Acrylate pressure-sensitive adhesive, oriented polystyrene expansion adhesive tape as well as preparation method and application thereof

A technology of acrylate and dimethacrylate, which is used in oriented polystyrene expanded tape and its preparation, and in the field of acrylate pressure-sensitive adhesive, can solve the problem of unstable viscosity, inability to meet the use environment of electrolyte resistance, and unfavorable stable operation of batteries And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

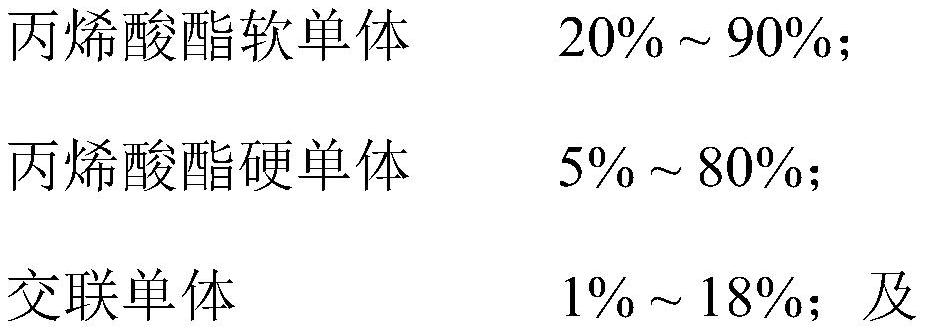

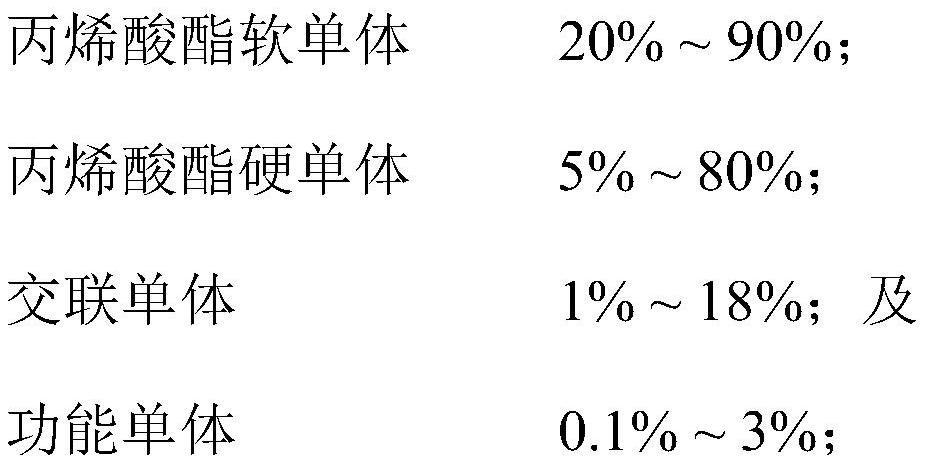

[0026] The preparation monomer of the above-mentioned acrylate pressure sensitive adhesive includes a specific content of acrylate soft monomer, acrylate hard monomer, crosslinking monomer and functional monomer, and the functional monomer is selected from 3 (ethoxy) bisphenol A At least one of dimethacrylate, 2 (ethoxy) bisphenol A dimethacrylate, and 4 (ethoxy) bisphenol A dimethacrylate. By introducing 0.1wt% to 3wt% of the prepared monomer into the pressure-sensitive adhesive, a specific type of functional monomer containing bisphenol A group has good compatibility with acrylate prepolymers, and by polymerizing The reaction types bisphenol A functional groups into the polymer backbone of acrylate pressure-sensitive adhesives, giving acrylate pressure-sensitive adhesives excellent chemical resistance, corrosion resistance, heat resistance and weather resistance, and controlling glass transition temperature At -40℃~-30℃, the chemical resistance, corrosion resistance, heat re...

Embodiment 1

[0064] 1. To prepare the pressure-sensitive adhesive for oriented polystyrene expansion tape, the glass transition temperature of the formula in this example is Tg=-33.3°C, and each component is weighed according to the formula shown in Table 1:

[0065] The acrylate pressure sensitive adhesive component formula of table 1 embodiment 1

[0066]

[0067]

[0068] The acrylate pressure-sensitive adhesive of the present embodiment is prepared according to the following steps:

[0069] 1) respectively take by weighing each component according to the formula of table 1;

[0070] 2) nitrogen is passed into the reaction kettle to discharge air, then 80% of the solvent is added to the reaction kettle, and the temperature is raised to 78 ℃~80 ℃ reflux;

[0071] 3) adding the prepared monomer into the feeding kettle, then dissolving 80% of the initiator with 10% of the solvent and adding it to the feeding kettle, stirring evenly, to obtain the mixed prepolymerized monomer;

[00...

Embodiment 2

[0080] 1. To prepare the pressure-sensitive adhesive for oriented polystyrene expansion tape, the glass transition temperature of the formula in this example is Tg=-36.3°C, and each component is weighed according to the formula shown in Table 2:

[0081] The acrylate pressure sensitive adhesive component formula of table 2 embodiment 2

[0082]

[0083] The acrylate pressure-sensitive adhesive of the present embodiment is prepared according to the following steps:

[0084] 1) respectively take each component according to the formula of table 2;

[0085] 2) nitrogen is passed into the reaction kettle to discharge air, then 80% of the solvent is added to the reaction kettle, and the temperature is raised to 78 ℃~80 ℃ reflux;

[0086] 3) adding the prepared monomer into the feeding kettle, then dissolving 80% of the initiator with 10% of the solvent and adding it to the feeding kettle, stirring evenly, to obtain the mixed prepolymerized monomer;

[0087] 4) adding 20% of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com