A method of making dental articles

A technology for products and teeth, applied in the field of dental product manufacturing, can solve problems such as limited efforts

- Summary

- Abstract

- Description

- Claims

- Application Information

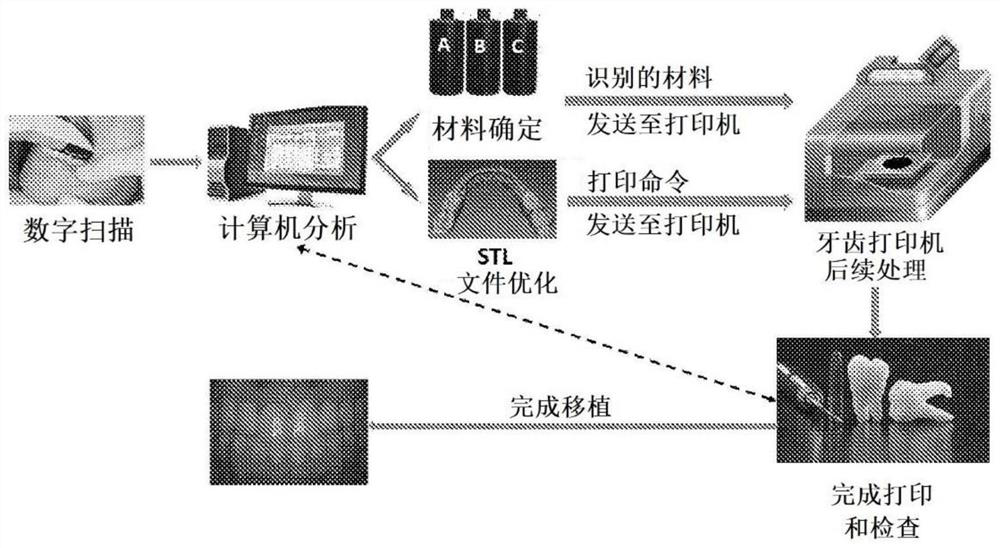

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

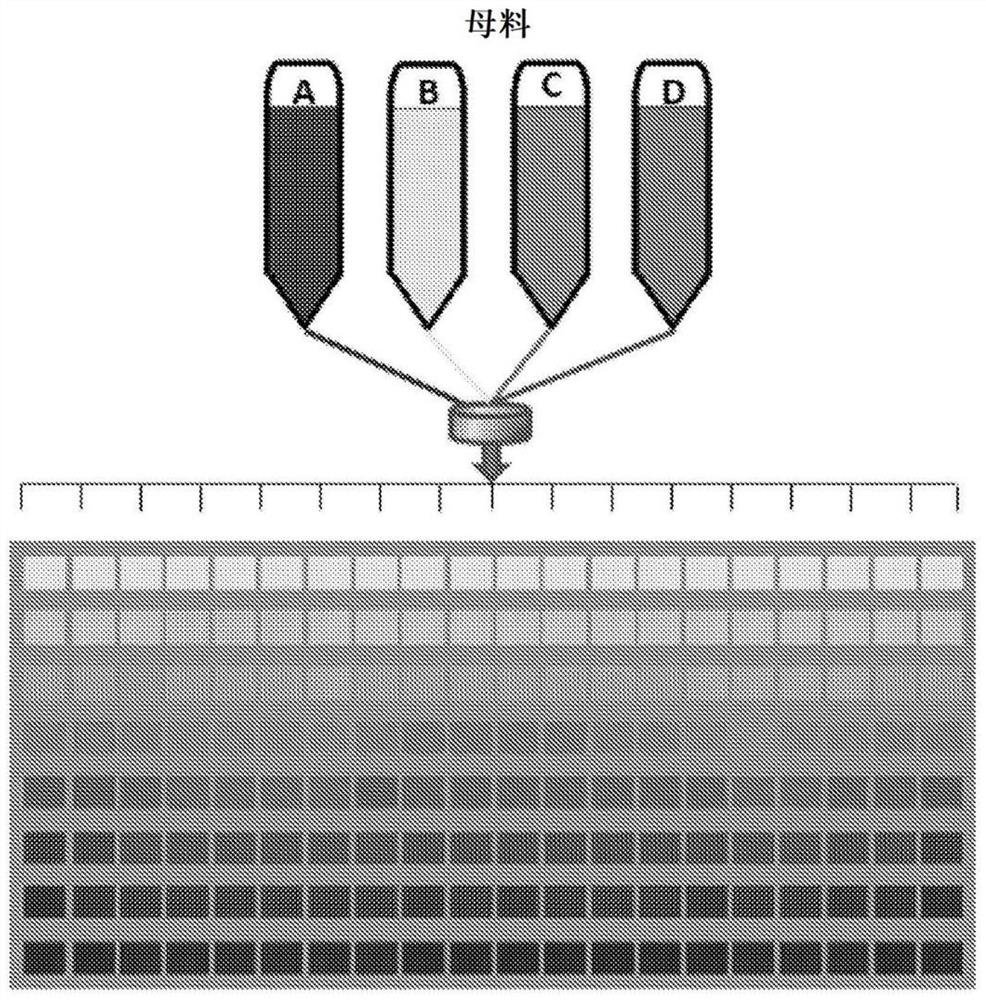

[0095] Example 1 - Masterbatch Resin Preparation

[0096] The formulations of Masterbatch Resins A, B, C and D are shown in Tables 1-4. To prepare Masterbatch Resin A, measure all components listed in Table 1 into a flask and stir in the dark for 8-24 hours until all solid contents dissolve and reach a homogeneous state. Masterbatch resins B, C and D were similarly prepared according to the compositions shown in Tables 2-4, respectively.

[0097] Table 1. Integration of Masterbatch Resin A

[0098] Element Percentage (weight%) bisphenol A dimethacrylate 50 polyethylene glycol diacrylate 30 Tetrahydrofuryl methacrylate 4 Silica (200nm particle size) 15 Phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide 0.8 2,5-bis(5-tert-butyl-benzoxazol-2-yl)thiophene 0.2

[0099] Table 2. Integration of Masterbatch Resin B

[0100] Element Percentage (weight%) bisphenol A dimethacrylate 50 polyethylene glycol diacryla...

Embodiment 2

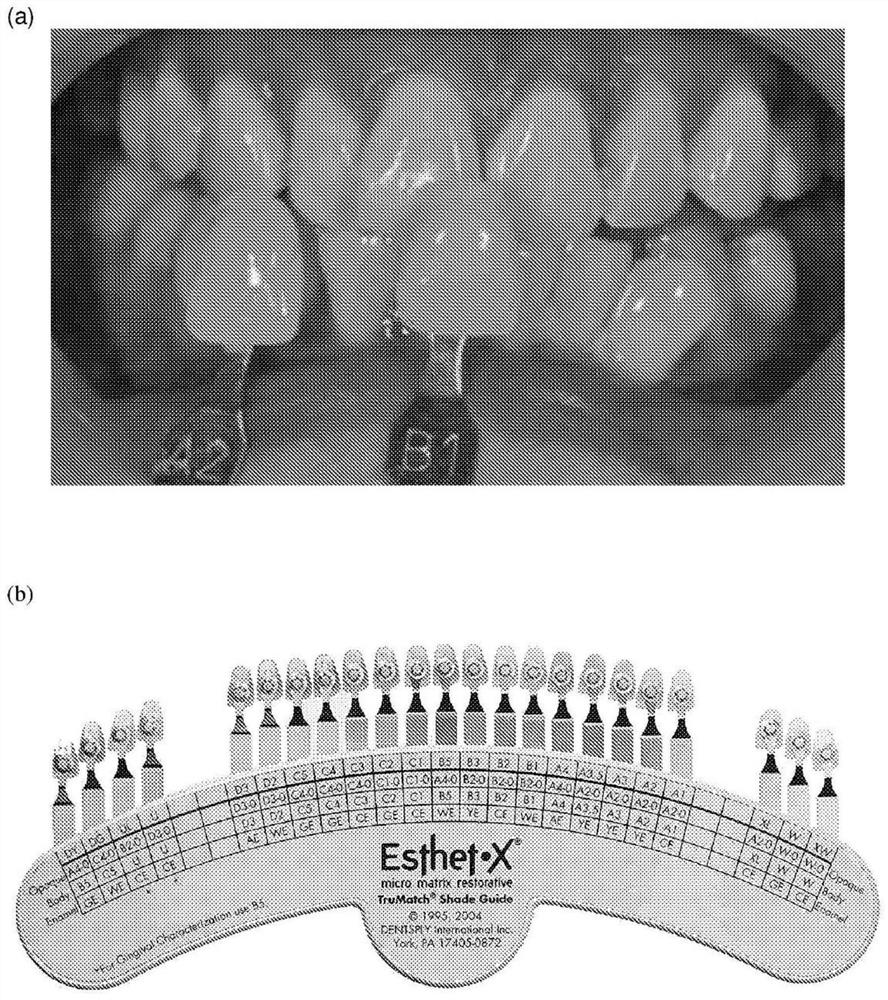

[0106] Example 2-36 Color array preparation

[0107] Mix masterbatch resins A, B and C from Example 1 in the proportions shown in Table 5 to construct Figure 5 The 36-color array shown. For example, test article 001 was prepared by mixing 20 grams of Resin A and 20 grams of Resin C in a bottle and stirring at room temperature for 2 hours until a homogeneous mixture was obtained. Other test products from 002 to 036 were similarly prepared according to the compositions shown in Table 5, respectively.

[0108] Table 5. Composition of color points on the 36-color array (mixing ratio)

[0109]

[0110]

[0111]

Embodiment 3

[0112] Example 3 - Color Calculation

[0113] Step 1: Measure the spectral reflectance S(λ) or transmittance of the target sample with a UV-Vis spectrometer, and calculate the X, Y and Z color coordinate values.

[0114] XYZ color coordinates are calculated according to the following formula:

[0115]

[0116]

[0117]

[0118]

[0119] where x - 、y - and z - is has such Figure 7 (a) CIE standard observation function for the function shown;

[0120] where I(λ) is the Figure 7 (b) Spectral power distribution of the CIE standard reference illuminant (D65 in this case) for the function shown. Integrals are calculated over the visible spectrum (390 nm to 830 nm).

[0121] Step 2: Convert the calculated X, Y and Z values into L* according to the following formula 1 、a* 1 and b* 1 value:

[0122]

[0123]

[0124]

[0125] in

[0126]

[0127]

[0128] Here, X n , Y n and Z n is the CIE XYZ tristimulus value referenced to the white point (th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com