Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

150 results about "Lincomycin-B" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lincomycin is a lincosamide antibiotic that comes from the actinomycete Streptomyces lincolnensis. A related compound, clindamycin, is derived from lincomycin by using thionyl chloride to replace the 7-hydroxy group with a chlorine atom with inversion of chirality.

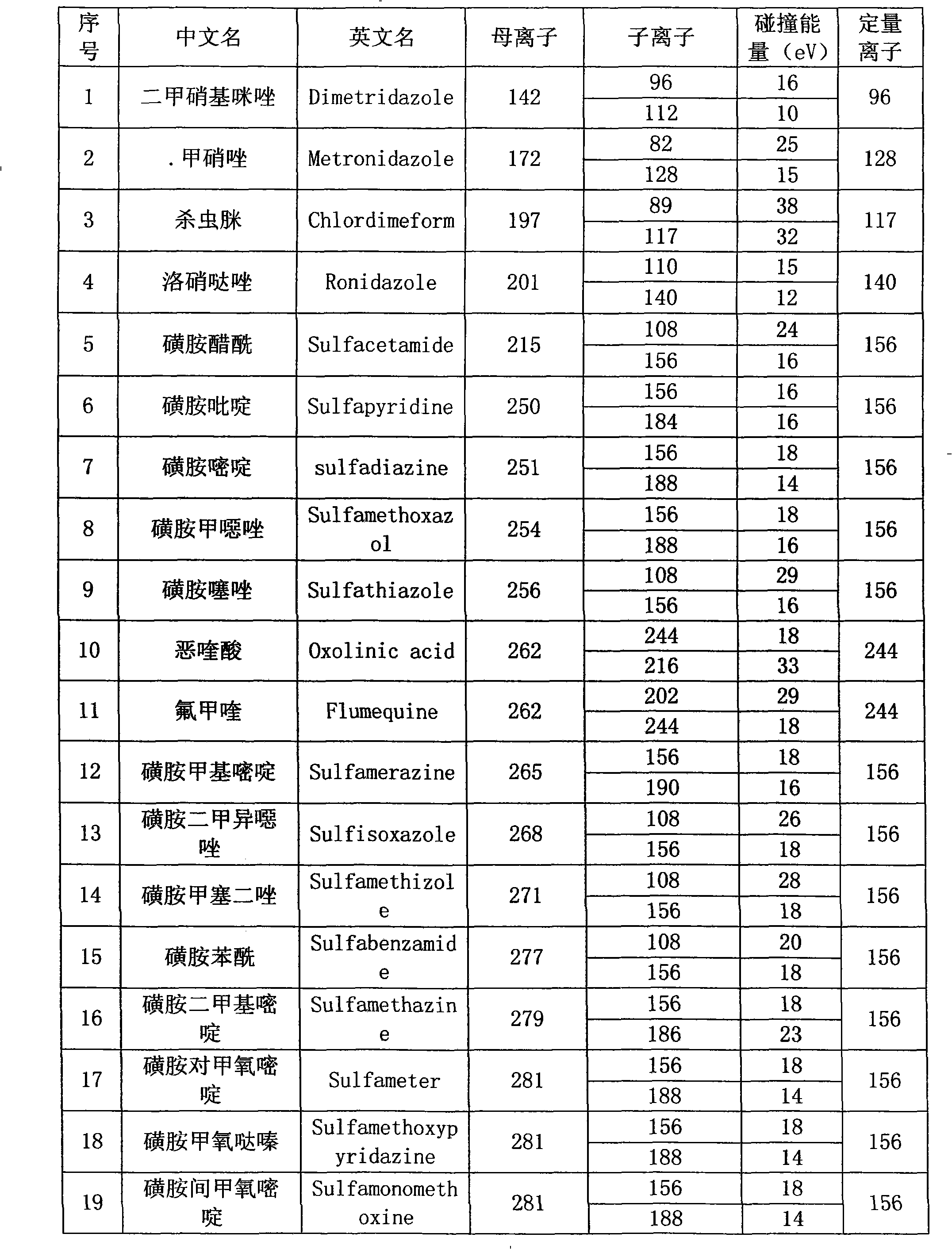

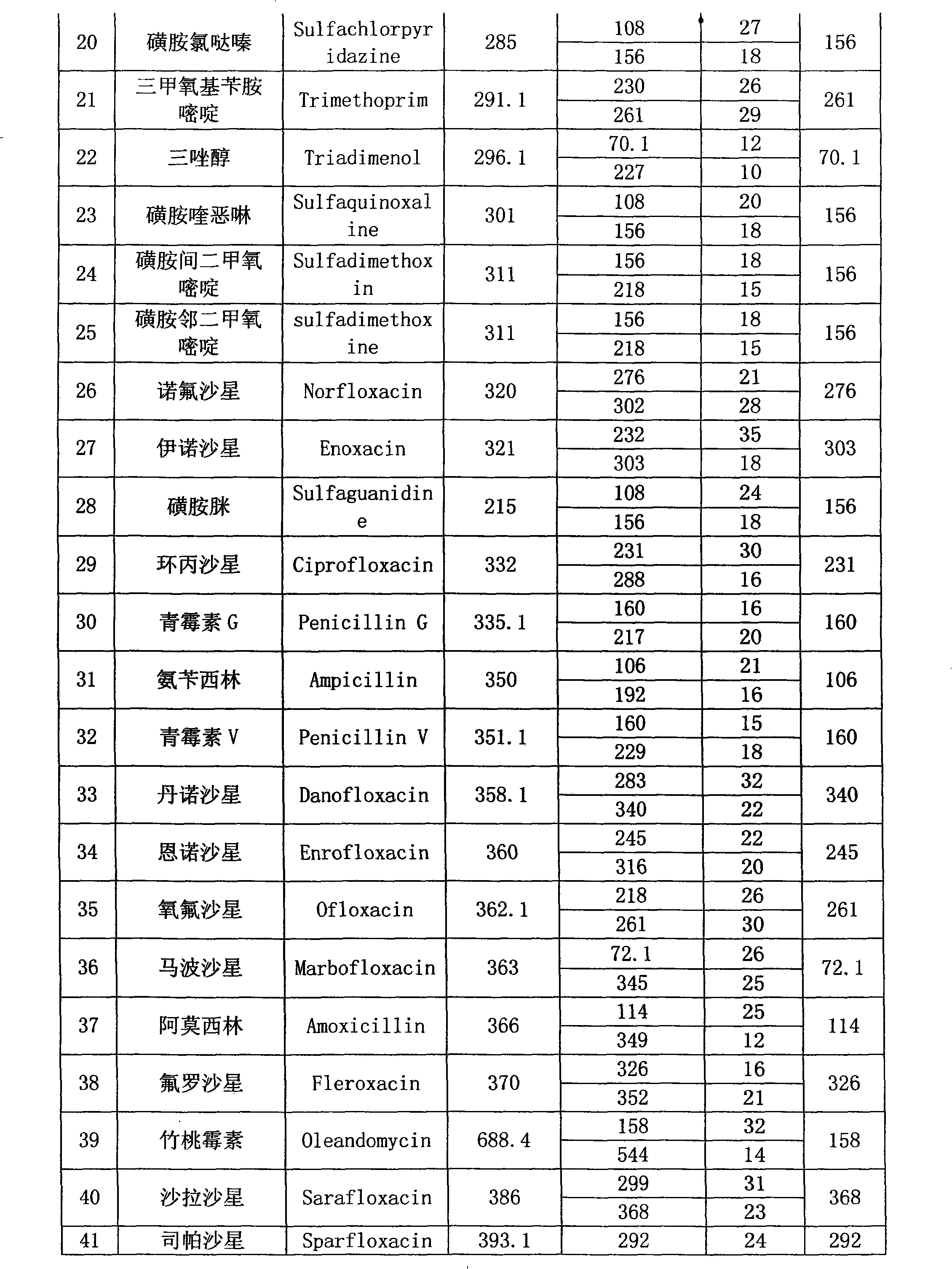

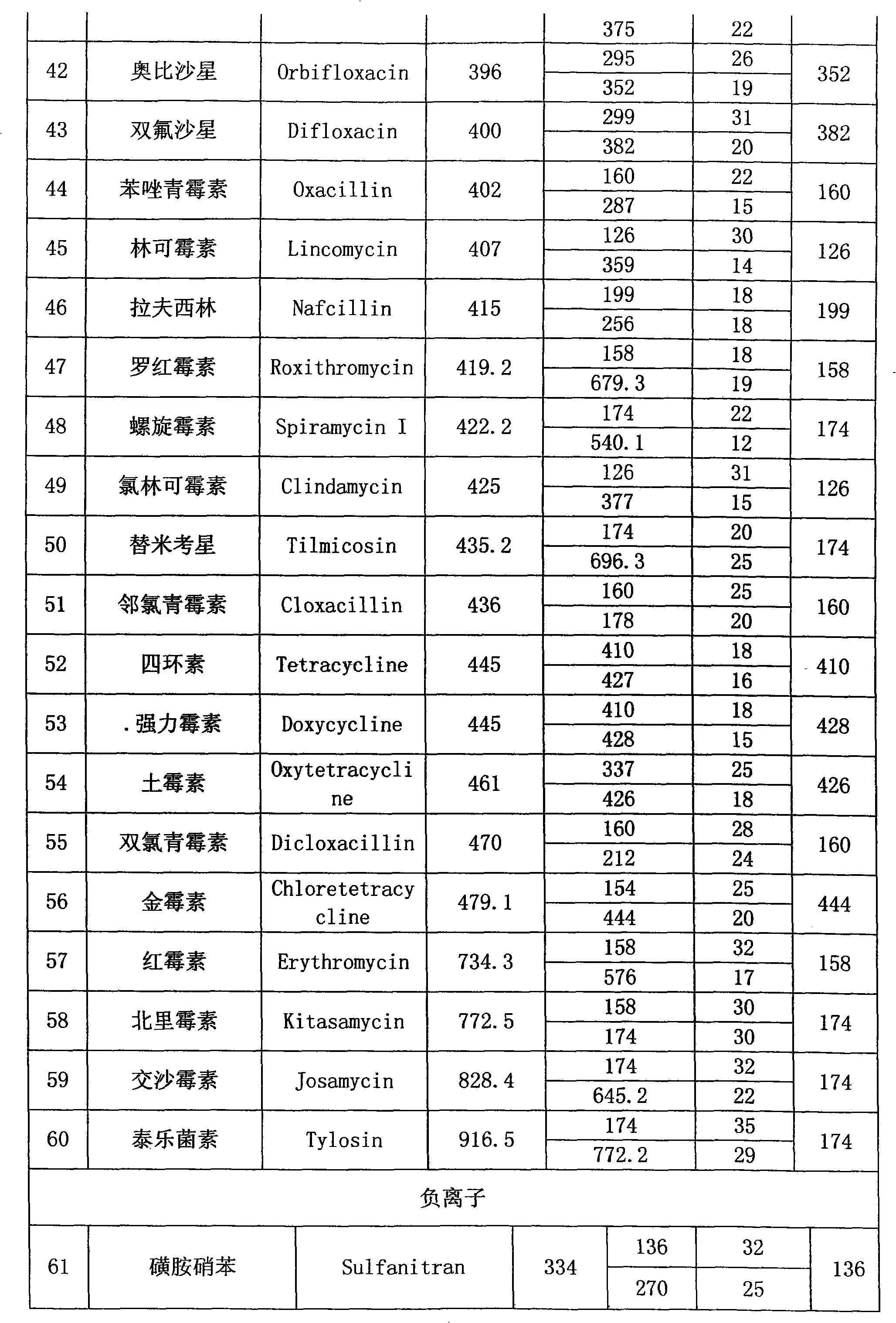

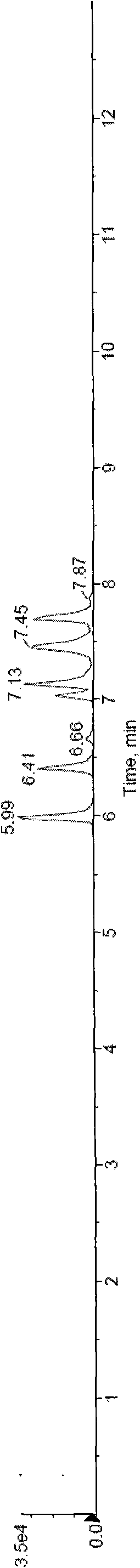

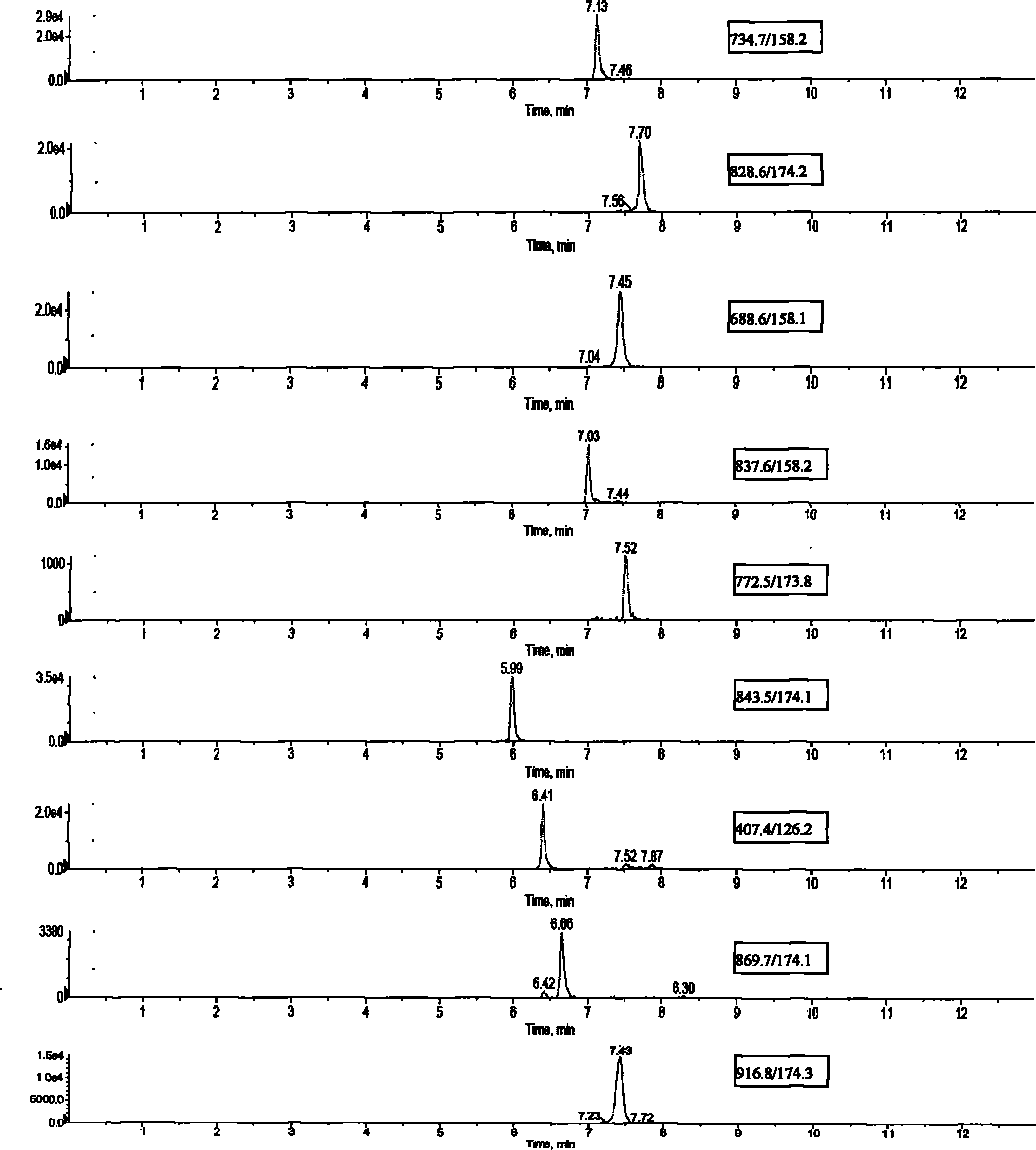

Method for simultaneously detecting multi-kind pesticide residues in bee products

InactiveCN101358953ASolve the problem of matrix effectFast wayComponent separationRetention timePhosphate

The present invention relates to a method of simultaneously detecting a plurality of agro-veterinary drug residues in bee products. The extracted liquid trichloroacetic acid or perchloric acid and the extracted liquid acetate, phosphate or borate solution are added into a sample; the pH value is controlled between 4.5 and 9.0; the mixed solution is centrifuged, the filtrate is added into a solid phase extraction column to be extracted, the extraction column is eluted and dried, the column is washed by oxalic acid-methanol solution, the volume of the eluent is defined by the aqueous solution of methanol, the eluent is added into liquid chromatography-tandem mass spectrometry to be analyzed and tested, the acquired chromatographic peak is contrasted with the known standard chromatographic peak of the drug, and according to the retention time and the abundance of the mass spectrum ions, the specific name of the detected drug is determined. The method only requires one pre-treatment of the sample, and thus can simultaneously extract 11 classes and more than 60 kinds of veterinary drug residues, such as sulfonamides, quinolones, macrolides, lincomycins, nitroimidazoles, beta-lactams, tetracyclines, chloromycetins, trinethoprims, chlordimeform, triadimenol and the like, the efficiency of analysis is high, and the detection cost is greatly reduced.

Owner:中华人民共和国江苏出入境检验检疫局

Method for separation of lincomycin

InactiveCN102746348AModerate consumptionSimple and fast operationSugar derivativesSugar derivatives preparationFiltrationPolystyrene

Owner:SHANGHAI INST OF PHARMA IND

Processing process of albiotic residue

InactiveCN101323862AIncrease gas production rateIncrease productionMicroorganism based processesWaste based fuelHigh concentrationSludge

The invention discloses a processing technology of the waste dregs of lincomycin. The technology comprises the steps that: the waste dregs of the lincomycin, the bacterial liquid of EM and the culture solution of alcohol yeast are mixed according to the proportion of 100: (0.5 to 1.5): (3 to 5) and stirred uniformly, and solid anaerobic fermentation is carried out for over 96 hours to remove antibiotics left in the waste dregs; the ferment material is diluted by water and prepared into 10 to 30 percent of a suspension which is uniformly stirred, and sheared and broken mechanically at high speed, reticular mycelium is cut into 'bacillus' shape by observation under a microscope, and by chemical detection: chemical oxygen demand (COD for short) is over 5000; a sheared solution is mixed with the high concentration organic wastewater of lincomycin by the proportion of 10 to 40: 100 put into a jar to carry out anaerobic fermentation and produce biogas. The method is practical, the gas production rate thereof is improved by over 30 percent, the indexes of an anaerobic system, such as the removal rate of COD, PH, degradation rate and sludge discharge, etc. are not affected, and facilities run normally.

Owner:南阳普康药业有限公司

Lincomycin Derivatives and Antimicrobial Agents Comprising the Same as Active Ingredient

InactiveUS20090156512A1High antibacterial activityTherapy is simpleAntibacterial agentsBiocideArylHalogen

This invention provides compounds of formula (I) or its pharmacologically acceptable salt or solvate, wherein A represents aryl or a monocyclic or bicyclic heterocyclic group, R1 represents a halide, nitro, substituted C1-6 alkyl, optionally substituted amino, C1-6 alkyloxycarbonyl, optionally substituted aryl, a heterocyclic group, or heterocyclic carbonyl, R2 represents a hydrogen atom or C1-6 alkyl, R3 represents C1-6 alkyl, all of R4, R5, and R6 represent a hydrogen atom, R7 represents C1-6 alkyl, m is 1 or 2, and n is 1. The compounds are novel lincomycin derivatives having a potent activity against resistant pneumococci. The compounds can be used as an antimicrobial agent and are useful for preventing or treating bacterial infectious diseases.

Owner:MEIJI SEIKA KAISHA LTD

Method for treating lincomycin fungi residues

InactiveCN101224998ABio-organic fraction processingClimate change adaptationSodium bicarbonateSocial benefits

The invention discloses a processing method of lincomycin fungus dregs, effectively settling the problem of degradation and clearance of residual lincomycin inside the fungus dregs and enabling the regeneration and reuse of wastes. The processing method of lincomycin fungus dregs can be realized through the following steps: the lincomycin fungus dregs, EM bacteria stock solution, accessories and water are used as materials; wherein, the total weight ratio of the lincomycin and the accessories is 1 to 3:1; the accessories comprise bran, brown sugar, sodium bicarbonate, table salt and peanut shell with the weight ratio of 50:6:3:16:125; wherein, the bran and the peanut shell are pulverized, then the sodium bicarbonate and table salt are added to the lincomycin fungus dregs in series, 40 to 50ml EM bacteria stock solution is measured for 1kg lincomycin fungus dregs added with brown sugar and diluted by water to 250ml, forming EM bacteria stock diffusion solution; then the EM bacteria stock diffusion solution is added to the mixture and mixed uniformly, added with water, and stored in a vessel for fermentation. The processing method of lincomycin fungus dregs has the advantages of simple method, waste reuse, and great economic and social benefits.

Owner:南阳普康药业有限公司

Method for simultaneously measuring residual quantities of lincomycin and macrolides in royal jelly

ActiveCN101846661AReduce dosageGood purification effectComponent separationMacrolide resistanceBottle

The invention relates to a method for simultaneously measuring residual quantities of lincomycin and macrolides in royal jelly by a liquid chromatography and a tandem mass spectrometer. Currently, the prior method can not achieve the goals of low detection cost and a detection limit less than 1 mu g / kg. The method comprises the steps of standard solution preparation, royal jelly sample treatment,standard curve making and royal jelly sample detection; in the step of royal jelly sample treatment, acetonitrile ammonia water with the volume concentration of 97% is used as the extracting solution, residues in a 50 ml glass centrifuge bottle after vacuum concentration are transferred by a phosphate buffer solution and mixed with ethyl acetate so as to carry out extraction; and finally, the detection sample solution is measured by a high performance liquid chromatograph and a ternary quadrupole tandem mass spectrometer to obtain the residual quantities of lincomycin and macrolides in royal jelly. The invention has the advantages of low detection cost and high detection efficiency, the detection limit reaches 0.2-0.9 mu g / kg, and the linearly related coefficient is 0.9914-0.9994.

Owner:杭州蜂之语蜂业股份有限公司

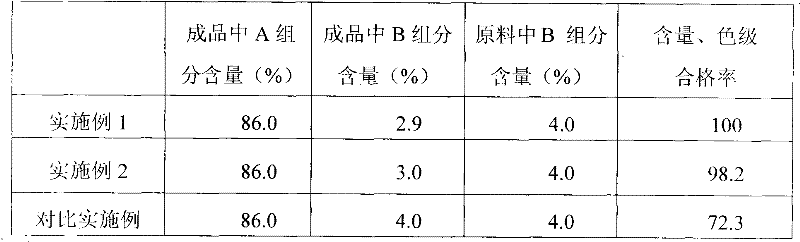

Production process for reducing component B content of lincomycin

InactiveCN102002079AReduce dosageReduce pollutionSugar derivativesSugar derivatives preparationWastewaterSolvent

The invention discloses a production process for reducing the component B content of lincomycin. The process method comprises: performing the absorption by macroporous resin on reverse extract of a solvent (including butanol or higher alcohol) extract, or aqueous solution of coarse lincomycin, or fermented filtrate of lincomycin or aqueous solution of recovered coarse lincomycin after pH adjustment by NaOH; washing by alkaline aqueous solution; desorbing with n-butyl alcohol; and producing finished products by normal processes. When the process method for reducing the component B content of lincomycin, which is provided by the invention, is used, the use amount of the alkaline aqueous solution for washing is lowered, the controllability of different requirements of users on the component B is improved, and the conventional process or equipment is improved; pollution caused to the environment is reduced greatly, the possibility for renewing waste water is increased; and the capacity ofabsorbing the reverse extract of the solvent extract of lincomycin is increased, the desorbing units are centralized, and at the same time, the labor intensity and production cost are reduced considerably and the large-scale industrial production can be realized easily.

Owner:BEIJING HUAZHI XINCHENG TECH

Artificial milk for porkets

InactiveCN101223914APromote digestion and absorptionLower pH valueMilk preparationAnimal feeding stuffDiseaseSolubility

The invention discloses an artificial milk for piglets, which is prepared, according to weight proportion, by the mixing and fine grinding of the following raw materials: whole milk powder, soybean protein powder, salt, Lincomycin, fragrance element, sodium glutamate, plasma protein powder, short-chain fatty acid, choline chloride, methionine, acidifier, coating VC, glucose, multi-vitamin, micro-mineral, zinc oxide, bicalcium phosphate, whey powder and threonine. The artificial milk for the piglets is not only characterized by good palatability, eating-inducing and anti-diarrhea effect, and having breast milk fragrance, but also characterized by high digestion and absorption rate, fast weight increasing, easy solubility in water, stability and non-deposit and enhancing immunity and disease resistance.

Owner:潍坊天普阳光饲料科技有限公司

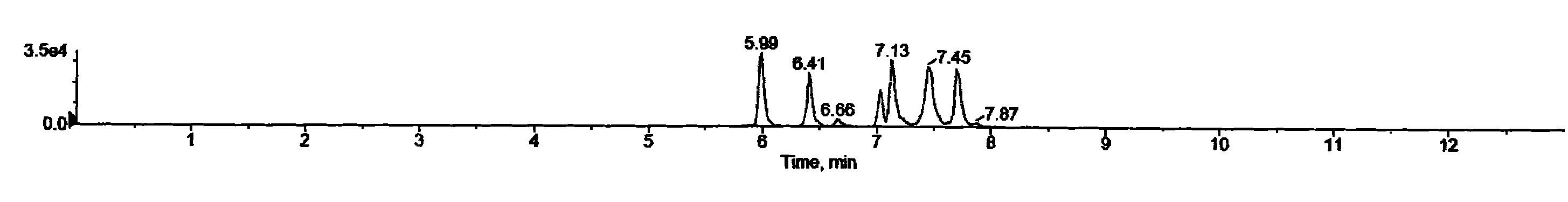

Coal water slurry made by combining lincomycin wet bacteria slag and coal

InactiveCN101457165ATake advantage ofAvoid pollutionLiquid carbonaceous fuelsSocial benefitsCoal water

The invention relates to a coal water slurry combined by a lincomycin wet bacteria slag and coal which effectively settles the application of the lincomycin wet bacteria slag and prevents the pollution problem to environment. The settled technical scheme comprises the following steps: the coal water slurry is prepared by the lincomycin wet bacteria slag, a coal dust, an additive agent and water, wherein the weight ratio of the lincomycin wet bacteria slag and the coal dust is: 5-501f lincomycin wet bacteria slag, 50-951253232014f coal dust, then sum of the lincomycin wet bacteria slag and coal dust is 50-70, the additive agent is 0. 1-5and water balance by weight percentage, firstly the additive agent, water and lincomycin wet bacteria slag are mixed and stirred to a uniform mixture solution, then the coal dust is added in the mixture solution to mix uniformly and the coal water slurry with a mass concentration of 50-70 ontaining the lincomycin wet bacteria slag and the coal dust is obtained. The coal water slurry has simple component and low cost, and is easy to produce. The incomycin wet bacteria slag is fully used, not only the novel fuel source is solved and a great deal of coal is saved, but also the pollution to environment by incomycin wet bacteria slag is prevented. The coal water slurry of the invention has a huge economy and social benefit.

Owner:李寒旭 +2

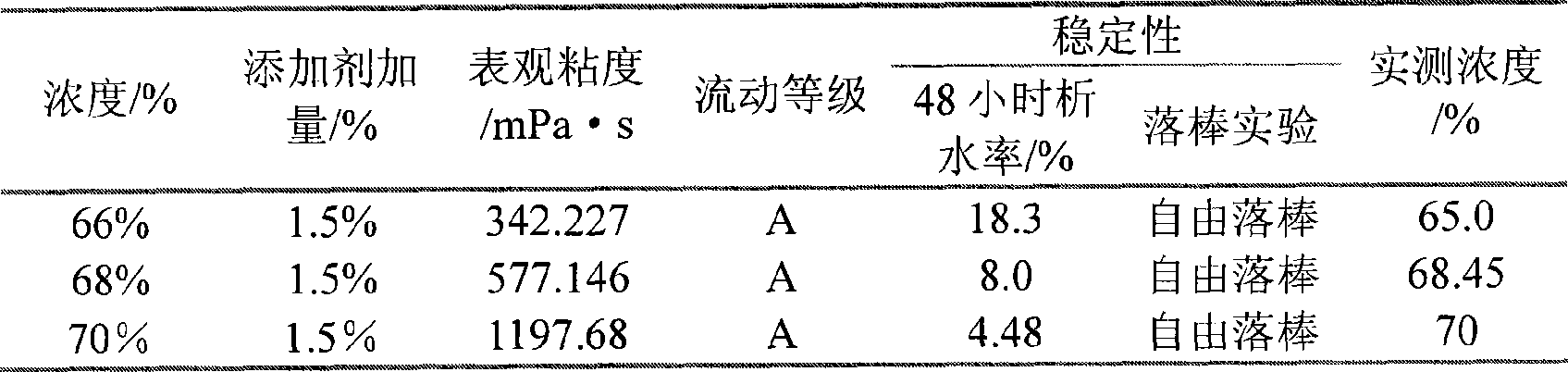

Bacillus subtilis L1, and application thereof in degradation of lincomycin residual in lincomycin residues

The invention discloses a Bacillus subtilis L1, and an application thereof in the degradation of lincomycin residual in lincomycin residues. The application is characterized in that the lincomycin residues are inoculated with a fermentation solution obtained by fermenting and culturing the Bacillus subtilis L1, and are cultured at 25-37 DEG C under 80-220 rpm to realize the degradation of lincomycin in the residues. The Bacillus subtilis L1 can degrade the lincomycin residual in lincomycin residues, and the lincomycin degradation rate within 6 days reaches 95.39%; and microorganisms for degrading antibiotics also can be used for degrading antibiotics in tap water or soil.

Owner:龙海市农丰源肥料有限公司

Method for extracting lincomycin by using resin to adsorb fermentation stock solution

ActiveCN104861007AReduce pollutionEasy to operateSugar derivativesSugar derivatives preparationTotal recoveryN-Butyl Alcohol

The invention discloses a method for extracting lincomycin lincomycin by using resin to adsorb a fermentation stock solution. The method comprises the following steps: (1), placing a fermentation solution in a pretreatment tank, adding a sodium hydroxide solution whiling stirring, heating, adding resin and stirring slowly to obtain filtered resin; (2) placing the filtered resin into alkaline water with the same volume, and adding deionized water to clean the resin; (3), placing the cleaned resin in a chromatographic column and eluting the resin with n-butyl alcohol; (4), taking lincomycin desorbed solution and adding activated carbon for decolorizing; (5) desalinating the decolorized liquid through a desalinating column to obtain lincomycin desalinating liquid; (6), concentrating; (7) drying to obtain the finished product of hydrochloric acid lincomycin. The method provided by the invention avoids the procedures of plate-frame pressure filtration or ceramic membrane filtration, solvent extraction, back extraction and the like in the traditional process, and has the advantages of being simple in operation, low in labor intensity, clean in working environment, simplified in process, small in occupied area, low in cost and small in environmental pollution; the total recovery is greater than 85%, and the purity of the finished product is greater than 98%.

Owner:景德镇富祥生命科技有限公司

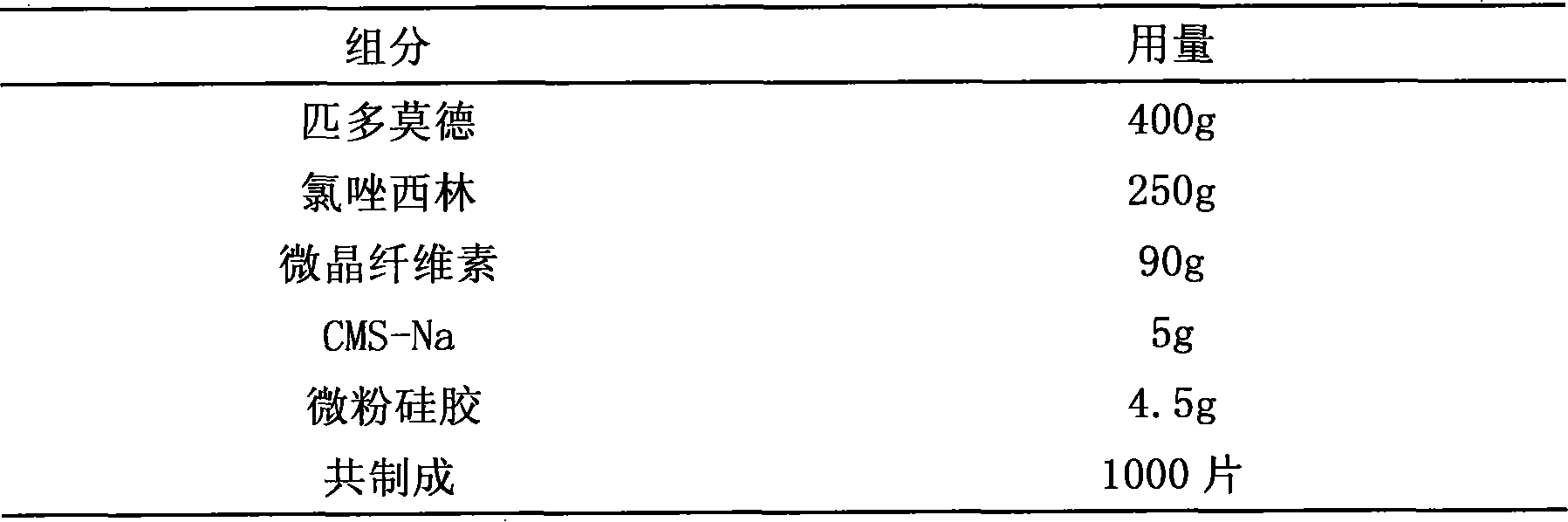

Pidotimod-containing pharmaceutical composition and preparation method thereof

InactiveCN101612152AAntibacterial agentsHeterocyclic compound active ingredientsAntifungalPenicillin

The invention provides a pidotimod-containing pharmaceutical composition and a preparation method thereof. The pidotimod-containing pharmaceutical composition consists of pidotimod and any antibacterial medicament. The antibacterial medicament may be any of beta-lactams (including as penicillins, cephems and unclassical beta-lactams), aminoglycosides, polymyxins, macrolides, lincomycins, norvancomycins, tetracyclines, chloromycetins, artificial antibacterial medicaments (including sulfonamides, quinolones and furofurans), cholesterols and antiviral medicaments. The unit dosage of the pidotimod is 0.1 to 2 grams, preferably 0.4 to 0.8 gram. The dosage of the antibacterial medicament is determined according to the dosage range of the antibacterial medicament. The composition of the pidotimod and the antibacterial medicament can exogenously and directly kill pathogenic bacteria through the antibacterial medicament and mobilize endogenous anti-infection immunity through an immunomodulator to improve anti-inflection effect, and has excellent synergy.

Owner:STAR LAKE BIOSCI CO INC ZHAOQING GUANGDONG

Extraction and refinement process of lincomycin

InactiveCN101648981ALarge adsorption capacityReduce pollutionSugar derivativesSugar derivatives preparationWastewaterDissolution

The invention discloses an extraction and refinement process of lincomycin for reducing the content of a component B. In the extraction and refinement process, the pH of a water dissolution liquid ofa lincomycin crude product extracted by a a lincomycin fermented filtering liquid or a solvent or a water solution for recycling the crude product by using active carbon particle column through NaOH for adsorption, and deabsorption is adopted by using n-butyl alcohol. By adopting the new extraction and refinement process of lincomycin for reducing the content of the component B, to the invention improves the traditional technology or the apparatus, reduces the environmental pollution, is beneficial for biochemical performance of waste water, increases the absorption volume of the lincomycin, saves two procedures of regeneration of acid-alkali, greatly reduces the labor intensity and the production cost, and is beneficial for large scale industrial production.

Owner:南阳普康药业有限公司 +1

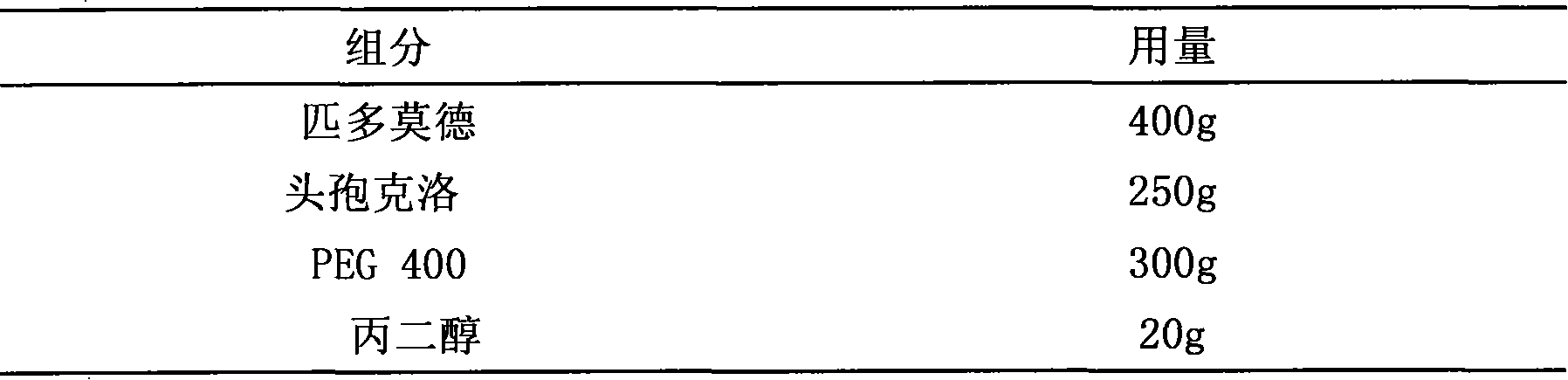

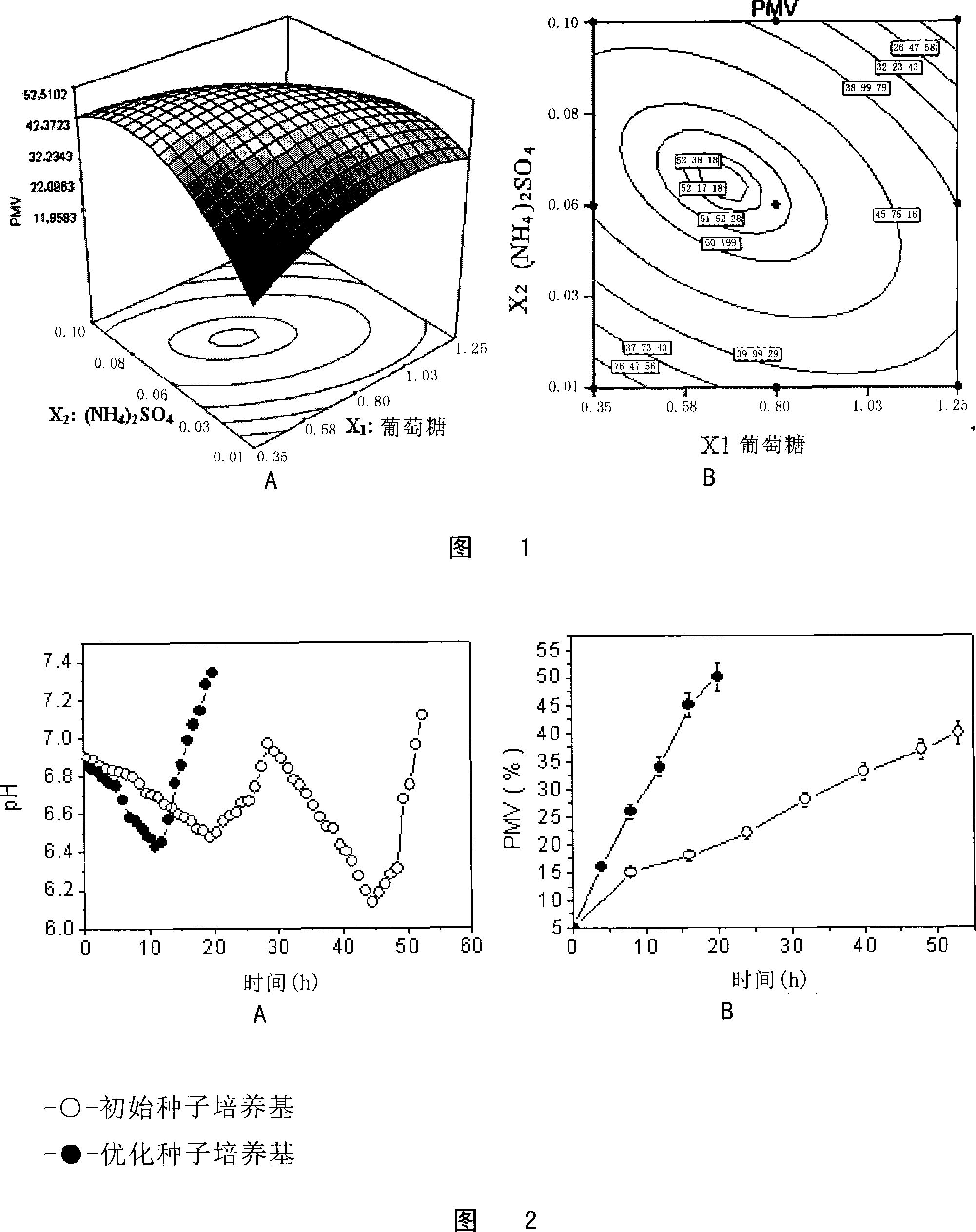

Seed culture medium produced with lincomycin ferment optimized with response surface method

InactiveCN101220343APromote growthIncrease speedBacteriaMicroorganism based processesAmmonium nitrateMixing ratio

The invention pertains to the field of microbial fermentation, which discloses a streptomyces lincolnensis seed culture medium; the culture medium comprises a carbon source, a nitrogen source, a phosphorus source and an inorganic salt; the culture medium further comprises the following necessary components: starch, glucose, soybean cake powder, ammonium nitrate and ammonium sulfate; the invention also discloses the optimized mixing ratio of all the necessary components. The culture medium of the invention has reasonable mixing ratio; the usage of the culture medium for culture can have high growth and reproduction rate of the streptomyces lincolnensis, short culture period and high bacteria concentration, thereby effectively avoiding the aging of the seeds and effectively improving the production efficiency of the follow-up lincomycin fermentation process.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Lincomycin extracting process with binary extractant including benzyl alcohol and n-octyl alcohol

InactiveCN1526717AGood physical and chemical propertiesImprove smellSugar derivativesSugar derivatives preparationRoom temperatureBENZYL ALCOHOL/WATER

The Lincomycin extracting process includes the steps of mixing benzyl alcohol and n-octyl alcohol in the volume ratio of 1.5-9 in room temperature, extracting fermented and filtered Lincomycin liquid with the binary extractant, back extraction with water solution of hydrochloric acid or sulfuric acid in 0.01-1 M concentration, and further refining of the back extracted liquid to obtain Lincomycin. The binary extractant of the present invention has low toxicity, less environmental pollution, little damage to persons, easy-to-control room temperature operation and improved operation environment. The present invention may be used widely in biomedicine preparing field.

Owner:HEBEI UNIV OF TECH

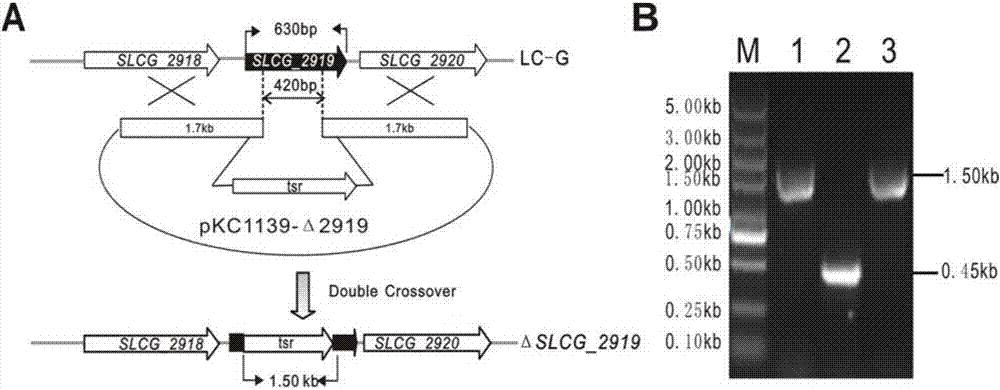

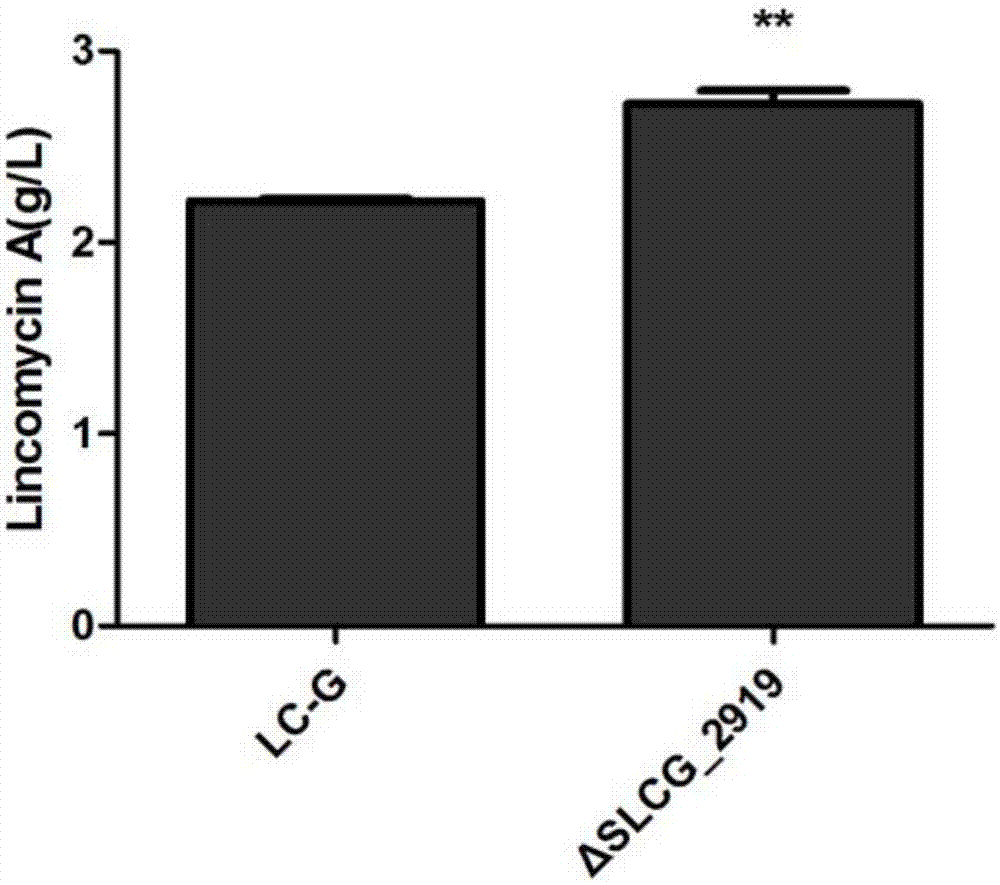

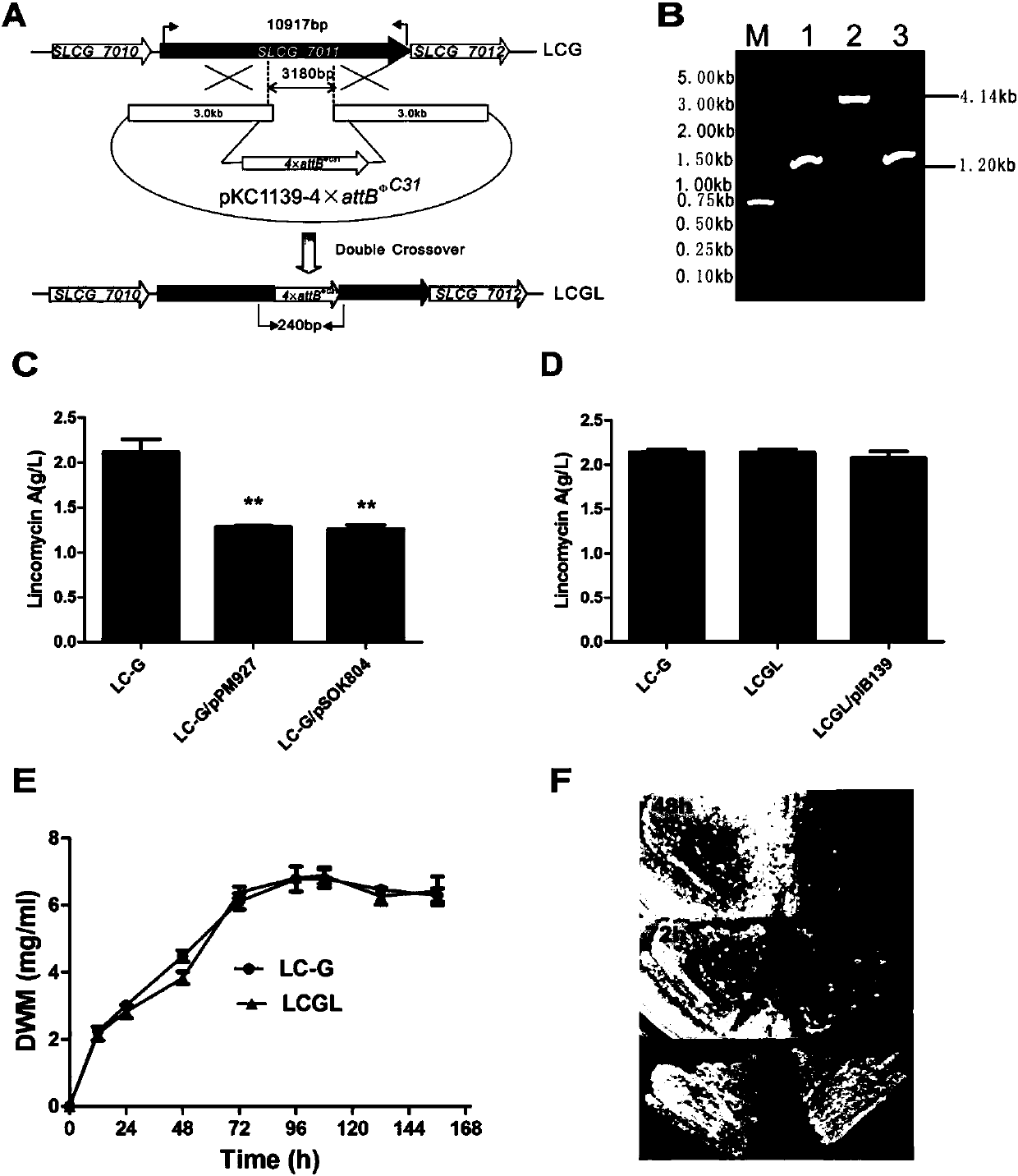

Method of increasing lincomycin output by modifying gene of streptomyces lincolnensis SLCG_2919

ActiveCN107881190AImprove fermentation yieldIncrease productionMicroorganism based processesPeptidesBiotechnologyGene engineering

The invention discloses a method of increasing the lincomycin output by modifying the gene of streptomyces lincolnensis SLCG_2919. According to the method, a TetR family transcription regulation geneSLCG_2919 is deleted from streptomyces lincolnensis by a gene engineering process to obtain an engineering strain with a high yield of lincomycin; the obtained strain can produce lincomycin through fermentation, the output is largely increased, and novel technical support is provided for increasing the lincomycin output in industrial production.

Owner:ANHUI UNIVERSITY

Culture medium and cultivation method for producing lincomycin by fermenting streptomyces lincolnensis

ActiveCN105754913AGood carbon sourceLow viscosityBacteriaMicroorganism based processesBiotechnologyFermentation

The invention relates to a culture medium and a cultivation method for producing lincomycin by fermenting streptomyces lincolnensis. By the use of a seed culture medium formula, a fermentation culture medium formula and a control process which are provided by the invention, the fermentation unit for large-scale production of lincomycin can be increased, and the fermentation cost can be reduced; furthermore, the environmental influence on raw and auxiliary materials can be reduced to the maximum extent; sufficient supply of the materials is guaranteed, and efficient production of lincomycin is realized.

Owner:HEILONGJIANG LIANSHUN BIOTECHNOLOGY CO LTD

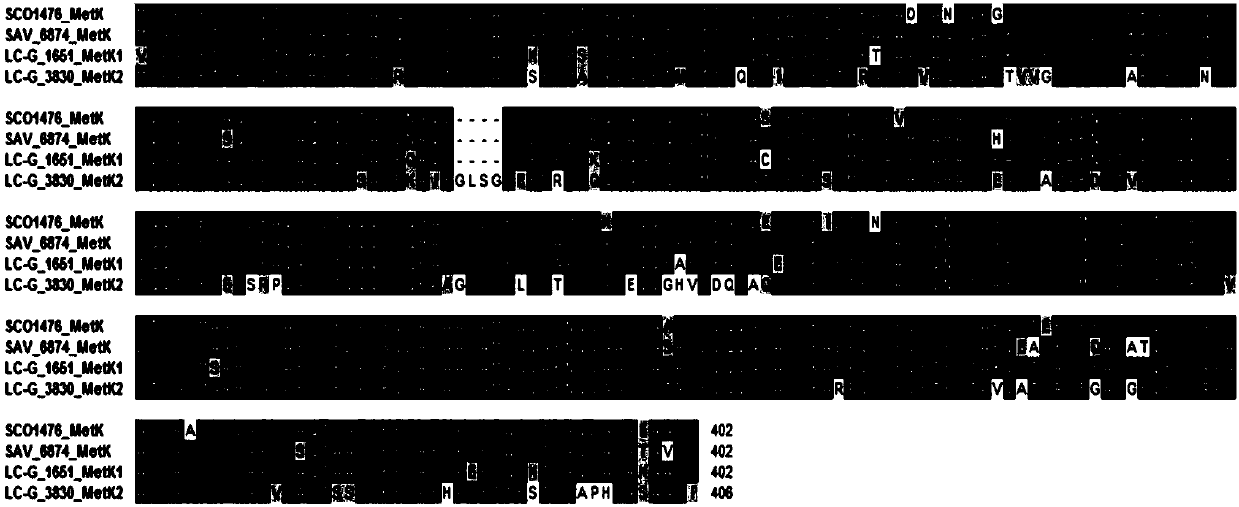

Method for increasing yield of lincomycin by co-expressing metK1 and metK2 genes in streptomyces lincolnensis

InactiveCN107746826AIncrease productionImprove fermentation yieldBacteriaTransferasesMicrobiologyGenetic engineering

The invention discloses a method for increasing the yield of lincomycin by co-expressing metK1 and metK2 genes in streptomyces lincolnensis. The method is characterized in that the metK1 and metK2 genes in the streptomyces lincolnensis are co-expressed through a genetic engineering way, so that an engineering strain with high lincomycin yield of the streptomyces lincolnensis is obtained; and the strain obtained by the technology can be fermented to increase the yield of the lincomycin.

Owner:ANHUI UNIVERSITY

Regulation and control of lincomycin course of fermentation by using ammonium ion and improvement of lincomycin volume of production

ActiveCN101220385AOptimizing Fermentation Production MethodsMicroorganism based processesFermentationMicroorganismFermentation

The invention pertains to the field of microbial fermentation and discloses an optimized lincomycin fermentation production method. The method includes that, the ammonium ion concentration in an initial fermentation culture medium is regulated to 57 plus or minus 5 mmol / L for culturing the streptomyces lincolnensis; when the ammonium ion concentration in the fermentation culture medium is 0.2 to 1.5 mmol / L, the ammonium ions are supplemented, then the ammonium ion concentration in the fermentation culture medium is controlled within 2 to 5mmol / L till the end of the fermentation. The invention studies the impact factors for producing lincomycin by utilizing the streptomyces lincolnensis on the large-scale level and sums up the optimized lincomycin fermentation method for the first time; the yield of the lincomycin can be greatly improved by using the method.

Owner:EAST CHINA UNIV OF SCI & TECH +1

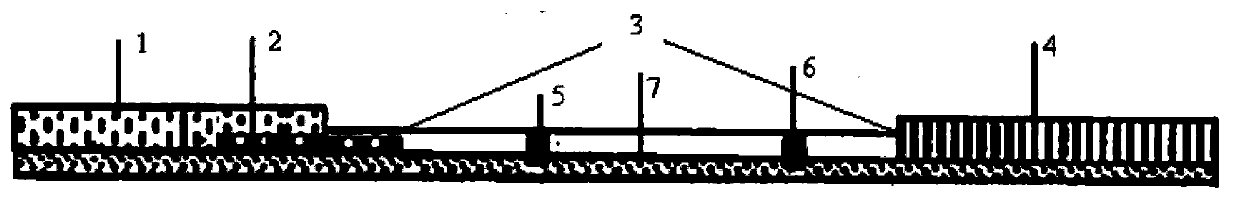

Detection method for lincomycin and special test paper therefor

ActiveCN103995107AIncreased sensitivityStrong specificityMaterial analysisMonoclonal antibodyCarrier protein

The invention discloses a detection method for lincomycin and a special test paper therefor. The test paper includes a sample adsorption pad, a conjugate release pad, a reaction membrane, and a water absorption pad connected in order. The conjugate release pad is coated with a colloidal gold labeled lincomycin prime specific antibody, which is a lincomycin polyclonal antibody or a lincomycin monoclonal antibody. The reaction membrane comprises a detection zone and a quality control zone, wherein the detection zone is coated with a conjugate of hapten and carrier protein, and the quality control zone is coated with an antiantibody. The method for detection of lincomycin by the test paper provided by the invention is simple, fast, visualized and accurate, and has the advantages of wide application range, low cost, and easy popularization and application.

Owner:BEIJING KWINBON BIOTECH

Preparation method of lincomycin hydrochloride injection

InactiveCN103830172AReduce contentQuality improvementAntibacterial agentsOrganic active ingredientsSodium bicarbonateEthylenediamine

The invention provides a preparation method of lincomycin hydrochloride injection, which comprises the following steps: (1) fetching 20,000ml of injection water, 6kg of lincomycin hydrochloride raw powder, 8g of EDTA (ethylenediamine tetraacetic acid)-2Na, 172g of anhydrous sodium bicarbonate and appropriate hydrochloric acid and anhydrous sodium bicarbonate for later use; (2) soaking a reaction kettle, a conveying pipeline and a constant-temperature water supply system with EDTA, and flushing for later use; (3) leading the stored injection water into a water storage tank, and connecting the water storage tank with a water outlet pipe through a pipeline; (4) injecting the injection water into the reaction kettle through the water outlet pipe, adding the lincomycin hydrochloride raw powder, and dissolving; (5) adding the anhydrous sodium bicarbonate into the solution after ultrafiltration to adjust the pH value, adding EDTA-2Na, sufficiently stirring, and then measuring the content; (6) if the liquid medicine is qualified, filling in a hundred-class environment to obtain the lincomycin hydrochloride injection. According to the method provided by the invention, the content of a lincomycin component B is effectively reduced in order to improve the quality of the lincomycin hydrochloride injection and reduce the preparation cost.

Owner:ANHUI HONGYE PHARMA

Preparation method of lincomycin hydrochloride injection

ActiveCN102475677AReduce contentQuality improvementAntibacterial agentsOrganic active ingredientsSodium bicarbonateActivated carbon

The invention discloses a preparation method of a lincomycin hydrochloride injection. The preparation method comprises the following steps of: (a) heating water for injection to 55-65 DEG C and dissolving raw powder of lincomycin hydrochloride; (b) regulating the pH of anhydrous sodium bicarbonate to be neutral, adding EDTA-2Na (ethylenediaminetetraacetic acid-disodium), fully and uniformly stirring, then removing pyrogen with 0.02% of activated carbon for injection and determining the content; and (c) filtering through a microporous filtering film, filling under a class-100 environment and circulating steam at the temperature of 100-105 DEG C for 15 minutes for sterilizing twice. According to the preparation method disclosed by the invention, a lincomycin B component can be degraded in the preparation process of the injection by improving the methods for regulating the temperature of liquid medicine, performing secondary sterilization and the like in the preparation process, so that the content of the lincomycin B component in the injection is reduced, the quality of a product is improved, and thus high cost caused by particular extraction and purification against raw materials is also avoided.

Owner:NORTH CHINA PHARMA COMPANY

Lincomycin wastewater advanced treatment and water recycling technology

InactiveCN102079607ARecovery propertiesLow regeneration costSludge treatment by de-watering/drying/thickeningInternal combustion piston enginesActivated sludgeDesorption

The invention relates to a lincomycin wastewater advanced treatment and water recycling technology. The technology is a complete wastewater treatment process consisting of four steps, namely wastewater treatment, activated sludge treatment, advanced treatment of activated carbon bed desorption solution and biogas recycling, wherein the filtrates of the activated sludge treatment, the advanced treatment of activated carbon bed desorption solution and the biogas recycling all enter a wastewater treatment collection pool to be subjected to circular treatment. The lincomycin wastewater treated by the technology has a wide range of application; the technology has the advantages of excellent pollutant removal effect, low operating cost, stability and reliability, and is convenient to operate; and when the treated wastewater meets the standards, the obtained water can replace industrial water to be directly used in industrialized production, thus the emissions of pollutants in the operation of the system can be reduced, the pollution of the wastewater to the environment can be eliminated, and remarkable economic benefits and social benefits can be obtained.

Owner:王冰

Emulsifiable paste for treating acne

InactiveCN104056257APromote differentiationPromote sheddingAntimycoticsHydroxy compound active ingredientsAnti virusVitamin b6

The invention relates to an emulsifiable paste for treating acne, which comprises the following raw materials by weight: 70-150 parts of ketoconazole, 70-150 parts of lincomycin, 1200-2400 parts of metronidazole, 300-1200 parts of moroxydine hydrochloride, 35-90 parts of viaminate, 5-20 parts of tretinoin, 200-350 parts of vitamin E, 80-200 parts of vitamin B6, 50-100 parts of lidocaine, 600-2000 parts of aloe extract product, 1000-2000 parts of coconut meat powder and 100-800 parts of collagen powder with molecular weight lower than 2KD. The emulsifiable paste has the advantages of antibacterial function, antifungal function and anti-virus function, can promote epidermal cell differentiation and shedding, epidermal cell proliferation and differentiation can be adjusted, cornification is avoided, sebum secretion is adjusted, the emulsifiable paste has the effects of relieving pain, relieving itching, mitigating pockmark and whitening skin, and can help luster recovery for skin.

Owner:谢一泓

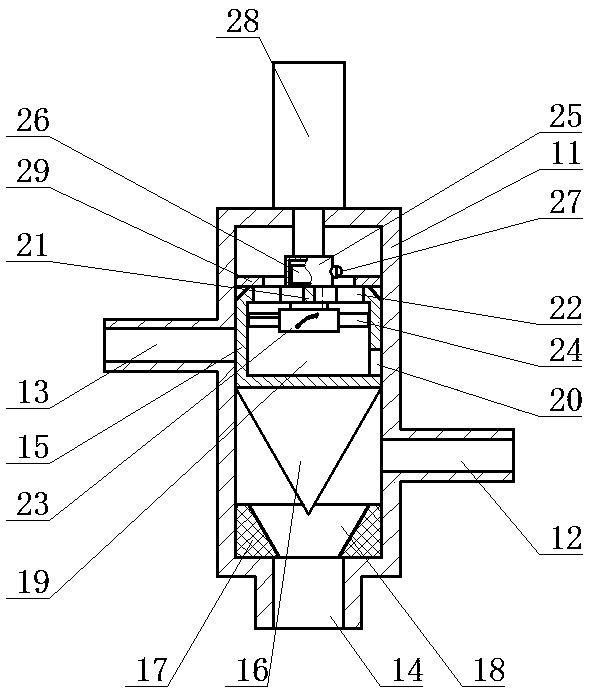

Method and device for preparing lincomycin hydrochloride

ActiveCN101624411AEfficient separationQuality improvementSugar derivativesAntiinfectives2-OctanolLincomycin Hydrochloride

The invention relates to a method and a device for preparing lincomycin hydrochloride. On the basis of the prior lincomycin hydrochloride production, repurifying processing procedure is added to prepare lincomycin hydrochloride with lincomycin B component less than or equal to 0.1 percent. The method is characterized by comprising the following steps: lincomycin hydrochloride with B component less than or equal to 1.0 percent is dissolved to have thetconcentration of 80000-100000 microgramme / ml, the pH value is adjusted to 10-11, extraction is carried out in extraction tower with 1 / 2-1 / 3 (weight ratio) of 2-octanol, the extraction temperature is 20-30 DEG C, the pH value of extraction liquid is adjusted to 2-4 by hydrochloric acid for back extraction, and acetone is used for crystallization. By adopting the method and the extraction tower device, the concentration of B component in lincomycin hydrochloride can be effectively reduced to be less than or equal to 0.1 percent, so that the quality of lincomycin hydrochloride is improved, and the yield is increased by 5-7 percent.

Owner:XINYU PHARM CO LTD

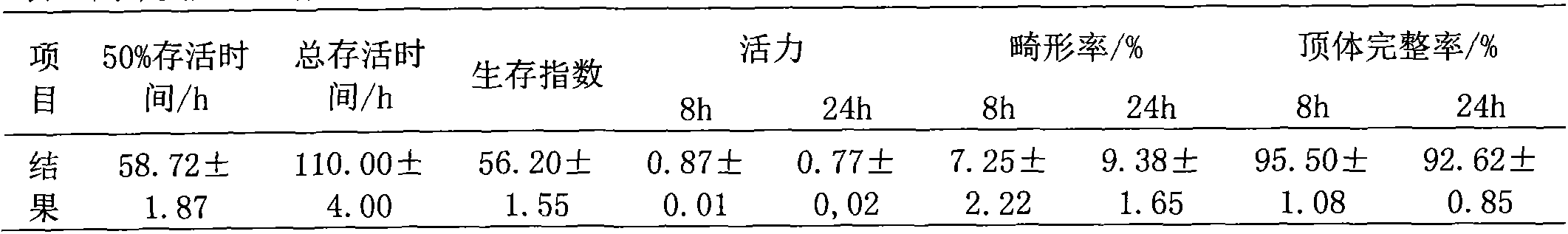

Dilute solution used for preserving racoon dog seminal fluid at normal temperature, and semen collection method

InactiveCN103380770AAnimal reproductionDead animal preservationSodium bicarbonateAdditive ingredient

The invention discloses a dilute solution used for preserving racoon dog seminal fluid at normal temperature, and a semen collection method. The dilute solution comprises following ingredients: 36 to 38g of glucose, 1.20 to 1.30g of sodium bicarbonate, 1.20 to 1.30g of ethylene diamine tetraacetic acid, 5.50 to 6.30g of sodium citrate, 0.65 to 0.85g of potassium chloride, 0.50 to 3.05g of bovine serum albumin, 0.05 to 0.30g of acetylcysteine, 0.50 to 1.20g of penicillin, 0.30 to 1.00g of streptomycin, 0.05 to 1.50g of lincomycin and 0.01 to 0.05g of spectinomycin; and a mixture of the ingredients above is diluted to 1000ml by adding triple-distilled water so as to obtain the dilute solution. Key steps of the semen collection method are that: female racoon dogs in heat are used as dummy teaser; conditioned reflex of male racoon dogs to artificial semen collection is formed by training; the training is repeated for 3 to 4 times until conditioned reflex is formed; and then the female racoon dogs are replaced by a female racoon dog-simulated dummy teaser which is filled with urine of female racoon dogs in heat so as to collect male racoon dog semen. The dilute solution and the semen collection method can be used for collecting racoon dog semen, diluting for preservation, realizing artificial insemination and obtaining offspring; and are capable of promoting the popularization of racoon dog artificial insemination technologies, and increasing economic benefits of racoon dog industry.

Owner:INST OF SPECIAL ANIMAL & PLANT SCI OF CAAS

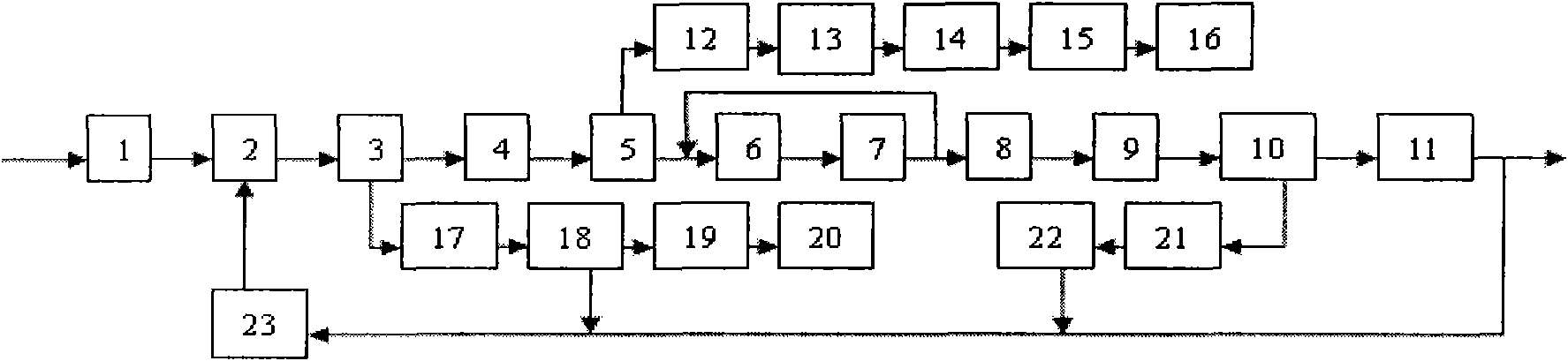

Lincomycin fermentation liquor treatment process

InactiveCN104177454AImprove business efficiencyHigh removal rateFungiSugar derivativesYeastFilter system

The invention discloses a lincomycin fermentation liquor treatment process. The lincomycin fermentation liquor treatment process comprises the following steps: (1) acidifying lincomycin fermentation liquor, and filtering the acidified lincomycin fermentation liquor in a ceramic membrane filter system; (2) carrying out nanofiltration, concentration and dehydration on the obtained ceramic membrane high-titer filtrate, then entering the treated ceramic membrane high-titer filtrate into a downstream production process, and returning ceramic membrane low-titer filtrate and nanofiltration filtrate to an upstream process to be recycled; and (3) collecting mushroom dregs after ceramic membrane filtration is completed, adding engineering bacteria, realizing harmless treatment, and carrying out secondary fermentation to obtain industrial yeasts. The lincomycin fermentation liquor treatment process provides strong technical support for upgrading and reconstruction of a lincomycin production enterprise, and market competitiveness of the lincomycin production enterprise is improved.

Owner:JIANGXI CLEANING MEMBRANE TECH +1

Lincomycin purification method

InactiveCN102633846AMethod environmentally friendlyReduce labor costsSugar derivativesSugar derivatives preparationAlkaline waterPurification methods

The invention belongs to the technical field of pharmaceutical products and provides a lincomycin purification method. The lincomycin purification method is mainly characterized in that alkaline water is taken as a mobile phase, a resin column is taken as a fixed phase, and adsorption, washing, resolution, vacuum concentration, crystallization, drying and other steps are performed for treatment. According to the lincomycin purification method provided by the invention, the content of a component B in lincomycin can be effectively reduced, and the lincomycin purification method has the advantages of low cost, environmental friendliness and no pollution.

Owner:南阳普康药业有限公司

Method used for separating and purifying lincomycin with molecular imprinting polymers

InactiveCN105037456AEasy to separateReduce consumptionSugar derivativesSugar derivatives preparationAbsorption columnMolecularly imprinted polymer

The invention discloses a method used for separating and purifying lincomycin with molecular imprinting polymers. The method comprises following steps: a lincomycin fermentation liquor is filtered, pH value is adjusted to 10 to 11 with a sodium hydroxide aqueous solution, and an extract liquor is obtained via 2 to 3 times of extraction with chloroform; the extract liquor is pumped into an adsorption column filled with the lincomycin molecular imprinted polymers, and adsorption separation is carried out until absorption column saturation is achieved; the absorption column is subjected to elution with a methyl alcohol-acetic acid mixed solution at 25 to 40 DEG C at a flow rate ranging from 3 to 5ml / min; an obtained eluent is subjected to vacuum concentration at 60 to 70 DEG C until the volume of the eluent is reduced to be one third to one half of an original volume, pH value is adjusted to be 0.5 to 2.0, and an obtained product is cooled to 0 to 10 DEG C, and is subjected to crystallizing and drying so as to obtain lincomycin. Purity of obtained lincomycin is 94.6%, yield is 81.93%, separation effect is excellent, and the method is suitable for industrial separation and extraction of lincomycin.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Method for preparing organic fertilizer from lincomycin fungi residues

InactiveCN107311729AEfficient destructionImprove the safety of useClimate change adaptationBioloigcal waste fertilisersPeroxydisulfateResource utilization

The invention provides a method for preparing an organic fertilizer from lincomycin fungi residues, and relates to harmless treatment and recovery of the lincomycin fungi residues. The method provided by the invention aims at realizing the harmless treatment and resource utilization of the lincomycin fungi residues. The method concretely comprises the following steps of collecting fresh lincomycin fungi residues; regulating the moisture content and the pH value; adding potassium peroxydisulfate and zinc acetate for treatment; performing centrifugation and precipitate collection; manufacturing the organic fertilizer. The lincomycin residues are damaged and removed; antibiotic drug resistant bacteria in the fungi residues are inactivated. The method has the advantages that the process is simple; the operation is easy. The potassium peroxydisulfate is used; the removal rate on the lincomycin is high and reaches 99.9 percent; the treatment cost is low; the period is short; the operation can be completed in half an hour. The fungi residue organic fertilizer does not contain antibiotic drug resistant bacteria; bacterium drug resistance cannot be caused in the soil; the use safety is high.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com