Heat-conductive double-sided adhesive based on EB curing and preparation method thereof

A heat-conducting double-sided adhesive, double-sided technology, applied in the field of heat-conducting adhesives, to achieve the effect of fast speed, high production capacity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

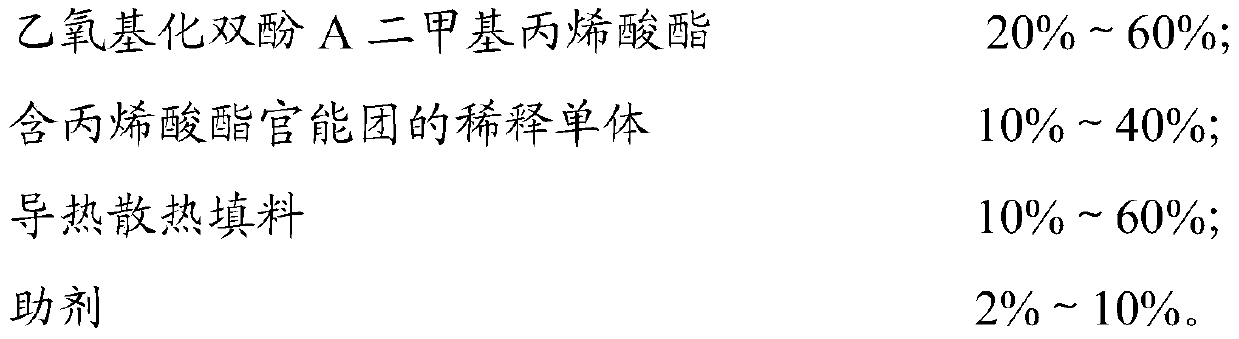

[0018] A method for preparing a thermally conductive double-sided adhesive based on EB curing, comprising the following steps: S1, fully ethoxylated bisphenol A dimethacrylate, diluting monomers containing acrylate functional groups, thermally conductive and heat-dissipating fillers and auxiliary agents After mixing evenly, grind to obtain EB cured thermally conductive glue; S2, apply the EB cured thermally conductive glue in step S1 to the PET double-sided release film, and place the coated PET double-sided release film in a nitrogen atmosphere Next, EB curing is carried out to obtain a thermally conductive double-sided adhesive. In this application, the ethoxylated bisphenol A dimethacrylate, diluting monomers containing acrylate functional groups, heat-conducting and heat-dissipating fillers and additives are fully mixed through a high-speed mixer, the speed of the high-speed mixer is ≥ 2500rpm, and the stirring time is 20min ~30min to obtain a uniformly stirred mixture, an...

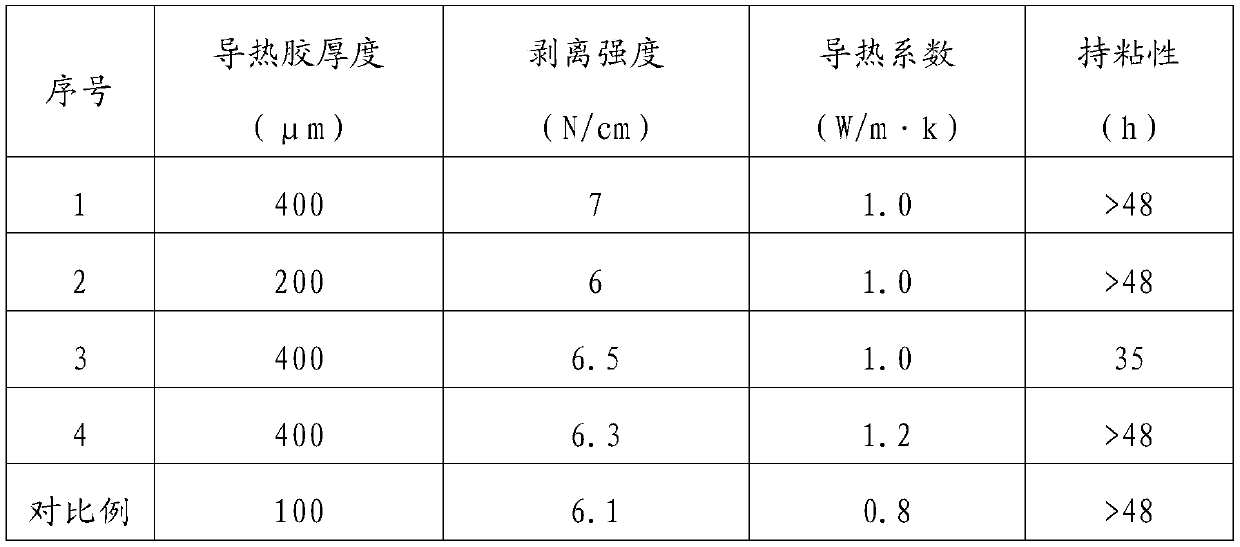

Embodiment 1

[0022] Preparation of EB curing thermally conductive glue: mix 15kg 8 ethoxylated bisphenol A dimethacrylates, 25kg 12 ethoxylated bisphenol A dimethacrylates, 15kg 2-phenoxyethyl acrylic acid Esters, 2kg cyclotrimethylolpropane cyclomethylal acrylate, 35kg alumina, 3kg dispersant BYK110, 1kg Degussa gas silicon A200 are put into the reaction vessel, and the high-speed mixer is used to fully stir and mix, and the stirring speed is ≥ 2500rpm, the stirring time is 20min to obtain a uniform mixture, and then use a sand mill to grind the homogeneous mixture. The number of grinding times is 2 times to obtain EB cured thermally conductive glue.

[0023] Preparation of EB-cured thermally conductive adhesive: First, apply the above-mentioned EB-cured thermally-conductive glue evenly on a PET double-sided release film with a thickness of 25 μm using a scraper coater. The weight is 40g, the release grammage of the other side is 20g, and the coating thickness of the EB curing thermally c...

Embodiment 2

[0025] Preparation of EB curing thermally conductive glue: mix 15kg 8 ethoxylated bisphenol A dimethacrylates, 25kg 12 ethoxylated bisphenol A dimethacrylates, 15kg 2-phenoxyethyl acrylic acid Esters, 2kg cyclotrimethylolpropane cyclomethylal acrylate, 35kg alumina, 3kg dispersant BYK110, 1kg Degussa gas silicon A200 are put into the reaction vessel, and the high-speed mixer is used to fully stir and mix, and the stirring speed is ≥ 2500rpm, the stirring time is 20min to obtain a uniform mixture, and then use a sand mill to grind the homogeneous mixture. The number of grinding times is 2 times to obtain EB cured thermally conductive glue.

[0026] Preparation of EB-cured thermally conductive adhesive: First, apply the above-mentioned EB-cured thermally-conductive glue evenly on a PET double-sided release film with a thickness of 25 μm using a scraper coater. The weight is 40g, and the release grammage of the other side is 20g, and the other side of the PET double-sided release...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com