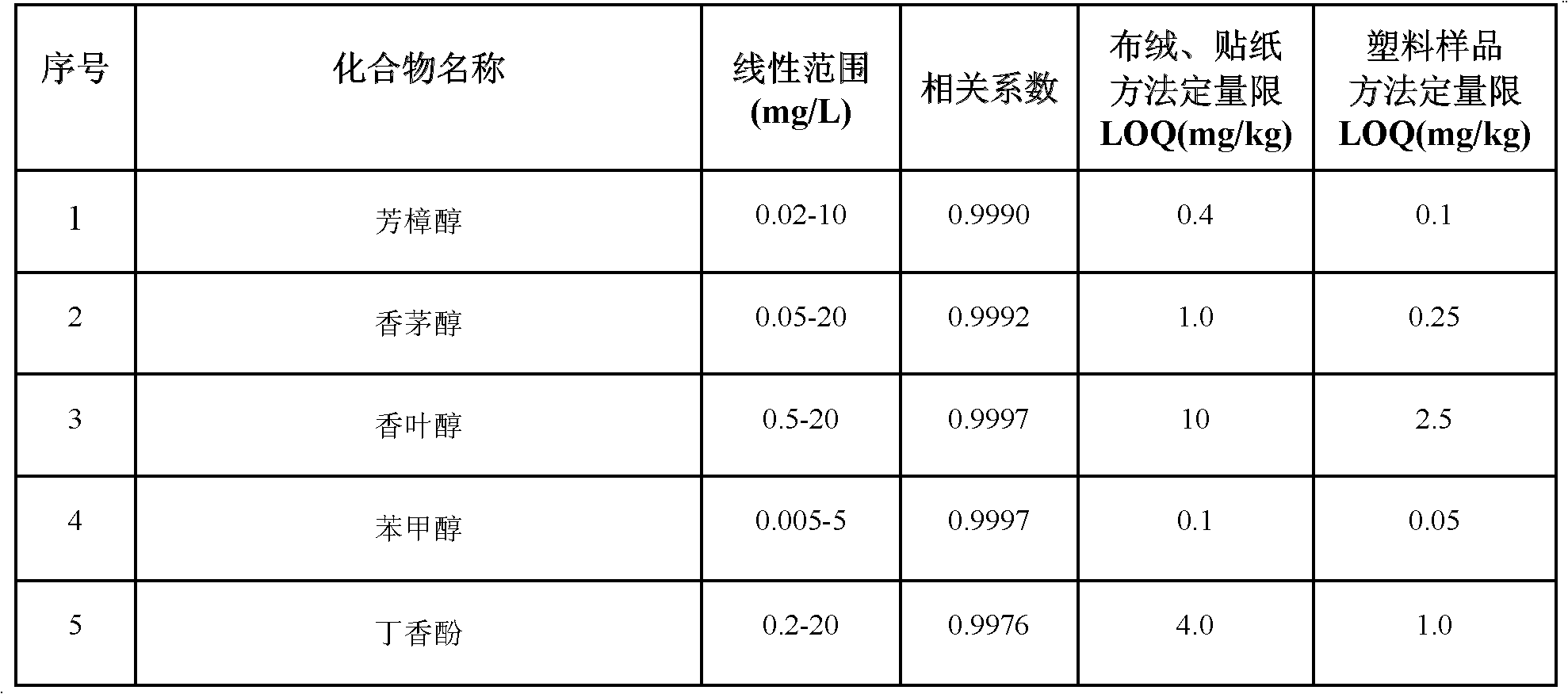

Method for simultaneously detecting residual amounts of 13 phenolic alcohol sensitization aromatics in toy

InactiveCN103105438AApplicable AnalysisHigh sensitivityComponent separation4-MethoxyphenolIsoeugenol

The invention relates to a method for simultaneously detecting residual amounts of 13 phenolic alcohol sensitization aromatics in a toy. The method realizes simultaneous detection of 13 phenolic alcohol sensitization aromatics such as benzyl alcohol, linalool, 4-methoxyphenol, citronellol, geraniol, 4-ethoxyphenol, anise alcohol, p-tert-butylphenol, cinnamyl alcohol, eugenol, isoeugenol, amylcinnamyl alcohol and farnesol in a toy for the first time by the gas chromatography-ion trap tandem mass spectrometry technology, and fills the technical gap. The method can be used for detecting plush toys, paster toys and plastic toys (prepared from ABS, PVC and PS materials), and has a wide application range and strong applicability. The ion trap tandem mass spectrometry realizes qualification and quantification by two-stage mass spectrometry MS / MS and thus the method has good qualification and quantification effects on a toy sample having a complex matrix.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

Solvent-free method for preparing tackified p-tert-butyl phenolic resin

A solvent-free method for preparing trackifying para-tertiary butyl phenol phenolic resin comprises the following components and dosage, with the dosage of weight part: 900-1000 parts of para-tertiary butyl phenol, 150-200 parts of 97% formaldehyde, 40-50 parts of 10% hydrochloric acid, 5-10 parts of oxalic acid, and 1.5-3.5 parts of surface-active agent, wherein, 97% formaldehyde and 10% hydrochloric acid are both weight percentage. The method overcomes the shortcoming of the existing method for preparing para-tertiary butyl phenol phenolic resin, which uses solvent; and the method has the advantages of simple synthetic process, low production cost and higher performance than that of the existing product, and avoids sudden gathering in the process of preparation, and the like.

Owner:WUHAN JINGHE CHEM

Multifunctional crude oil tank farm treating agent

ActiveCN103275753AReduce contentReduce dirty oil contentDewatering/demulsification with chemical meansDiethylene glycol monobutyl etherSolubility

The invention relates to a multifunctional crude oil tank farm treating agent which is prepared by the following raw materials in percentage by weight: 55%-65% of a modified polyether demulsifying agent, 10%-15% of a synergist, 3%-5% of a dispersant and 20%-30% of a solvent, wherein the modified polyether demulsifying agent is one or a plurality of nonyl phenolic resin polyether, nonyl phenol aldehyde resin polyether, tertiary butyl phenolic resin polyether and tertiary butyl phenol amine aldehyde resin polyether polymerized by nonyl phenol, m-dinonylphenol or p-tert-butylphenol as an initiator, or a condensation product of the nonyl phenol, the m-dinonylphenol, the p-tert-butylphenol, vinylamines and methanal as the initiator with propylene epoxide and ethylene oxide; the synergist is a non-ionic surface active agent; the dispersant is polyacrylic acid or polyacrylamide; and the solvent is one or a plurality of diethylene glycol monobutyl ether, terpene or naphtha. The multifunctional crude oil tank farm treating agent is suitable for pretreating of various types of temporary stored or long-term stored crude oil entering the tank farm. A product has oil solubility, and the usage amount is low.

Owner:沈红新 +1

Manufacturing method for preparing methanol diesel fuel from industrial methanol

InactiveCN101935559AGood stability without delaminationNo corrosionLiquid carbonaceous fuelsTert butyl phenolAlkylphenol

The invention discloses a manufacturing method for preparing methanol diesel fuel from industrial methanol. The method comprises the following steps of: putting ethanolamine and naphthenic acid into the industrial methanol according to a certain proportion and mixing to obtain denatured methanol for later use; selecting alkylphenol ethoxylates, dimethyl carbonate, ethyl oleate and para-tert-butyl phenol according to a proportion, sequentially adding the alkylphenol ethoxylates, the dimethyl carbonate, the ethyl oleate and the para-tert-butyl phenol into a container and stirring for 20 to 30 minutes so as to obtain a methanol diesel fuel modifier for later use; and adding 75 percent diesel fuel mixed liquor into 20 percent denatured methanol, stirring fully and uniformly, adding 5 percent diesel fuel modifier and fully mixing so as to obtain finished methanol diesel fuel. A methanol diesel fuel product has the advantages of no delamination, high stability, no corrosion, no swelling, no emulsification, high explosive force, convenient use, readily available raw materials, low manufacturing cost and easy popularization.

Owner:唐山市隆泰科技有限公司

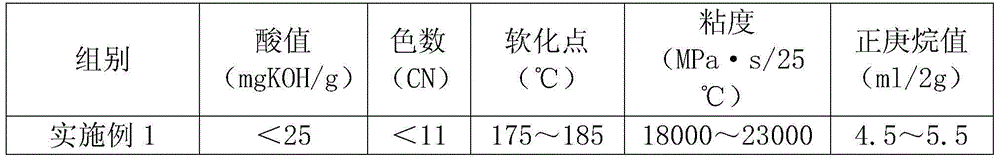

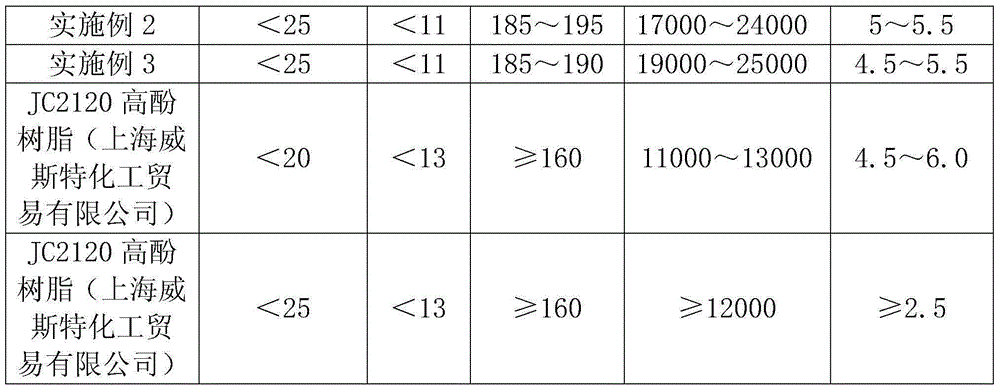

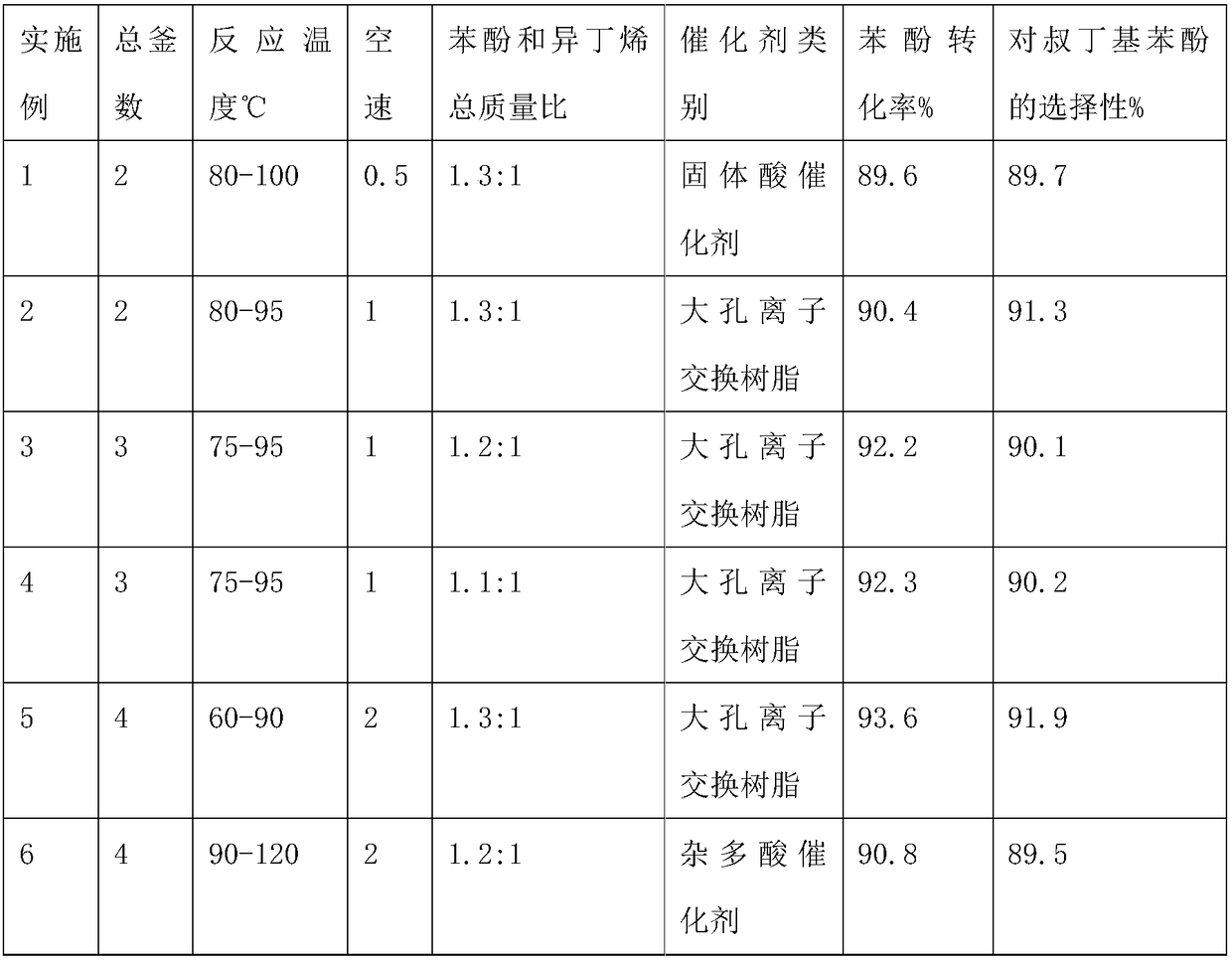

Preparation method for vegetable oil modified rosin phenolic resin

The invention provides a preparation method for vegetable oil modified rosin phenolic resin. The preparation method comprises the following steps of firstly, feeding rosin into a reaction kettle, raising the temperature to be 180DEG C, adding vegetable oil, continuously raising the temperature to be 210 to 215DEG C and keeping the temperature for 1 to 1.5 hours, and carrying out addition reaction; secondly, feeding pentaerythritol and magnesium oxide into the reaction kettle, reducing the temperature to be 160 to 170DEG C, feeding dodecylphenol and p-tert-butylphenol according to the mole ratio of 1:1.01 to 1.03, then continuously reducing the temperature to be 120 to 130DEG C, feeding paraformaldehyde according to the mole ratio of phenol to aldehyde being 1:2.0 to 2.1, and keeping the temperature for 2 to 2.5 hours; thirdly, raising the temperature in the reaction kettle to be 260 to 270DEG C, keeping the temperature, carrying out esterification reaction until an acid value is smaller than 25mgKOH / g, and carrying out reduced pressure distillation to obtain a low-boiling-point substance, namely the vegetable oil modified rosin phenolic resin. The resin prepared by the preparation method provided by the invention has the advantages of high viscosity, good solubility, high molecular weight, uniformity in distribution and suitability for offset lithography of ink.

Owner:桂林兴松林化有限责任公司

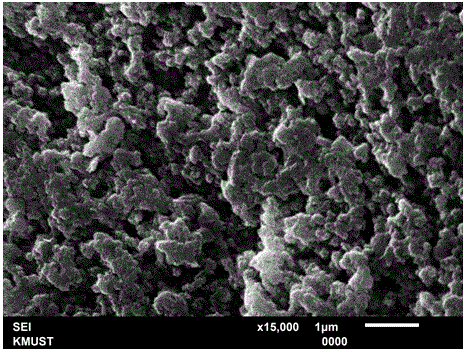

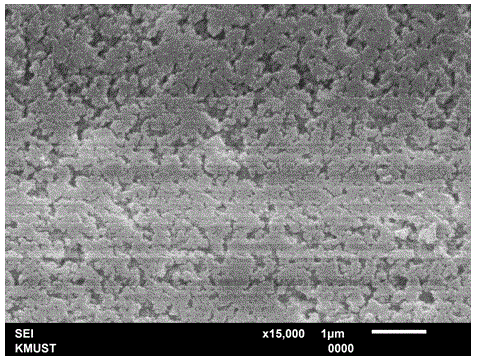

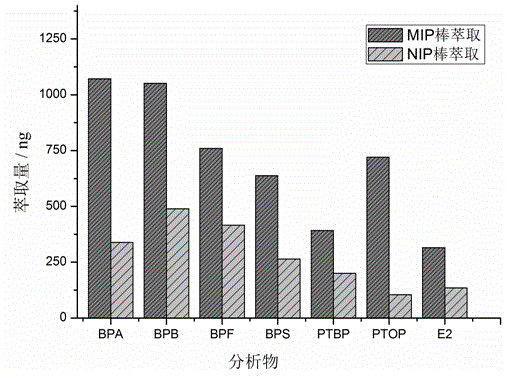

Preparation method of molecular imprinting sorptive extraction stirring bar by using alternative template

InactiveCN104923191AWith detachableSolve wear and tearOther chemical processesPreparing sample for investigationWater bathsFunctional monomer

The invention relates to a preparation method of a molecular imprinting sorptive extraction stirring bar by using an alternative template, belonging to the technical field of analytical chemistry and sample pretreatment. The method includes firstly using p-tert-butylphenol as a template molecule, dissolving the template molecule and a functional monomer in a solvent, uniformly mixing by ultrasound and standing, then adding a crosslinking agent and an initiator to obtain an assembly solution, and removing oxygen by ultrasound; injecting the assembly solution into a glass capillary with an inner diameter of 1.4mm, then inserting into a glass capillary with an outer diameter of 1.0mm, performing water bath heating for polymerization, removing the larger glass capillary, taking out the small glass capillary, cutting into appropriate length with a blade, inserting a iron core and sealing ends, sleeving silicon tubes on both ends, and cleaning with methanol, to obtain the molecular imprinting sorptive extraction stirring bar using p-tert-butylphenol as the alternative template. The obtained stirring bar can be applied to extraction analysis of trace amount of environmental estrogen bisphenol A in a water sample.

Owner:KUNMING UNIV OF SCI & TECH

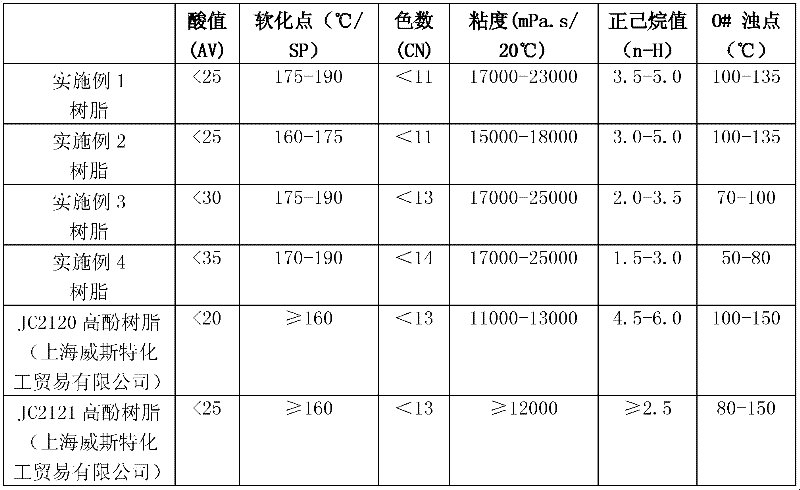

Preparation method of mixed phenolic rosin modified phenolic resin

The invention discloses a preparation method of mixed phenolic rosin modified phenolic resin. Under the alkaline conditions, p-tert-octyl phenol, p-nonylphenol and p-tert-butylphenol react with formaldehyde to obtain a mixed phenolic solvent type phenolic resin condensation product, and in the presence of a catalyst, the condensation product undergoes rosin modification and mixed polyalcohol esterification to form the phenolic resin. The mixed polyalcohol comprises glycerol and pentaerythritol. The prepared phenolic resin is high in softening point and good in viscosity, the miscibility of a solvent is good, the color is light, the molecular weight distribution is uniform, and the phenolic resin is suitable for manufacture of printing ink and is suitable for components of ink for offset printing or intaglio printing.

Owner:桂林兴松林化有限责任公司

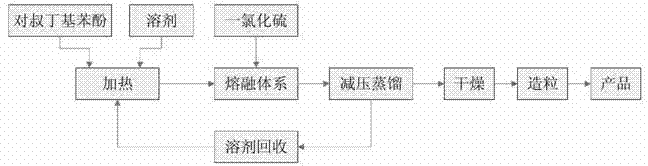

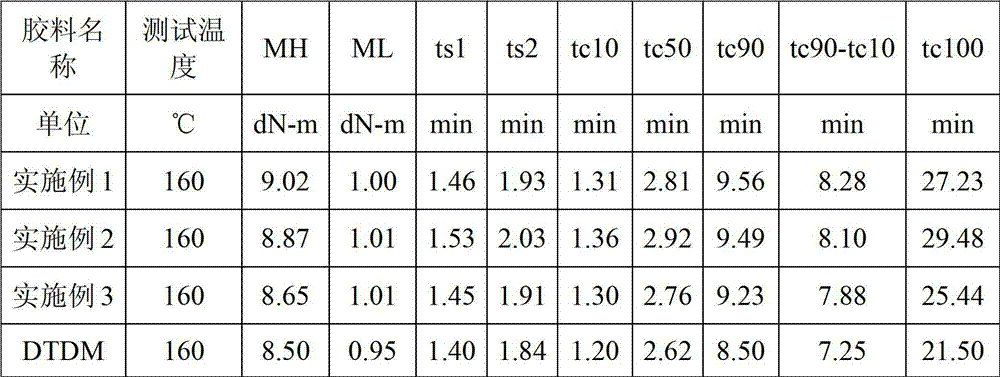

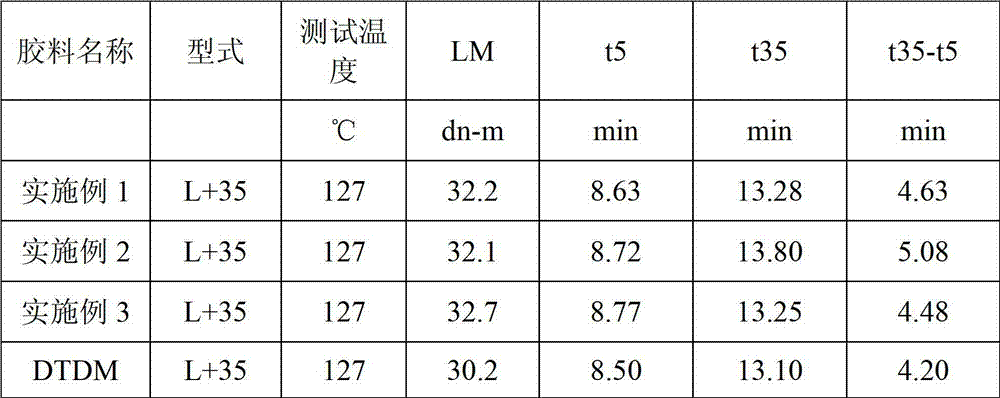

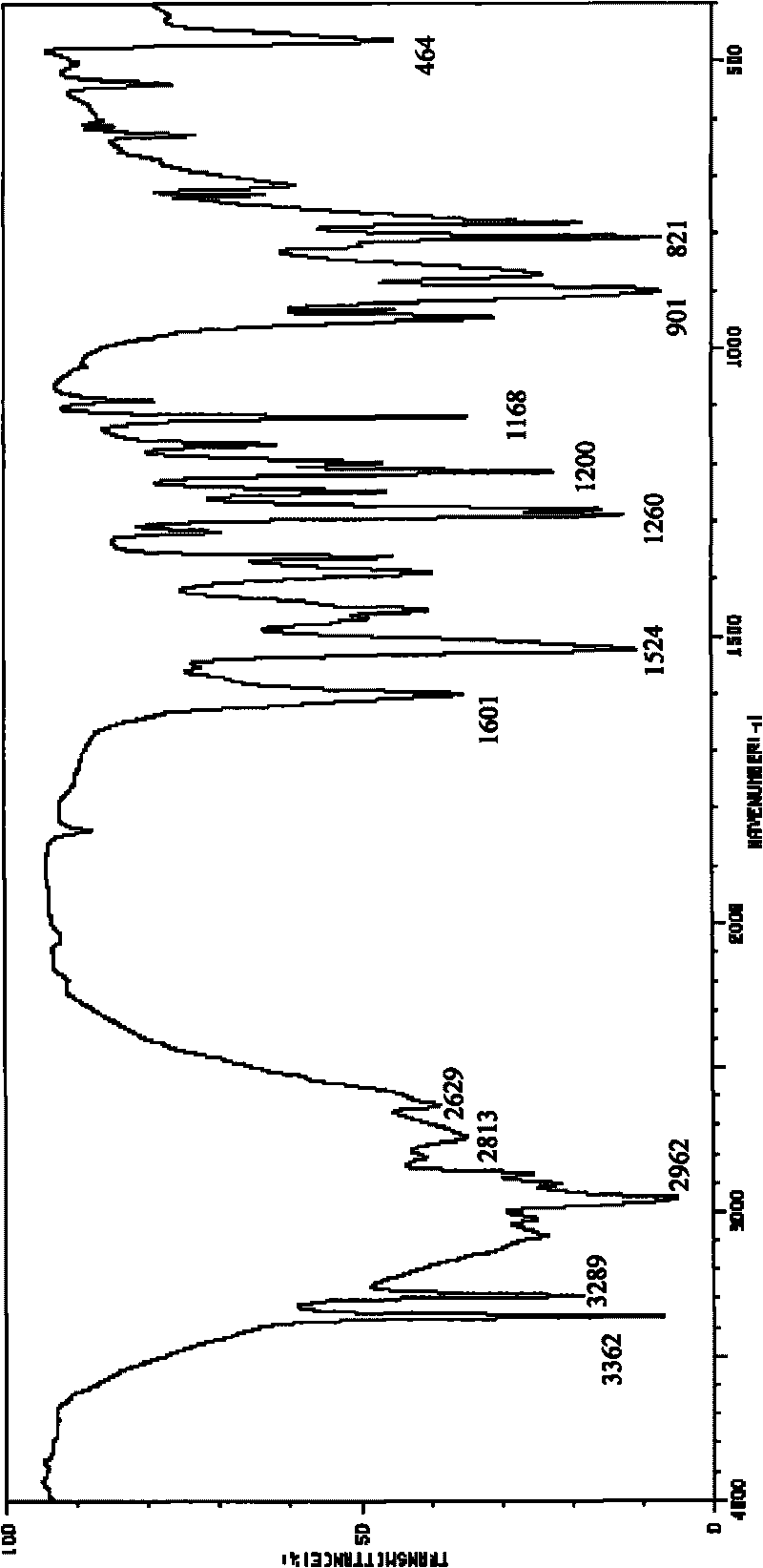

Preparation process of P-tert-butylphenol disulphide vulcanilzer

InactiveCN102964282AEasy to operateLow equipment requirementsHydropoly/poly sulfide preparationAlkaneBisulfide

The invention relates to a preparation process of P-tert-butylphenol disulphide vulcanilzer and belongs to the technical field of preparation methods of rubber auxiliary. The P-tert-butylphenol disulphide vulcanilzer is synthesized by reaction of P-tert-butylphenol and sulphur chloride in liquid phase alkane solvent, the P-tert-butylphenol disulphide vulcanilzer is heated in the solvent until solid is completely dissolved, sulphur chloride is dropwise added into a system, reduced pressure distillation is directly carried out after reaction is completely finished, and the solid after distillation is directly subjected to pelleting, so that the target product is obtained. The preparation process provided by the invention is easy to operate, equipment requirement is low, production cycle is short, and the alkane is used for substituting trichloro ethylene to be taken as reaction solvent, so that the preparation process provided by the invention is environment-friendly, safe and applicable to industrial production.

Owner:阳谷华泰(北京)新材料科技有限公司

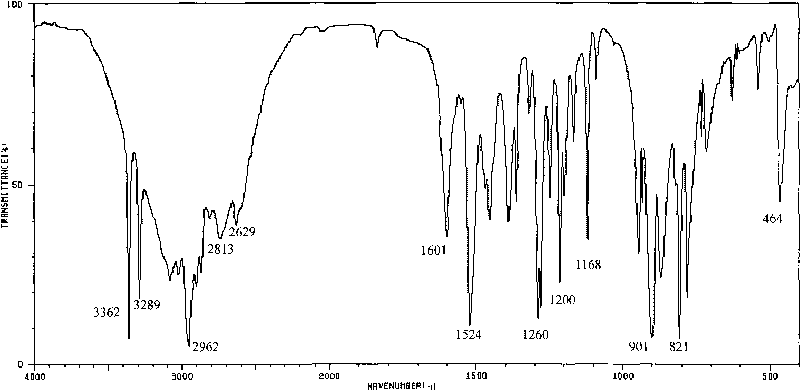

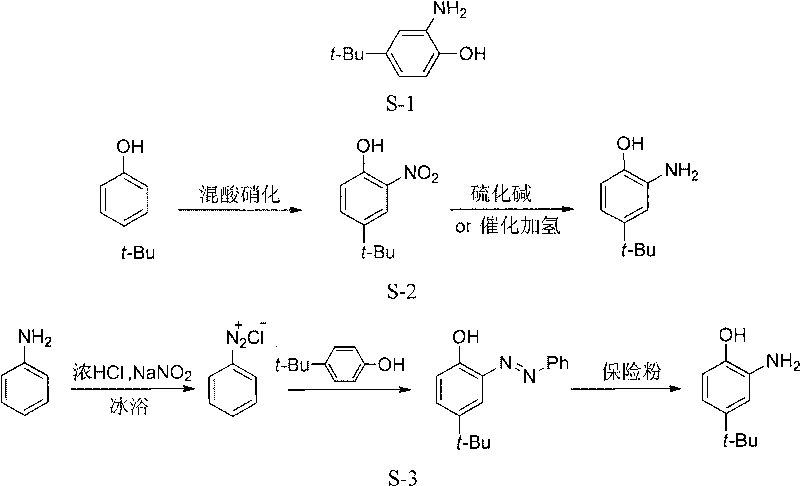

Method for preparing o-amino-p-tertiary butyl phenol

InactiveCN101696172AImprove conversion rateSimple post-processingOrganic compound preparationAmino-hyroxy compound preparationTert butyl phenolHydrogen

The invention discloses a method for preparing o-amino-p-tertiary butyl phenol. The o-amino-p-tertiary butyl phenol is prepared through reducing reaction by using the o-nitro-p-tertiary butyl phenol as a raw material and hydrazine hydrate as a hydrogen source under the action of a catalyst, wherein the catalyst is FeCl3, salts containing crystal water of the FeCl3 or aqueous solution of the FeCl3; the molar ratio of the FeCl3 and the o-nitro-p-tertiary butyl phenol is between 1 percent and 10 percent; and the molar ratio of the hydrazine hydrate and the o-nitro-p-tertiary butyl phenol is 1.6-2.5:1. The method has the characteristics of succinct process, high yield, low cost, less discharge of the three wastes, and the like.

Owner:ZHEJIANG UNIV

Synthesis process of p-tert-butyl phenol formaldehyde resin

The invention belongs to the technical field of synthesis of p-tert-butylphenol formaldehyde resin, and discloses a synthesis process of p-tert-butylphenol formaldehyde resin. The synthesis process comprises the following steps: adding a formaldehyde solution and ammonia water into a reaction kettle; uniformly adding p-tert-butylphenol, then heating to boiling, and maintaining for 150-180 minutes;cooling, adding acetic acid, neutralizing and stirring, and adding toluene for extraction; after standing for layering, draining wastewater; adding oxalic acid and tap water, stirring, standing for layering, and then draining wastewater; detecting pH which approximates 7-7.5, desolventizing the toluene under normal pressure, vacuumizing, and discharging under vacuum to obtain tert-butyl phenol formaldehyde resin. According to the process, the ammonia water is alkalescent, so that reaction is relatively mild, and the p-tert-butyl phenol formaldehyde resin prepared by the method is stable in product index and stable in use performance.

Owner:河北泽田化工有限公司

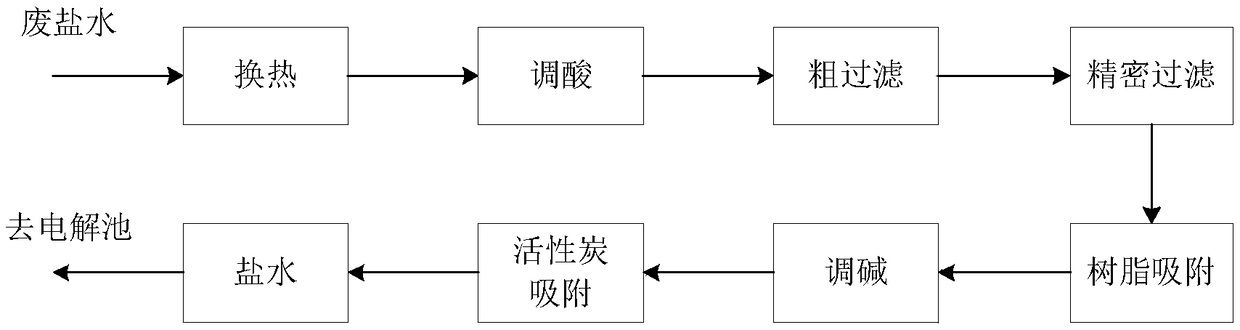

Treatment method for waste salt water generated in production process of polycarbonate

InactiveCN109231544AAchieving zero emissionsSolve pollutionWater contaminantsTreatment involving filtrationAlkali ionsP-tert-Butylphenol

The invention relates to a treatment method for waste salt water generated in the production process of polycarbonate. The treatment method comprises the following steps: the temperature of the wastesalt water generated in the production process of the polycarbonate PC and containing bisphenol A, p-tert-butylphenol and quaternary ammonium salt is regulated to 20-60 DEG C by a heat exchanger, thenthe waste salt water is introduced into an acid-regulating kettle, and the pH value is regulated to 1-4; then trace suspended solids are removed by a coarse filter and a precise filter, and the wastesalt water is conveyed to a high-position groove; the waste salt water flows into macroporous resin adsorbing columns by gravity to be adsorbed, then enters an alkaline-regulating kettle, and the pHvalue is regulated to 10-14; finally, the waste salt water enters active-carbon adsorbing columns to be adsorbed. The treatment method has the beneficial effects that phenolic organic matters in the waste salt water of the PC can be completely removed, and most of quaternary ammonium salt is removed; in the treated salt water, the content of the quaternary ammonium salt is less than 1ppm, the content of TOC (Total Organic Carbon) is less than 10ppm and the content of TN (Total Nitrogen) is less than 3ppm; as a raw material, the treated salt water can be used for a process for preparing causticsoda by a chlor-alkali ion membrane, and can not cause increase of voltage of an electrolytic cell, so that sodium chloride and water in the waste salt water can be recycled, and the recycling of thematerials is realized.

Owner:QINGDAO UNIV OF SCI & TECH +2

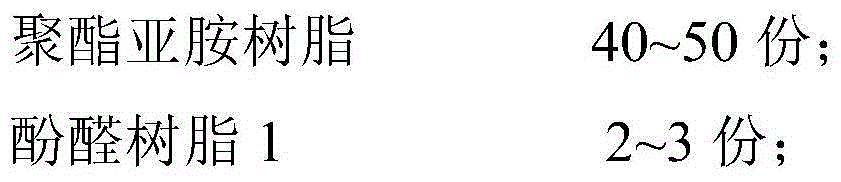

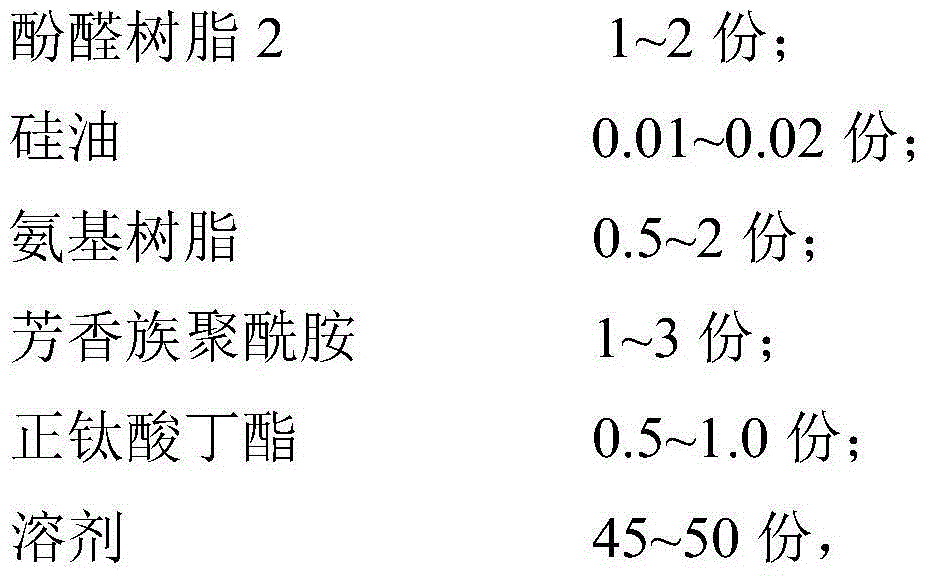

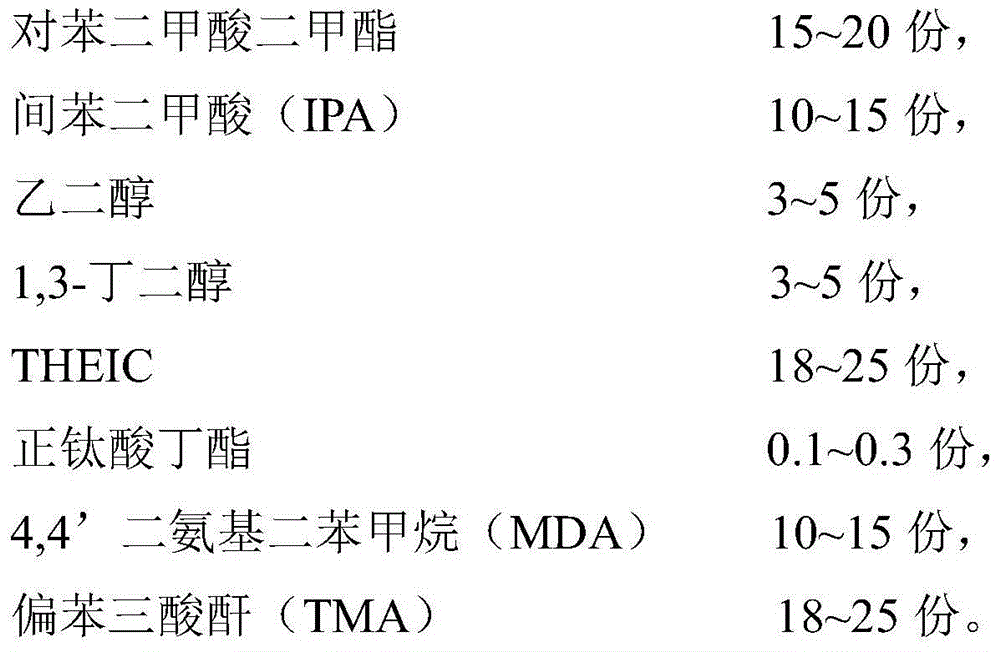

Preparation method of flexible polyester imide enameled wire insulating paint

The invention discloses a flexible polyester imide enameled wire insulating paint. The formula of the paint is as below: 40-50 parts of polyester imide, 2-3 parts of phenolic resin 1 (cresol phenolic resin), 1-2 parts of phenolic resin 2 (tert butyl phenol phenolic resin), 0.01-0.02 parts of silicone oil, 0.5-2 parts of amino resin, 1-3 parts of aromatic polyamide, 0.5-1 parts of tetrabutyl titanate, and 45-50 parts of a solvent. The enameled wire prepared by the invention has the advantages: the enameled wire paint film good flexibility, and the paint film does not crack after extending by 25% and winding by 1 time diameter of conductor; the enameled wire has good brine pinhole property without pinhole after extension by 5%; and the enameled wire has thermal level reaching 200.

Owner:艾仕得绝缘材料(安徽)有限公司

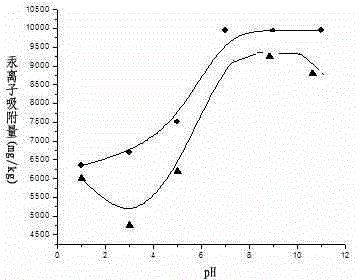

Method for adsorbing mercury ions in waste water by means of charcoal particles made from poplar branches

InactiveCN104445752AImprove adsorption capacityImprove adsorption strengthOther chemical processesWater contaminantsHydrogen SulfateFiltration

A method for adsorbing mercury ions in waste water by means of charcoal particles made from poplar branches comprises the steps of obtaining fourth carbonized particles through four steps; regulating the PH value of waste water containing mercury to 8, adding 50g poly-tert-butylphenoldisulfide, ferrous sulfide and sodium hydrogen sulfate to each liter of waste water containing mercury according to a mass ratio of 1:2:4, stirring the mixture for 1h, then regulating the PH value of the waste water containing mercury to 6.5, adding 50g sodium alcohol ether sulphate and sodium hypochlorite to each liter of waste water containing mercury according to a mass ratio of 1:4, stirring the mixture for 2h, conducting filtration, then regulating the PH value of the waste water containing mercury to 9-12, adding 50g fourth carbonized particles to each liter of processed waste water containing mercury, and stirring the mixture for 8h at the speed of 120rpm.

Owner:QINGDAO AGRI UNIV

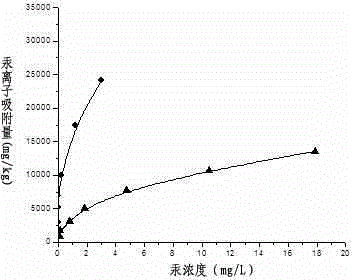

Industrial continuous process for preparation of p-tert-butylphenol

InactiveCN108558611AGood choiceImprove conversion rateOrganic chemistryOrganic compound preparationP-tert-ButylphenolWastewater

The invention discloses an industrial continuous process for preparation of p-tert-butylphenol. According to the process, phenol and isobutene are used as raw materials and allowed to pass through a fixed-bed reactor under the action of a catalyst, wherein continuous operation via multiple tandem kettles is carried out in the fixed-bed reactor; phenol is added from a first kettle; isobutene is added in a manner of multi-kettle continuous introduction; a reaction device is directly connected with a rectification device for separation of the raw materials and a product; the raw materials are returned to a catalytic tower for continuous operation; and the product is directly connected with a product storage tank after rectification. The method has the beneficial effects of good selectivity, high conversion rate, high yield, and almost no wastewater during production.

Owner:QINGDAO UNIV

Preparation method of rosin modified phenolic resin

The invention discloses a preparation method of rosin modified phenolic resin, and relates to the technical field of phenolic resin. The preparation method includes the steps that phenol and aluminum chloride anhydrous are added to a reaction still, temperature rises, polymerized formaldehyde is added while the solution is stirred, the solution is adjusted to be alkaline, temperature rises, and reaction is conducted, wherein the phenol is one or more of cresol, P-tert-butylphenol and dodecylphenol; rosin is added for modification, temperature rises, and reaction is conducted; polyhydric alcohols and metaphosphoric acid are added, and temperarure rise and reaction are conducted in stages, wherein polyhydric alcohols are one or more of pentaerythritol, xylitol and sorbitol. The rosin modified phenolic resin is good in viscosity, better in oil solubility, high in softening point, and suitable for planographic or intaglio printing ink.

Owner:GUANGXI ZHONGCHANG RESIN

Special cable for oil platform

InactiveCN106380647AImprove mechanical propertiesExcellent hot air aging performanceRubber insulatorsMelamine phosphatePolyvinyl chloride

The invention discloses a special cable for an oil platform. The special cable comprises a cable core and a sheath, wherein a modified nitrile rubber composite material is prepared from the following raw materials in parts by weight: 100 parts of nitrile rubber, 38 to 43 parts of ethylene propylene diene rubber, 2 to 5 parts of ethylene-vinyl acetate, 2 to 8 parts of chlorinated polyethylene, 0.5 to 2 parts of stearic acid, 0.5 to 3 parts of zinc oxide, 1 to 2 parts of p-tert-butylphenol-formaldehyde resin, 0.5 to 2 parts of DCBP, 0.5 to 1.5 parts of trimethylol-propane trimethacrylate, 3 to 15 parts of silicon aluminum carbon black, 2 to 10 parts of nanosilicon dioxide, 3 to 15 parts of aedelforsite, 3 to 15 parts of polyvinyl chloride, 1 to 5 parts of melamine phosphate, 2 to 10 parts of 6-chloro-N,N-diethyl-1,3,5-triazine-2,4-diamine, 10 to 30 parts of phosphorus silicon and nitrogen fire retardants, 1 to 2.5 parts of diethylene glycol distearate, 1 to 3 parts of 2-deoxy-2,2 difluoro-pentofuranose-1-ketone-3,5-dibenzoate, 1 to 3 parts of anti-aging agents, 0.5 to 2 parts of accelerants and 0.5 to 2 parts of silane coupling agents. The special cable for the oil platform provided by the invention has the advantages that the mechanical property is excellent; the aging-resistant and low-temperature-resistant performance is good; the fire-resistant and oil-resistant performance is excellent.

Owner:重庆三峡电线电缆科技股份有限公司

Rubber material for motor cushion block

InactiveCN105482198AImprove hydrophobicityImprove mechanical propertiesRubber materialHexamethylenetetramine

The invention discloses a rubber material for a motor cushion block. The rubber material is prepared from, by weight, 40-80 parts of nitrile butadiene rubber, 15-30 parts of cis-rich butadiene rubber, 30-40 parts of isoprene rubber, 1-3 parts of zinc oxide, 0.5-1.5 parts of magnesium oxide, 1.5-2.5 parts of p-tert-butylphenol-formaldehyde resin, 0.5-1.2 parts of accelerant CZ, 0.5-1.5 parts of hexamethylenetetramine, 40-50 parts of carbon black, 20-40 parts of calcined clay, 15-35 parts of nano-vermiculite, 10-30 parts of modified nano-montmorillonite, 5-15 parts of glass fiber, 10-30 parts of heavy calcium carbonate, 5-12 parts of grain graphite, 1-3 parts of antiager 4010NA, 1-3 parts of antiager IPPD, 1-3 parts of antiager D and 1-3 parts of coal tar. The rubber material is good in hydrophobic performance and mechanical performance, resistant to high temperature and ageing and long in service life.

Owner:崇夕山

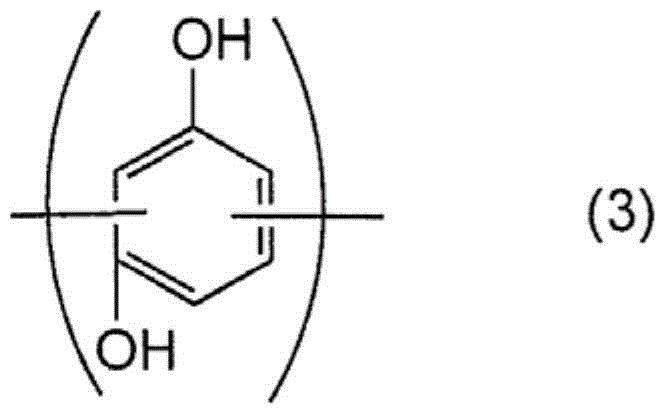

Cocondensate and method for producing same, and rubber composition containing cocondensate

Provided are: a cocondensate having a softening point of 150 DEG C or lower and containing a structural unit derived from p-tert-butylphenol, a structural unit derived from o-phenylphenol, and a structural unit derived from resorcin; a method for producing the cocondensate by reacting a mixture of p-tert-butylphenol and o-phenylphenol with formaldehyde in the presence of an alkali, and then performing reaction with a 0.8-fold molar quantity or more of resorcin with respect to the total amount of p-tert-butylphenol and o-phenylphenol; and a rubber composition containing the cocondensate.

Owner:TAOKA CHEM COMPANY

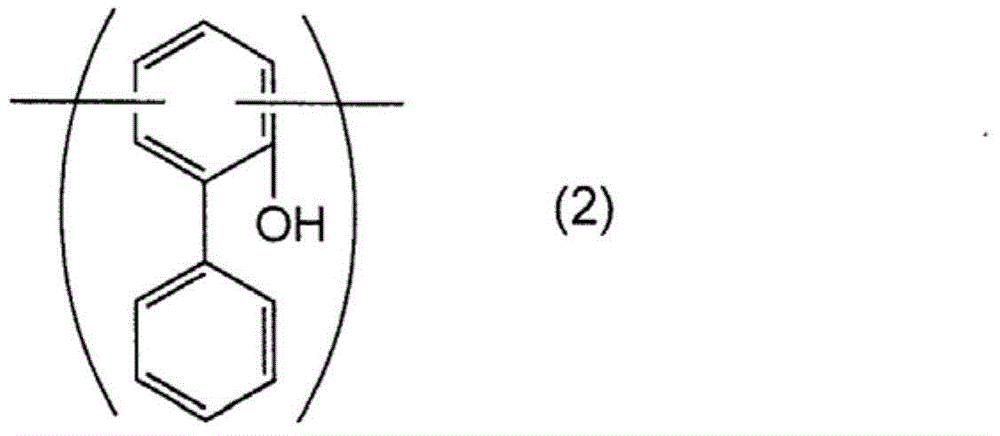

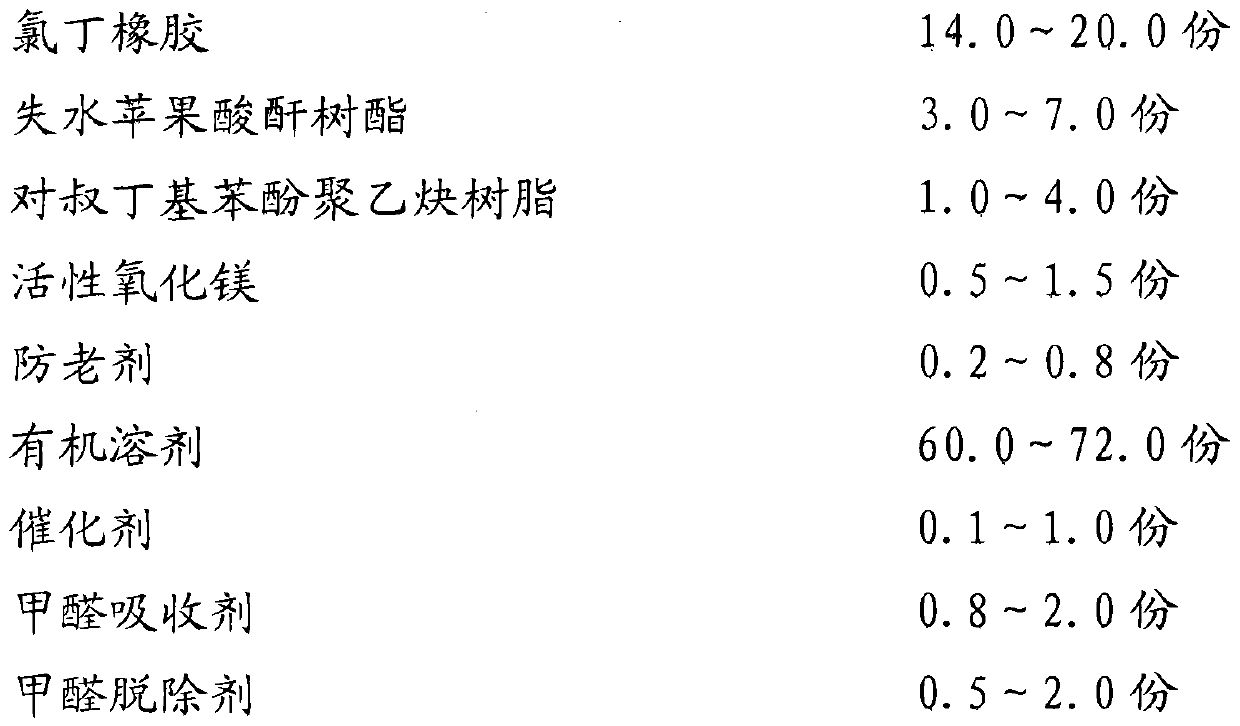

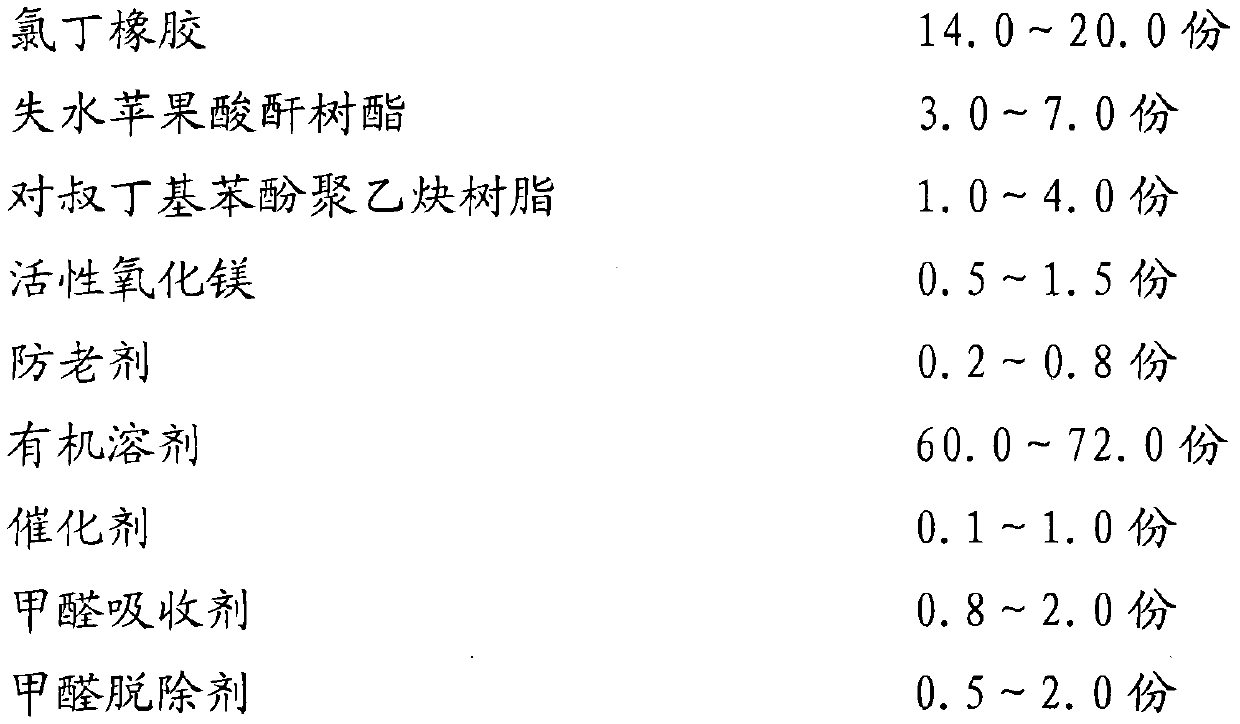

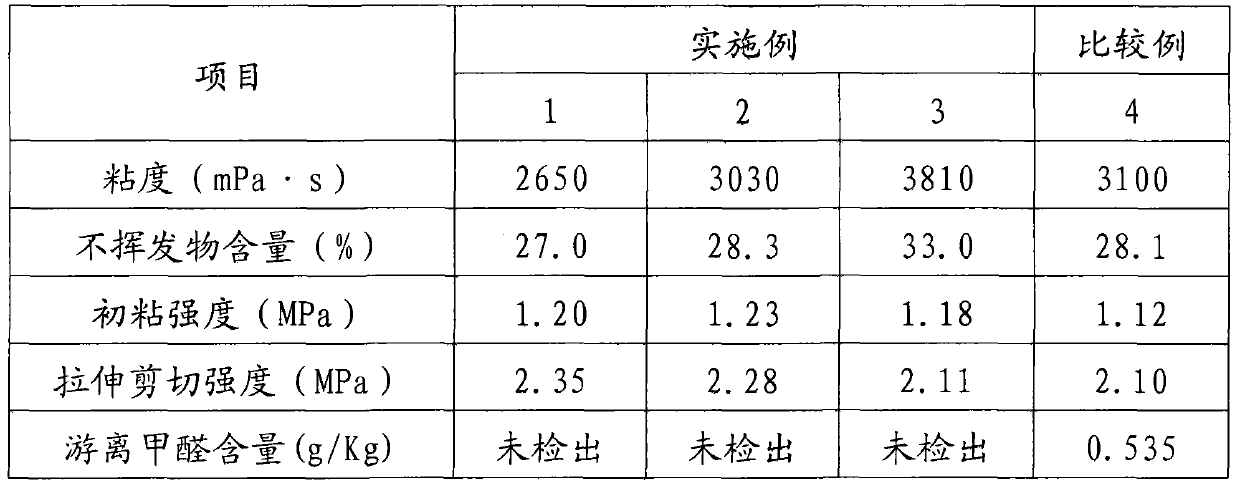

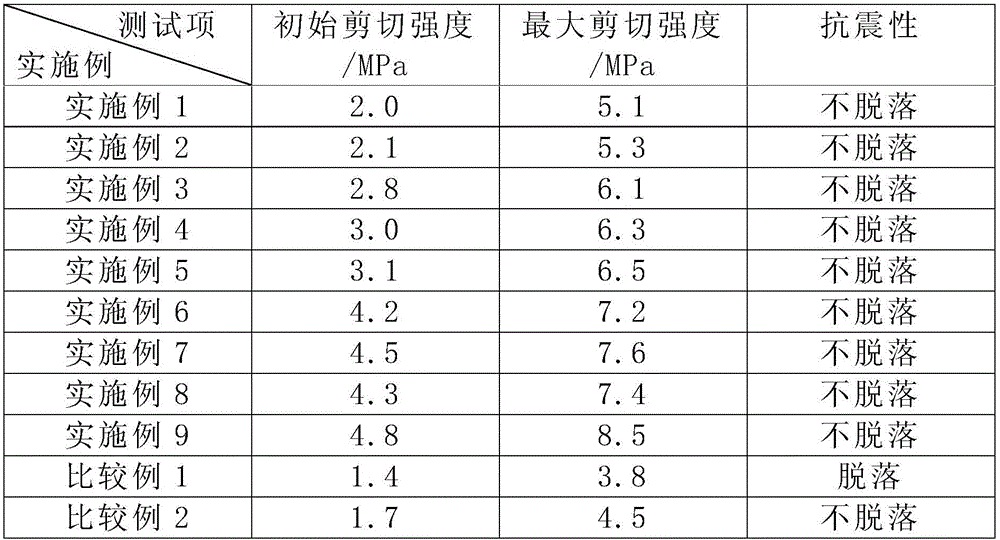

Polychloroprene adhesive and preparation method thereof

ActiveCN103497704AIncrease contentMeet environmental protection requirementsNon-macromolecular adhesive additivesMacromolecular adhesive additivesEnvironmental resistanceHalohydrocarbon

The invention discloses a polychloroprene adhesive and a preparation method thereof. The polychloroprene adhesive is characterized by being composed of following main components: chloroprene rubber, dehydrated malic acid resin, p-tert-butyl phenol polyacetylene resin, active magnesium oxide, an anti-aging agent, a solvent, a catalyst, a formaldehyde absorbent, and a formaldehyde remover. The polychloroprene adhesive and the preparation method thereof have the advantages that: (1) the polychloroprene adhesive does not contain benzene, methyl benzene, dimethyl benzene, and halohydrocarbons toxic solvents, has a high content of non-volatile materials, and can satisfy the environmental requirements; (2)the preparation method substitutes hydrated malic acid resin and p-tert-butyl phenol polyacetylene for phenolic resin as the tackifying agent, thus controls the release of free formaldehyde from the source, and at the same time guarantees a good adhesive property; (3) a formaldehyde absorbent and a formaldehyde remover are added, can continuously release negative ions, firstly captures free formaldehyde and then eliminates the free formaldehyde, has a high capture efficient of free formaldehyde and a long effective time, and is capable of continuously eliminating the free formaldehyde released from the decorating materials for a long time.

Owner:GUANGDONG SANVO CHEM IND TECH

Aqueous high-strength nail-free adhesive

ActiveCN106753094AImprove composite bond strength performancePlay a role in thickeningMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesP-tert-ButylphenolButadiene-styrene rubber

The invention relates to an aqueous high-strength nail-free adhesive, belongs to the technical field of adhesive materials, and aims to solve the problems of environment pollution and low adhesiveness. The aqueous high-strength nail-free adhesive comprises the following components in parts by weight: 65-75 parts of a styrene-butadiene-styrene copolymer, 100-120 parts of silane, 75-85 parts of terpene resin, 45-55 parts of C9 petroleum resin, 8.0-10 parts of p-tert-butylphenol phenol-formaldehyde resin, 100-120 parts of rosin glycerin ester, 280-300 parts of an organic solvent, 120-150 parts of a plasticizer and 30-40 parts of packing. The aqueous high-strength nail-free adhesive provided by the invention is free of chloroprene rubber, good in environmental-friendliness, relatively good in temperature resistance and high in adhesive strength.

Owner:台州密得邦粘合材料有限公司

Synthesis method of high-softening-point tackifying resin for rubber

The invention discloses a synthesis method of high-softening-point tackifying resin for rubber. The synthesis method comprises the following steps: adding alkyl substituted phenol and a metal acetate catalyst into a reaction kettle and replacing N2 for air in the kettle, wherein the alkyl substituted phenol is p-nonyl phenol or p-dodecylphenol or p-tert-octylphenol or p-tert-butyl phenol or p-tert-butylphenol, and the metal acetate catalyst is calcium acetate or zinc acetate or cadmium acetate or copper acetate or cobalt acetate; heating the alkyl substituted phenol and the catalyst under the stirring state, introducing acetylene or allylene or 1-butyne or 1-pentyne or 1-hexin, and performing a constant-temperature reaction; and drying the product obtained after the reaction in a vacuum drying box to prepare the high-softening-point tackifying resin for rubber. Compared with the existing preparation method of a tackifier, the synthesis method has the advantages of simple process, low cost and high adhesive property. The softening point of the obtained tackifying resin for rubber is more than 142 DEG C, and the adhesive strength of the tackifying resin for rubber is more than 1.0 kN / m after the tackifying resin for rubber is stored for 100 hours.

Owner:SHANDONG LAIWU RUNDA NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com