Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36 results about "Bisphenol A dimethacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

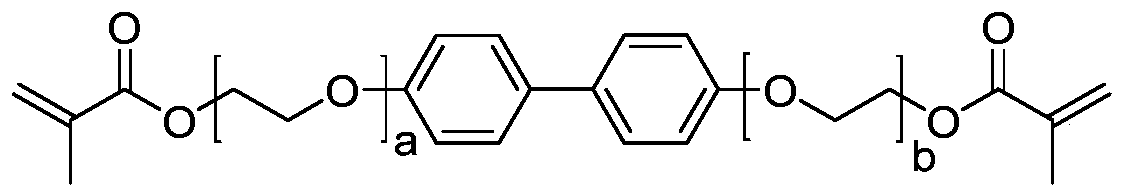

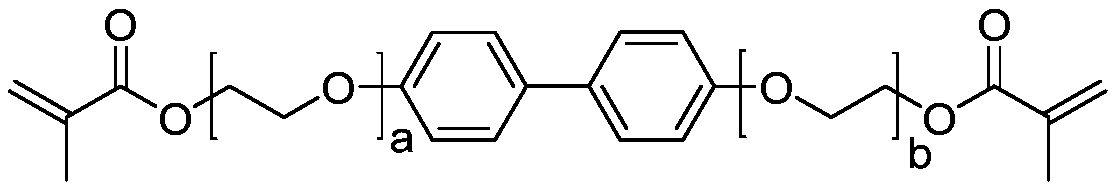

Bisphenol A dimethacrylate >98% CAS Number 3253-39-2. Linear Formula [H 2 C=C(CH 3)CO 2 C 6 H 4] 2 C(CH 3) 2. Molecular Weight 364.43 . EC Number 221-846-9. MDL number MFCD00008585. PubChem Substance ID 24849606

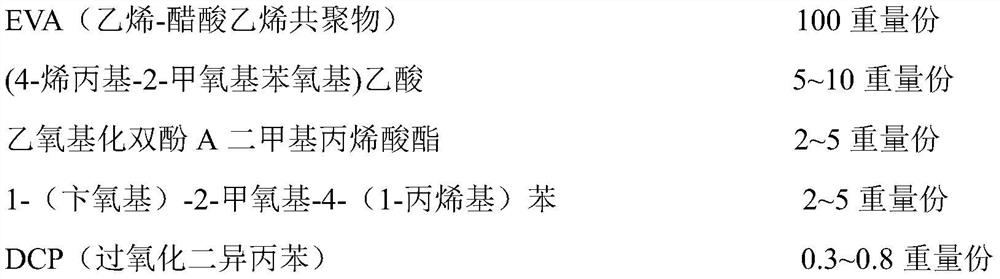

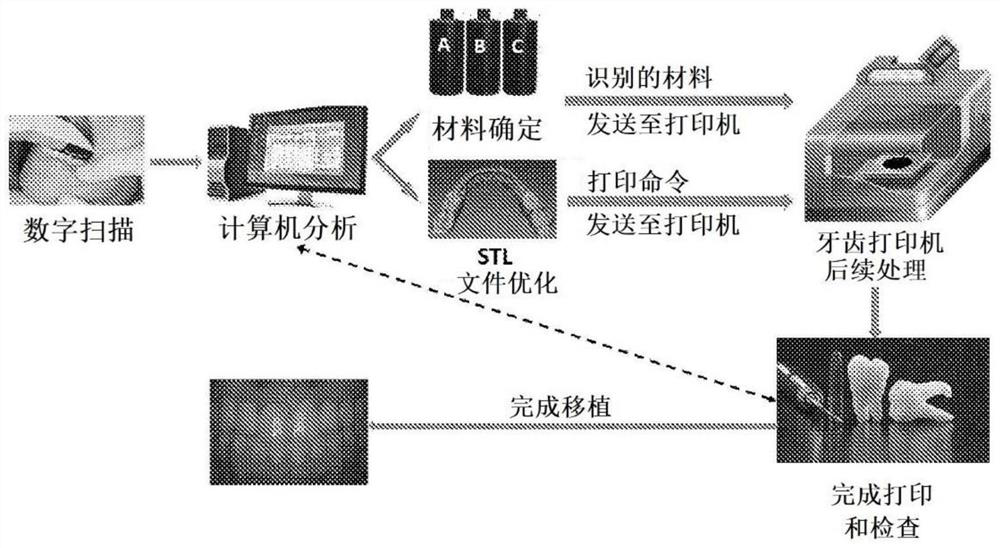

Photo-curable resin compositions and method of using the same in three-dimensional printing for manufacturing artificial teeth and denture base

ActiveUS20140239527A1Simple and easilyLow viscosityAdditive manufacturing apparatusImpression capsMeth-Oligomer

A composition includes a light-curable viscous mixture that includes: 0-50% by weight of a poly(methyl methacrylate) / methyl methacrylate solution; 5-20% by weight of at least one kind of multifunctional aliphatic (meth)acrylate; 5-40% by weight of at least one kind of aliphatic urethane (meth)acrylate oligomer; 25-65% by weight of at least one kind of difunctional bisphenol-A dimethacrylate; 0.1 to 5% by weight of at least one kind of a photoinitiator; 0.05 to 2% by weight of at least one kind of light stabilizer; and 0.1 to 3% by weight of color pigment based on the total weight of the composition.

Owner:DENTCA

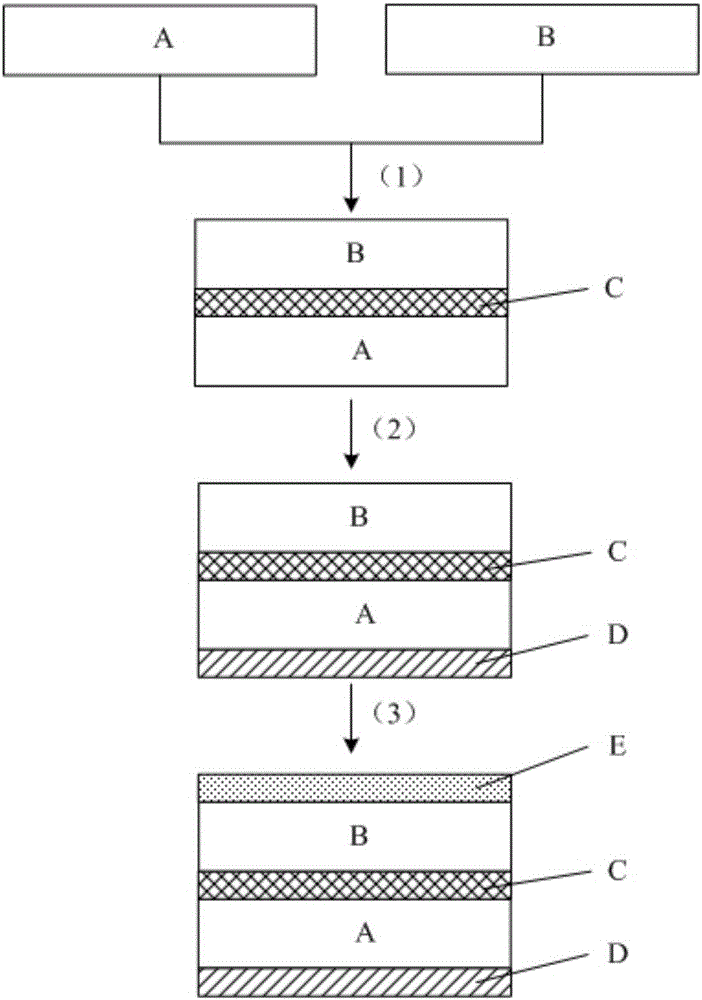

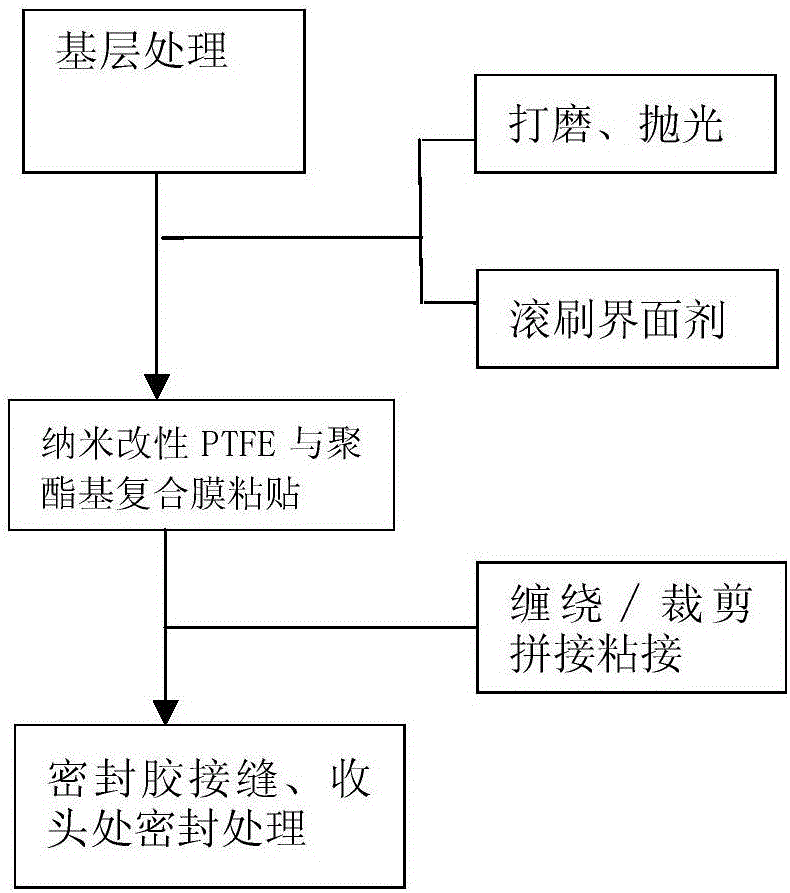

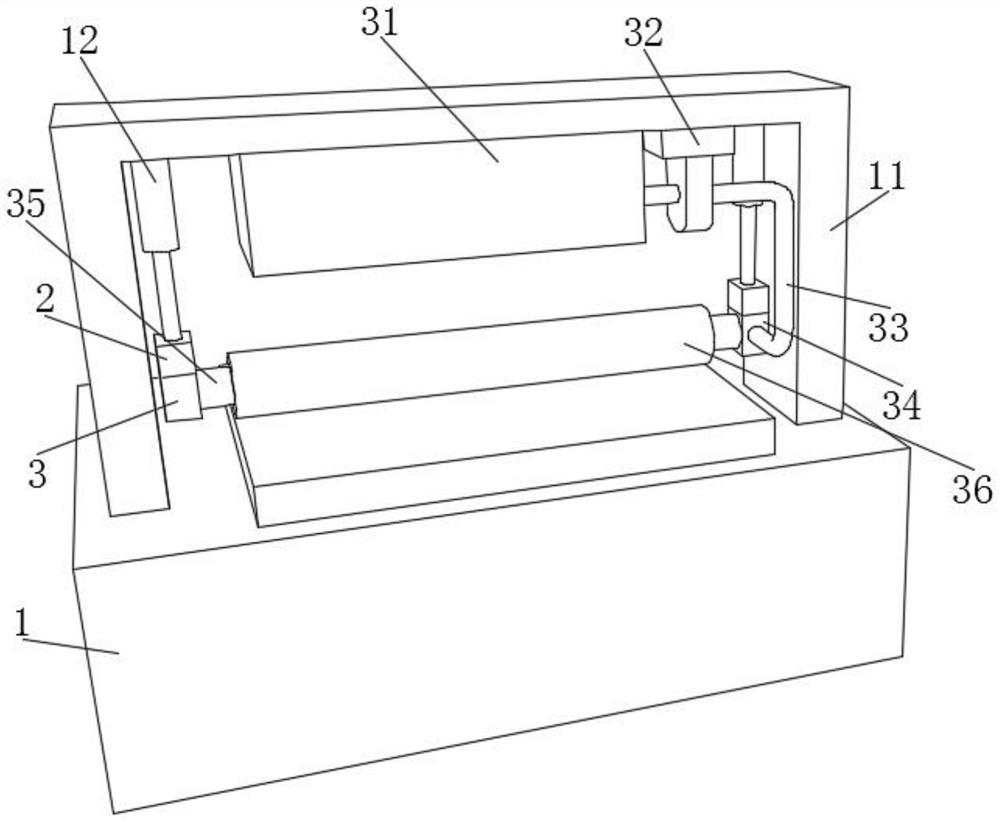

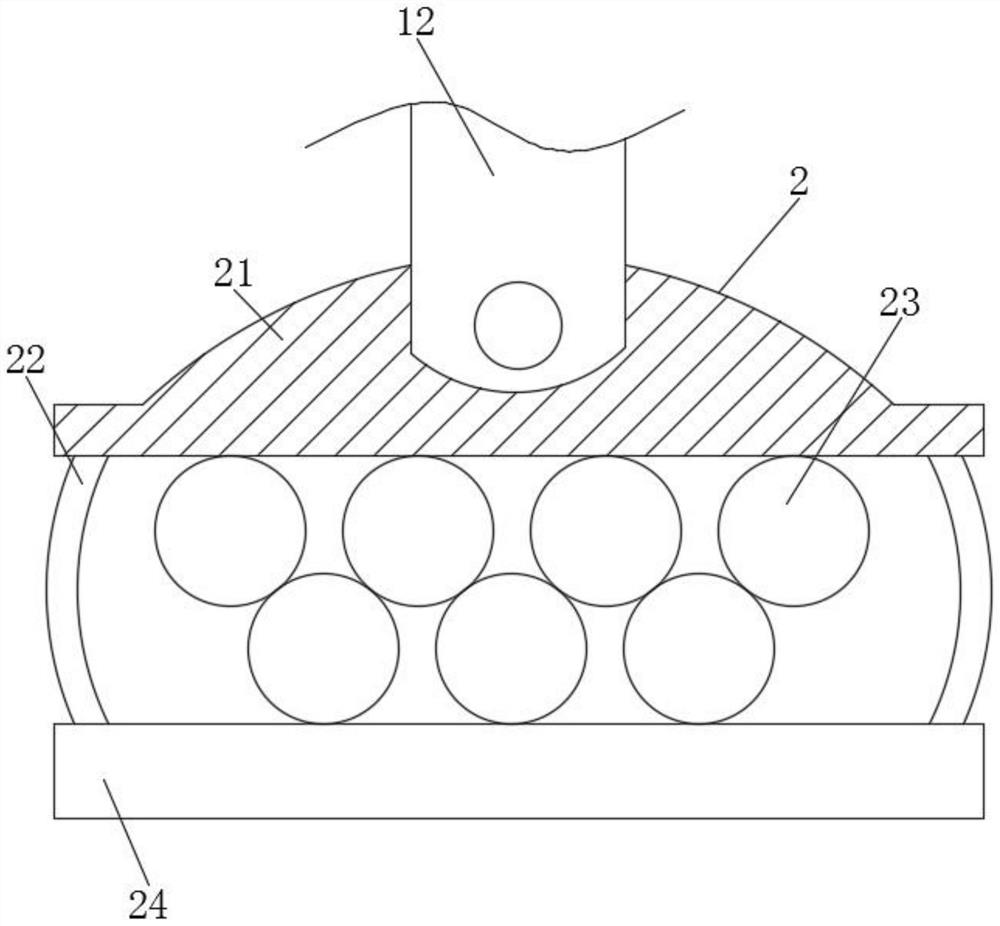

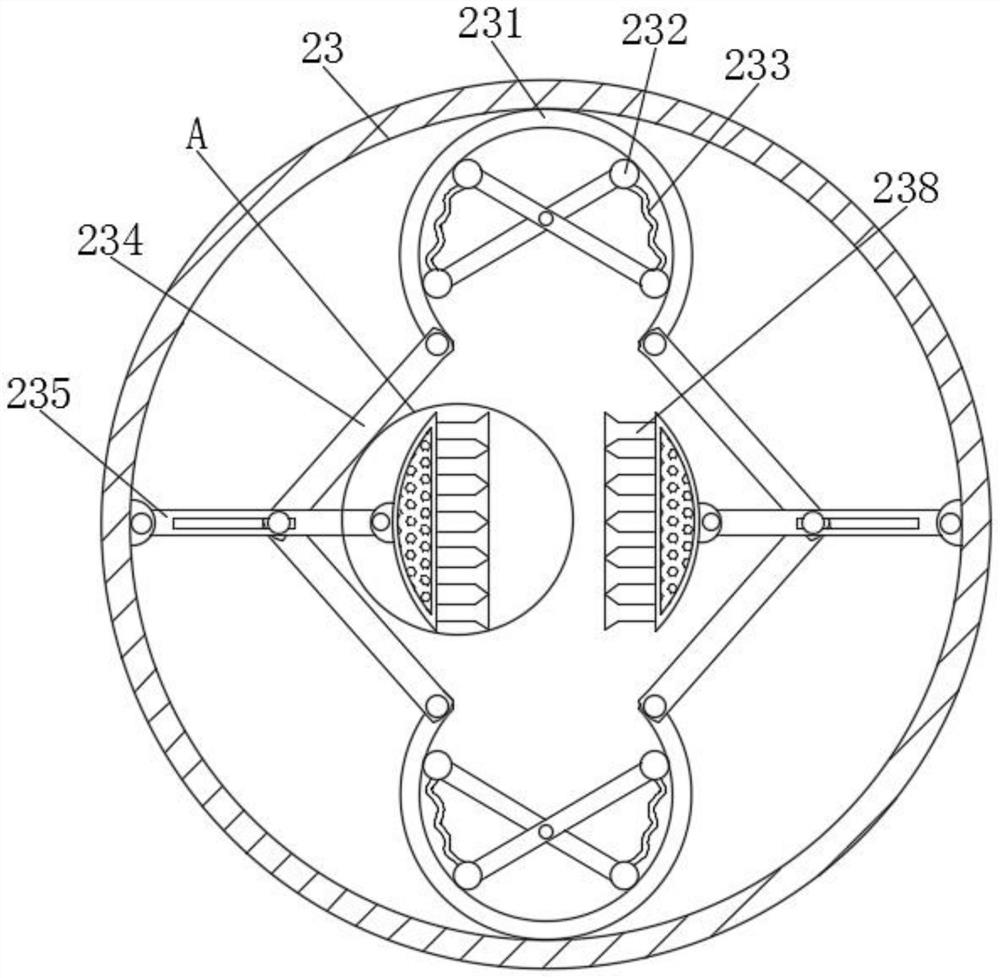

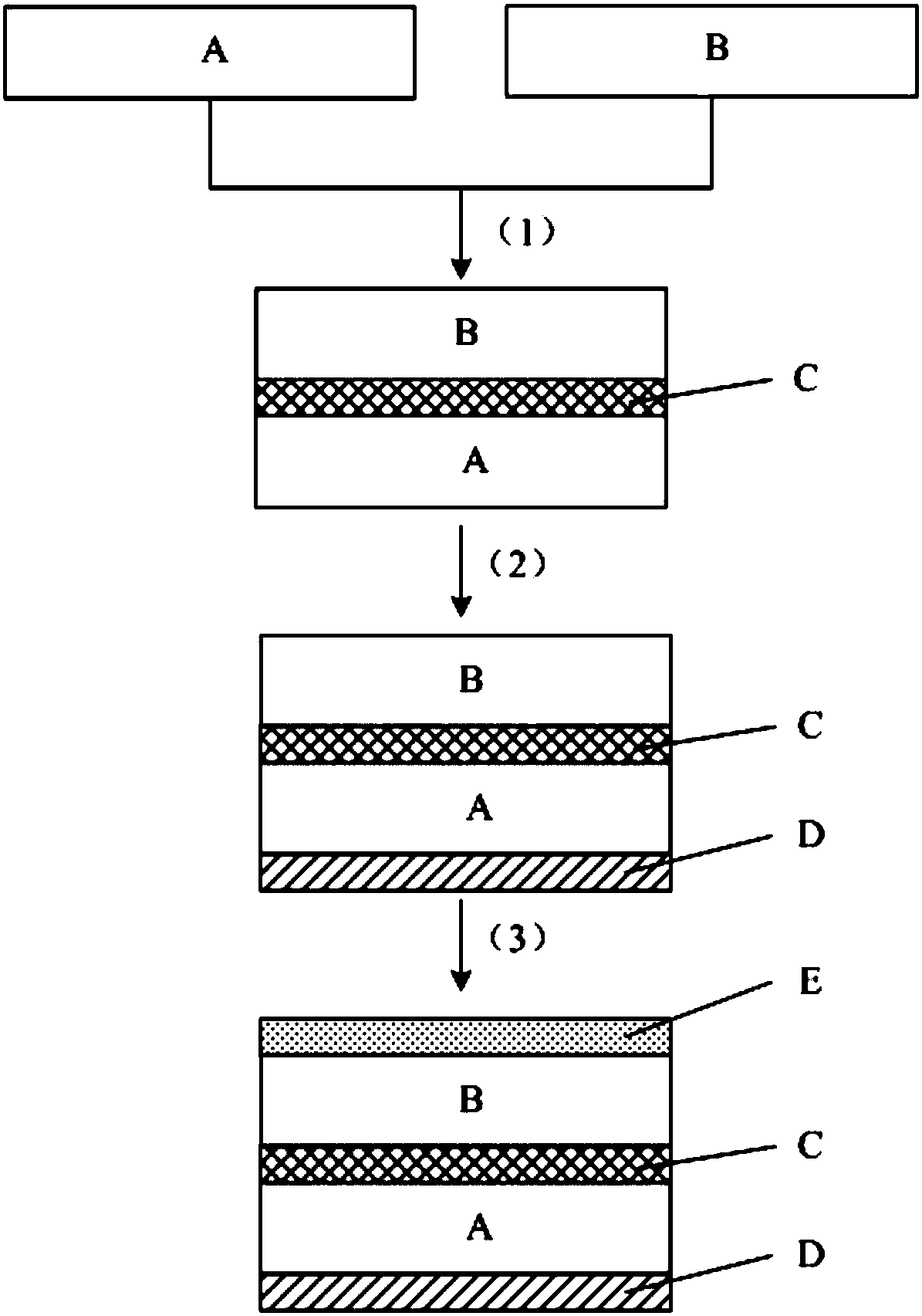

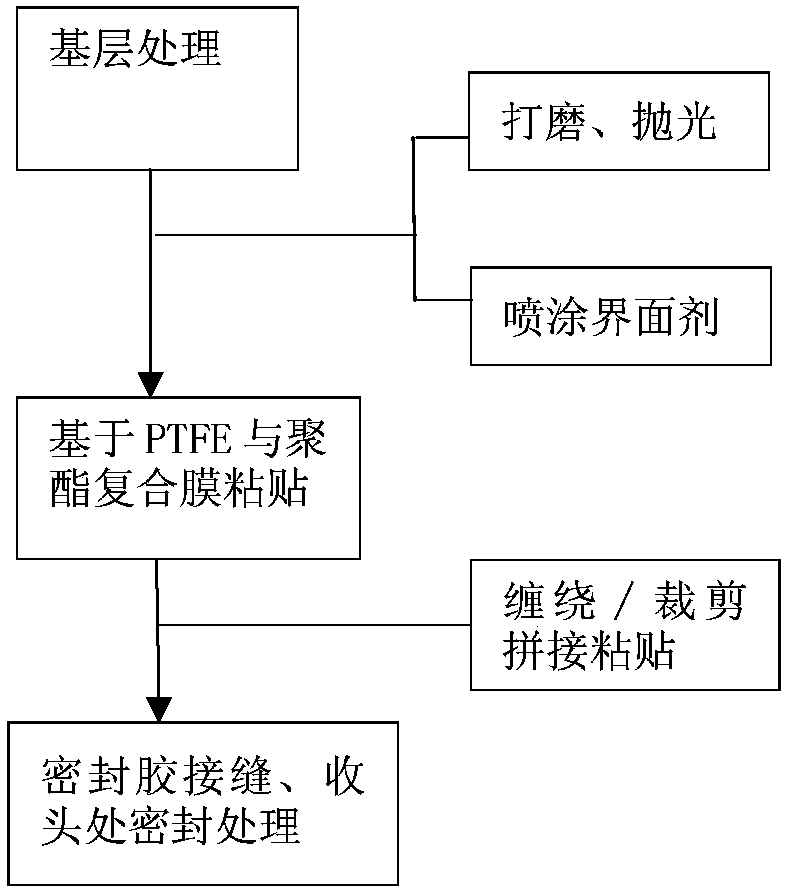

Preparation method and application of nano-modified PTFE and polyester-based composite film for preventing fan blades from icing

ActiveCN106313811ASolving non-adhesive technical problemsConvenient engineering constructionSynthetic resin layered productsLaminationPolyesterComposite film

The invention provides a preparation method and application of a nano-modified PTFE and polyester-based composite film for preventing fan blades from icing. The method includes the steps of PTFE film modification, lamination complexing and photo-crosslinked adhesive application. A modifier is prepared from antimony-doped tin oxide nano-crystals, nano-titanium dioxide, nano-silicon carbide, an organic fluorine waterproofing agent and pentaerythritol tri-(3-aziridinyl)-propionate; in lamination complexing, a bonding complexing agent is prepared from 3-isocyanatomethyl-3,5,5-trimethylcyclohexyl isocyanate, vinyl acetate, ethyl carbamate, alpha-linolenic acid, (2)ethoxylated bisphenol A dimethacrylate, trimethylolpropane triacrylate and benzoyl peroxide; a photo-crosslinked adhesive is prepared from a poly[butyl acrylate-glycidyl methacrylate-n-butoxy methacrylamide]copolymer, vinyl acetate, butyl acrylate, an acrylate derivative, a photoinitiator and dimethylformamide. The method and the composite film solve the non-adhesion problem that a PTFE film can not be pasted on the surfaces of fan blades with an adhesive directly.

Owner:NANJING HAOHUI HI TECH CO LTD

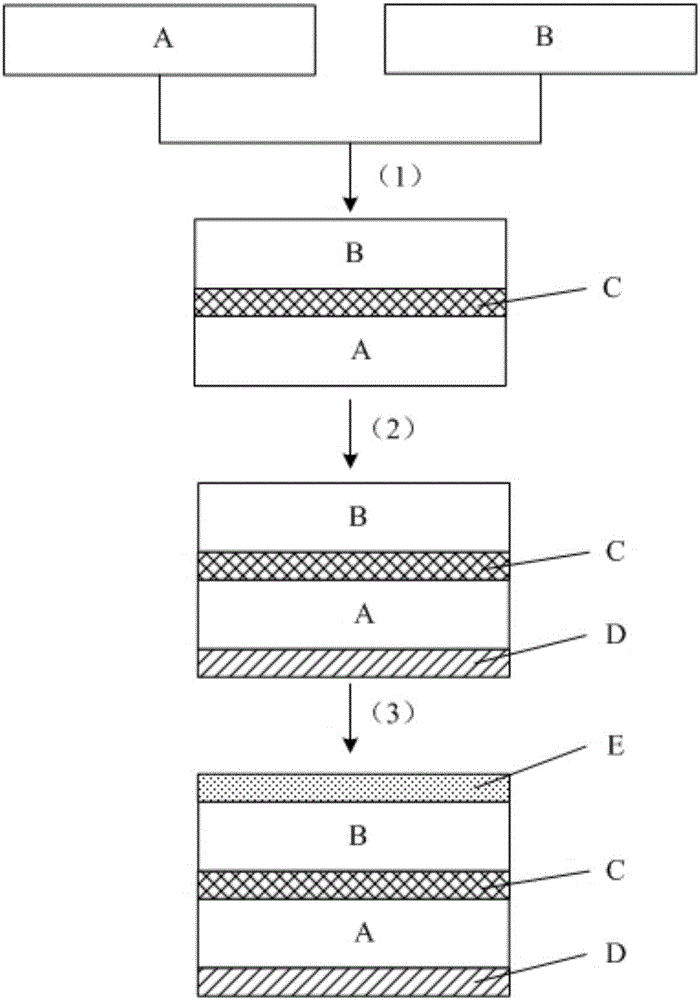

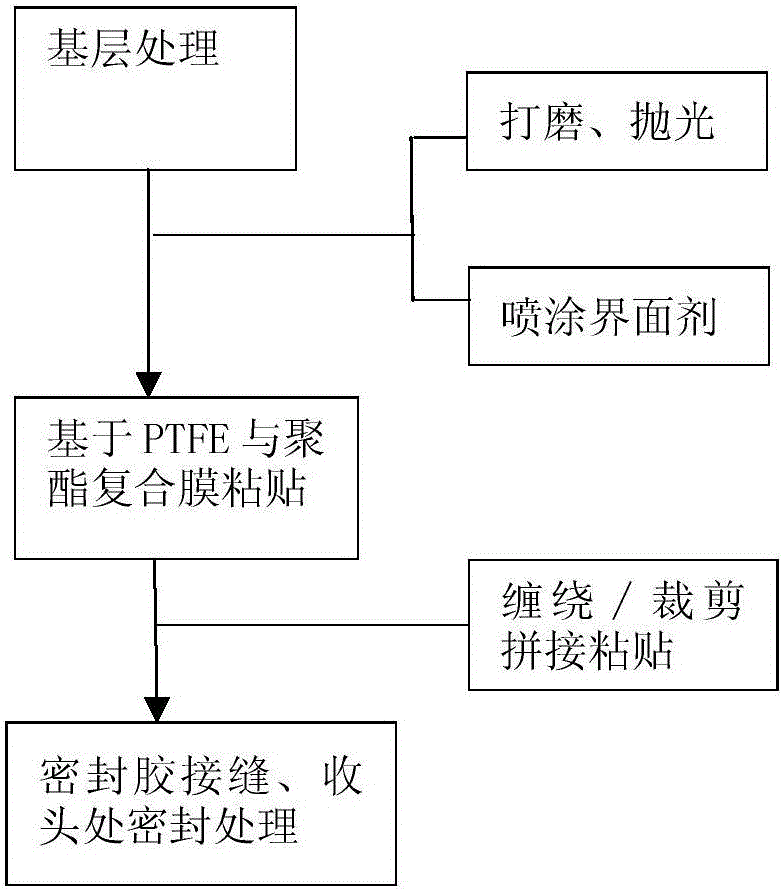

Preparation method and application of PTFE and polyester-based composite film for preventing wind turbine blades from icing

ActiveCN106313812AHigh peel strengthHigh bonding strengthNon-macromolecular adhesive additivesSynthetic resin layered productsPolyesterBenzoyl peroxide

The invention discloses a preparation method and application of a PTFE and polyester-based composite film for preventing wind turbine blades from icing. The method includes the steps that a bonding composite agent is adopted for lamination complexing, an interface adhesive is applied, and a pressure-sensitive adhesive is adopted for photo-initiated pressure-sensitive adhesive application. The bonding complexing agent is prepared from 3-isocyanatomethyl-3,5,5-trimethylcyclohexyl isocyanate, vinyl acetate, ethyl carbamate, alpha-linolenic acid, benzoyl peroxide and (4)ethoxylated bisphenol A dimethacrylate; the photo-initiated pressure-sensitive adhesive is prepared from a poly[butyl acrylate-glycidyl methacrylate-n-butoxy methacrylamide]copolymer, butyl acrylate, (4)ethoxylated bisphenol A dimethacrylate, 4,4'-bis(diethylamino)benzophenone and dimethylformamide. The method and the composite film solve the non-adhesion technical problem that a PTFE film can not be pasted on the surfaces of wind turbine blades with an adhesive directly, the bonding peel strength is improved, and the composite film is suitable for wind turbine blades of various models.

Owner:NANJING HAOHUI HI TECH CO LTD

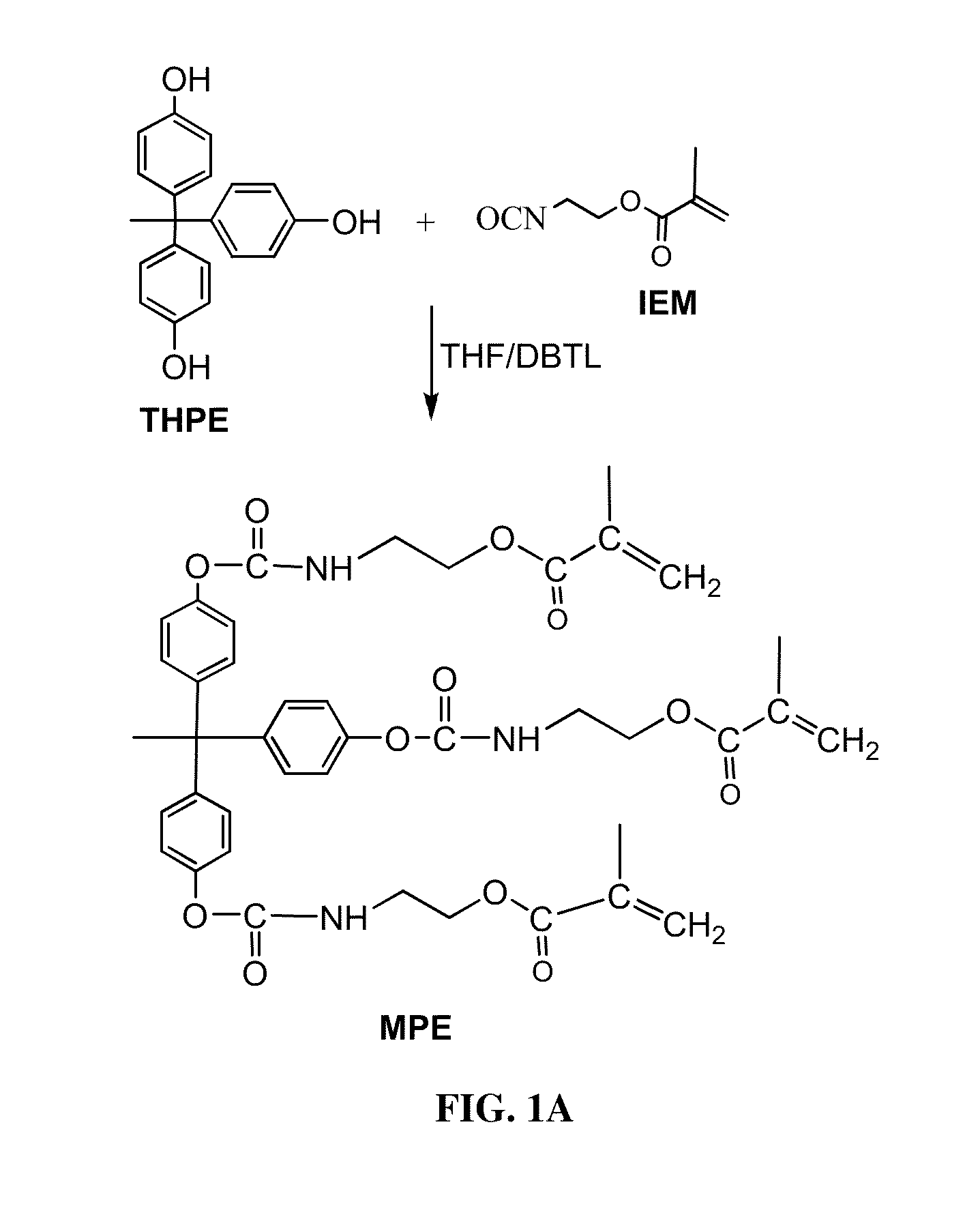

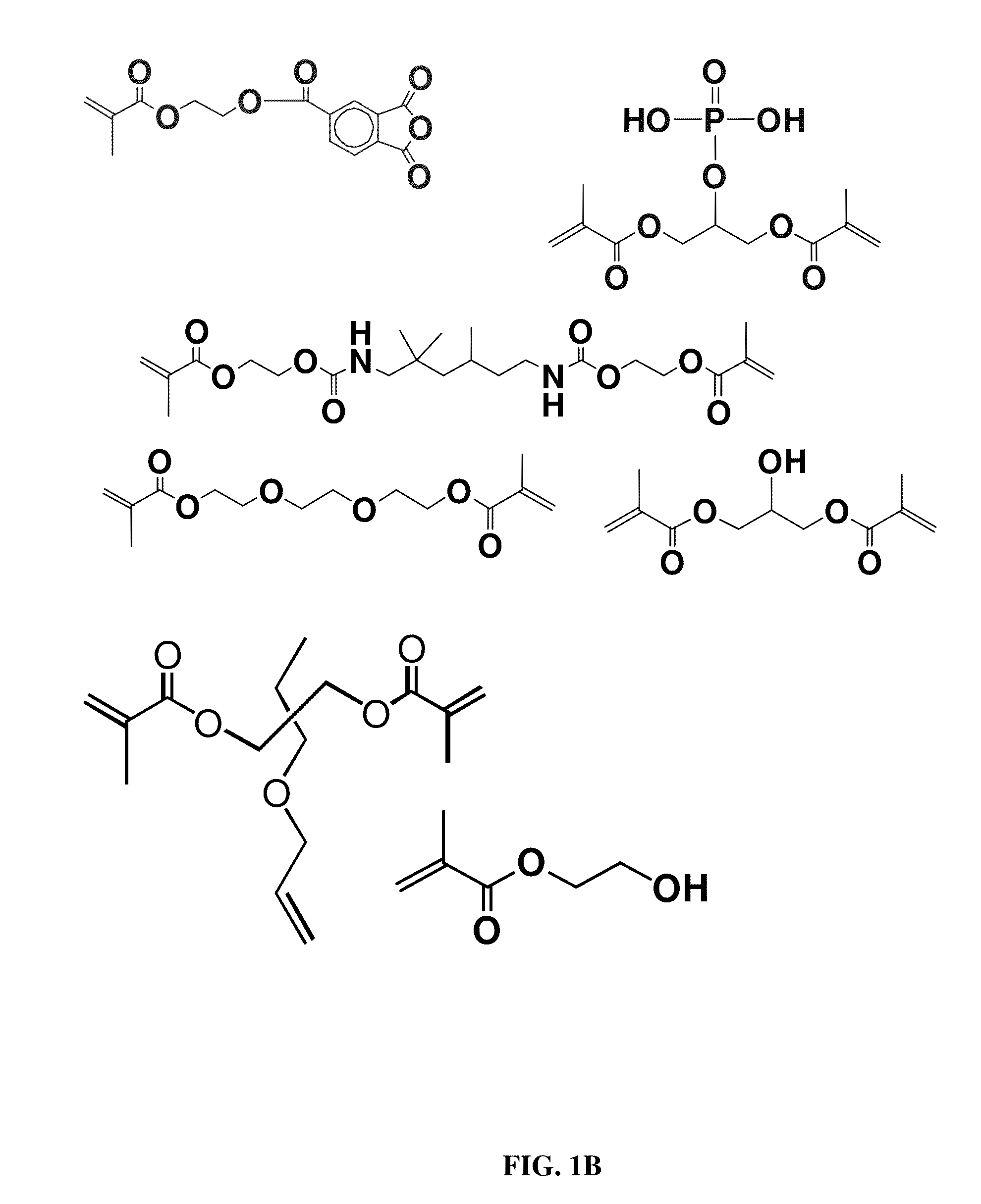

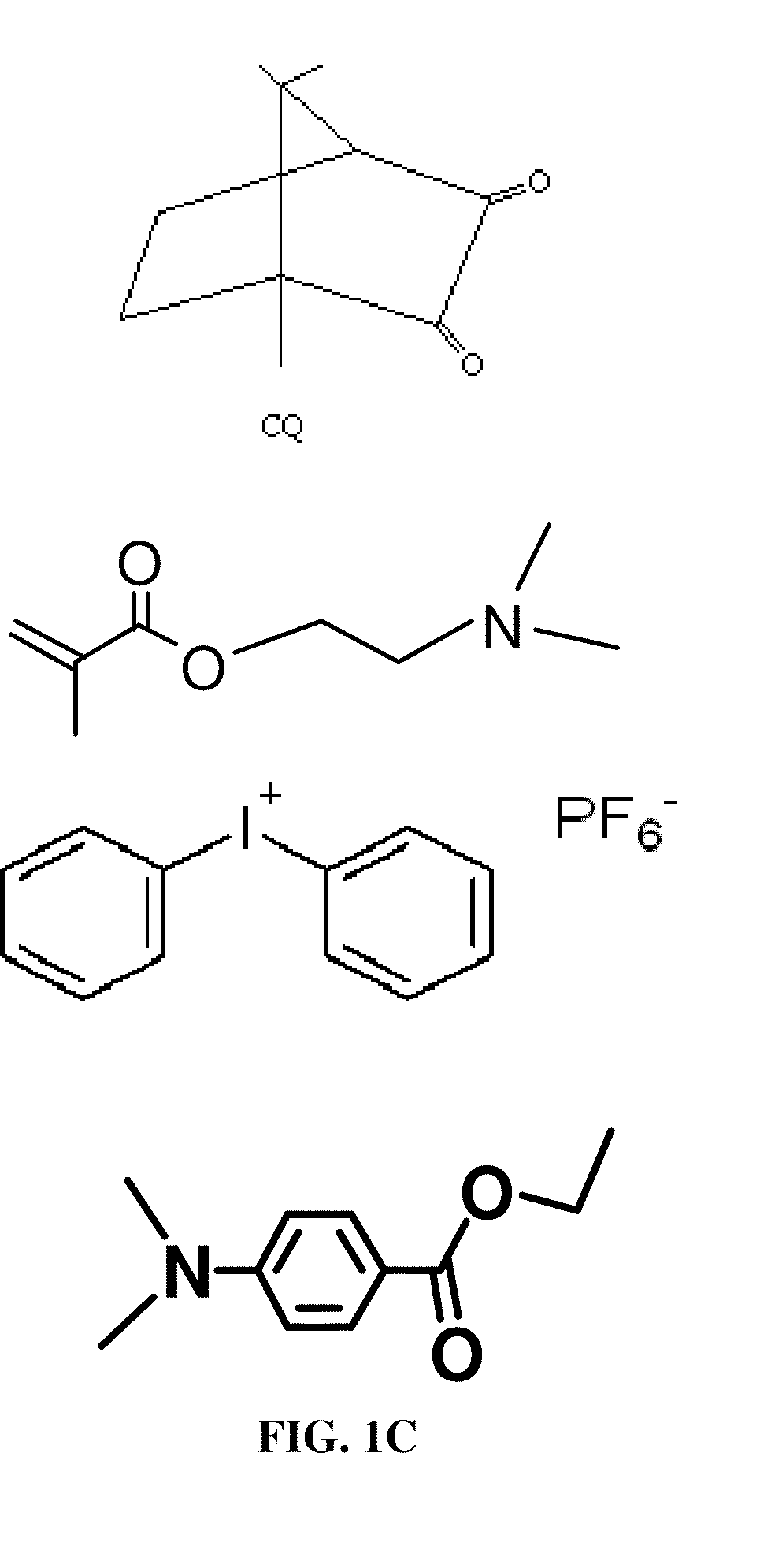

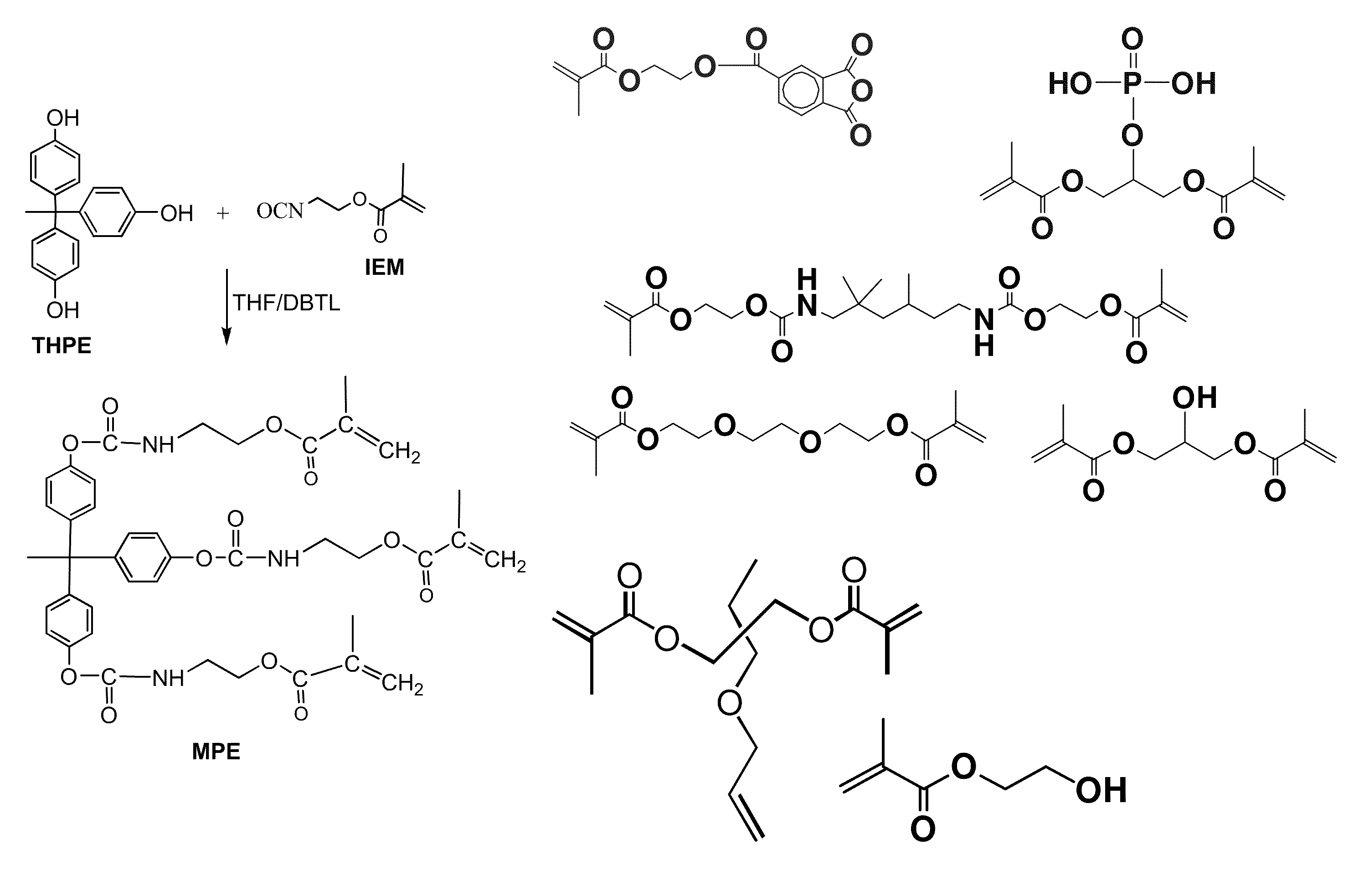

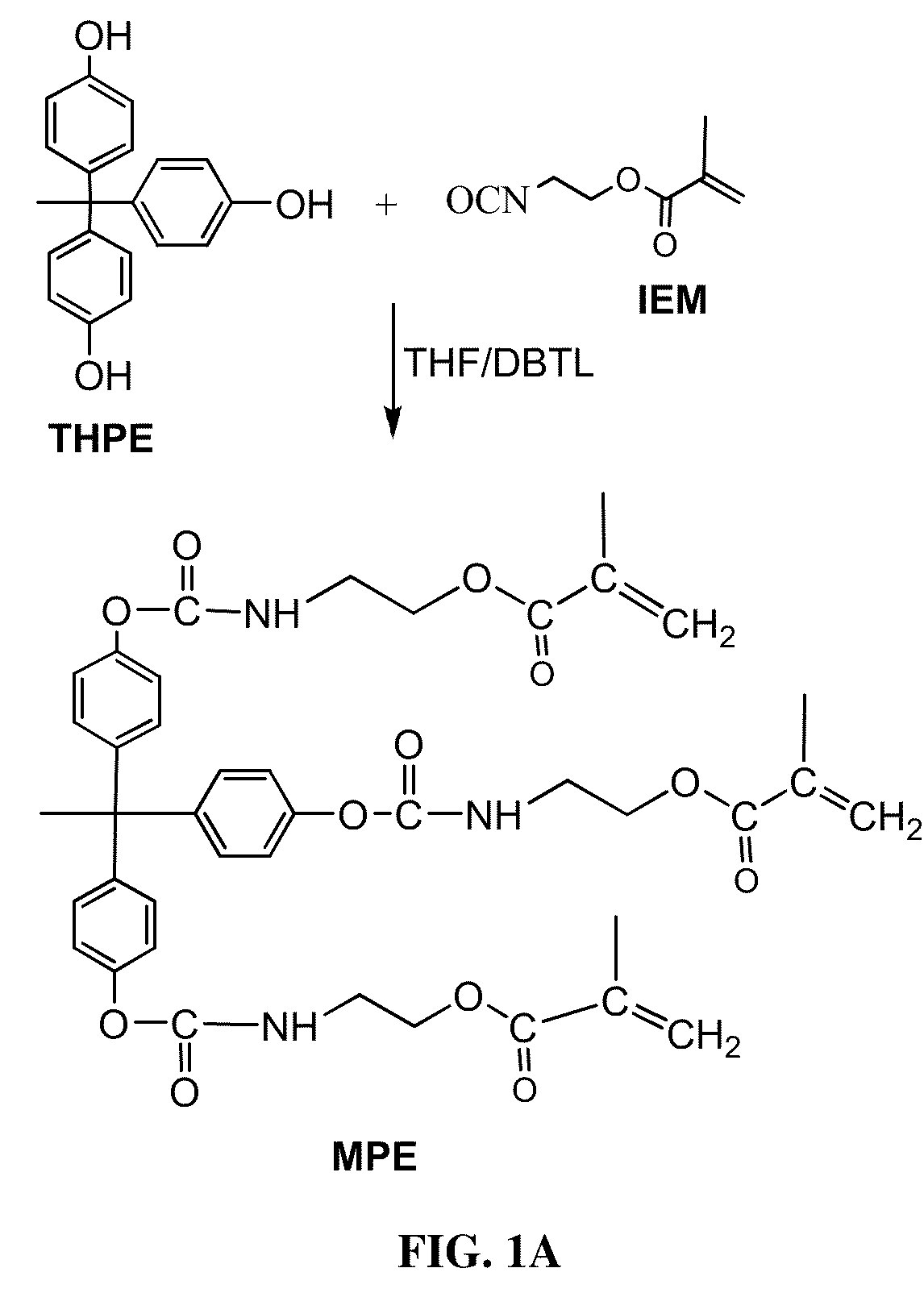

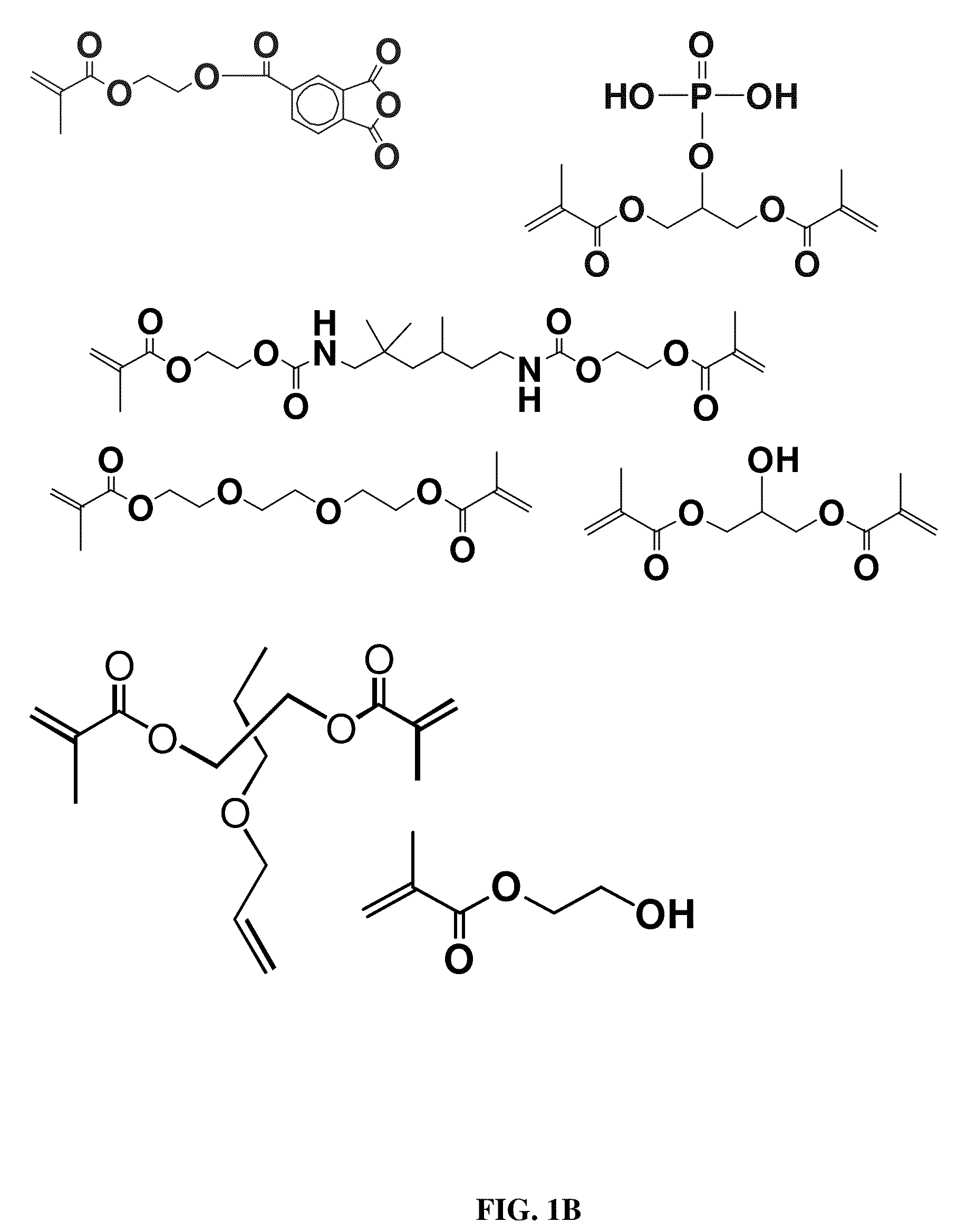

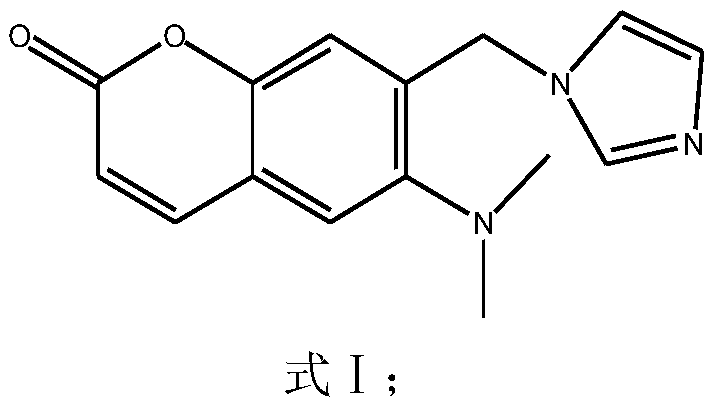

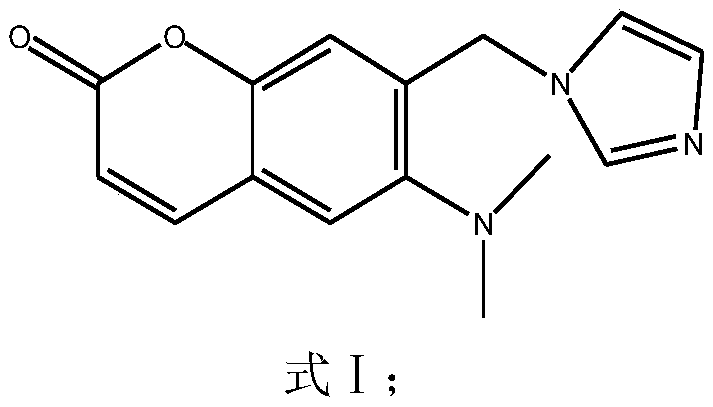

Novel monomer for dental compositions

A novel monomer, 1,1,1-tri-[4-(methacryloxyethylaminocarbonyloxy)-phenyl]ethane (MPE) can be used in preparing dental compositions The MPE monomer can be combined into a dental adhesive with hydroxyethyl methacrylate (HEMA) and BisGMA (bisphenol A dimethacrylate). The MPE polymer can be polymerized with a photoinitiator system, such as a system that includes an iodonium salt. The iodonium salt can be diphenyliodonium hexafluorophosphate.

Owner:UNIVERSITY OF KANSAS

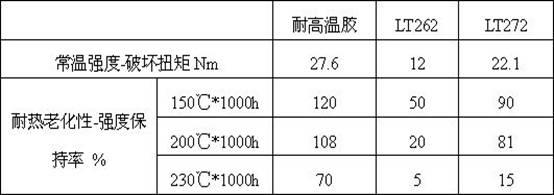

High-temperature resistant anaerobic locking glue and preparation method thereof

InactiveCN102604547ATo meet the needs that cannot adapt to high temperature conditionsImprove heat aging resistanceNon-macromolecular adhesive additivesOrganic non-macromolecular adhesivePolyesterFumed silica

The invention relates to a high-temperature resistant anaerobic locking glue and a preparation method of the high-temperature resistant anaerobic locking glue. The anaerobic locking glue comprises 45 parts of (2) ethoxylated bisphenol A dimethacrylate, 20 parts of hydroxypropyl methacrylate, 15 parts of boric acid, 12.39 parts of bisphenol A fumaric acid polyester, 3 parts of fumed silica, 0.8 part of benzoic hydrazine, 0.6 part of o-benzene sulfonyl imine, 1.0 part of ethylenediamine tetraacetic acid disodium salt, 2.0 parts of cumene hydroperoxide, 0.2 part of fast red, and 0.01 part of para-benzoquinone. The anaerobic locking glue can be used for a short time at the temperature blow 230 DEG C and a long time at the temperature above 200 DEG C. The thermal aging resistance of the anaerobic locking glue at 230 DEG C is improved significantly. The anaerobic locking glue has a wide range of application and overcomes the defects that the existing ordinary anaerobic glue can not adapt to the high-temperature working condition.

Owner:TONSAN ADHESIVES INC

Photocurable photochromic material and preparation method thereof

ActiveCN105670602AShorten production timeImprove impact resistanceTenebresent compositionsOptical partsWeather resistanceDiacrylate ester

The invention discloses a photocurable photochromic material and a preparation method thereof. The photocurable photochromic material is composed of 30%-70% of bisphenol A dimethacrylate, 10%-60% of poly(ethylene glycol) diacrylate, 10%-30% of polyfunctional acrylate monomer and the balance modifying additives, wherein the sum of weight percentages is 100%. The photocurable photochromic material and the preparation method thereof have the advantages that lens production time is shortened from 20 hours to 15 minutes, impact resistance of lenses is improved to prevent breakage in use, and weather resistance of the lenses can be improved as well to avoid cracks in a fierce cold-hot change process.

Owner:JIANGSU MAAT OPTICAL CO LTD

Visible-light-cured adhesive and preparation method thereof

ActiveCN103740286ALiquidLiquidityNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveGlycidyl methacrylatePentaerythritol

The invention provides a visible-light-cured adhesive including the following components: by weight, 20-50% of methacrylate monomer, 10-30% of a methacrylate diluent, less than 5% of a visible light initiator, 30-68% of silica, glass powder or alumina powder and 0.1-5% of nano fumed silica, the methacrylate monomer is at least one substance from bisphenol A-glycidyl dimethacrylate, ethoxylated bisphenol A dimethacrylate, pentaerythritol tetraacrylate, dipentaerythritol pentaacrylate and dipentaerythritol hexaacrylate, and the invention also provides a preparation method of the visible-light-cured adhesive. The visible-light-cured adhesive is low in mobility, short in curing time, highin bonding strength, and suitable for industrial application.

Owner:BEIJING POLYSTAR HITECH CO LTD

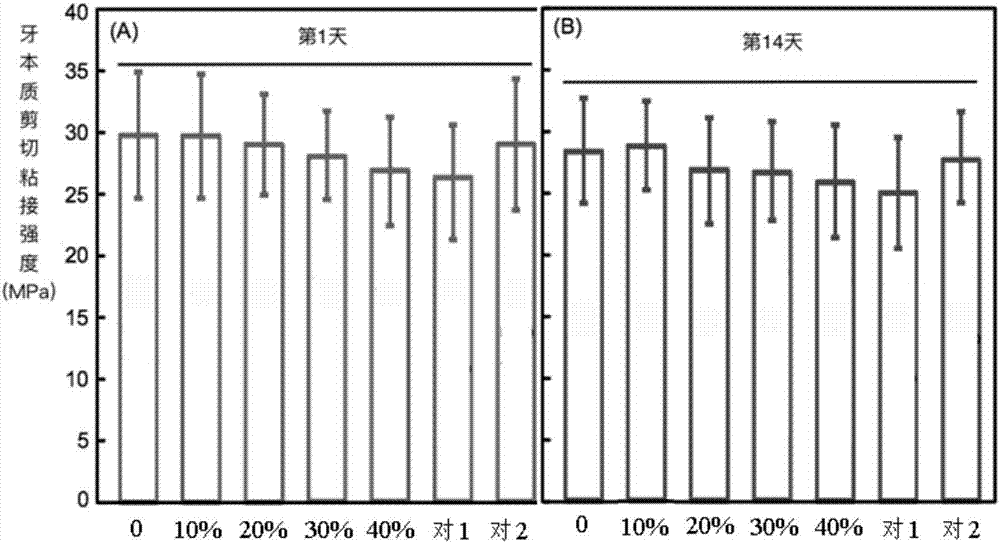

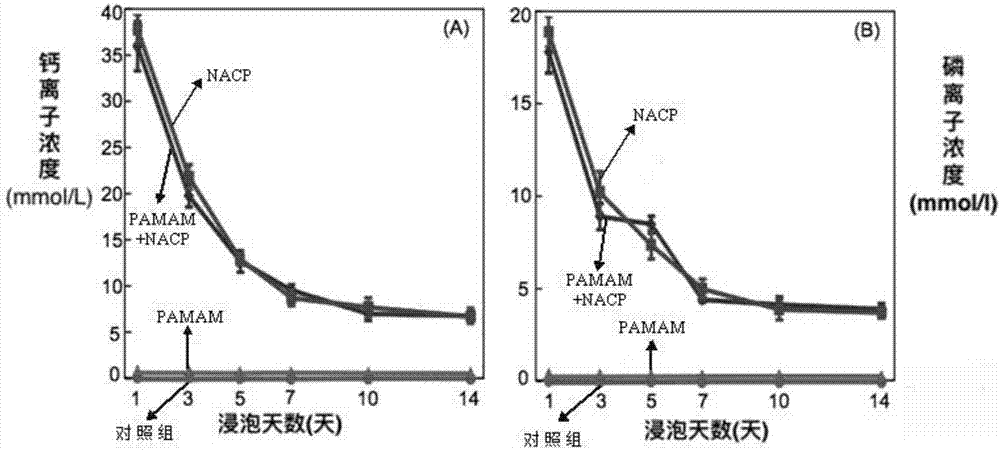

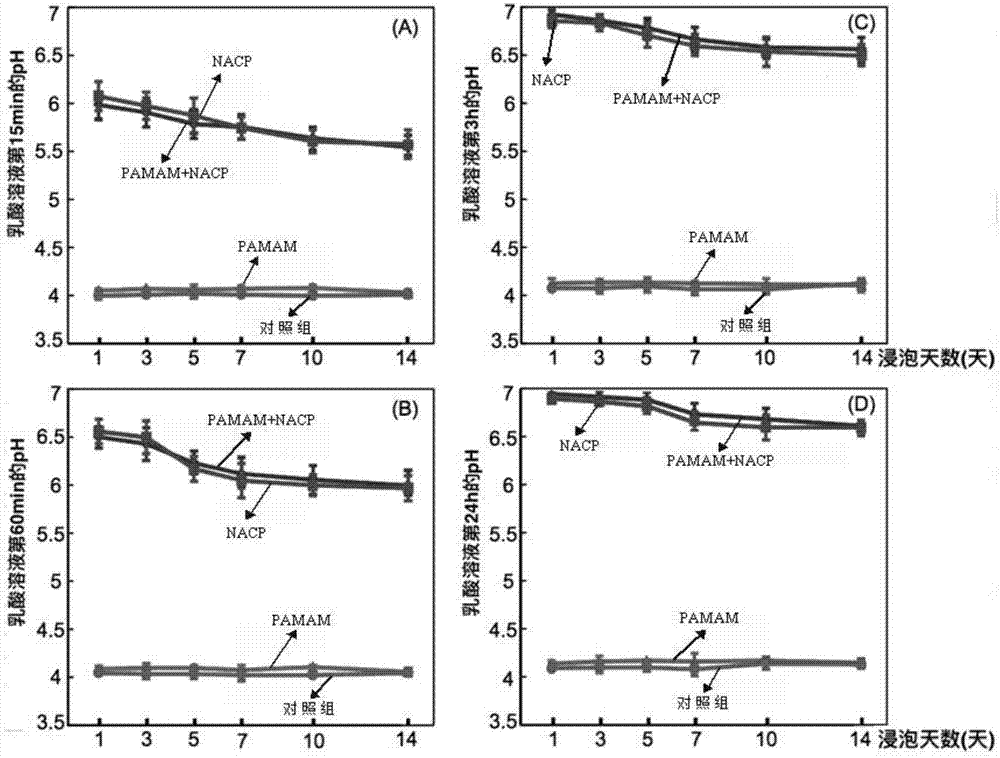

Binder used for simulating aptyalia pathological oral environment and application thereof

InactiveCN107028769AAchieve remineralizationGood adhesionImpression capsMedical preparations(Hydroxyethyl)methacrylateBisphenol A dimethacrylate

The invention discloses a binder used for simulating aptyalia pathological oral environment and an application thereof. The method for simulating aptyalia pathological oral environment is characterized in that lactic acid is added in a NaCl solution until the pH value of the solution is 4; the binder comprises the following components by mass percentage: 40% of amorphous calcium phosphate nanoparticles and 60% of PEHB; wherein the PEHB comprises the following components by weight percentage: 42% of phenyltriglycerol dimethyl acrylate, 42% of ethoxy bisphenol A dimethacrylate, 1% of phenyl di(2,4,6-trimethylbenzoyldiphenyl) phosphorus oxide, 10% of hydroxyethyl methylacrylate, and 5% of bisphenol A glycidyl methacrylate. The binder can simultaneously perform bonding protection and inhibit caries development, can effectively realize the re-mineralization of demineralized dentine, can release the calcium and phosphor ions, neutralizes local acidic environment, can realize re-mineralization of acidic environment lacking of calcium and phosphor, and can be clinically used for preventing root caries of the elderly and rampant caries of extreme oligosialia patients.

Owner:SICHUAN UNIV

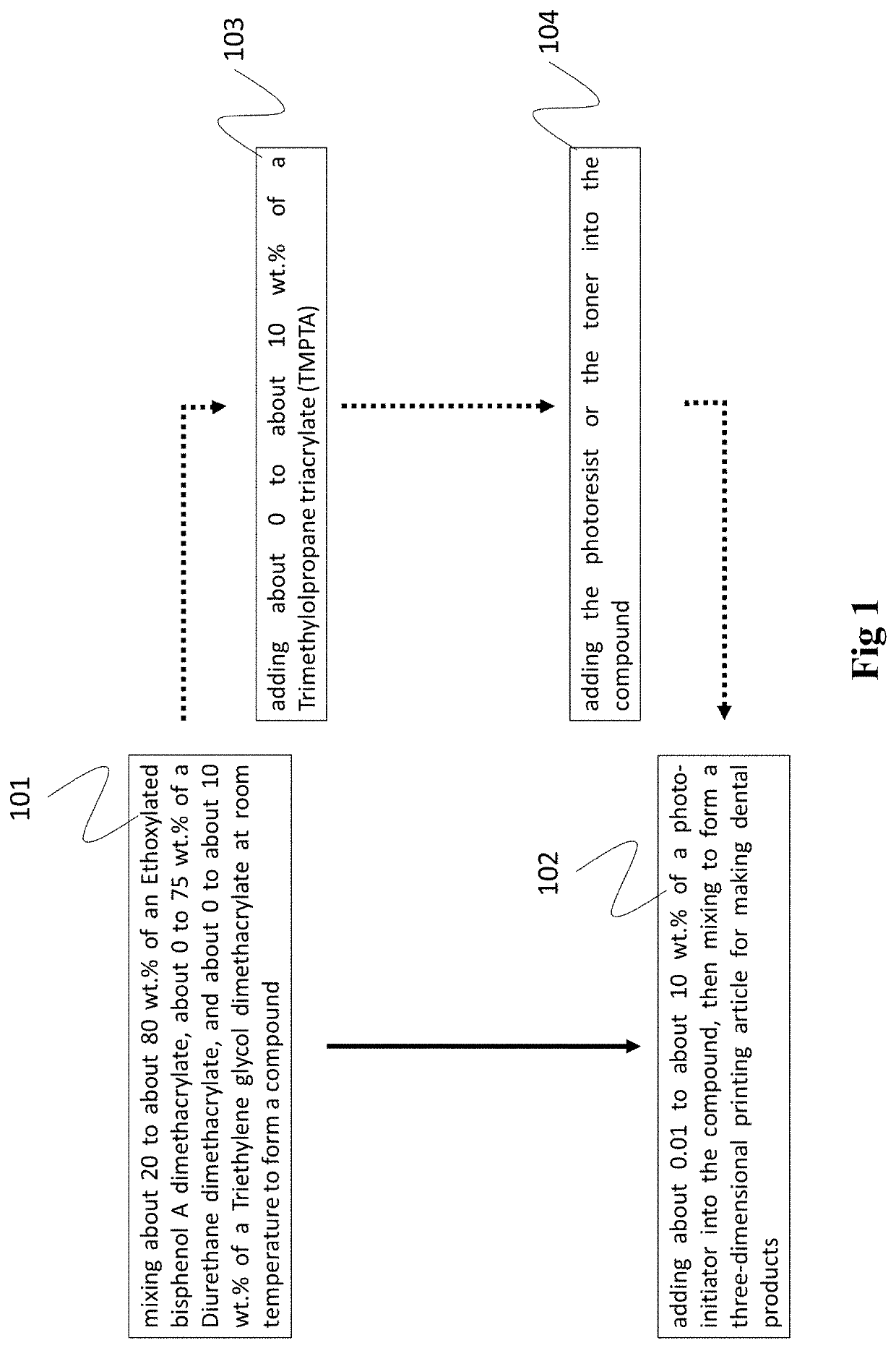

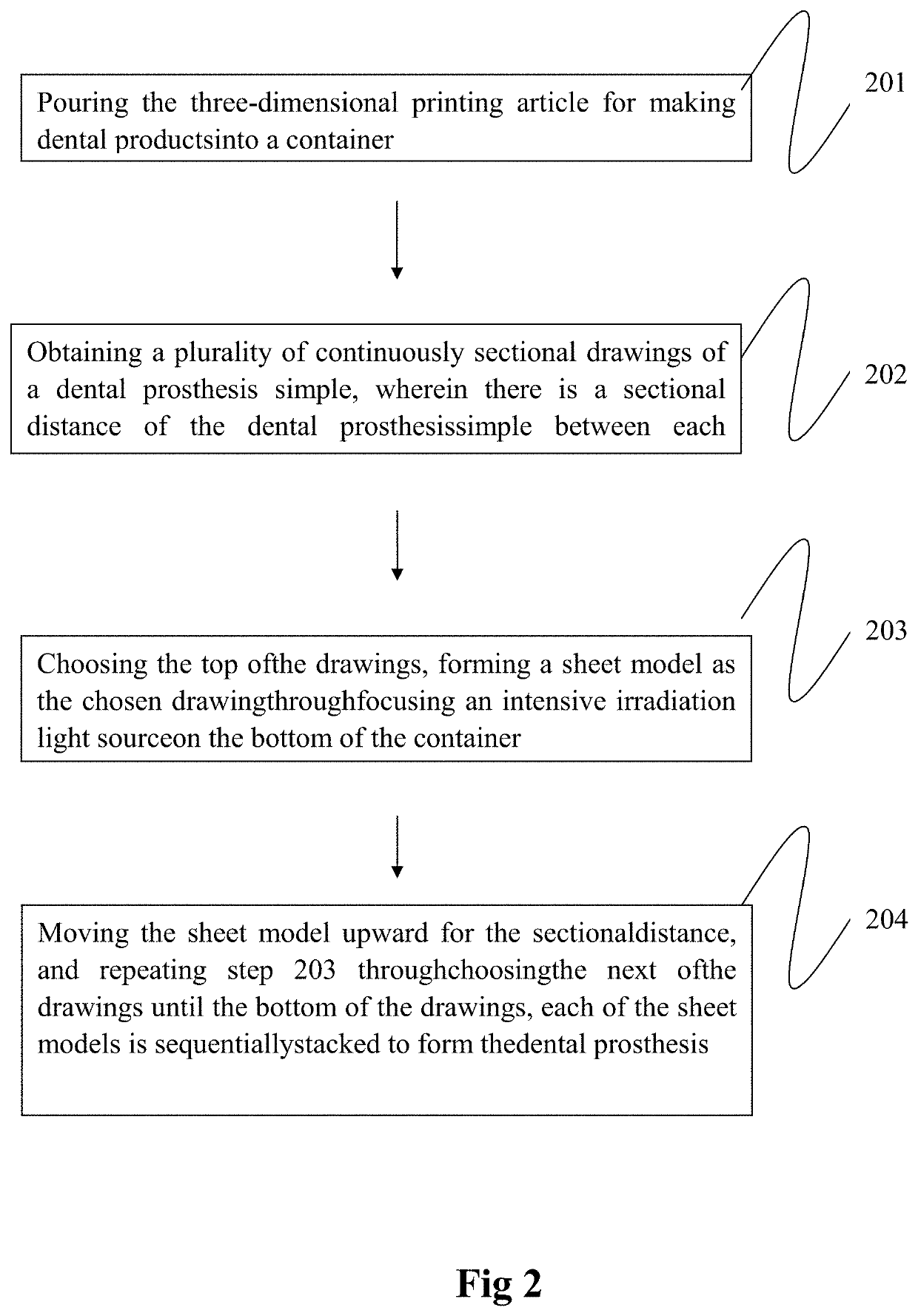

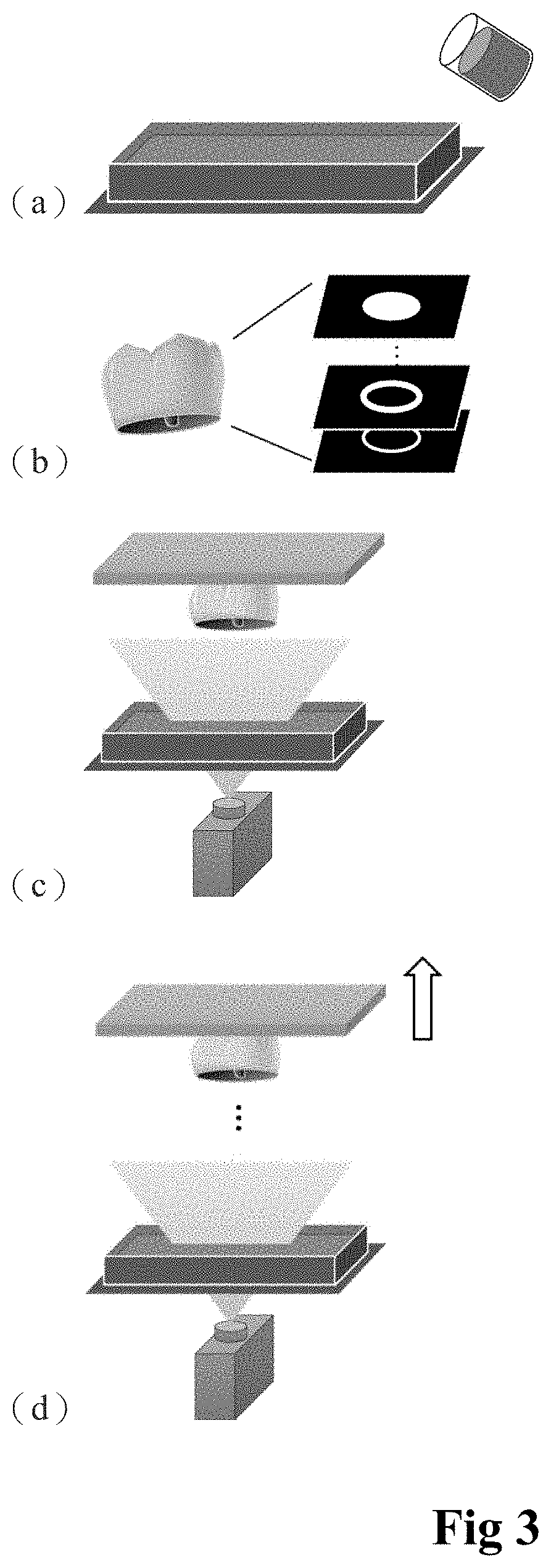

Three-dimensional printing methods and materials for making dental products

ActiveUS20180258290A1Low costGood biocompatibilityDevelopersCoatingsTriethyleneglycol dimethacrylateDental Product

Owner:NAT YANG MING CHIAO TUNG UNIV

High-flexibility and high-resolution photosensitive epoxy acrylic resin composition

The invention discloses a high-flexibility and high-resolution photosensitive epoxy acrylic resin composition. The composition mainly comprises 100 parts by weight of alkali-soluble photosensitive epoxy acrylic resin with an acid value of 60-150 mg KOH / g, 1-40 parts by weight of epoxy resin, 1-40 parts by weight of an acrylate monomer and 0.1-10 parts by weight of a photoinitiator and 0.5-2 partsby weight of a coloring agent, wherein the acrylate monomer comprises 1-10 parts by weight of a long-chain ethyoxyl bisphenol A dimethacrylate bifunctional monomer. The composition has excellent bending resistance, high resolution, acid and alkali resistance and tin soldering heat resistance.

Owner:HANGZHOU FIRST ELECTRONIC MATERIAL CO LTD

Photo-curable resin compositions and method of using the same in three-dimensional printing for manufacturing artificial teeth and denture base

ActiveUS10357435B2Suitable viscosity and curing rateEffective timeImpression capsAdditive manufacturing apparatusMeth-Oligomer

A composition includes a light-curable viscous mixture that includes: 0-50% by weight of a poly(methyl methacrylate) / methyl methacrylate solution; 5-20% by weight of at least one kind of multifunctional aliphatic (meth)acrylate; 5-40% by weight of at least one kind of aliphatic urethane (meth)acrylate oligomer; 25-65% by weight of at least one kind of difunctional bisphenol-A dimethacrylate; 0.1 to 5% by weight of at least one kind of a photoinitiator; 0.05 to 2% by weight of at least one kind of light stabilizer; and 0.1 to 3% by weight of color pigment based on the total weight of the composition.

Owner:DENTCA INC

Three-dimensional printing methods and materials for making dental products

The present invention provides a three-dimensional printing article for making dental products and the preparation method thereof, which comprises: Ethoxylated bisphenol A dimethacrylate, Diurethane dimethacrylate, Triethylene glycol dimethacrylate, and Diphenyl (2,4,6-trimethylbenzoyl) phosphine oxide. It not only improves the present time-consuming and labor-intensive dental device making, but also can be used in mass production of dental devices.

Owner:NAT YANG MING CHIAO TUNG UNIV

Acrylate pressure-sensitive adhesive, oriented polystyrene expansion adhesive tape as well as preparation method and application thereof

ActiveCN113403007AGood chemical resistanceImprove corrosion resistanceNon-macromolecular adhesive additivesEster polymer adhesivesPolymer scienceFunctional monomer

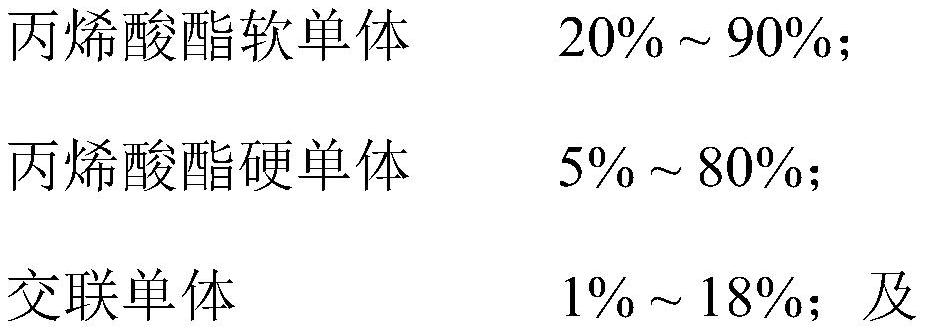

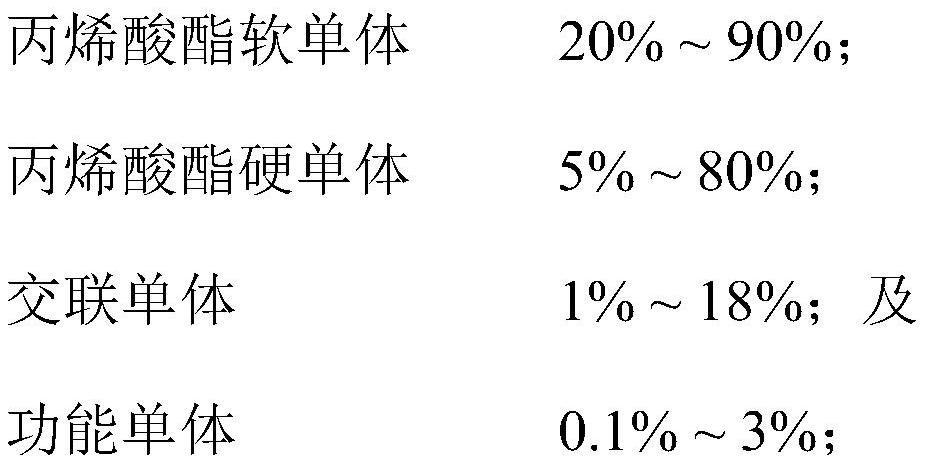

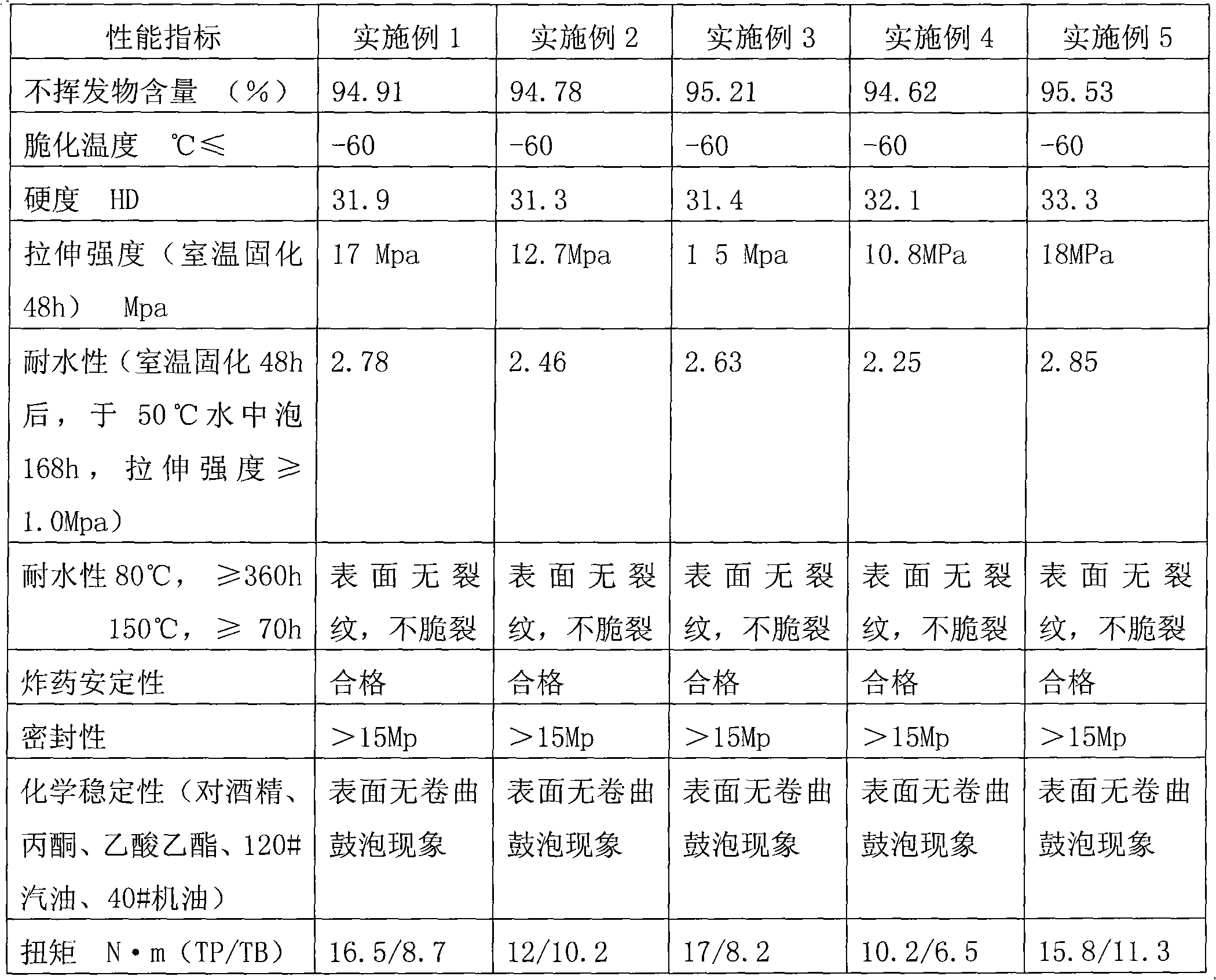

The invention provides an acrylate pressure-sensitive adhesive, an oriented polystyrene expansion adhesive tape as well as a preparation method and application thereof. The preparation monomers of the acrylate pressure-sensitive adhesive comprise the following components in percentage by mass: 20%-90% of acrylate soft monomer, 5%-80% of acrylate hard monomer, 1%-18% of crosslinking monomer and 0.1%-3% of functional monomer, wherein the functional monomer is selected from 3 (ethyoxyl) bisphenol A dimethacrylate, 2 (ethyoxyl) bisphenol A dimethacrylate and 4 (ethyoxyl) bisphenol A dimethacrylate; and the glass transition temperature of the acrylate pressure-sensitive adhesive is from -40 DEG C to -30 DEG C. By introducing a specific type of bisphenol A group-containing functional monomer into the pressure-sensitive adhesive and controlling the glass transition temperature of the pressure-sensitive adhesive, the acrylate pressure-sensitive adhesive has excellent chemical resistance, corrosion resistance, heat resistance and weather resistance, and is especially suitable for preparing the oriented polystyrene expansion adhesive tape.

Owner:广东宏昌新材料科技有限公司

Photocurable photochromic material and preparation method thereof

ActiveCN105670602BShorten production timeImprove impact resistanceTenebresent compositionsOptical partsPolymer scienceCrazing

Owner:JIANGSU MAAT OPTICAL CO LTD

Antibiotic light-cured eyeglass

InactiveCN106010158ALow costGood light transmissionPolyester coatingsBisphenol A dimethacrylateBamboo charcoal

The invention relates to the field of photocuring, in particular to an antibacterial photocuring lens, the raw materials of which are calculated in parts by weight: 10-20 parts of methacrylate stearate, 70-90 parts of bisphenol A dimethacrylate, rosin 10-20 parts of base hyperbranched polyester acrylate resin, 1-3 parts of nano-bamboo charcoal fiber, 3-10 parts of nano-titanium dioxide, 3-8 parts of photoinitiator, 3-10 parts of auxiliary agent, low cost, environmental protection, and The manufactured lens has good light transmission performance, good antibacterial and antibacterial effect, and has certain self-cleaning property.

Owner:CHENGDU NASHUO TECH

Sealing adhesive and preparation method thereof

InactiveCN101914348AMeet higher quality requirementsImprove toughnessOther chemical processesOrganic non-macromolecular adhesiveEpoxyTemperature resistance

The invention provides a sealing adhesive and a preparation method thereof. The sealing adhesive is prepared from in parts by weight: 20-40 parts of ethoxylated bisphenol A dimethacrylate, 5-20 parts of modified E-44 epoxy resin, 0.2-5 parts of lauryl acrylate, 30-60 parts of triethylene glycol dimethacrylate, 1-5 parts of initiator, 0.001-0.05 part of stabilizing agent, 0.5-4 parts of accelerator, 0.02-5 parts of secondary accelerator, 0.05-1.5 parts of metal chelating agent and 4-6 parts of filler. The preparation method comprises the following steps of: except the accelerator, mixing other raw materials and heating to raise the temperature; stirring at the temperature of 55-70DEG C for 3-5 hours to completely dissolve the solid; and then cooling to reduce the temperature, adding the accelerator at the temperature of 40-50DEG C and uniformly stirring to obtain the sealing adhesive. The sealing adhesive maintains all advantages of acrylate resin adhesives and remarkably improves the toughness, the torque value, medium resistance and low temperature resistance.

Owner:陈玉梅

Preparation method of liquid for absorbing blue light of LED light source and low-blue-light LED lamp

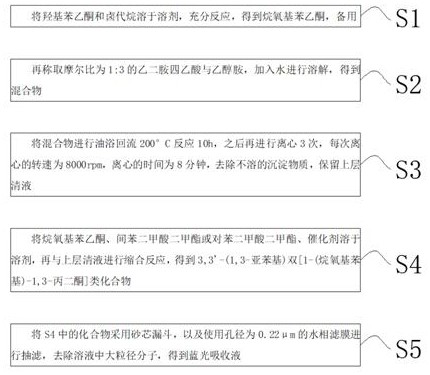

PendingCN113603834APromote absorptionFunction increaseOrganic compound preparationCarbonyl compound preparationMeth-Polyethylene glycol

The invention discloses a liquid for absorbing blue light of an LED light source in the technical field of preparation of blue light absorbing liquids. The liquid is prepared from the following raw materials in parts by mass: 30-60 parts of matrix resin, 15-20 parts of ethoxylated bisphenol A dimethacrylate, 8-15 parts of polyethylene glycol dimethacrylate, 6-12 parts of trimethylolpropane trimethacrylate, 2-7 parts of a light stabilizer, 1-3 parts of an antioxidant, 1.5-4.5 parts of an ultraviolet light absorber and 0.5-1 part of polymethyl methacrylate. The ultraviolet-blue light absorbing material product prepared by the preparation method disclosed by the invention has a good function of absorbing ultraviolet light (300-400nm) and blue light (400-475nm). The carbon dots are simple to synthesize, the cost is low, and the product is environment-friendly. The product is stable in optical property and rich in organic groups on the surface, can be well dispersed in polymethyl methacrylate, reduces the use amount of an initiator in the polymerization reaction process of methyl methacrylate, and also can absorb blue light in a certain range.

Owner:深圳市辉灿科技有限公司

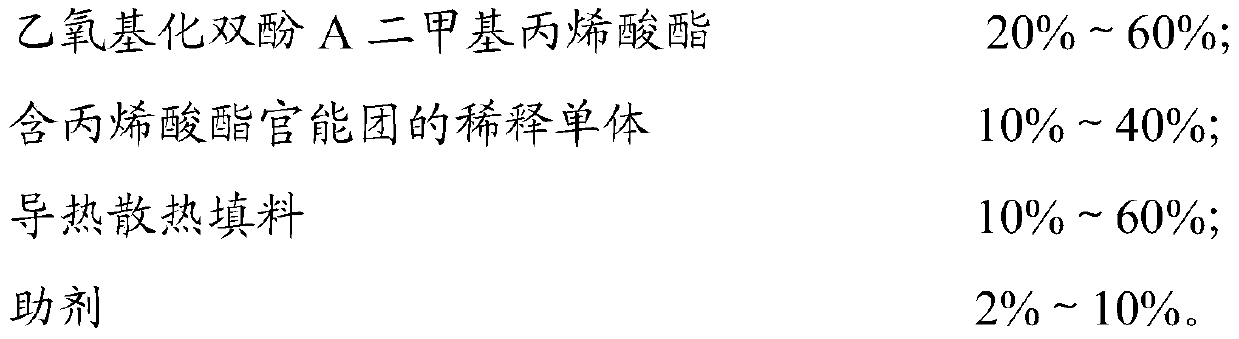

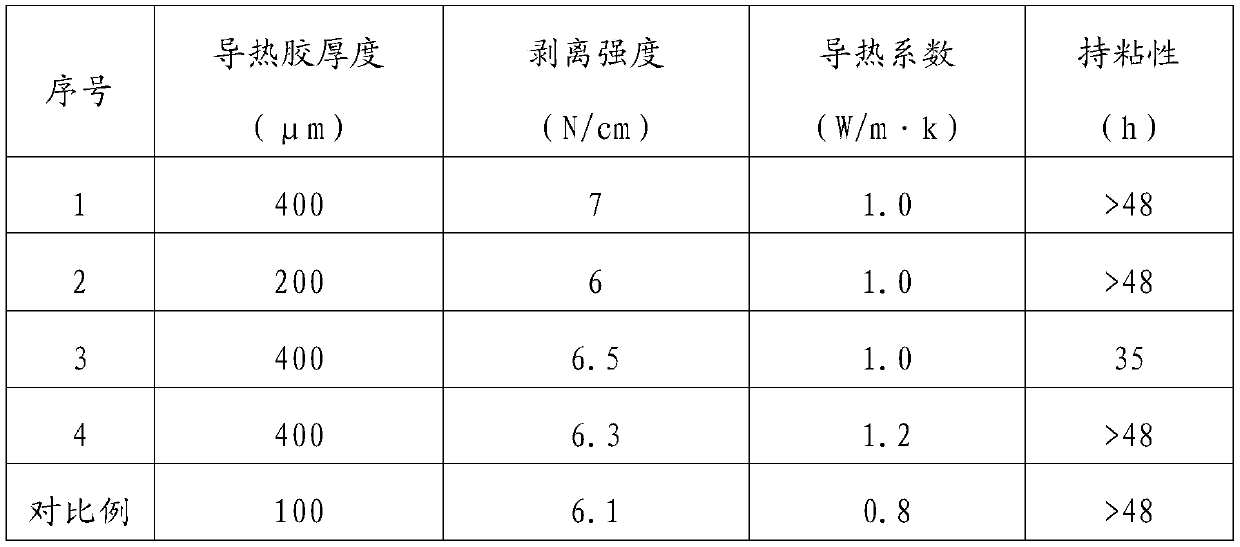

Heat-conductive double-sided adhesive based on EB curing and preparation method thereof

InactiveCN110396373AImprove adhesionImprove thermal conductivityNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveAdhesiveBisphenol A dimethacrylate

The invention relates to a heat-conductive double-sided adhesive based on EB curing. The heat-conductive double-sided adhesive is prepared from the following main components in percentages by mass: 20% to 60% of ethoxylated bisphenol A dimethacrylate, 10% to 40% of a diluted monomer containing an acrylate functional group, 10% to 60% of a heat-conductive and heat-dissipating filling material and 2% to 10% of an auxiliary agent. According to the invention, a VOC-free heat-conductive double-sided adhesive component is designed and can be cured by an EB curing process; by application of the EB curing process, low cost, environmental friendliness, rapid speed and high productivity are achieved; meanwhile, the heat-conductive double-sided adhesive prepared by using the method provided by the invention has excellent adhesiveness and heat conductivity.

Owner:CGN DASHENG ELECTRON ACCELERATOR TECH

Monomer for dental compositions

Owner:UNIVERSITY OF KANSAS

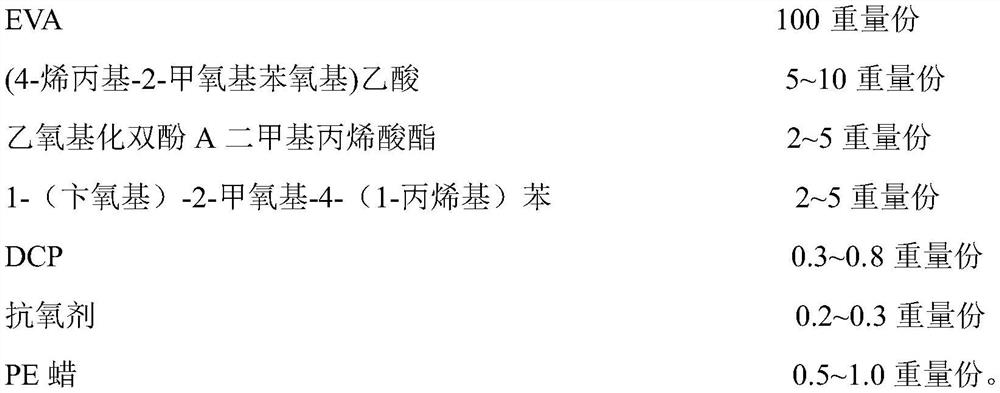

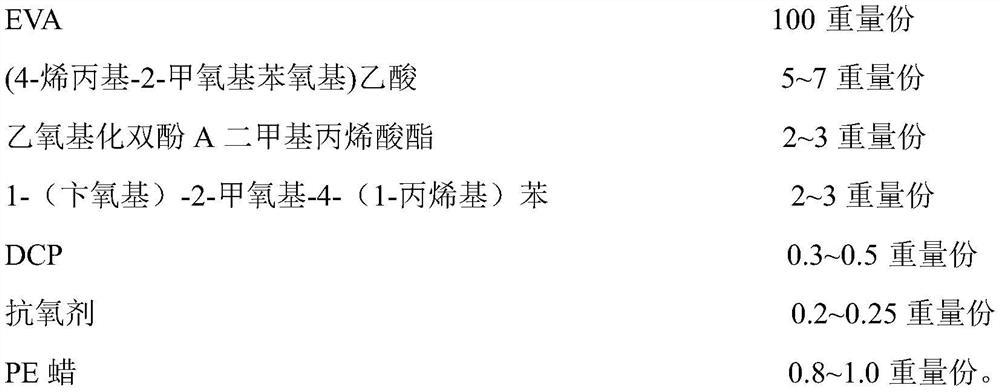

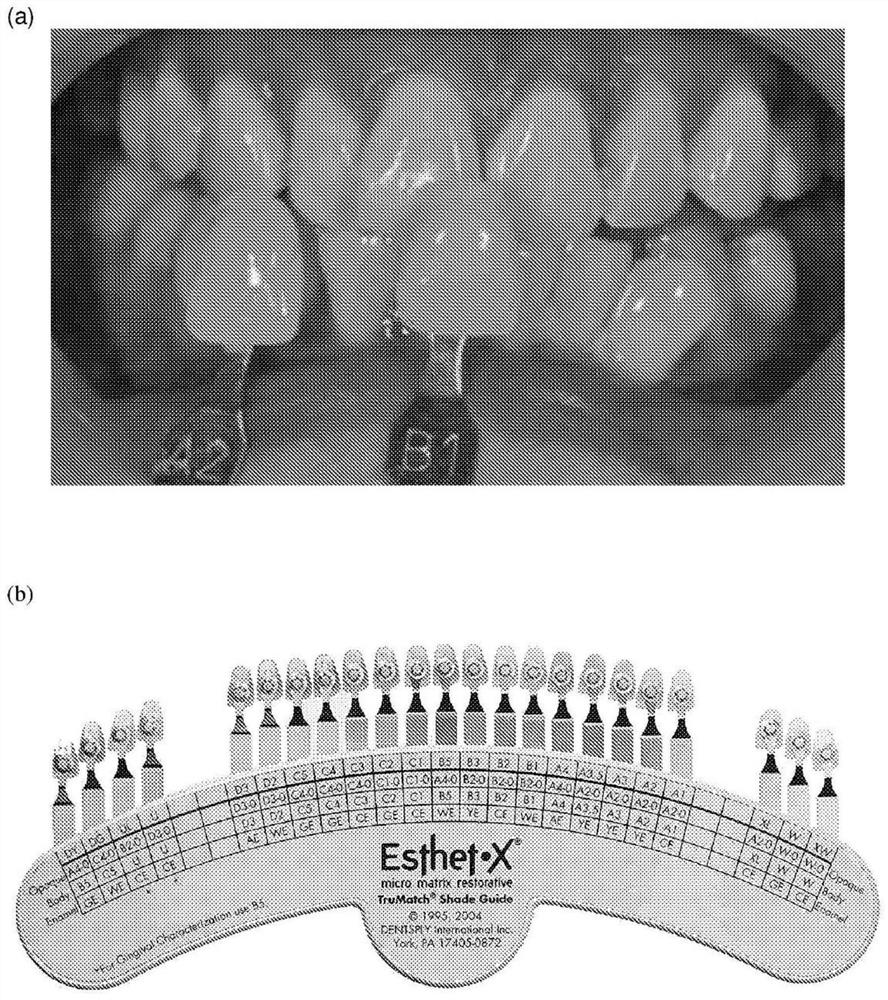

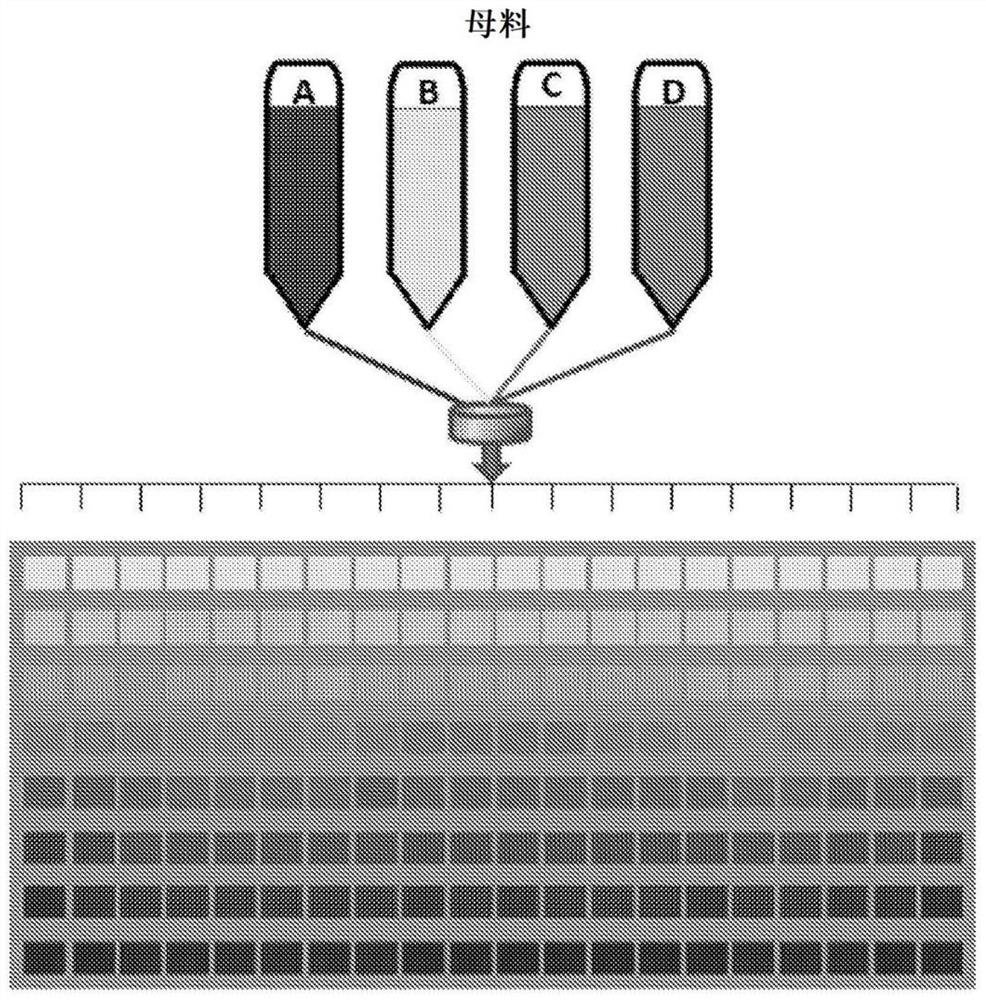

Hard PVC plastic high-impact modifier and preparation method thereof

The invention discloses a hard PVC plastic high-impact modifier which is prepared from the following components in parts by weight: 100 parts of EVA, 5-10 parts of (4-allyl-2-methoxyphenoxy)acetic acid, 2-5 parts of ethoxylated bisphenol A dimethacrylate, 2-5 parts of 1-(benzyloxy)-2-methoxy-4-(1-propenyl)benzene, 0.3-0.8 part of DCP, 0.2-0.3 part of an antioxidant, and 0.5 to 1.0 part of PE wax.By adopting the modifier disclosed by the invention, the impact strength and toughness of the hard PVC material are greatly improved, and other properties such as rigidity and the like of hard PVC areimproved to a certain extent, so that the modifier is an efficient and high-impact-resistance modifier for hard PVC plastics.

Owner:JIANGSU BAOYUAN GAOXIN ELECTRIC

A method of making dental articles

Owner:AGENCY FOR SCI TECH & RES

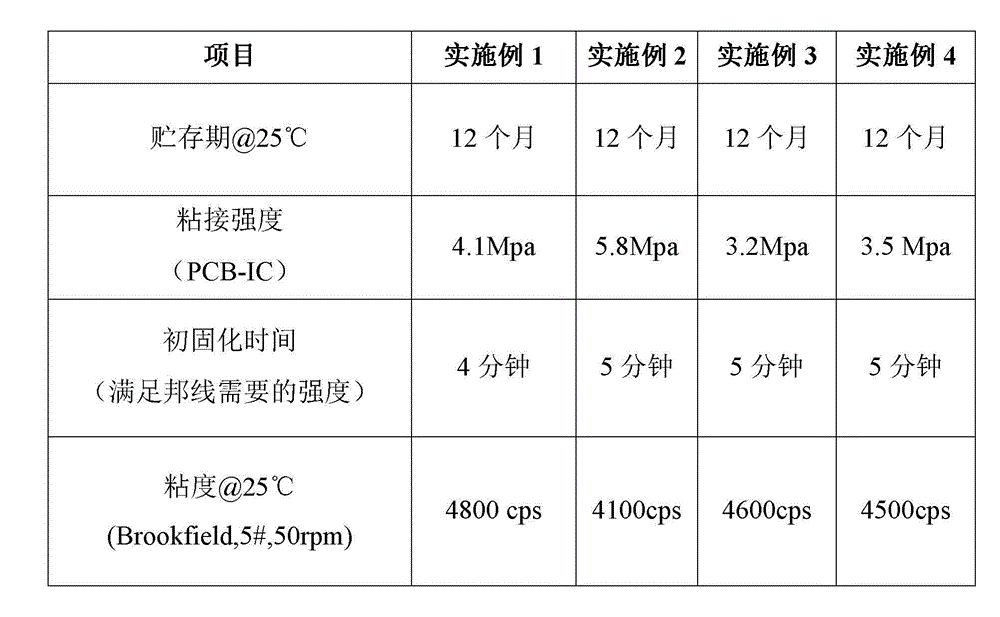

Drying-out-free type die bonding glue and preparation method thereof

ActiveCN102863910BStable storageExtended shelf lifeOrganic non-macromolecular adhesiveSaccharinBisphenol A dimethacrylate

Owner:NICHE TECH KAISER SHANTOU

A kind of visible light curing adhesive and preparation method thereof

ActiveCN103740286BLiquidLiquidityNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveGlycidyl methacrylateAdhesive

The invention provides a visible-light-cured adhesive including the following components: by weight, 20-50% of methacrylate monomer, 10-30% of a methacrylate diluent, less than 5% of a visible light initiator, 30-68% of silica, glass powder or alumina powder and 0.1-5% of nano fumed silica, the methacrylate monomer is at least one substance from bisphenol A-glycidyl dimethacrylate, ethoxylated bisphenol A dimethacrylate, pentaerythritol tetraacrylate, dipentaerythritol pentaacrylate and dipentaerythritol hexaacrylate, and the invention also provides a preparation method of the visible-light-cured adhesive. The visible-light-cured adhesive is low in mobility, short in curing time, highin bonding strength, and suitable for industrial application.

Owner:BEIJING POLYSTAR HITECH CO LTD

Anti-icing artificial turf and production method thereof

InactiveCN106366732AWater repellentImprove waterproof performanceAntifouling/underwater paintsOther chemical processesAziridineCarvacryl acetate

The invention discloses an anti-icing artificial turf. Anti-icing attached emulsion is sprayed to grasses and comprises 4-methyl cyclohexyl isocyanate, ethyl carbamate, alpha-linolenic acid, bisphenol ethoxide A dimethacrylate, trimethylolpropane triacrylate, benzoyl peroxide, butyl acrylate, 2-hydroxy-1, 2-diphenylethanone, vinyl acetate, antimony doped tin oxide nanocrystal, nanometer titania, nanometer silicon carbide, pentaerythritol tri-(3-aziridine)-propionate, ethylene-vinyl acetate, polyoxyethylene alcohol ether, dimethyl silicone polymer, polyether modified silicone, cosolvents, adhesion promoters and organic fluorine waterproof agents. The anti-icing artificial turf has excellent water repellency and waterproof, anti-freezing and anti-icing performances, and still keeps excellent performances when in use in rainy cold environments.

Owner:江蘇聯創人造草坪股ふん有限公司

Wearproof photocuring lens

InactiveCN105820723ALow costGood light transmissionPolyester coatingsHyperbranched polyesterAging resistance

The invention relates to the field of photocuring, in particular to a wear-resistant photocuring lens. The raw materials are: 10-20 parts of laurate methacrylate, 70-90 parts of bisphenol A dimethacrylate, rosin 10-20 parts of base hyperbranched polyester acrylate resin, 1-3 parts of graphene, 3-8 parts of photoinitiator, 3-10 parts of auxiliary agent, low cost, environmental protection, and the lens produced has good light transmission performance , Excellent wear resistance and anti-aging performance.

Owner:CHENGDU NASHUO TECH

OCA (optically clear adhesive) acoustic film and preparation method thereof

The invention provides an OCA (optically clear adhesive) acoustic film which is prepared from the following raw materials: a modified OCA adhesive emulsion, polylactic acid, an antioxidant and a coupling agent A, wherein the modified OCA adhesive emulsion is prepared from the following raw materials: acrylic acid, an acrylate adhesive, polyurethane acrylate oligomer, bisphenol A dimethacrylate, adefoaming agent, a cross-linking curing agent, nano aluminum trioxide, polyformaldehyde and a compound coupling agent B. The acoustic film prepared by a method provided by the invention has a smooth and stable surface, the ratio of of diameters to thicknesses is large, very good acoustic characteristics are achieved very good responsiveness within an acoustic frequency range of 0.025-25000Hz is achieved, the sensitivity is up to 55-110mv / pa, and the static pressure sensitivity is up to 7[mu] m / pa.

Owner:兰飞

Anti-icing artificial turf and construction method of artificial turf

PendingCN114232412ACapable of anti-icingWon't slipLiquid surface applicatorsPaving detailsVinyl etherYarn

The invention discloses an anti-icing artificial turf and a construction method of the artificial turf, and relates to the technical field of artificial turfs, the anti-icing artificial turf comprises grass filaments and base cloth, an anti-icing coating is uniformly attached to the outer surface of the grass filaments, and the anti-icing coating is prepared from a base material, an anti-icing additive and an adhesion promoter according to a certain component proportion. According to the anti-icing artificial turf disclosed by the invention, the grass yarns, the base cloth and the anti-icing coating are matched, firstly, the grass yarns are subjected to one-time injection molding through an injection molding machine, then the grass yarns and the base cloth are bonded through strong glue, and then a layer of anti-icing coating material is attached to the outer surfaces of the grass yarns, so that the artificial turf has the anti-icing capability; under the action of an anti-icing additive tetrafluoroethylene-perfluoroalkyl vinyl ether copolymer, acrylic polysiloxane and ethoxylated bisphenol A dimethacrylate, dew is difficult to attach to the outer surface of the grass yarn, and the problem that the dew is condensed into ice at a low temperature and is attached to the outer surface of the grass yarn is avoided.

Owner:江苏易华人造草坪有限公司

Preparation method and application of composite film based on ptfe and polyester for anti-ice coating of wind power blades

ActiveCN106313812BConvenient engineering constructionSolving non-adhesive technical problemsNon-macromolecular adhesive additivesSynthetic resin layered productsPolyesterAdhesive cement

The invention discloses a preparation method and application of a PTFE and polyester-based composite film for preventing wind turbine blades from icing. The method includes the steps that a bonding composite agent is adopted for lamination complexing, an interface adhesive is applied, and a pressure-sensitive adhesive is adopted for photo-initiated pressure-sensitive adhesive application. The bonding complexing agent is prepared from 3-isocyanatomethyl-3,5,5-trimethylcyclohexyl isocyanate, vinyl acetate, ethyl carbamate, alpha-linolenic acid, benzoyl peroxide and (4)ethoxylated bisphenol A dimethacrylate; the photo-initiated pressure-sensitive adhesive is prepared from a poly[butyl acrylate-glycidyl methacrylate-n-butoxy methacrylamide]copolymer, butyl acrylate, (4)ethoxylated bisphenol A dimethacrylate, 4,4'-bis(diethylamino)benzophenone and dimethylformamide. The method and the composite film solve the non-adhesion technical problem that a PTFE film can not be pasted on the surfaces of wind turbine blades with an adhesive directly, the bonding peel strength is improved, and the composite film is suitable for wind turbine blades of various models.

Owner:NANJING HAOHUI HI TECH CO LTD

Special adhesive for optical film

InactiveCN113388329AImprove mechanical propertiesImprove anti-sheddingNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceMeth-

The invention discloses a special adhesive for an optical film, and belongs to the technical field of optical adhesive film materials. The special adhesive for the optical film is prepared from the following components in parts by weight: 30 to 60 parts of o-phenyl phenoxyethyl acrylate, 20 to 40 parts of ethoxylated bisphenol A dimethacrylate, 1 to 5 parts of an initiator, 1 to 10 parts of an organic silicon additive, 5 to 10 parts of tetrahydrofurfuryl alcohol acrylate, 5 to 10 parts of trihydroxymethyl cyclohexyl acrylate, 0 to 10 parts of bisphenol fluorene acrylate, and 0 to 10 parts of a modifier. The special adhesive for the optical film has the advantages of very high light transmittance, strong adhesive force, high peel strength, excellent mechanical property and excellent anti-falling performance.

Owner:广西向东电子科技有限公司

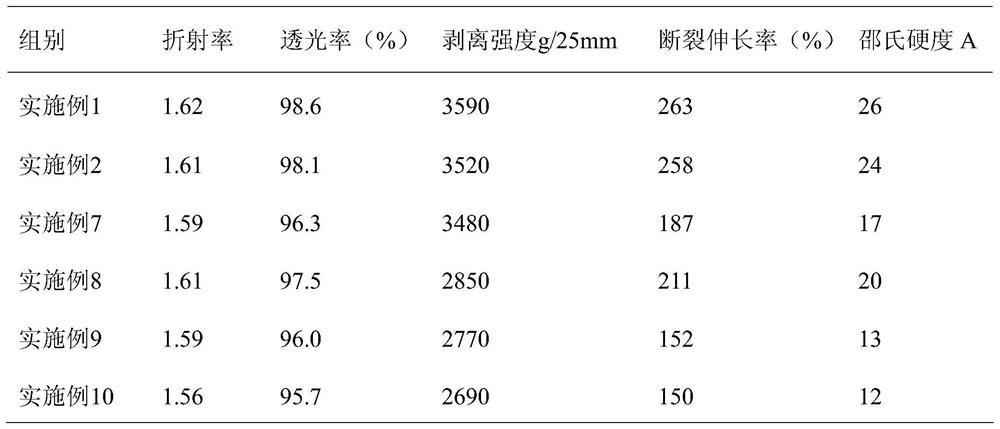

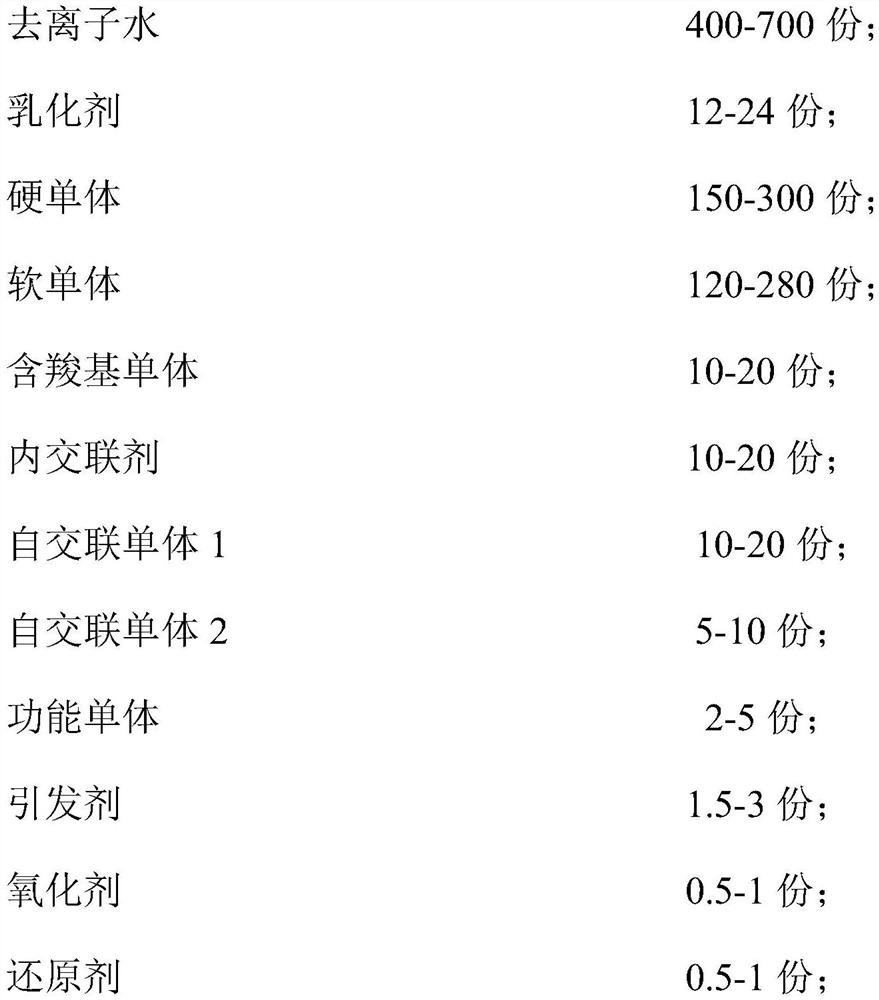

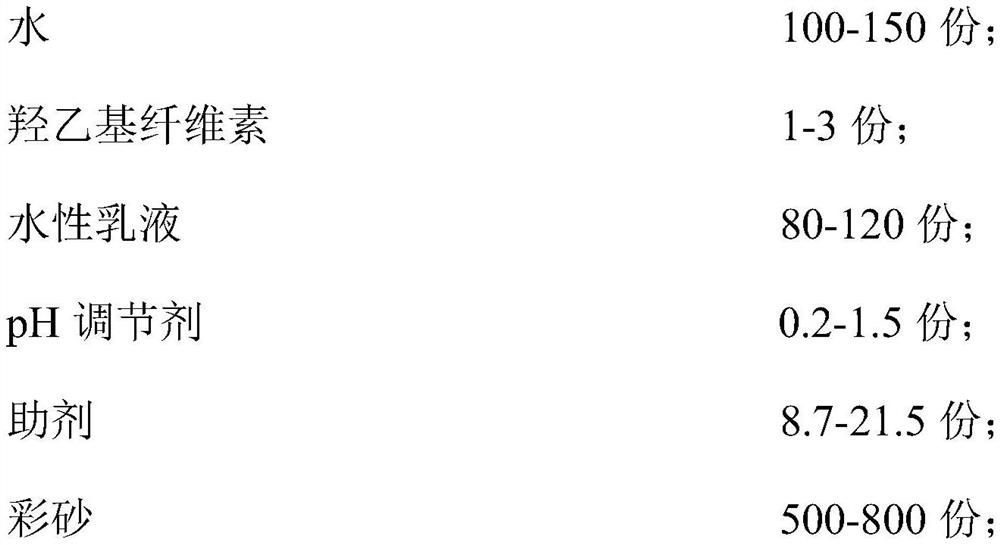

Water-based emulsion, preparation method thereof and temperature-change-resistant construction real stone paint prepared from water-based emulsion

The invention provides a water-based emulsion, a preparation method of the water-based emulsion and a temperature-change-resistant construction real stone paint prepared from the water-based emulsion, and the water-based emulsion is prepared from the following raw materials in parts by weight: 400-700 parts of deionized water; 12 to 24 parts of an emulsifier; 150 to 300 parts of a hard monomer; 120 to 280 parts of a soft monomer; 10-20 parts of a carboxyl group-containing monomer; 10 to 20 parts of an inner cross-linking agent; 110 to 20 parts of a self-crosslinking monomer; 25 to 10 parts of a self-crosslinking monomer; 2-5 parts of a functional monomer; 1.5 to 3 parts of an initiator; 0.5-1 part of an oxidizing agent; 0.5-1 part of a reducing agent; the internal cross-linking agent comprises ethoxylated bisphenol A dimethacrylate; wherein the self-crosslinking monomer 1 comprises acetoacetic acid ethyl methacrylate, and the self-crosslinking monomer 2 comprises adipic acid dihydrazide. The water-based emulsion disclosed by the invention has a relatively high drying speed, and can be used for reducing the chromatic aberration of the dried real stone paint when being used for the real stone paint.

Owner:ASIA PAINT SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com