Preparation method of molecular imprinting sorptive extraction stirring bar by using alternative template

A technology of molecular imprinting and replacing templates, which is applied in the fields of analytical chemistry and sample pretreatment, can solve the problems of template molecule leakage, affecting the accuracy of target analytes, etc., and achieve the effect of avoiding wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

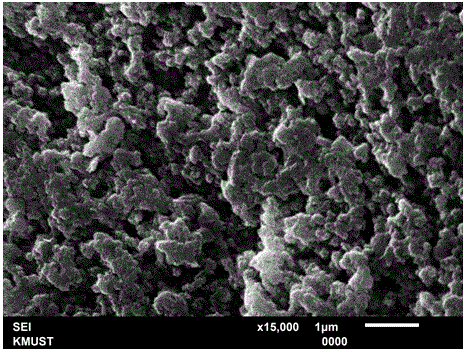

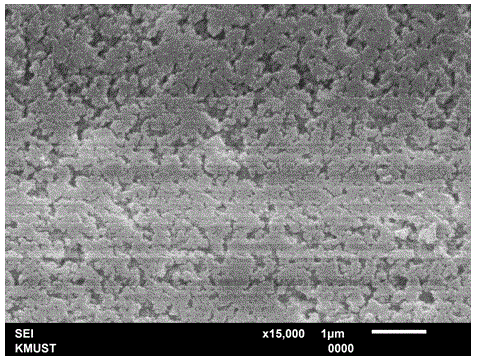

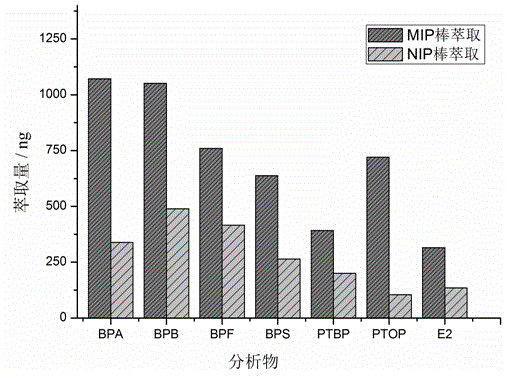

Image

Examples

Embodiment 1

[0035] The preparation method of the molecularly imprinted adsorption and extraction stirring rod for replacing the template, the specific steps are as follows:

[0036] Step 1, capping one end of a glass capillary with an inner diameter of 1.4mm, and preparing one end of a glass capillary with an outer diameter of 1.0mm;

[0037] Step 2. Dissolve 150mg of p-tert-butylphenol (1.0mmol) as a template molecule, template molecule and 284mg of functional monomer (4mmol) in 5mL of polymerization solvent, ultrasonically mix evenly and let it stand for 15h to obtain a mixed solution, add to the mixed solution Add 3.8mL crosslinking agent (20mmol) and 37.6mg initiator (0.23mmol) in turn and mix well to obtain an assembly solution, in which the molar ratio of template molecule, functional monomer and crosslinking agent is 1:4:20, and the template in the mixed solution The concentration of the molecule is 0.114mmol / mL, and then ultrasonic deoxygenation; wherein the functional monomer is ...

Embodiment 2

[0046] The preparation method of the molecularly imprinted adsorption and extraction stirring rod for replacing the template, the specific steps are as follows:

[0047] Step 1, capping one end of a glass capillary with an inner diameter of 1.4mm, and preparing one end of a glass capillary with an outer diameter of 1.0mm;

[0048] Step 2. Dissolve 150mg of p-tert-butylphenol (1.0mmol) as a template molecule, template molecule and functional monomer (3.5mmol) in 7.5mL of polymerization solvent, ultrasonically mix evenly and let stand for 10h to obtain a mixed solution. Add cross-linking agent (13mmol) and initiator (0.20mmol) in sequence and mix well to obtain an assembly solution, wherein the molar ratio of template molecules, functional monomers, and cross-linking agents is 1:3.5:13, and the concentration of template molecules in the mixed solution 0.134mmol / mL, and then ultrasonically deoxygenated; wherein the functional monomer is acrylamide; the crosslinking agent is ethyl...

Embodiment 3

[0052] The preparation method of the molecularly imprinted adsorption and extraction stirring rod for replacing the template, the specific steps are as follows:

[0053] Step 1, capping one end of a glass capillary with an inner diameter of 1.4mm, and preparing one end of a glass capillary with an outer diameter of 1.0mm;

[0054] Step 2. Dissolve 150mg of p-tert-butylphenol (1.0mmol) as a template molecule, template molecule and functional monomer (4mmol) in 13.7mL of polymerization solvent, ultrasonically mix evenly and let stand for 10h to obtain a mixed solution. Add crosslinking agent (46mmol) and initiator (0.36mmol) in sequence and mix well to obtain an assembly solution, in which the molar ratio of template molecules, functional monomers, and crosslinking agents is 1:4:46, and the concentration of template molecules in the mixed solution is 0.073mmol / mL, and then ultrasonically deoxygenated; wherein the functional monomer is acrylamide; the crosslinking agent is ethyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com