Aqueous high-strength nail-free adhesive

A nail-free, high-strength technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of environmental protection and the inability to fully utilize the bond strength of SBS rubber, etc. problem, to achieve the effect of improving the bond strength performance and improving the bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

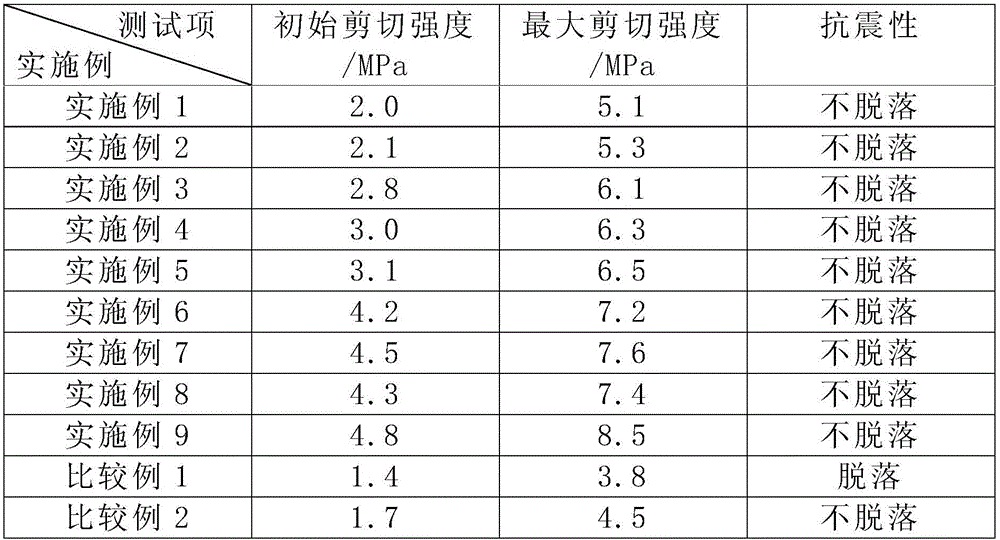

Examples

Embodiment 1

[0023] The water-based high-strength nail-free glue of the present embodiment comprises parts by weight of the following components:

[0024] Styrene-butadiene-styrene copolymer (SBS): 65; dimethyldiethoxysilane: 100; terpene resin: 85; C9 petroleum resin: 55; p-tert-butylphenol formaldehyde resin (2402 resin): 10; rosin glyceride (138 resin): 120; gasoline: 100; ethyl acetate: 100; ethane: 50; polytetrahydrofuran diol: 120; Calcium: 20.

[0025] The water-based high-strength nail-free glue can be prepared by the following methods:

[0026] Weigh the raw materials according to the weight of the following components, first add gasoline, ethyl ester, ethane and SBS rubber into the mixing tank, start the mixer, stir at a stirring speed of 300 rpm, stir for 1 hour to 1.5 hours, and stir until Dissolve completely; Then, put in the above-mentioned weighed 2402 resin and dimethyldiethoxysilane, and reduce the stirring speed to 200 rpm, stir for 10 minutes, then throw in the corresp...

Embodiment 2

[0028] The water-based high-strength nail-free glue of the present embodiment comprises parts by weight of the following components:

[0029]Styrene-butadiene-styrene copolymer (SBS): 75; mercaptosilane: 110; terpene resin: 75; C9 petroleum resin: 45; p-tert-butylphenol formaldehyde resin (2402 resin): 8.0; rosin Glyceride (138 resin): 110; gasoline: 200; cyclohexane: 50; polyether triol: 150; filler light calcium carbonate: 30.

[0030] The specific preparation method of the water-based high-strength nail-free glue is the same as that in Example 1, and will not be repeated here.

Embodiment 3

[0032] The water-based high-strength nail-free glue of the present embodiment comprises parts by weight of the following components:

[0033] Styrene-butadiene-styrene copolymer (SBS): 70; end-capped mercaptosilane: 100; terpene resin: 81; C9 petroleum resin: 50; p-tert-butylphenol formaldehyde resin (2402 resin): 9.0 ; Rosin glyceride (138 resin): 100; Gasoline: 150; Ethyl acetate: 150; Polyether triol: 60; Polytetrahydrofuran diol: 70; 15. Wherein, the above-mentioned blocked mercaptosilane is (CH 3 O) 3 Si-CH 2 -S-C(=O)-C 17 h 35 ;

[0034] The specific preparation method of the water-based high-strength nail-free glue is the same as that in Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com