Manufacturing method of paper/plastic container with heat insulation surface layer

A technology of container and manufacturing method, which is applied in the field of manufacturing of paper/plastic containers with heat-insulating surface, can solve problems such as environmental hazards, environmental resource consumption, and plastics are not easy to degrade, and achieve the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

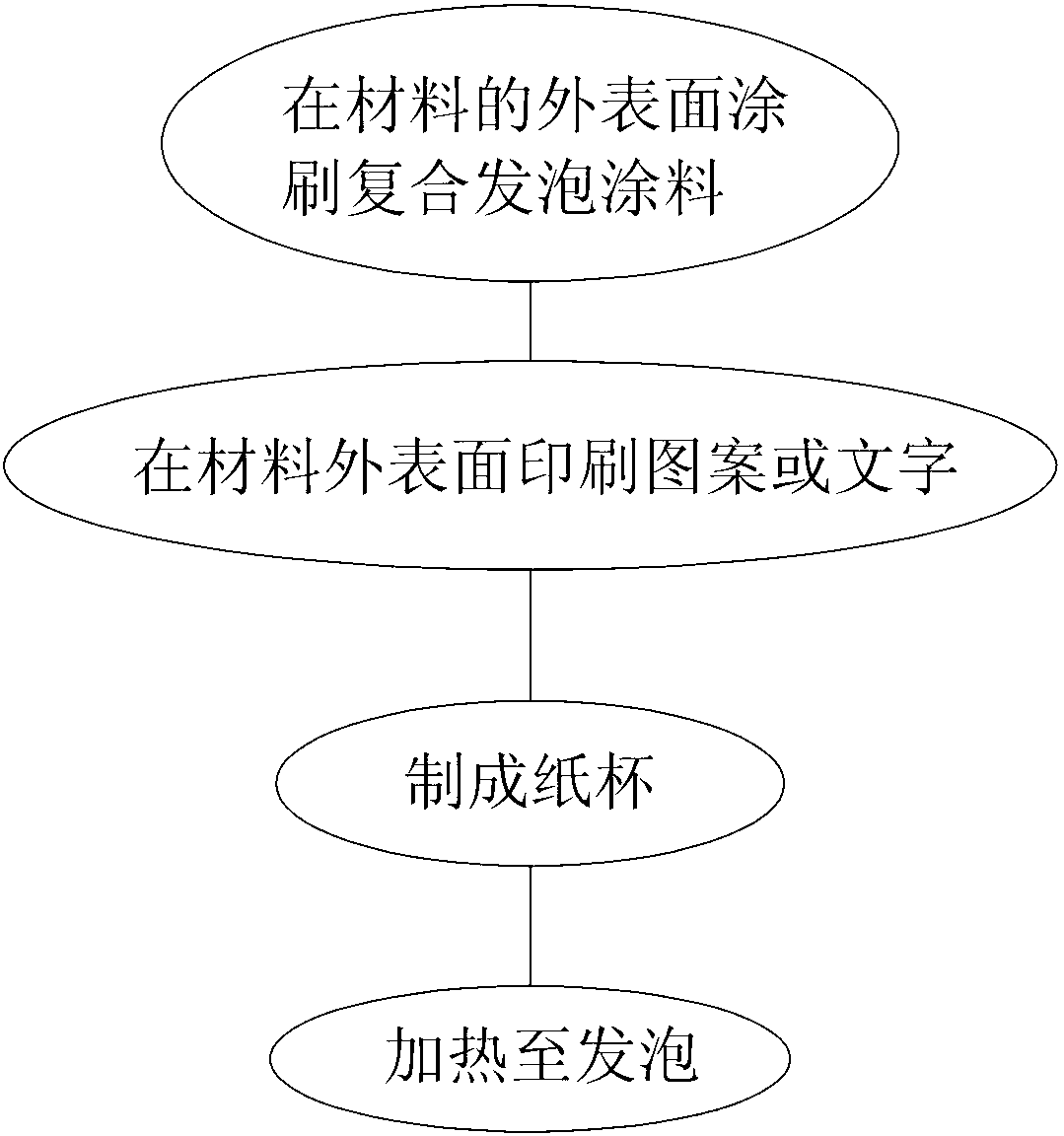

[0029] Embodiment 1: as figure 1 -Shown in 3, a method for preparing a paper / plastic container with a thermal insulation surface layer is characterized in that, comprising the following steps:

[0030] a. Brush the composite foam coating on the outer surface of the material used to make the container 1 (thus forming the coating layer 2). The composite foam coating is applied on the material by means of rotation, spraying, printing, etc., and preferably The other is to paint on the part where the user may hold the container 1, so as to achieve the purpose of saving materials without affecting the use effect;

[0031] b. The material processed in the previous step is made into a container, and the cup-making machinery used is available in the market;

[0032] c. The prepared container 1 is heated again, so that the foaming coating on the outer layer of the container 1 is heated and foamed (forming such as image 3 The bulging microbubbles are shown in 3). During the heat...

Embodiment 2

[0039] Embodiment 2: This embodiment is basically the same as Embodiment 1, except that in step a, patterns or characters are first printed on the outer surface of the material, and then the composite foaming paint is applied on the outer surface of the material.

Embodiment 3

[0040] Embodiment 3: This embodiment is basically the same as Embodiment 1, except that in step a, after the composite foam coating is applied on the outer layer of the material, patterns or characters are printed on the outer layer of the material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com