Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68 results about "Aluminium smelting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminium smelting is the process of extracting aluminium from its oxide, alumina, generally by the Hall-Héroult process. Alumina is extracted from the ore bauxite by means of the Bayer process at an alumina refinery.

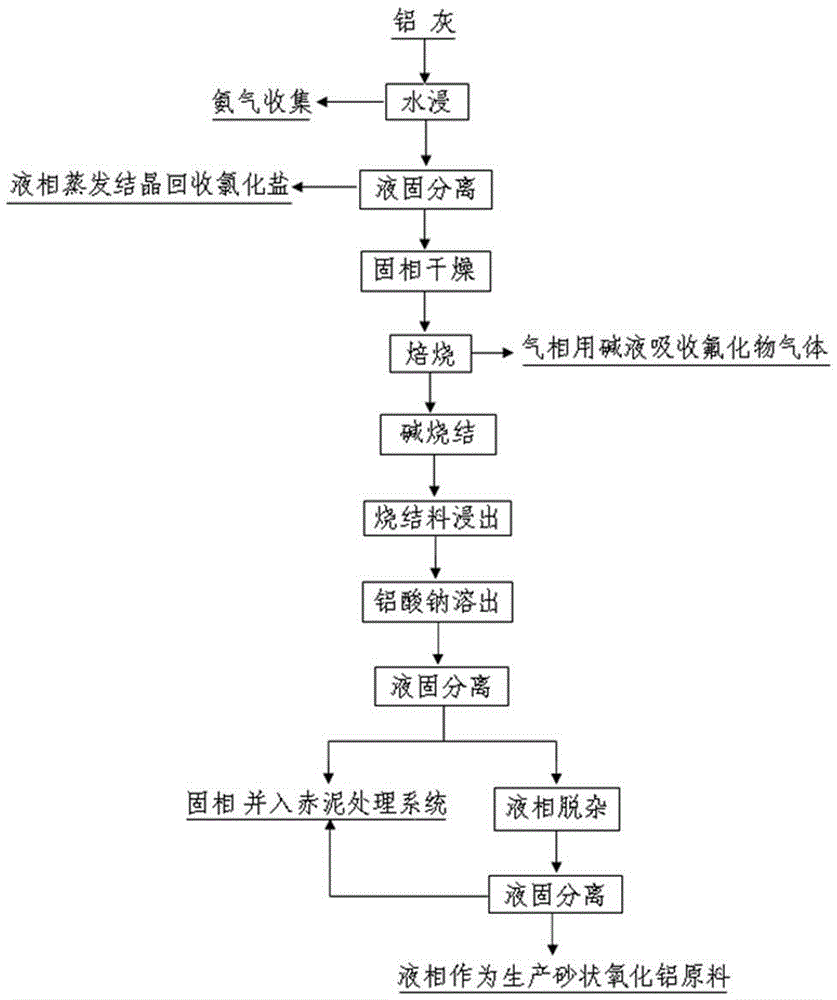

Method for harmless disposal and recycling of aluminum ash

ActiveCN105271327ATo achieve the purpose of comprehensive recycling of resourcesGreat social valueAmmonia preparation/separationAluminium oxides/hydroxidesMetallic aluminumSodium aluminate

The invention discloses a method for harmless disposal and recycling of aluminum ash. The method comprises steps of raw material water immersion nitrogen and chlorine removal, calcination fluorine removal, alkali fusion sintering, sintering material dissolving-out and purifying impurity removal. Aluminum ash generated in metal aluminum smelting process is employed as a raw material, after metal aluminum is recycled through secondary processing, nitrides are removed through water immersion, fluorides are removed through calcinations, alkali fusion sintering is carried out, the sintering materials are dissolved out, impurities are removed through a sodium aluminate solution, the processed aluminum ash is employed as a raw material for producing sand-shaped aluminum oxide. Ammonia gas generated in the aluminum ash harmless disposal process can be employed as an ammonium production raw material, a chlorination liquid generated can be employed as a chlorate production raw material, and silicon fluoride gas generated in the calcination process is absorbed by an aqueous solution. The method is simple and practical, environmental protection benefits are high, the production efficiency is high, the device investment is low, and energy consumption is low. Harmless and recycling disposal of hazardous wastes can be achieved. The obtained product can be applied in practical production.

Owner:YUNNAN WENSHAN ALUMINUM

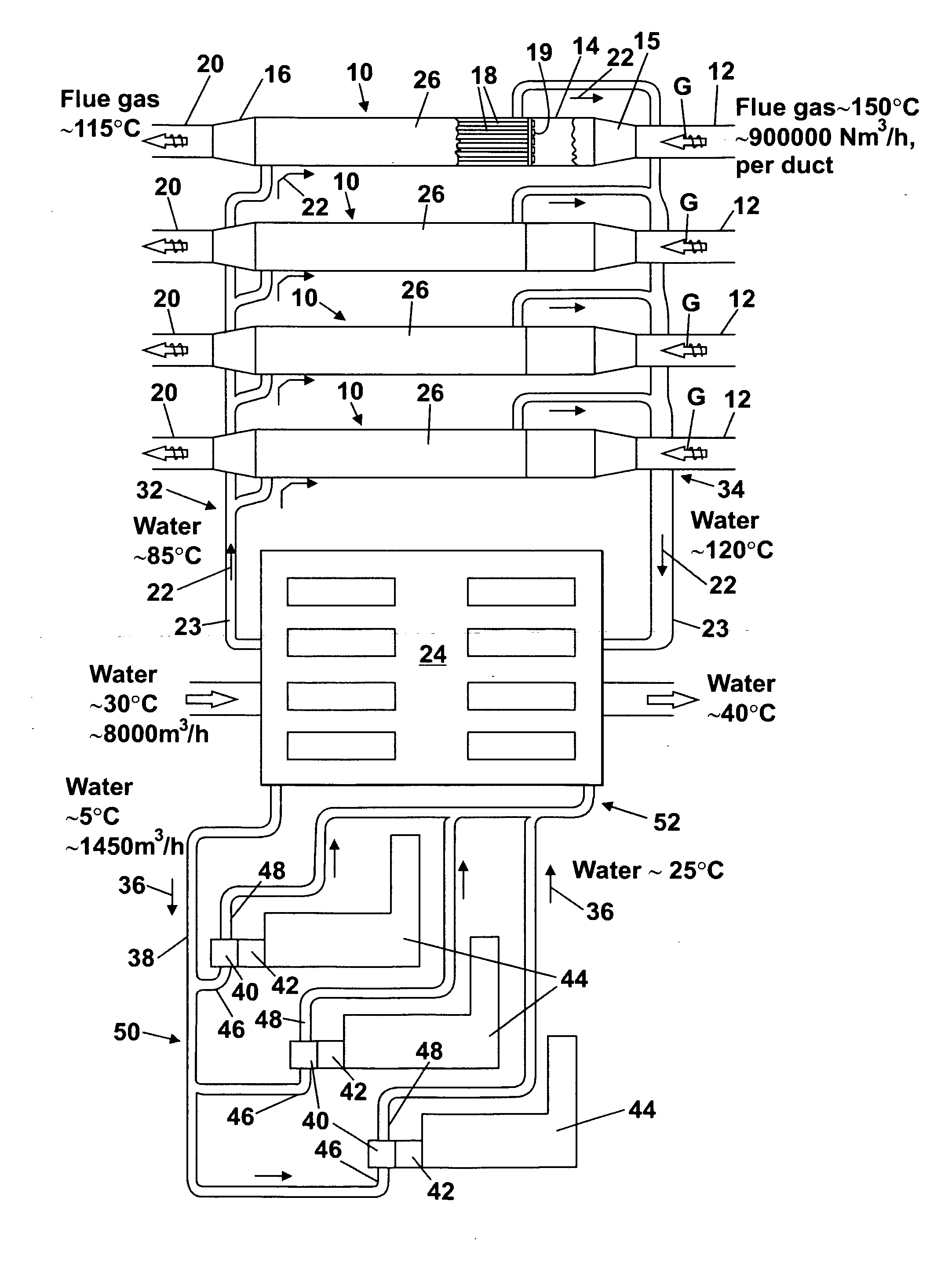

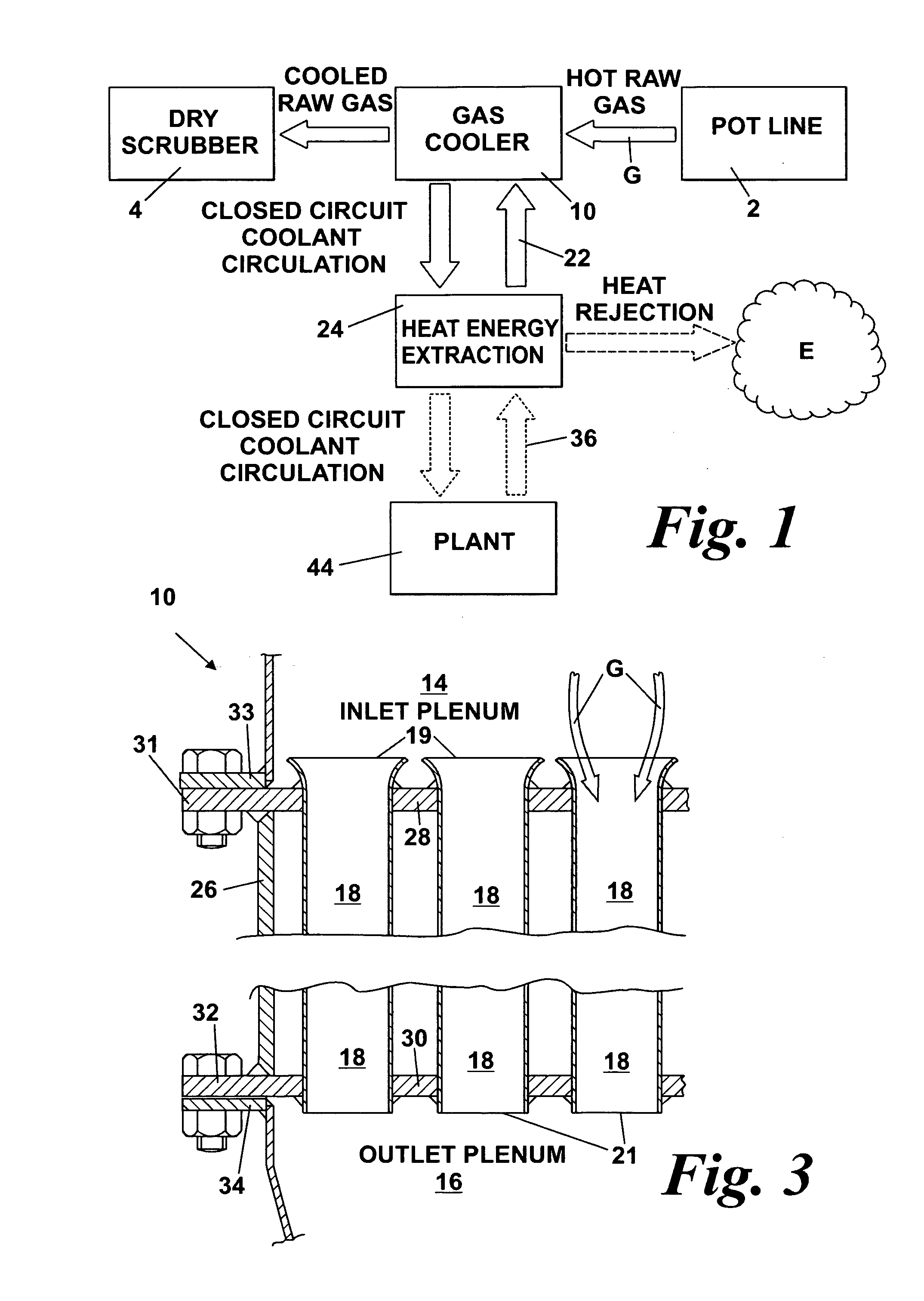

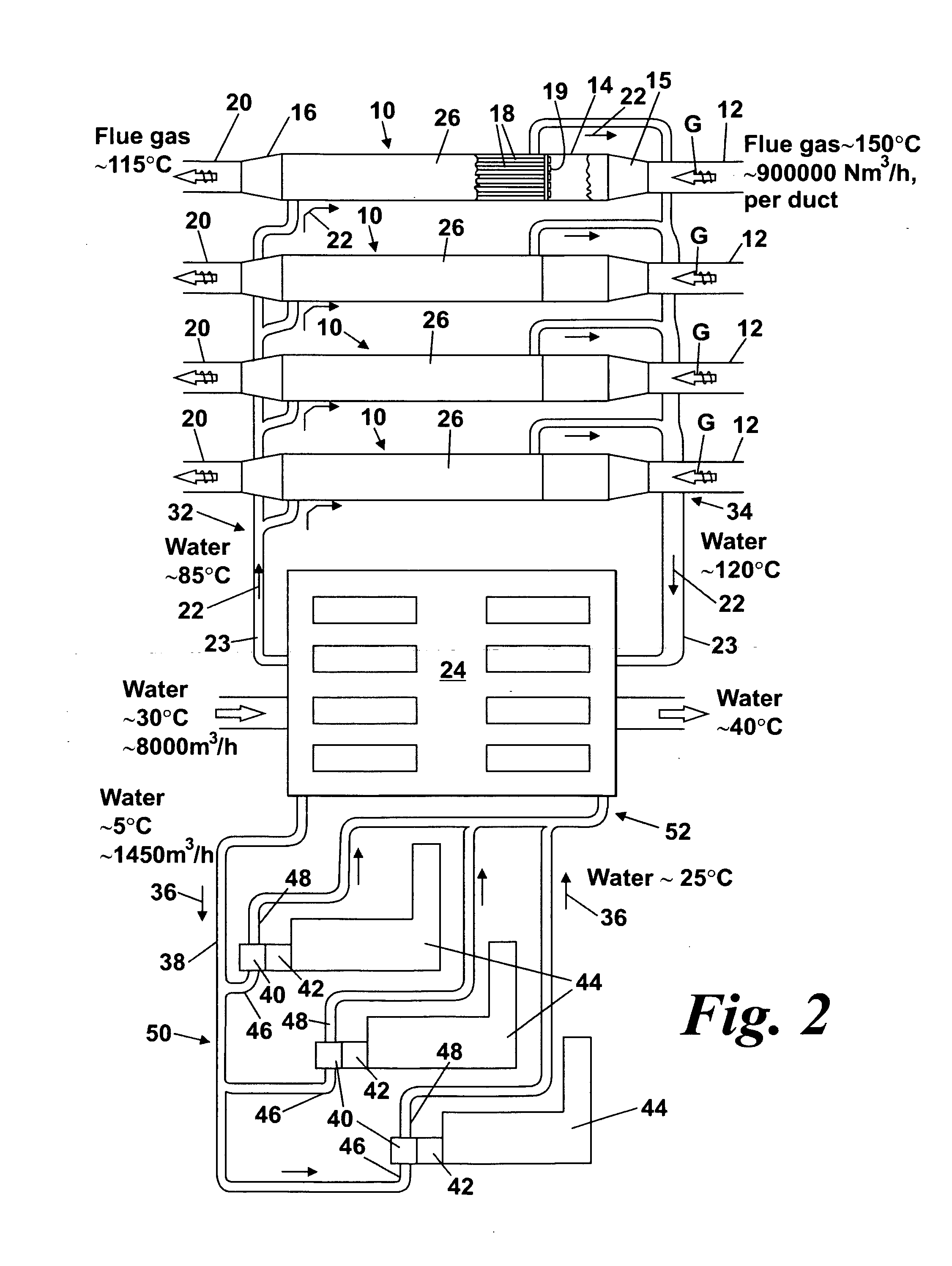

Flue gas cooling and cleaning system

ActiveUS20100101760A1Improve scrubbing efficiencyImprove recycling efficiencyIncreasing energy efficiencyHeat exchanger casingsFlue gasProcess engineering

An improved flue gas cooler (10), or bank of coolers (10), handles flue gas G from aluminium reduction cells in an aluminium smelter plant. The or each flue gas cooler (10) has a gas inlet chamber (14), a gas outlet chamber (16), and a matrix of gas cooling tubes (18) extending between the inlet chamber and the outlet chamber. Each cooling tube (18) has a bell-shaped inlet end (19) comprising an aerodynamically curved gas-accelerating profile effective to facilitate streamlined flow of flue gas G into the tube. The improved flue gas cooler makes it possible to connect the flue gas cooler to receive hot raw flue gas G direct from the aluminium reduction cells without getting clogged by dust and sublimates present in the flue gas. Once cooled, the flue gas can be safely passed on to a flue gas cleaning plant of the dry scrubbing type. The improved flue gas coolers are advantageously part of a system for using heat energy from the flue gas, in which a closed circuit coolant circulation system circulates coolant through the flue gas cooler and a heat exchange arrangement (24). Heat energy extracted from the coolant by the heat exchange arrangement (24) may be used to increase the efficiency of further plant coupled to the heat exchange arrangement.

Owner:REEL ALESA AG

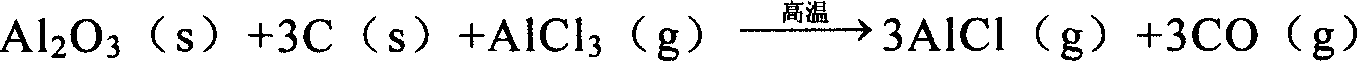

Vacuum carbon heat reduction aluminium smelting method

A process for refining Al from alumina ore by vacuum carbothermic reduction method includes such steps as loading alumina ore, reducing agent and chlorinating agent in internally heated vacuum furnace, reaction at 1270-1570 deg.C under 5-400 Pa for 100-120 min to obtain AlCl, and lowering the temp to lower than 900 deg.C to obtain metallic Al with high purity (more than 95%) and AlCl3 with more than 78% in recovery rate.

Owner:KUNMING UNIV OF SCI & TECH

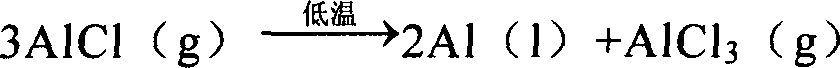

Preparation and using methods for slurry type iron-based red mud arsenic removing agent

InactiveCN102115225AStable formDifficult to dissolve againOther chemical processesWater/sewage treatment by sorptionRed mudToxic industrial waste

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

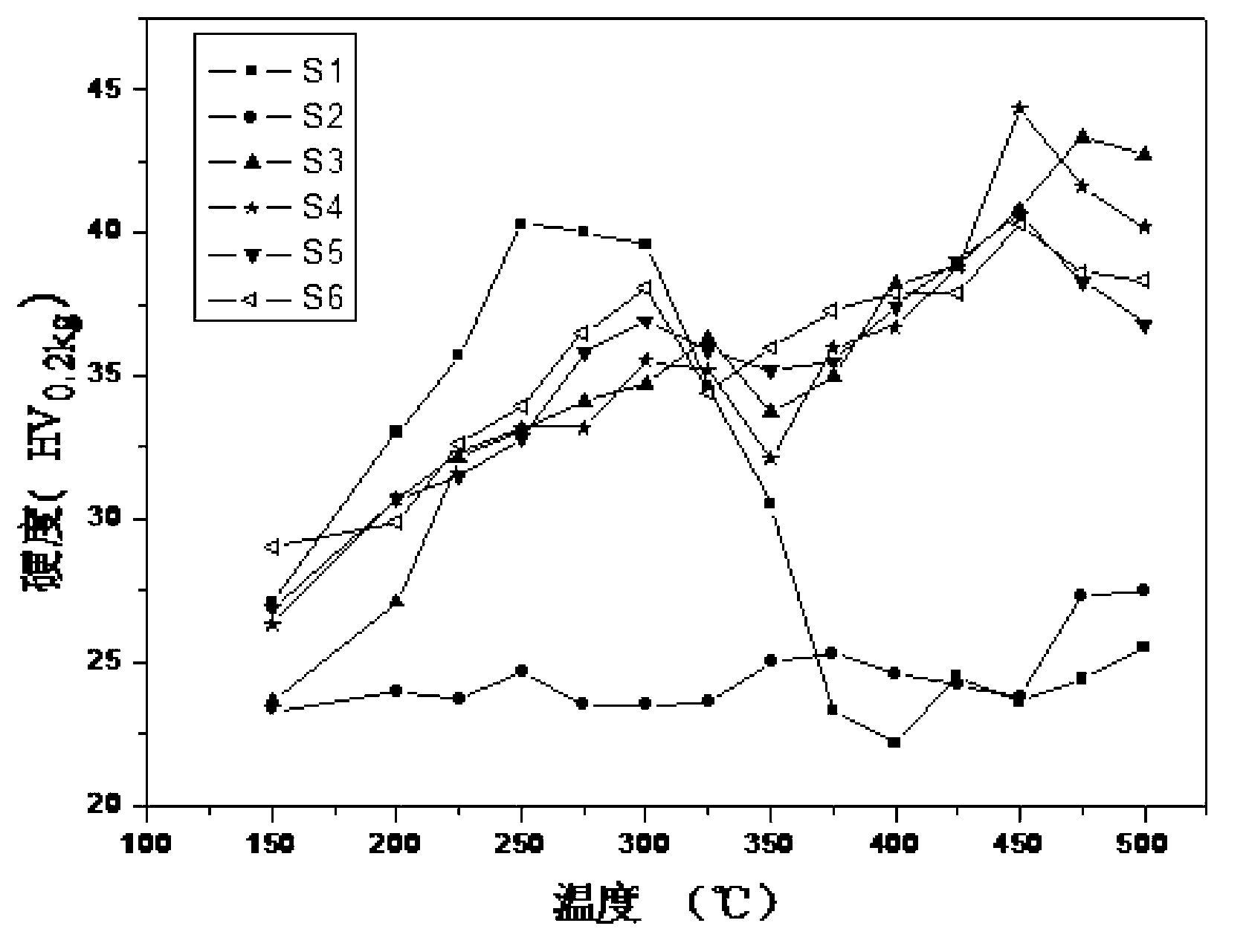

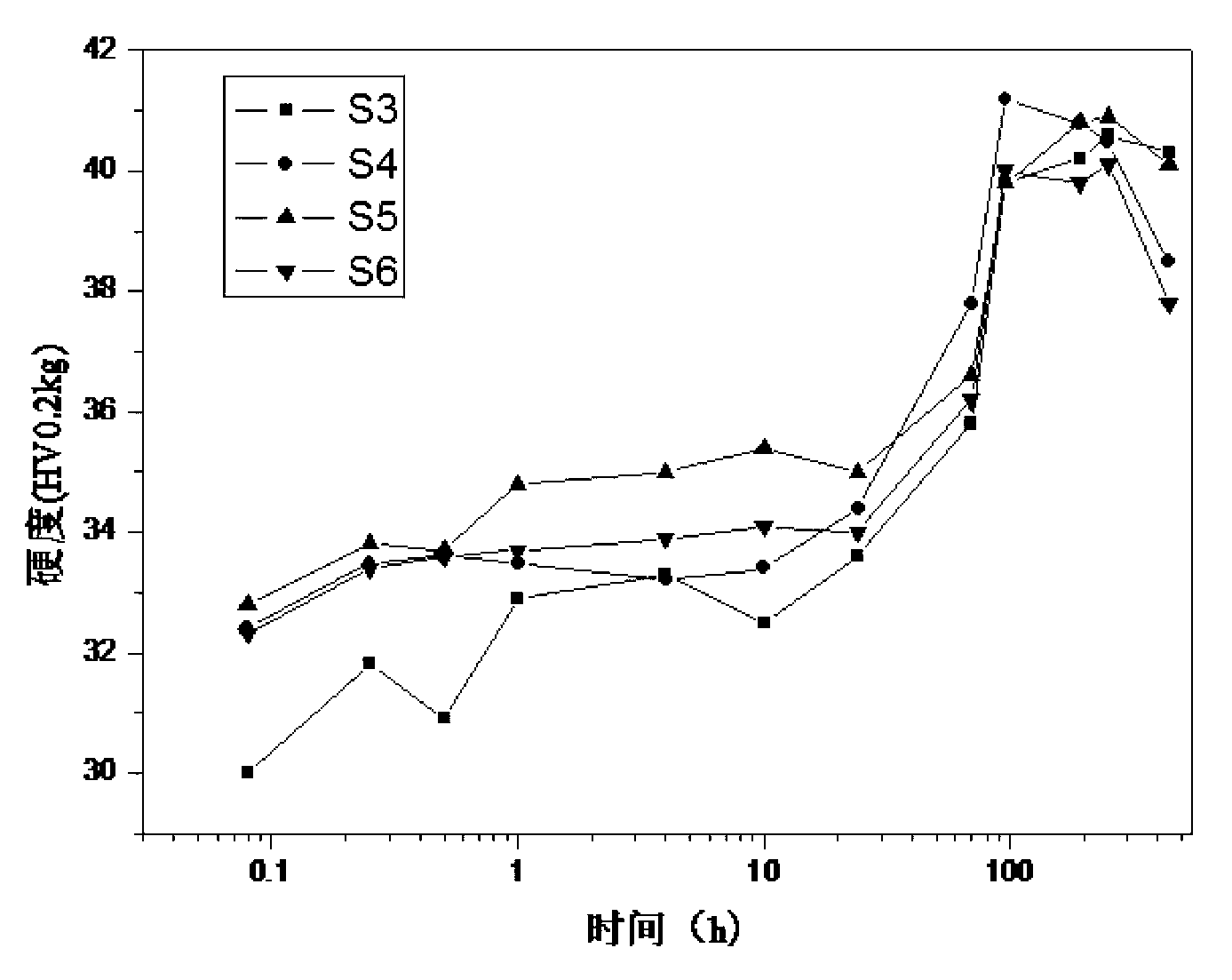

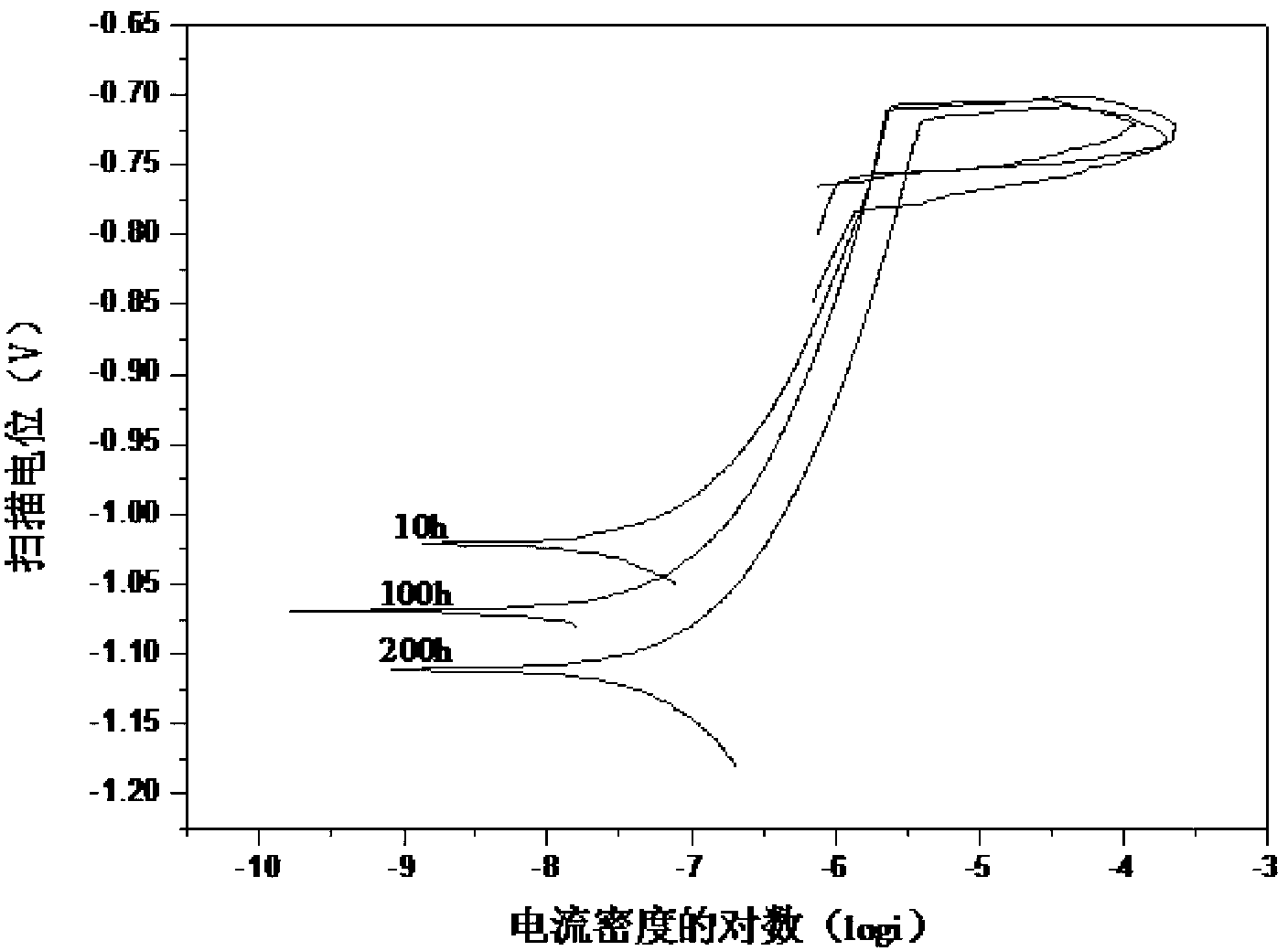

Electrochemical corrosion-resistant reinforced Al-Zr-Er alloy material and preparation method thereof

The invention discloses an electrochemical corrosion-resistant reinforced Al-Zr-Er alloy material and a preparation method thereof, and belongs to the technical field of metal alloy. According to the invention, an aluminum matrix comprises the following constituents by weight percent: 0.21-0.29 percent of zirconium and 0.06-0.26 percent of erbium. The preparation method comprises the following steps: adding the AlEr-AlZr intermediate alloy during the aluminium smelting process at the temperature of 750-780 DEG C; casting with an iron die, and allowing ingoting to be subjected to homogenizing processing, rolling and solution treatment; and finally, allowing the quenched alloy to be subjected to isochronal aging heat treatment at the temperature between 200-500 DEG C at intervals of 25 DEG C and to be subjected to isothermal aging heat treatment at the temperature of 375+ / -10 DEG C. According to the invention, the alloy is greatly improved in strength due to aging heat treatment, and is improved in electrochemical corrosion resistance at the same time, and is different from the phenomenon that a current aluminum alloy is worse in corrosion resistance after being reinforced through heat treatment.

Owner:BEIJING UNIV OF TECH

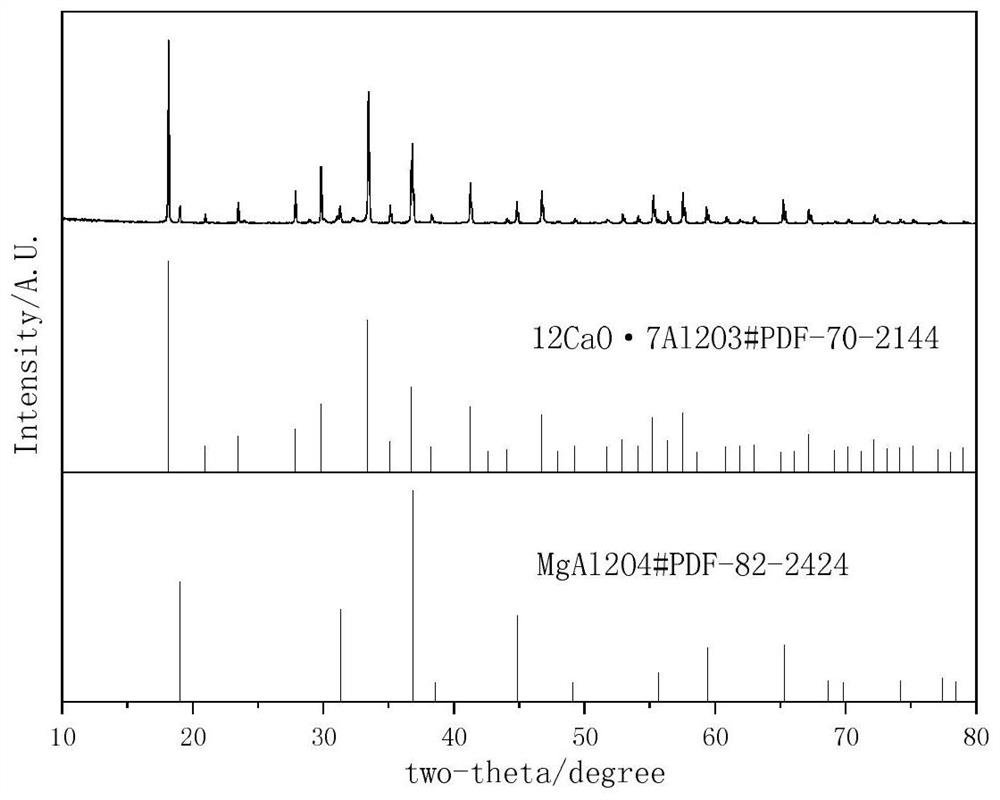

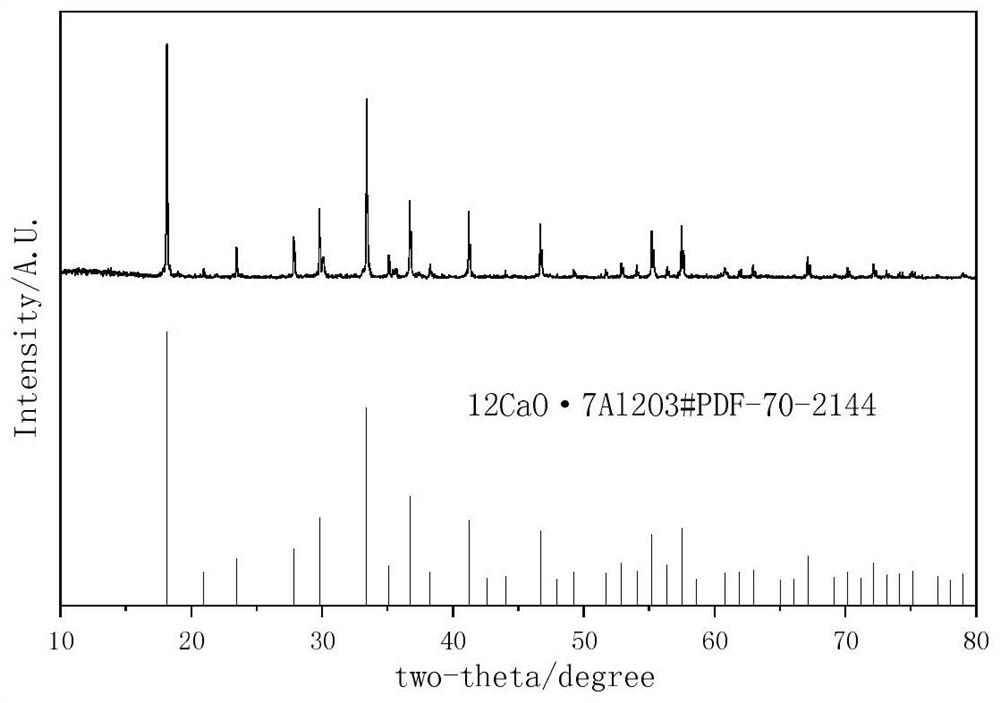

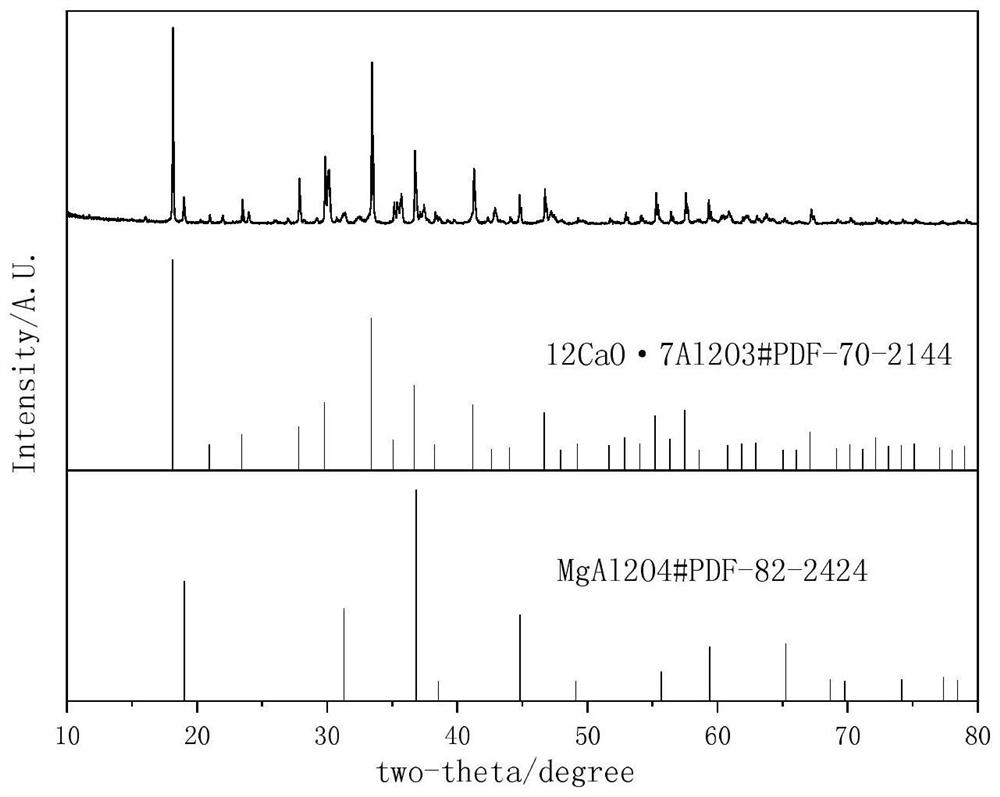

Method for preparing calcium aluminate by synergistic treatment of high-magnesium aluminum ash and fly ash

ActiveCN112607758AImprove decomposition rateIncrease spawn rateCalcium aluminatesAluminium silicatesCalcium aluminatesFly ash

The invention discloses a method for preparing calcium aluminate by synergistic treatment of high-magnesium aluminum ash and fly ash, which comprises the following steps: carrying out wet ball milling on high-magnesium aluminum ash, fly ash and quick lime, and sequentially carrying out washing, solid-liquid separation and roasting treatment on the ball-milled material to obtain a calcium aluminate product. According to the method, a calcium aluminate series product capable of being used for iron and steel smelting desulfurization is obtained by taking the aluminum ash generated in the aluminum smelting processing process as a raw material, so that the comprehensive utilization of hazardous wastes is realized, a relatively high economic value can be obtained, and the method is simple to operate and environment-friendly, and meets the industrial production requirements.

Owner:CENT SOUTH UNIV

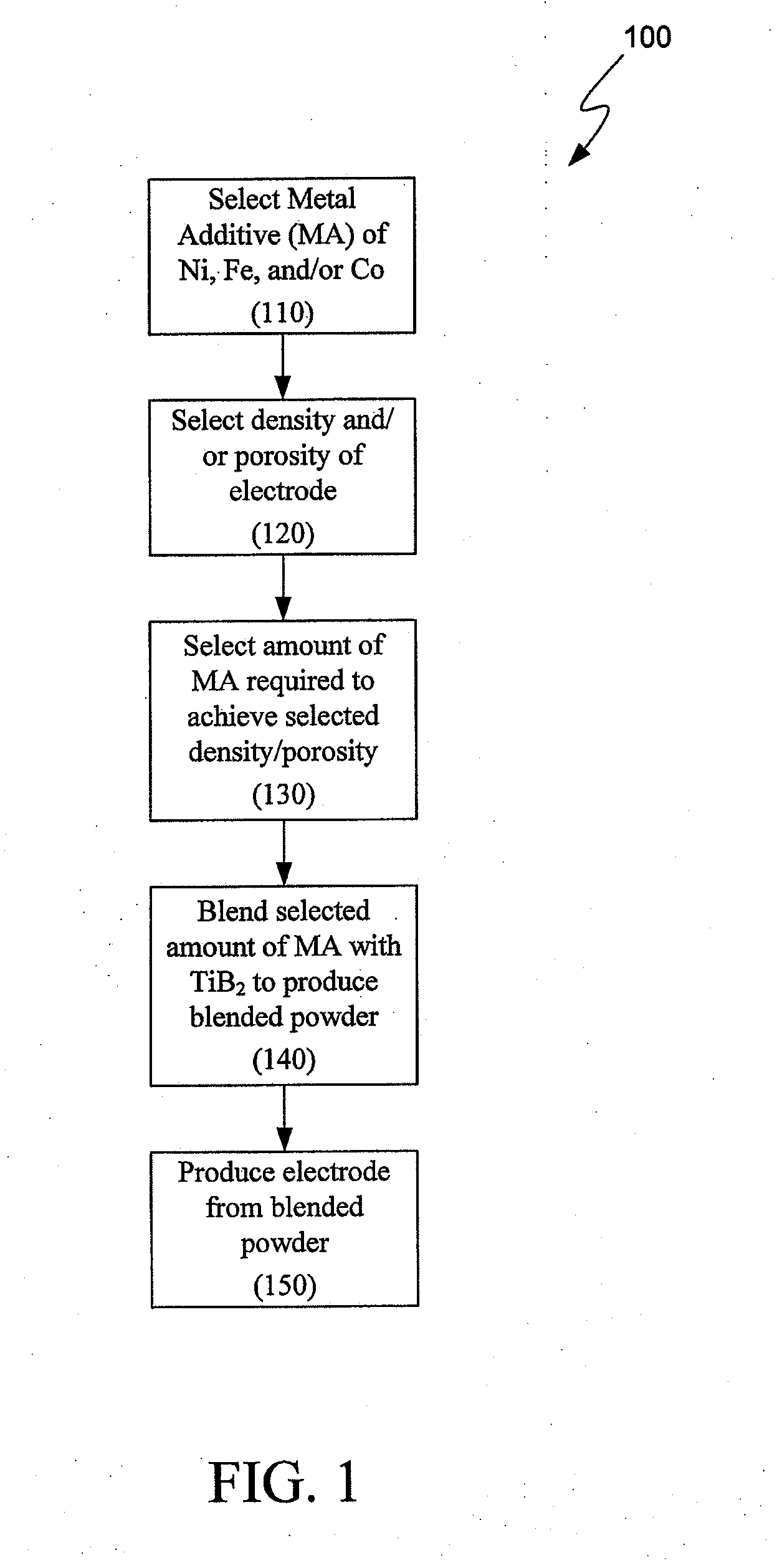

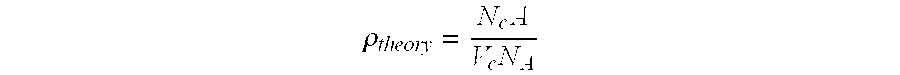

Composition for making wettable cathode in aluminum smelting

ActiveUS20110024304A1Promote productionEasy to useOther chemical processesCell electrodesPorosityAluminium smelting

Compositions for making wettable cathodes to be used in aluminum electrolysis cells are disclosed. The compositions generally include titanium diboride (TiB2) and metal additives. The amount of selected metal additives may result in production of electrodes having a tailored density and / or porosity. The electrodes may be durable and used in aluminum electrolysis cells.

Owner:ARCONIC INC

Aluminum-based sandwich panel for construction industry and preparation method thereof

The invention discloses an aluminum-based sandwich panel for the construction industry and a preparation method of the aluminum-based sandwich panel. The aluminum-based sandwich board has the structure formed by combing an aluminum panel, a core material and an aluminum panel in sequence, wherein the core material and the panels are in metallurgical bonding; the core material is a composite material consisting of ceramic particles and aluminum; the ceramic particles are any one of or the combination of multiple of alumina balls, alumina hollow balls, pulverized fuel ash particles and floating balls. The preparation method of the aluminum-based sandwich panel comprises the following steps of: filling a mold; preheating the mold in a casting chamber; smelting aluminum in a smelting crucible, generating negative pressure of the casting chamber to enable an aluminium smelting body to enter the mold from bottom to top; condensing the smelting body in the mold in the smelting crucible after pressurization; and carrying out surface treatment on a casting. The aluminum-based sandwich panel prepared by the invention has the functions of temperature preservation, heat insulation, noise reduction and decoration, thus the aluminum-based sandwich panel can be widely applied in the construction field.

Owner:元泰达新材料江苏有限公司

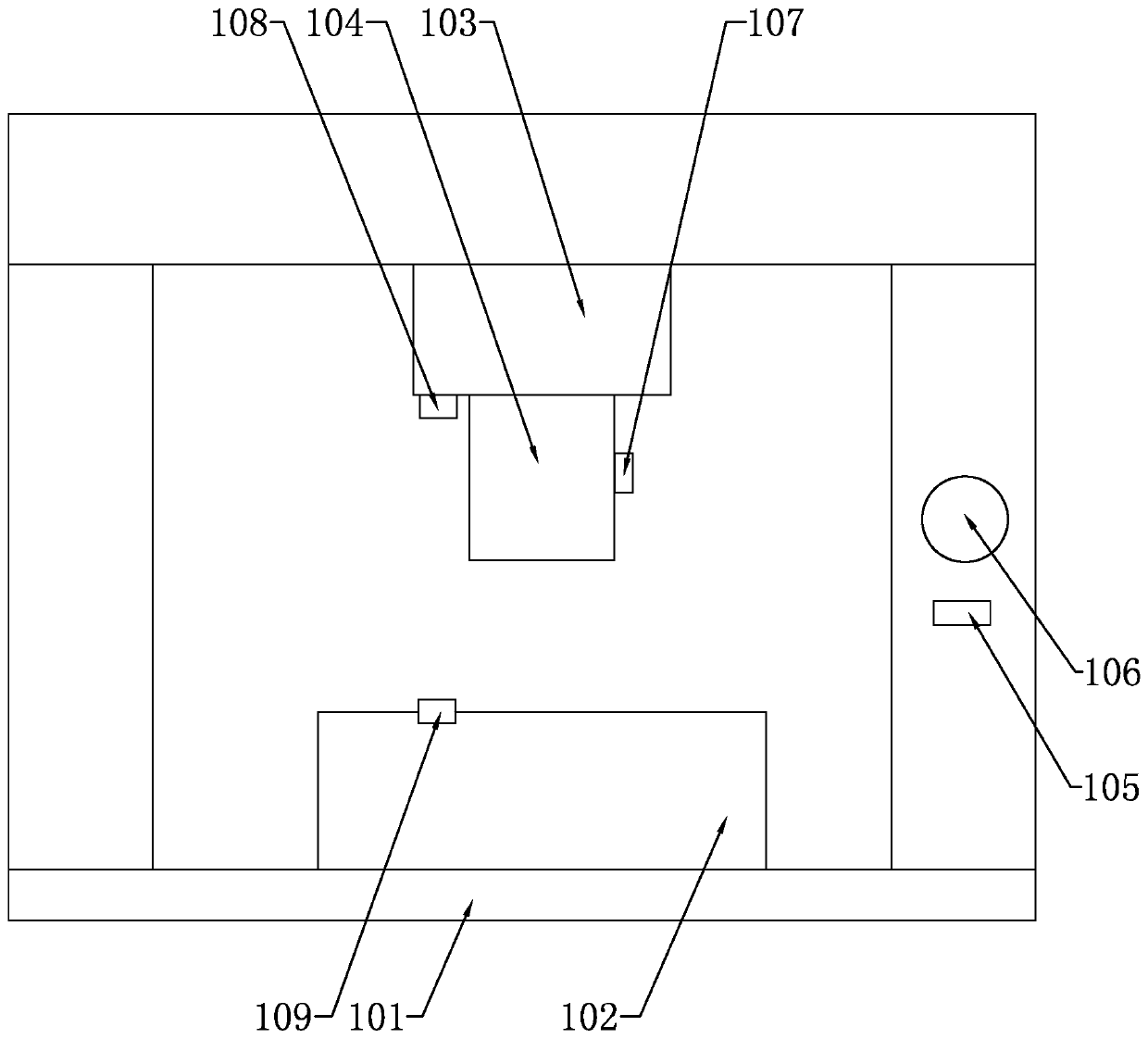

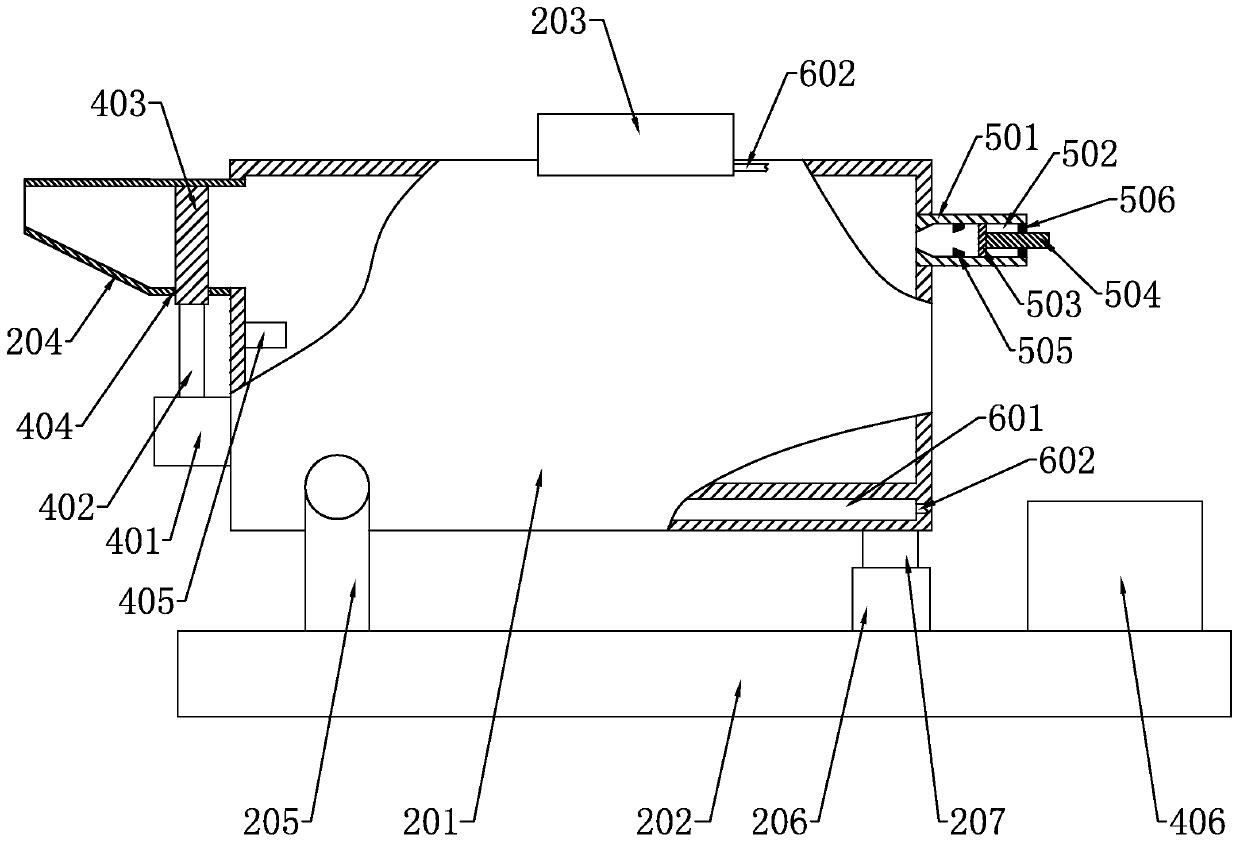

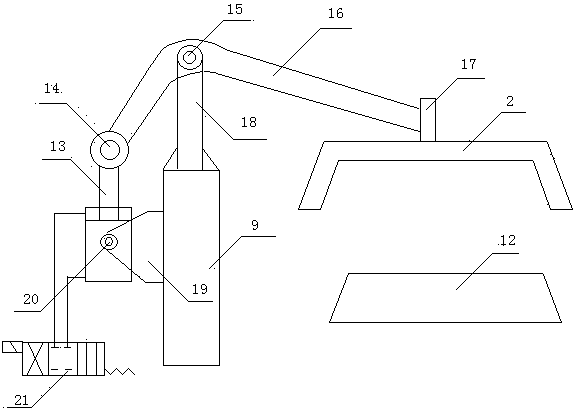

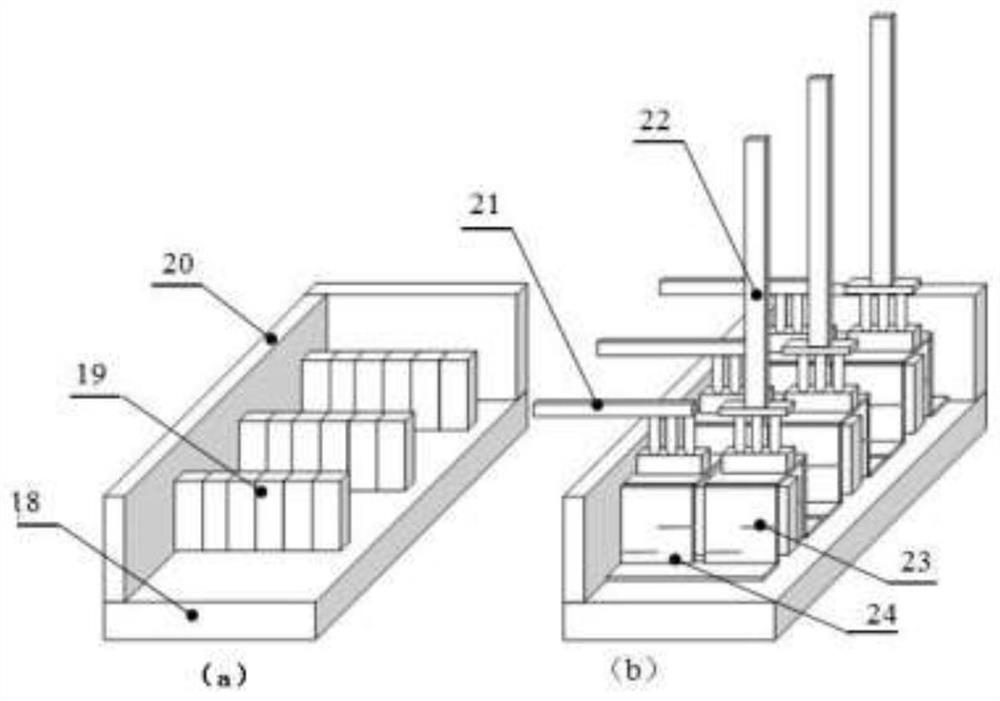

Intelligent conveying system for die-casting molten aluminium

The invention discloses an intelligent conveying system for die-casting molten aluminium. The intelligent conveying system for the die-casting molten aluminium is suitable for the technical field of die-casting molten aluminium conveying, and aims at solving the problem that air oxidation for the molten aluminium is promoted due to violent shake in existing molten aluminium transport, thus the quality of the molten aluminium is declined. The invention provides an intelligent conveying system for die-casting molten aluminium. The system comprises a molten aluminium smelting furnace, a running crucible, a running crucible clamp, an AGV transport trolley, a transport control cabinet, a transport rail, an operation area, a lifting mechanism and a molten aluminium storage crucible. The intelligent conveying system for the die-casting molten aluminium, which is disclosed by the invention, is capable of realizing unmanned and intelligent molten aluminium conveying, and ensures the quality of the molten aluminium and effectively ensures the production quality of die-casting through an online detection technology.

Owner:营口华峰动力发展股份有限公司

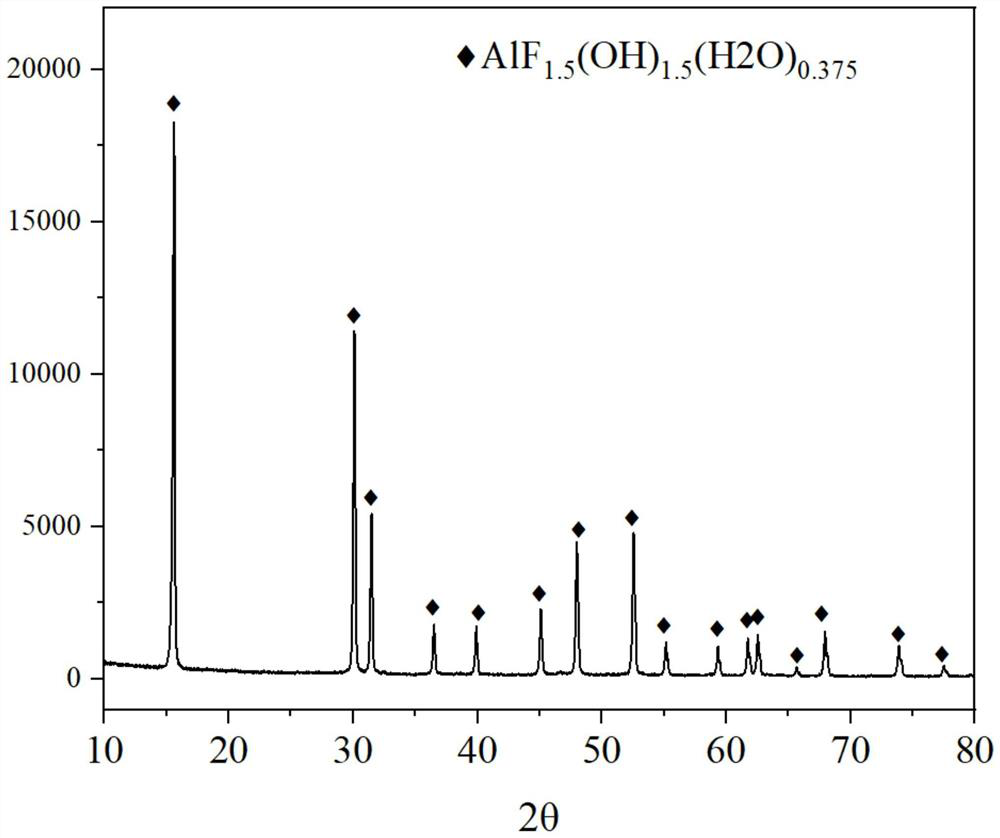

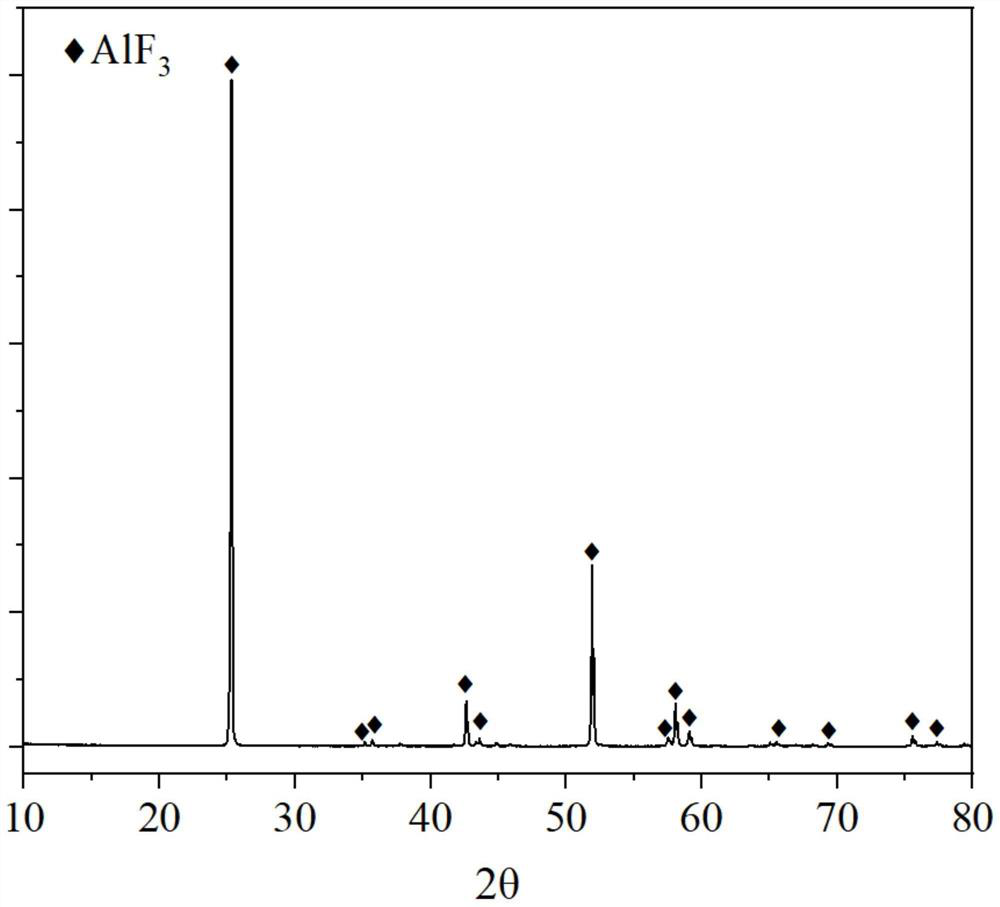

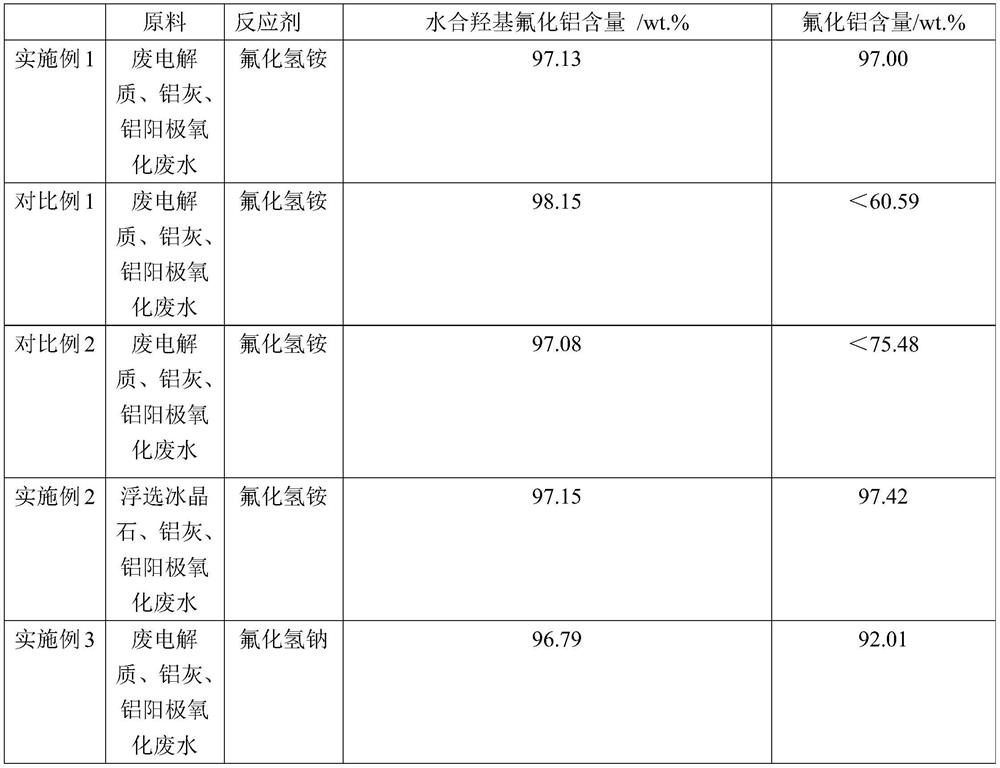

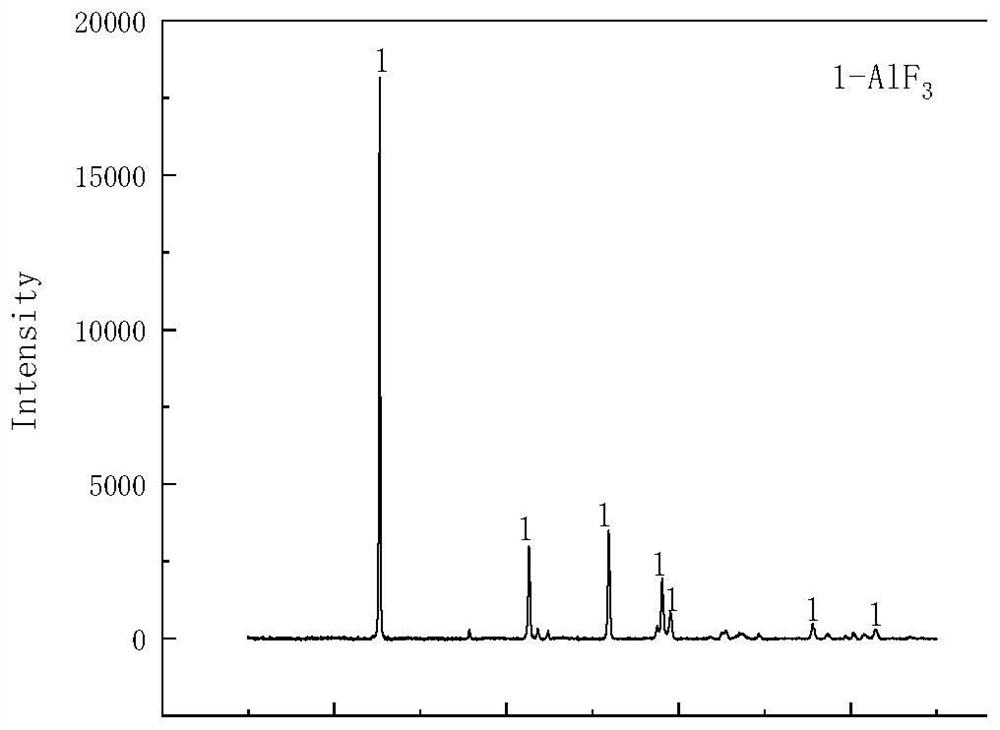

Method for preparing aluminum fluoride product through combined treatment of multiple wastes and aluminum fluoride product

PendingCN113501536AHigh feasibilitySimple processAluminium fluoridesAluminum fluorideHydrogen fluoride

The invention relates to a method for preparing an aluminum fluoride product through combined treatment of multiple wastes and the aluminum fluoride product. The method comprises mixing and leaching fluorine-containing waste particles, aluminum ash powder and to-be-treated aluminum anodic oxidation wastewater, and then performing solid-liquid separation to obtain leachate and filter residues; adjusting the pH value of the leachate to 3-5, carrying out solid-liquid separation to obtain a solid phase, drying the solid phase to obtain aluminum hydroxyfluoride powder, uniformly mixing the aluminum hydroxyfluoride powder with a reactant, and carrying out heat treatment to obtain a heat treatment product; when the reactant comprises at least one of potassium hydrogen fluoride, sodium hydrogen fluoride and lithium hydrogen fluoride, washing and drying the heat treatment product to obtain an aluminum fluoride product; when the reactant is composed of at least one of ammonium fluoride and ammonium bifluoride, determining that the heat treatment product is the aluminum fluoride product. According to the method, fluorine-containing waste, aluminum ash and aluminum anodic oxidation waste water in the aluminum smelting and processing industry are integrated, valuable aluminum and fluorine elements are efficiently recycled in the form of aluminum hydroxyfluoride, the process is simple, and the feasibility is high.

Owner:CENT SOUTH UNIV

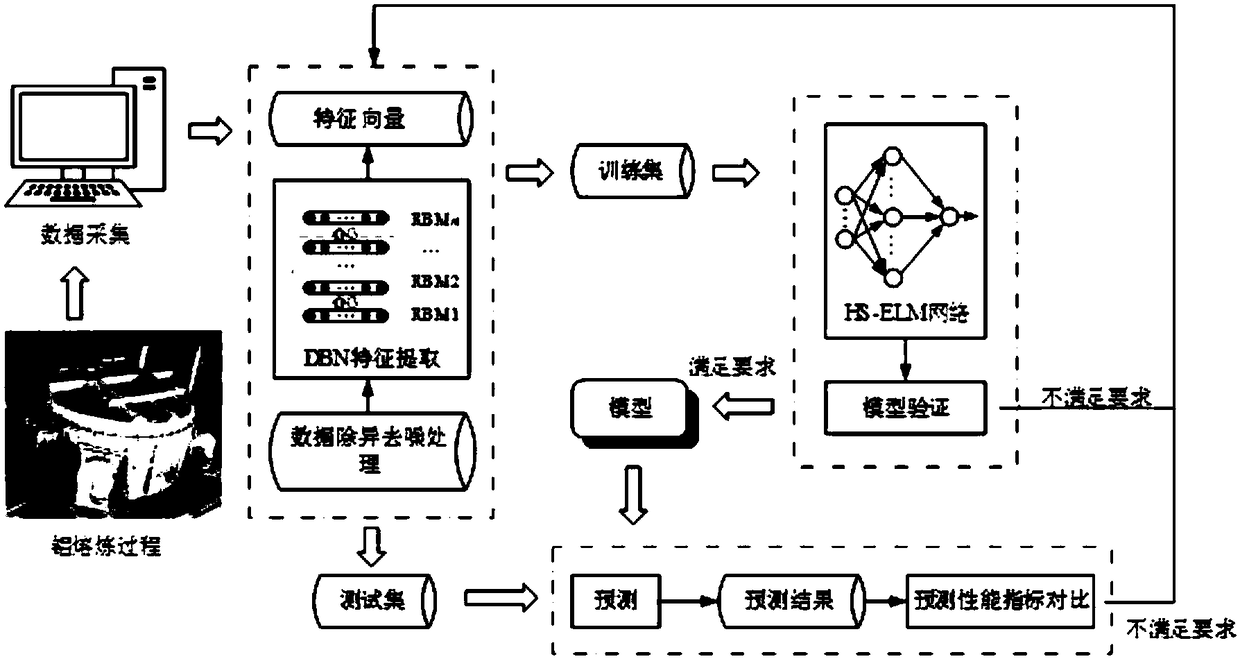

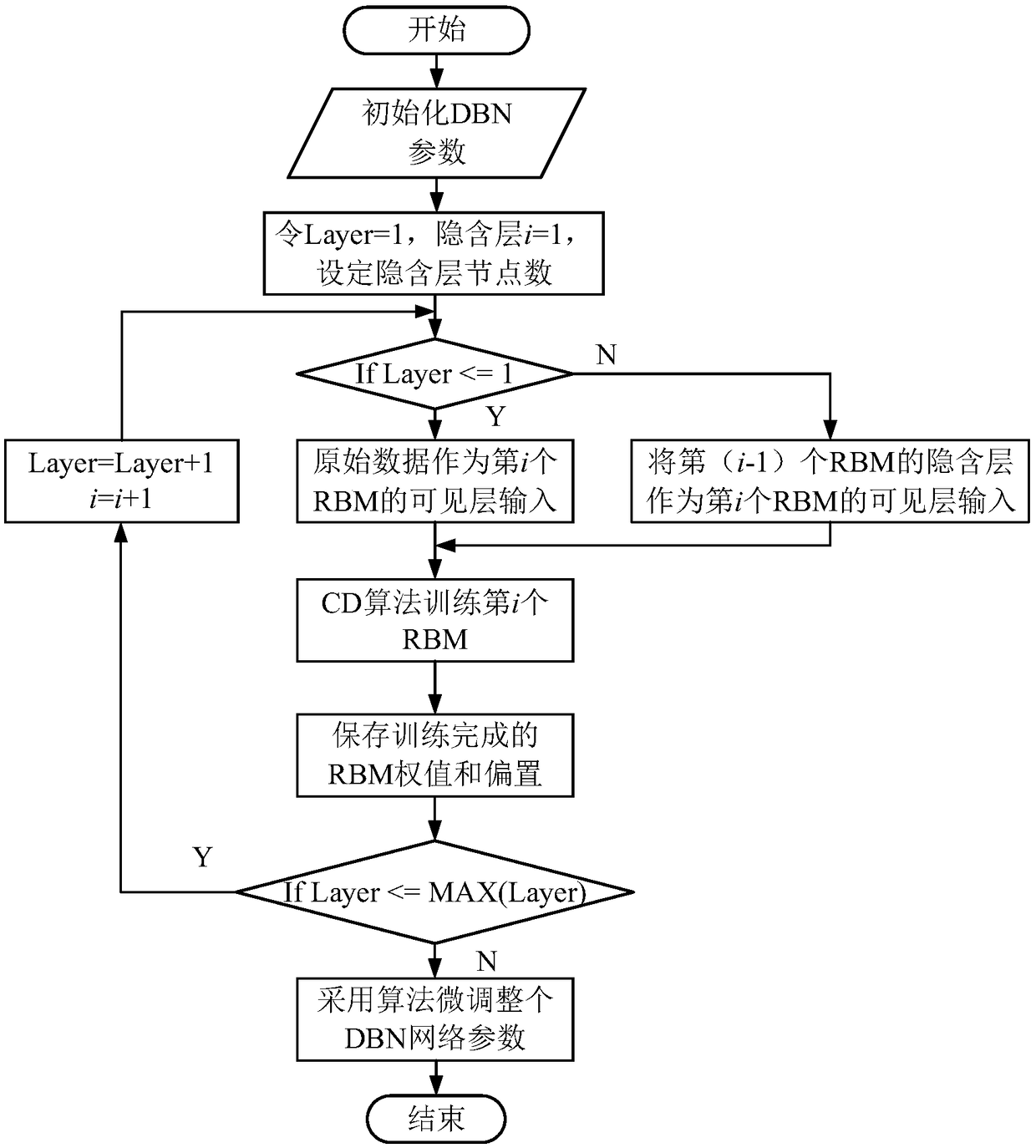

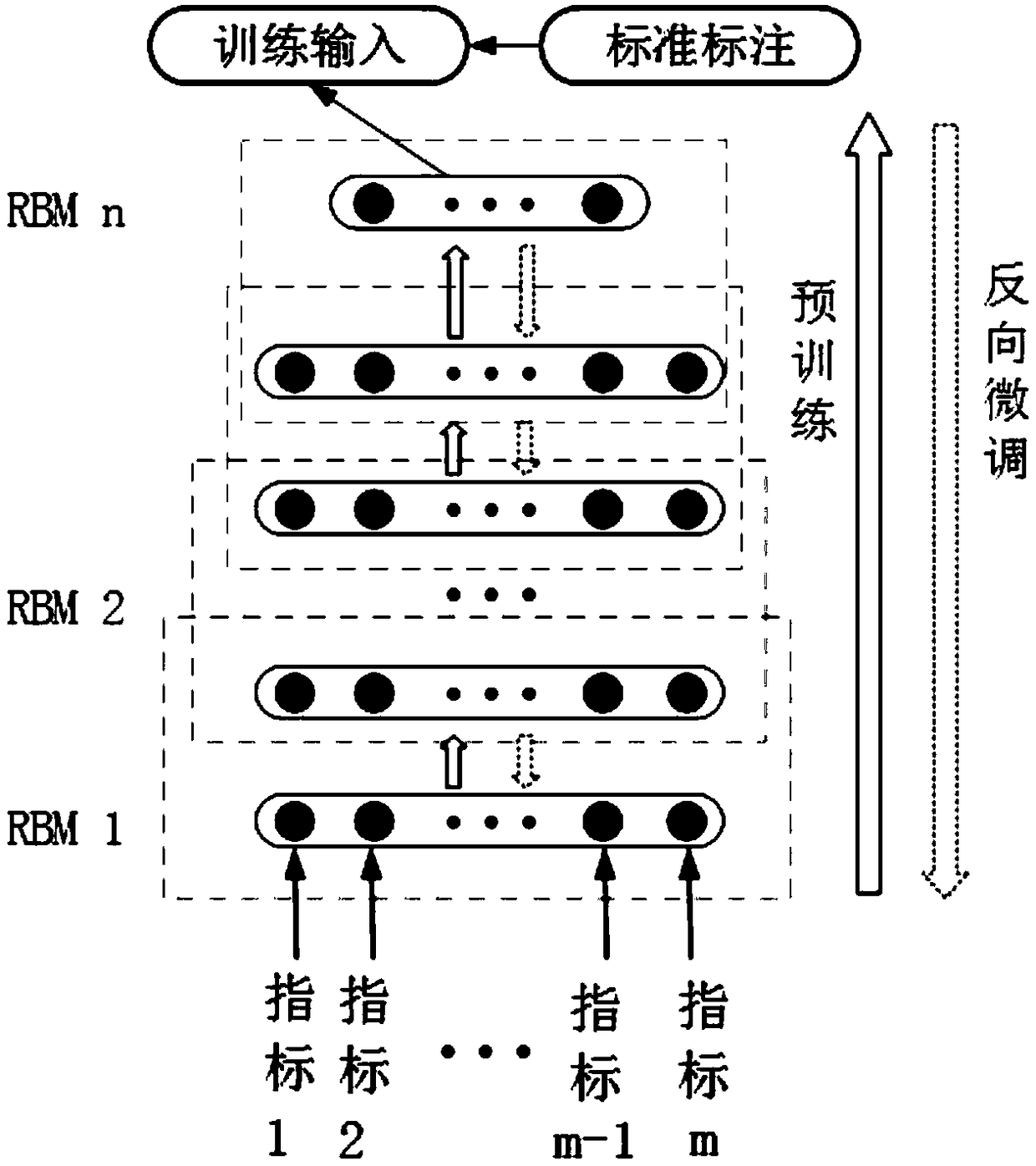

Aluminum smelting process furnace box temperature prediction method based on deep belief network

ActiveCN108897354ARich cognitionAccurate predictionTemperatue controlDeep belief networkFeature vector

The invention discloses an aluminium smelting process furnace box temperature prediction method based on a deep belief network. The method comprises the following steps that 1, a plurality of sets oforiginal data are acquired; 2, for the original data acquired in the step 1, abnormal data is eliminated, and noise is removed to obtain normal data; 3, for the normal data obtained in the step 2, thedeep belief network is used for feature extraction to obtain feature vectors; 4, the sets of feature vectors are divided into a training set and a testing set, and a prediction model is built, wherein through the sets of feature vectors in the training set, the prediction model is trained constantly to obtain a trained prediction model; 5, each set of feature vectors in the testing set is used for testing the trained prediction model, if the testing stability is good, the prediction model can be used for predicting a furnace box temperature, and if the testing stability is not good, the step3 is returned to. According to the aluminium smelting process furnace box temperature prediction method based on the deep belief network, the furnace box temperature can be predicted through other indexes easy to detect, components and parts are not prone to be damaged, and the economic benefits are good.

Owner:GUANGXI UNIV

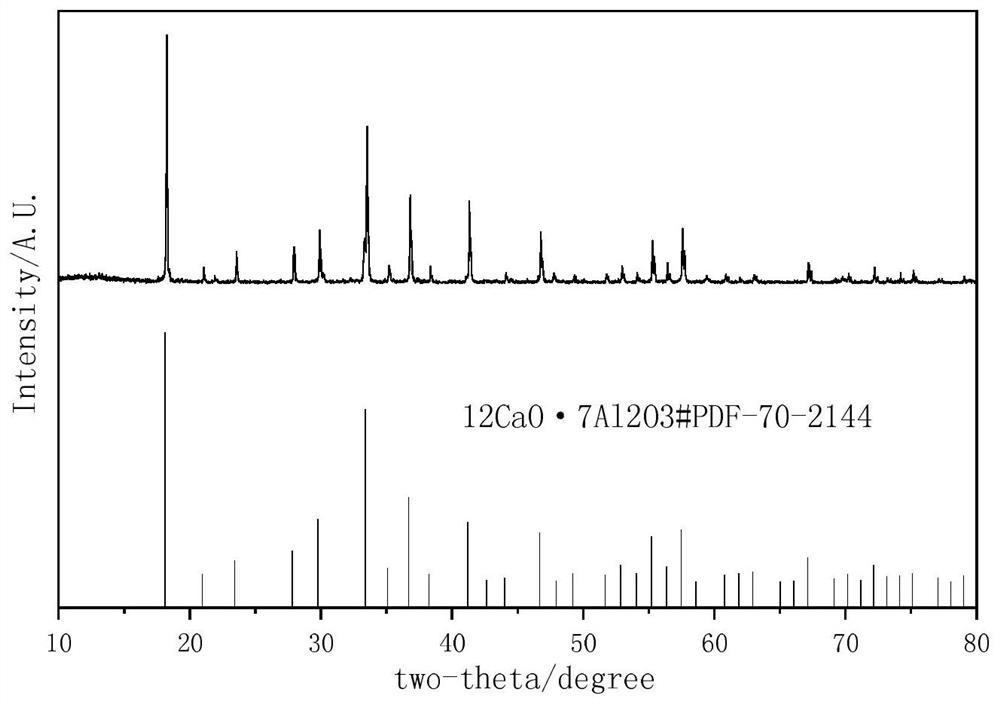

Method for synchronously activating, inerting, removing impurities and melting calcium aluminate by using low-magnesium aluminum ash

ActiveCN112723400AHigh economic valueRealize decomposition and removalCalcium aluminatesMachining processCalcium aluminates

The invention discloses a method for synchronously activating, inerting, removing impurities and melting calcium aluminate by using low-magnesium aluminum ash, wherein the method comprises the steps: carrying out wet ball milling on a mixed raw material of the low-magnesium aluminum ash and a calcium-containing additive, and sequentially carrying out solid-liquid separation, drying and roasting treatment on the ball-milled material to obtain a calcium aluminate series product. According to the method, the calcium aluminate series product capable of being used for iron and steel smelting desulfurization is prepared from the low-magnesium aluminum ash generated in the aluminum smelting machining process, comprehensive utilization of hazardous waste is achieved, high economic value can be obtained, and the method is easy to operate, low in cost, environmentally friendly and capable of meeting the industrial production requirement.

Owner:CENT SOUTH UNIV

Absorbing agent for separating formaldehyde from air and preparation method thereof

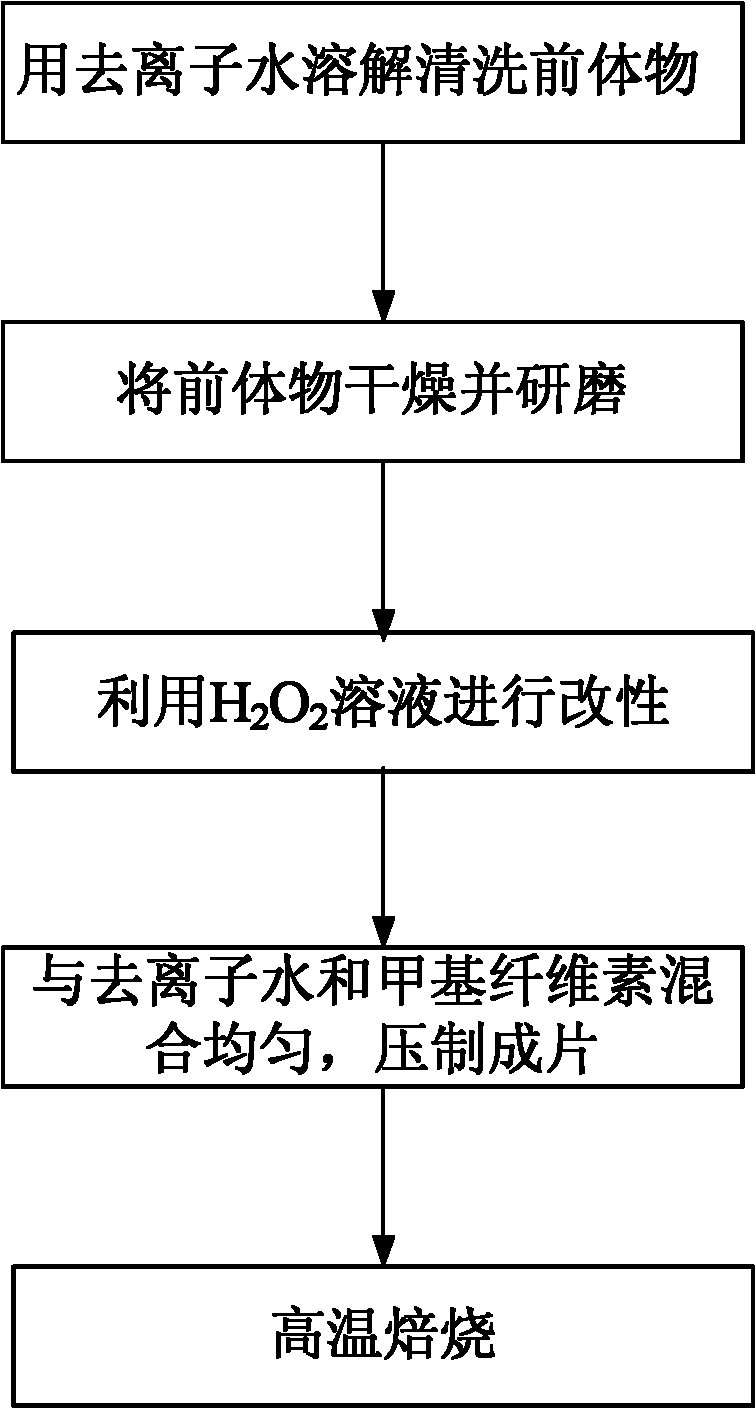

InactiveCN102179231AImprove adsorption capacityLarge adsorption capacityOther chemical processesDispersed particle separationParticulatesAbsorption capacity

The invention provides an absorbing agent for separating formaldehyde from air and a preparation method thereof. The absorbing agent is obtained by taking red mud produced by the Bayer-process aluminium-smelting technique as a precursor and carrying out chemical modification and high-temperature roasting. The absorbing agent is red particles, the distribution range of internal micropore diameter of the absorbing agent is 0.9-2.7nm, and the appearance size is 0.45-0.9mm, so that the absorbing agent is beneficial to catching and removing trace formaldehyde in the air. In the absorbing agent provided by the invention, compared with the existing material for formaldehyde absorption, catalysis and purification, under a high air speed, the gas-phase low concentration formaldehyde can be absorbed in a high-efficiency manner, the absorption capacity is large, the service life is long, the used raw materials are from solid slag, namely red mud produced in the aluminium-smelting process in the aluminium industry, the source is wide, the cost is low, the prepared absorbing agent can achieve the purpose of using waste to treat harm and is beneficial to realizing clean production.

Owner:BEIHANG UNIV

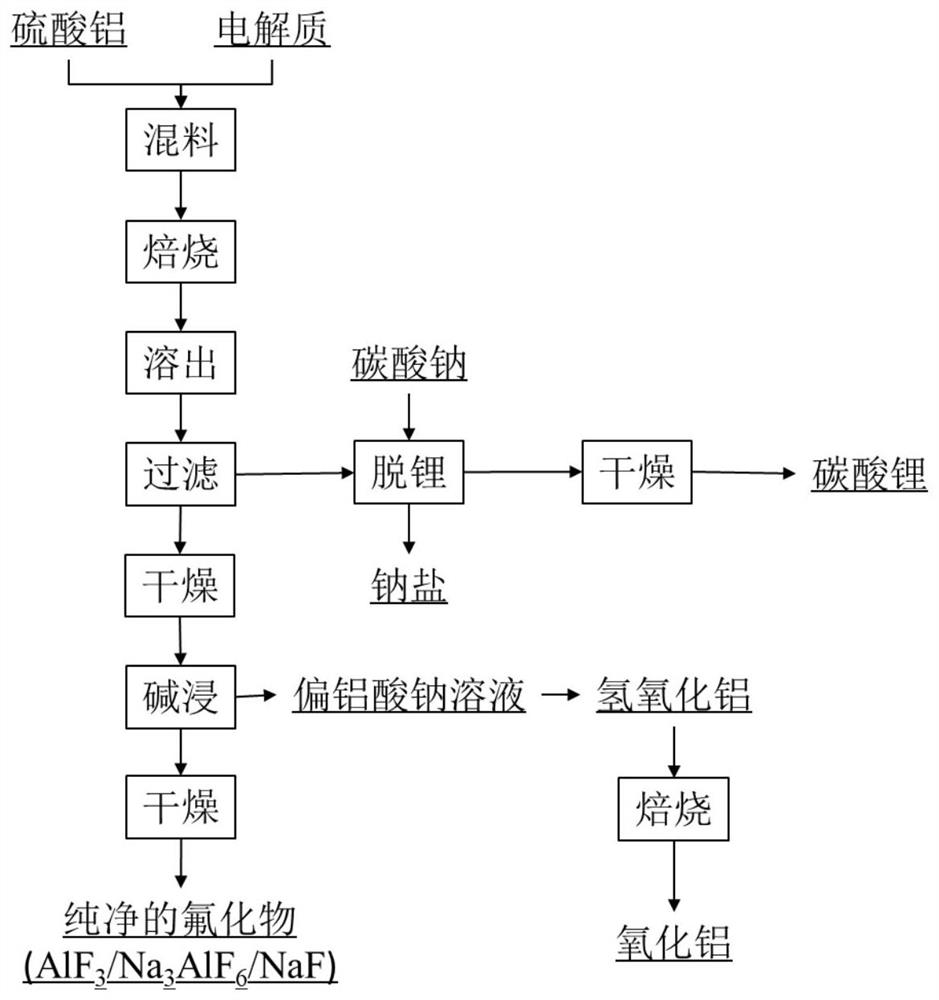

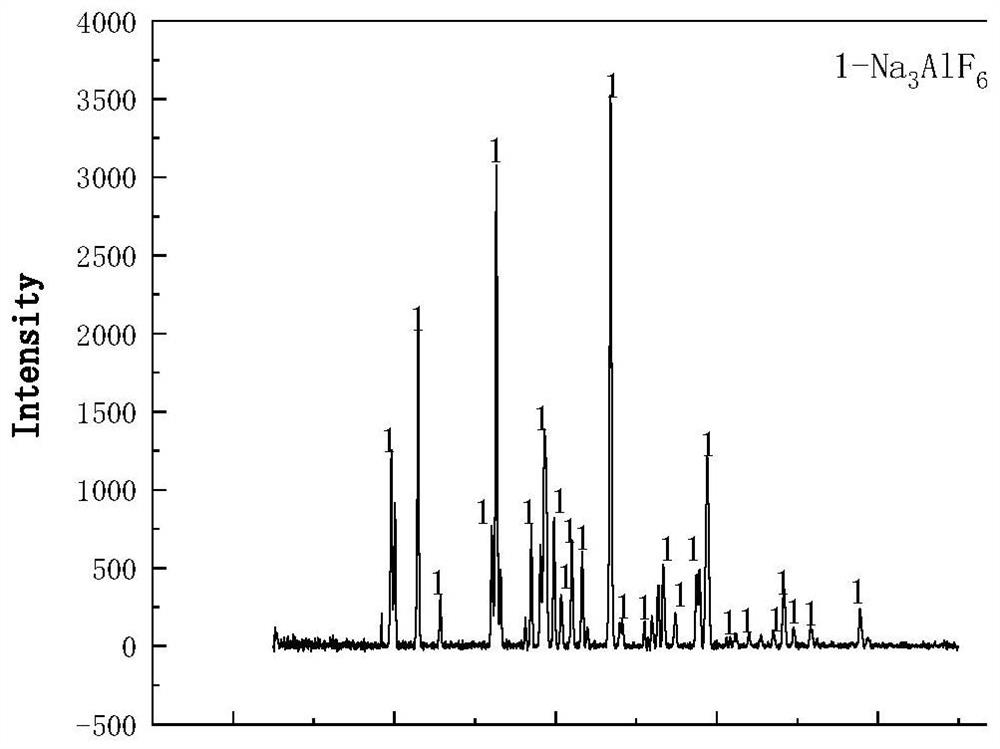

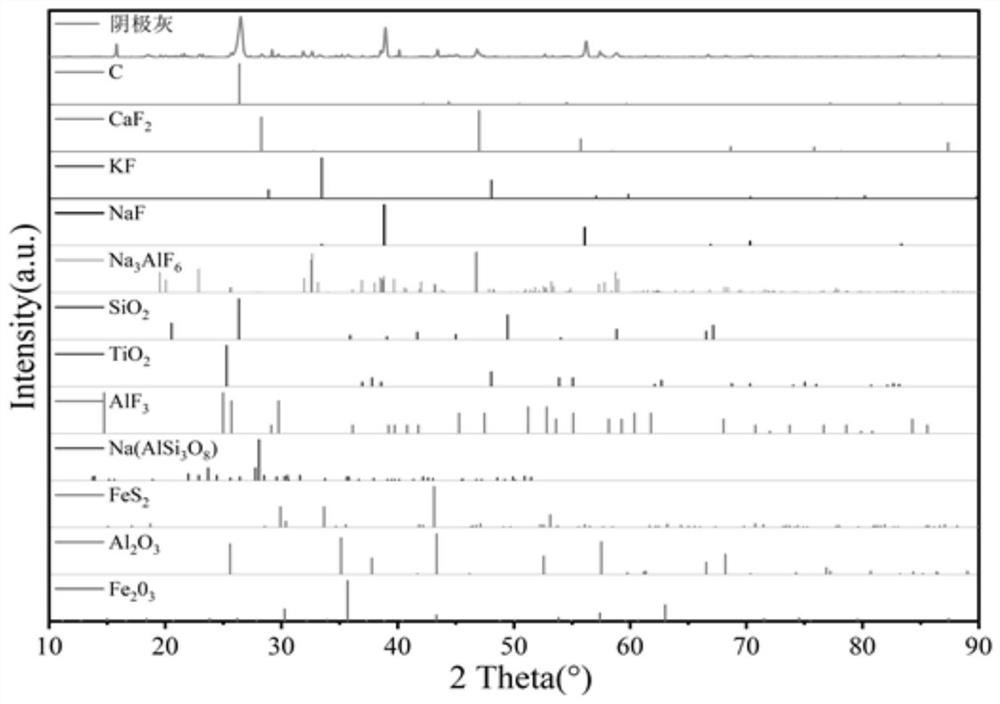

Method for recovering fluoride salt from complex aluminum electrolyte

ActiveCN114314625AConducive to stable productionThe process is simple and greenAlkali metal fluoridesAluminium fluoridesEngineeringWaste recycling

The invention belongs to the technical field of aluminum smelting solid waste recycling and reusing, and particularly relates to a method for recycling fluoride salt from complex aluminum electrolyte. According to the method for recovering the fluoride salt from the complex aluminum electrolyte, the complex aluminum electrolyte and the aluminum sulfate are used as raw materials, the processes of roasting, acid pickling dissolution, alkaline leaching, lithium removal, potassium removal, sodium removal and the like are sequentially carried out, a pure fluoride product (aluminum fluoride / sodium fluoride) is prepared, the whole process flow is simple and green, and the yield is high. According to the method, the fluorine element, the lithium element and the like in the complex aluminum electrolyte are recycled at the same time, HF is not generated, the resource utilization efficiency and economic benefits are improved, and stable production of electrolytic aluminum enterprises is promoted.

Owner:NORTHEASTERN UNIV

Process of producing regenerative aluminium oxide by floatation method

InactiveCN1454848ASolving the Difficulties of Recycling Secondary AluminaReduce the cost of aluminum smeltingSolid waste disposalFlotationElectrolysisNonferrous metal

The present invention relates to a process of producing regenerated alumina by floatation method, which it includes the following steps: collecting waste material containing alumina, breaking and pulveriling it, adding floatation agent to make intermittent floatation to obtain regenerated alumina, after floatation is completed, making water phase and solid phase separation, dehydrating regenerated alumina obtained by floatation, finally drying the dehydrated regenerated alumina. Said product can be used as raw material to produce the aluminum ingot or alloy aluminium with Ao-grade and below said grade, and can effectively reduce aluminium-smelting cost.

Owner:邹建明

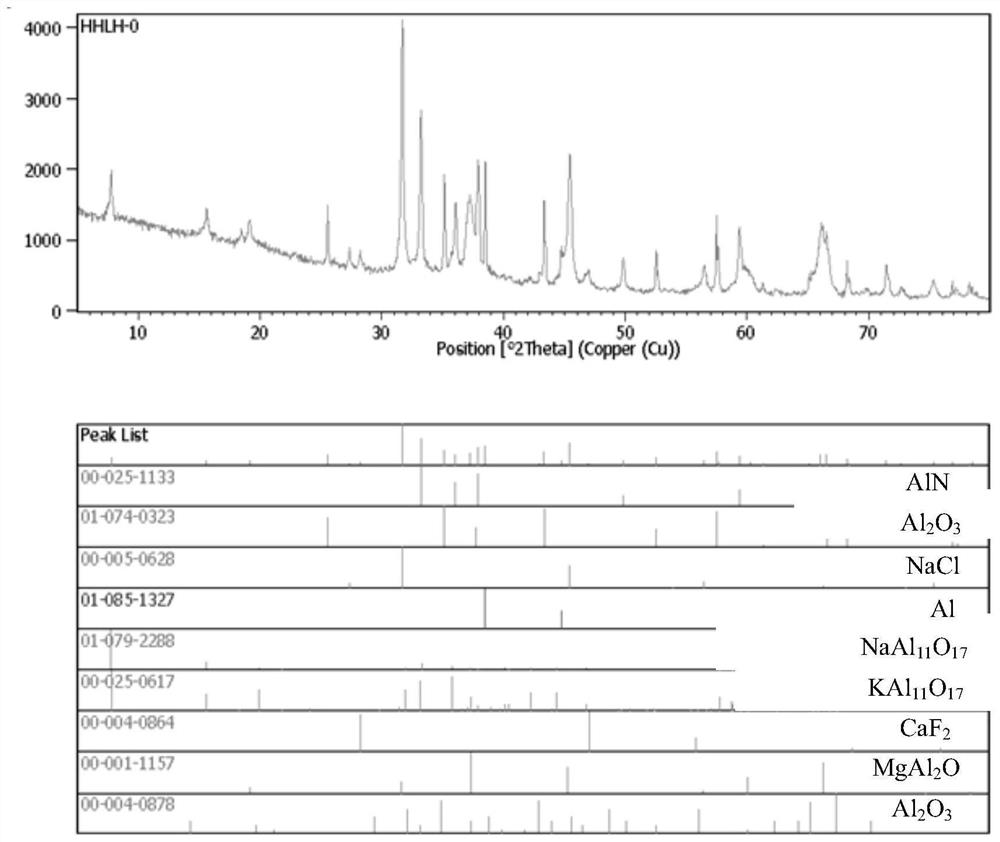

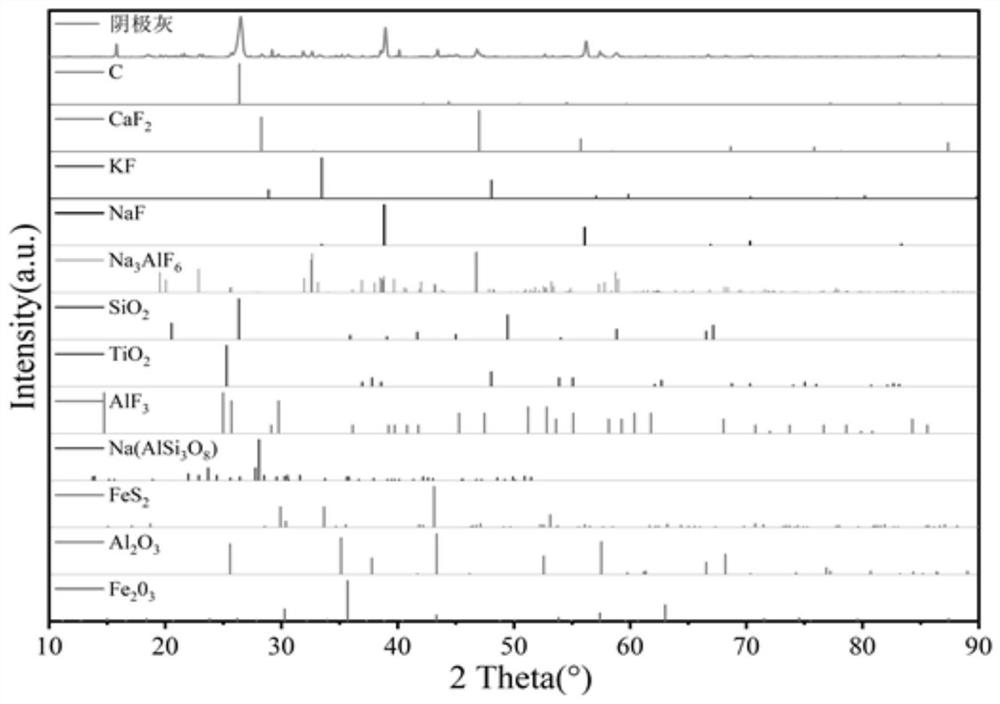

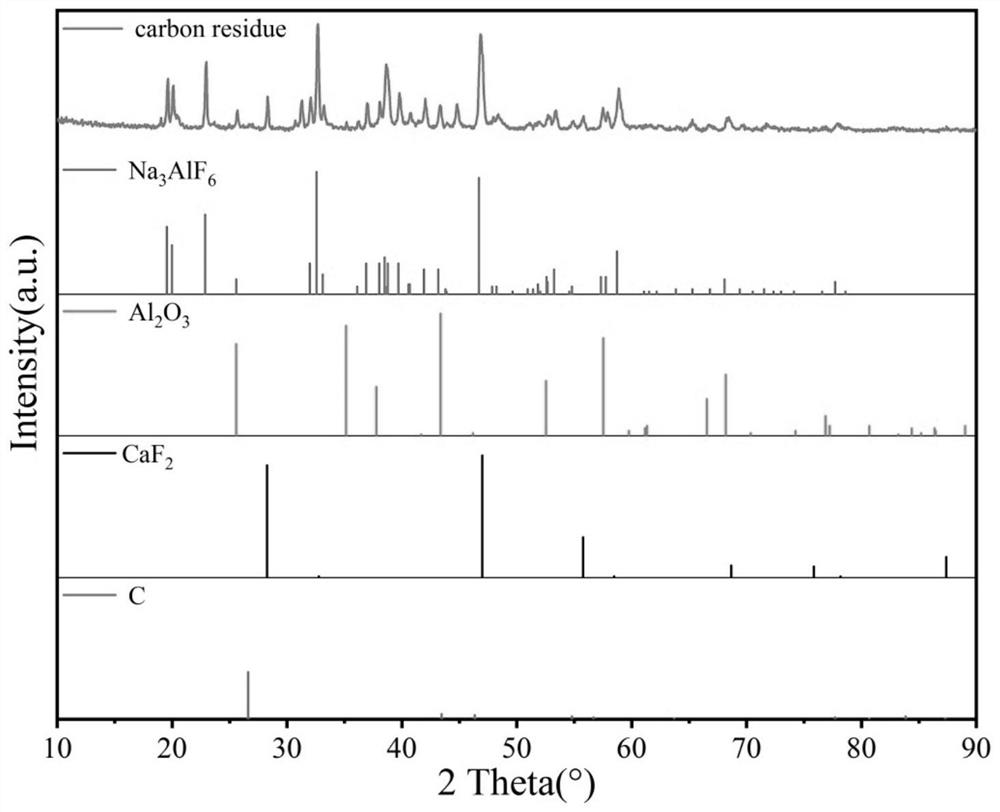

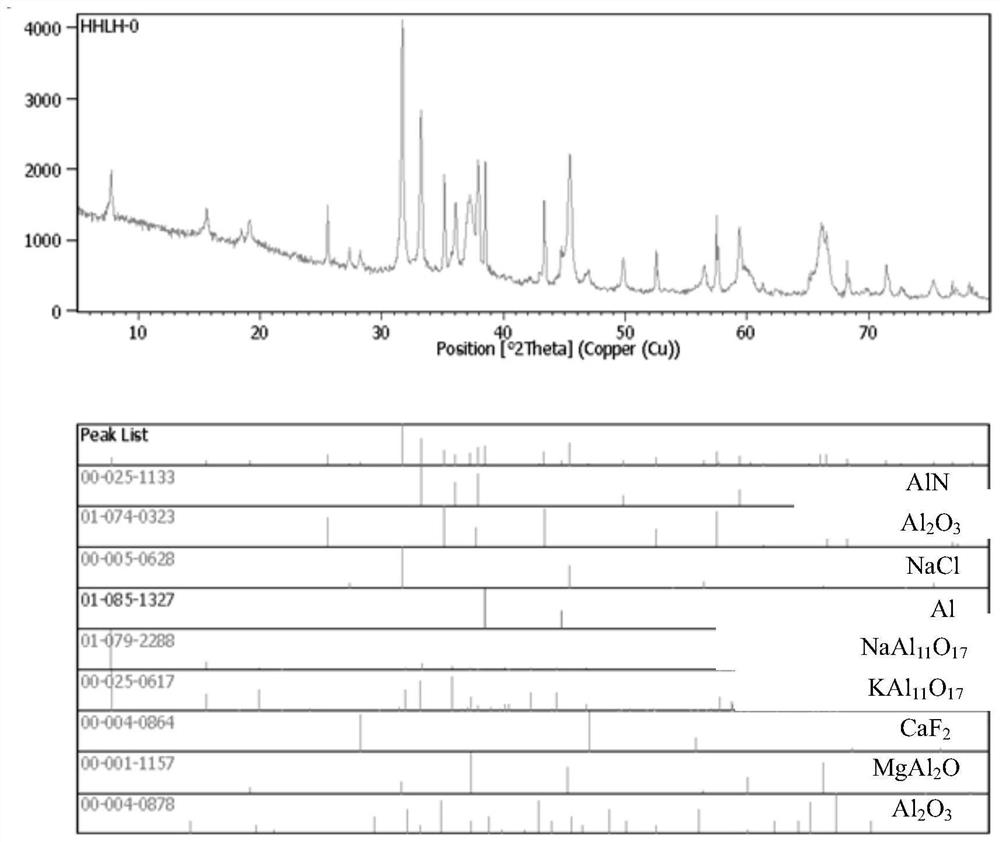

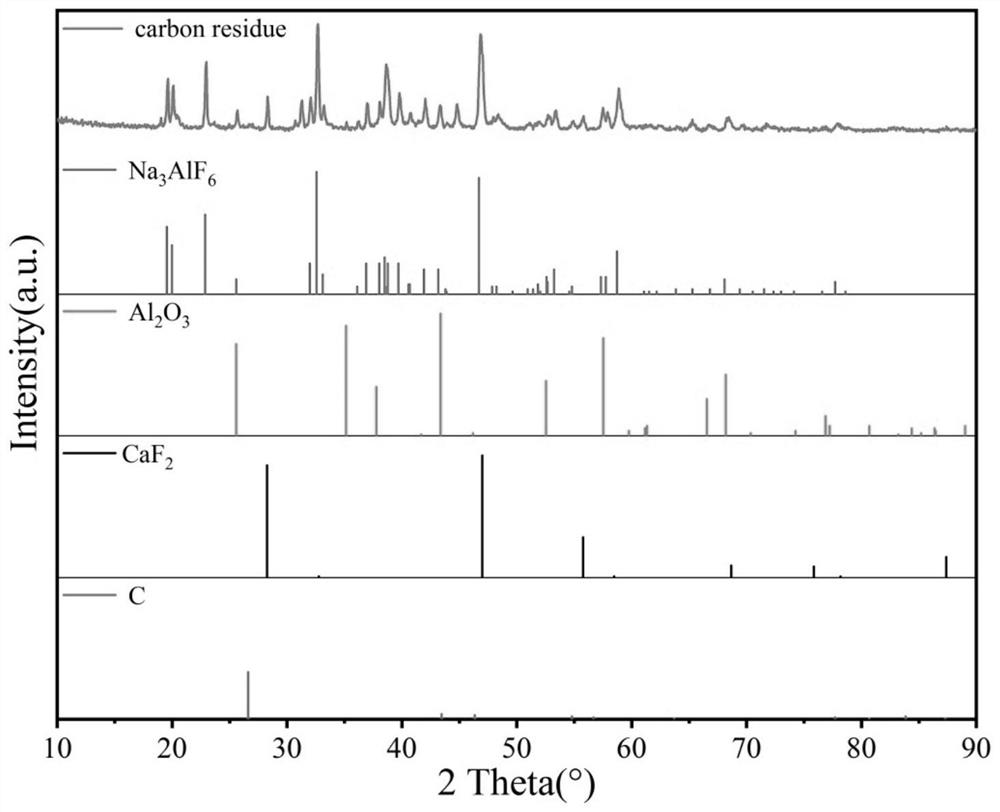

Method for linkage recovery of various kinds of solid waste materials in aluminum smelting process

ActiveCN113278808AHigh recovery rateLow consumptionSulfate/bisulfate preparationAluminium fluoridesAluminium electrolysisSmelting process

The invention discloses a method for linkage recovery of various kinds of solid waste materials in an aluminum smelting process. Specifically, component characteristics of aluminum ash, cathode ash and carbon residues are fully utilized, linkage recovery of various kinds of solid waste materials in the aluminum smelting process is comprehensively considered, the recovery rate of valuable elements of fluorine and aluminum is high (90 percent or higher), the product purity is high (the purity of a mixture of main products AlF3 and Al2O3 is 98 percent or higher), the method can be used for an aluminum electrolysis process, the whole technical profit additional value is high, reagent consumption and energy consumption are small, the ecological environment protection is facilitated, the material consumption and cost are effectively reduced, and economic benefits and environmental benefits of the solid waste material recovery are improved.

Owner:YUNNAN RUNXIN ALUMINUM

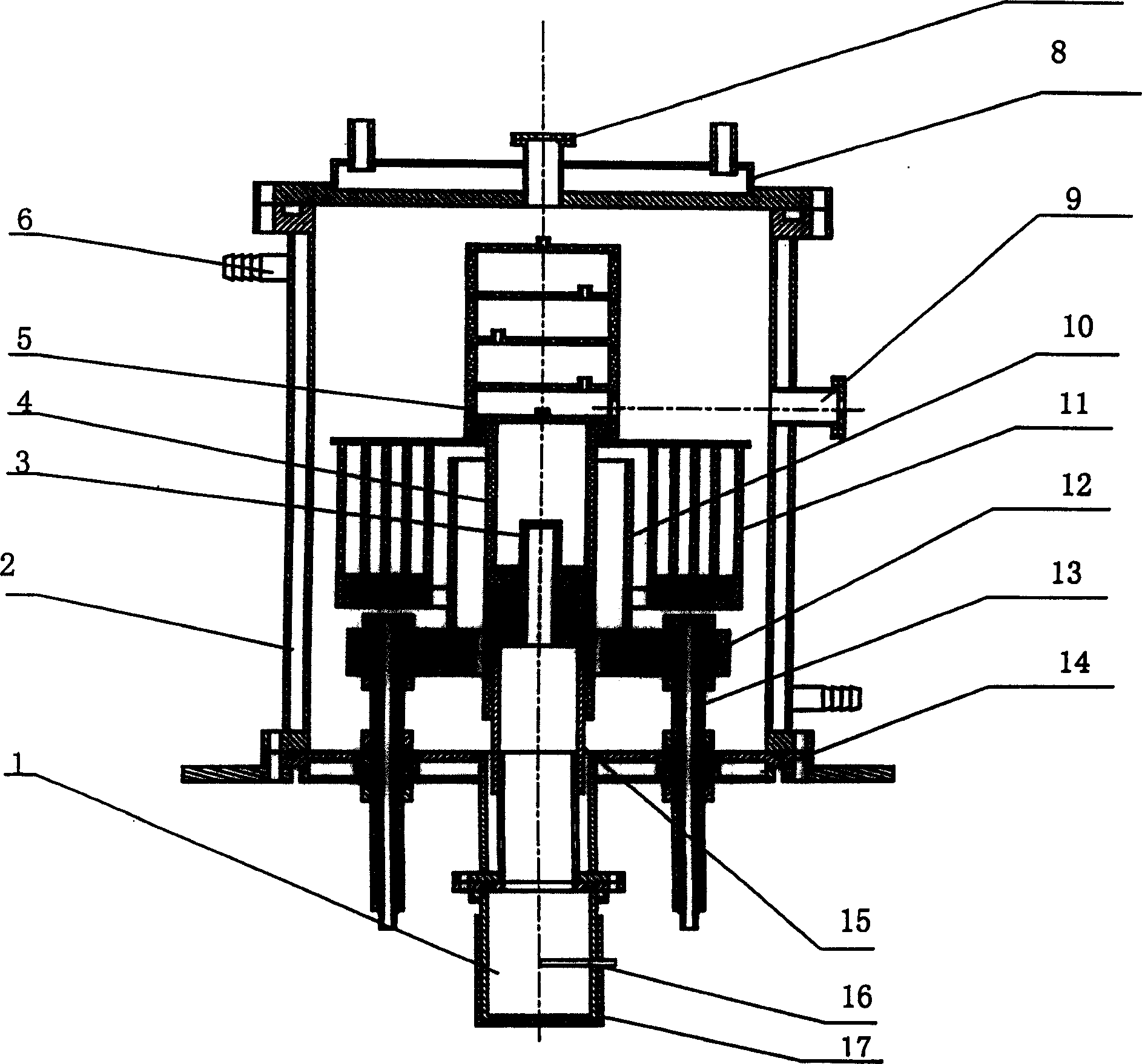

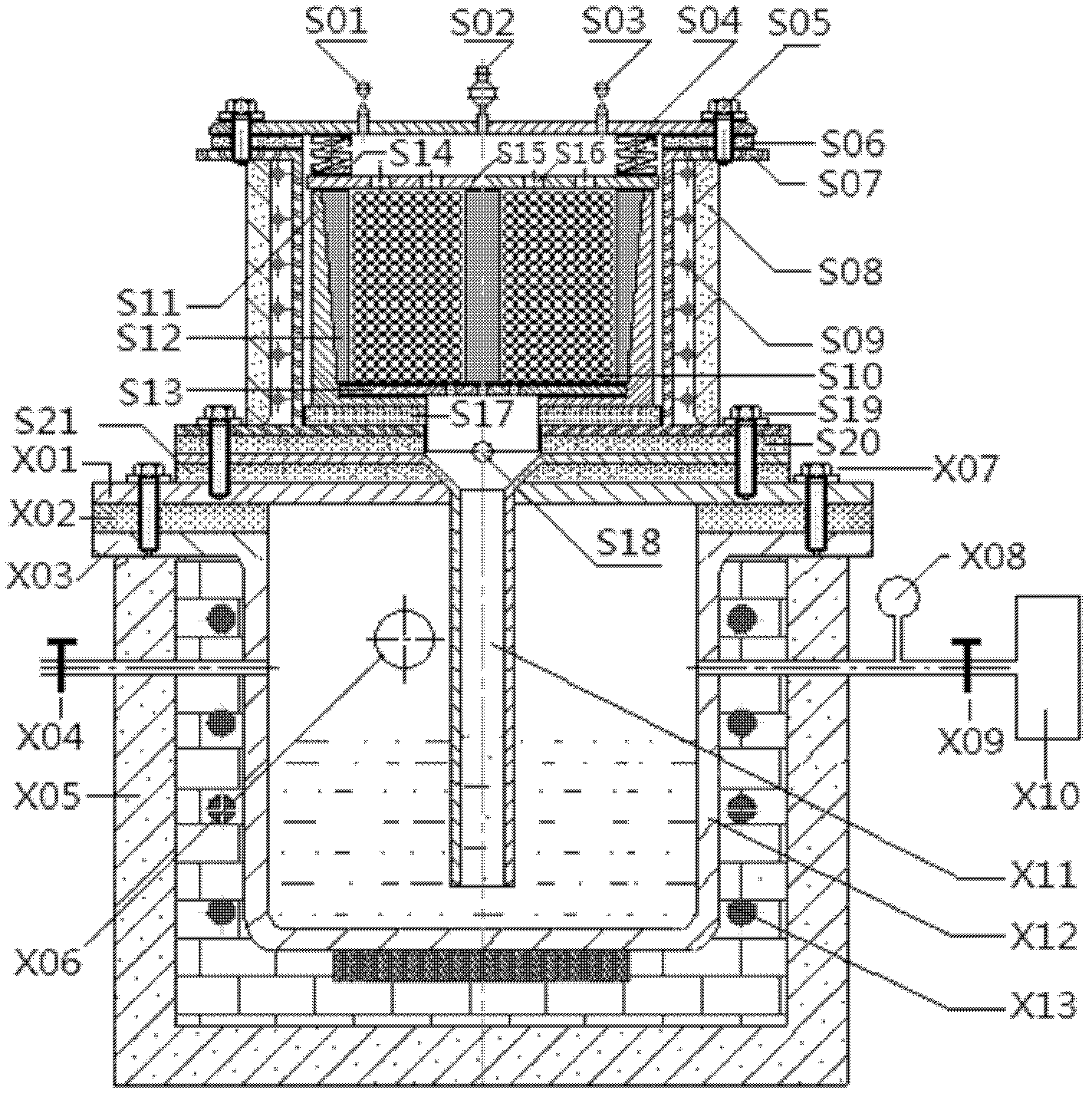

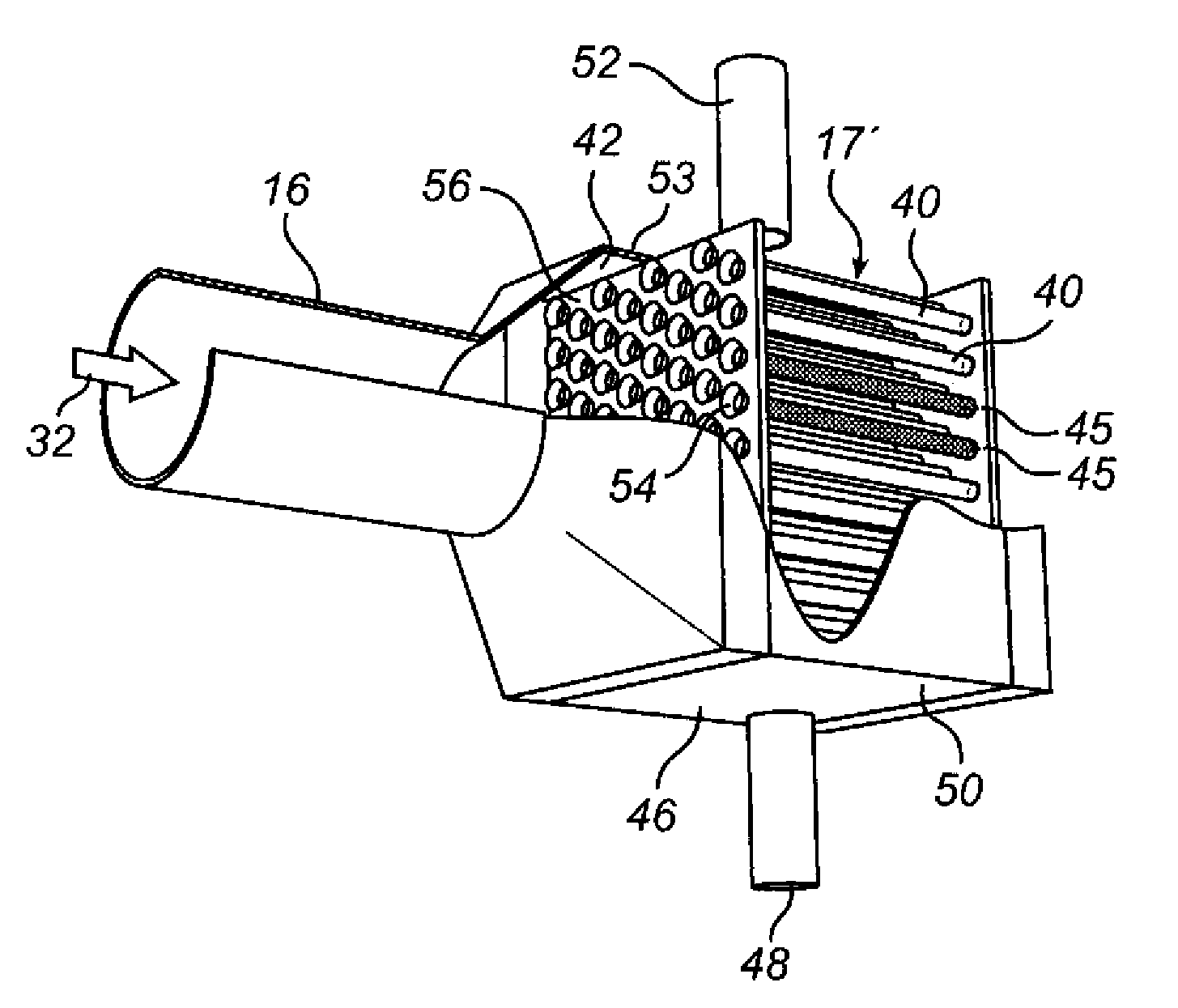

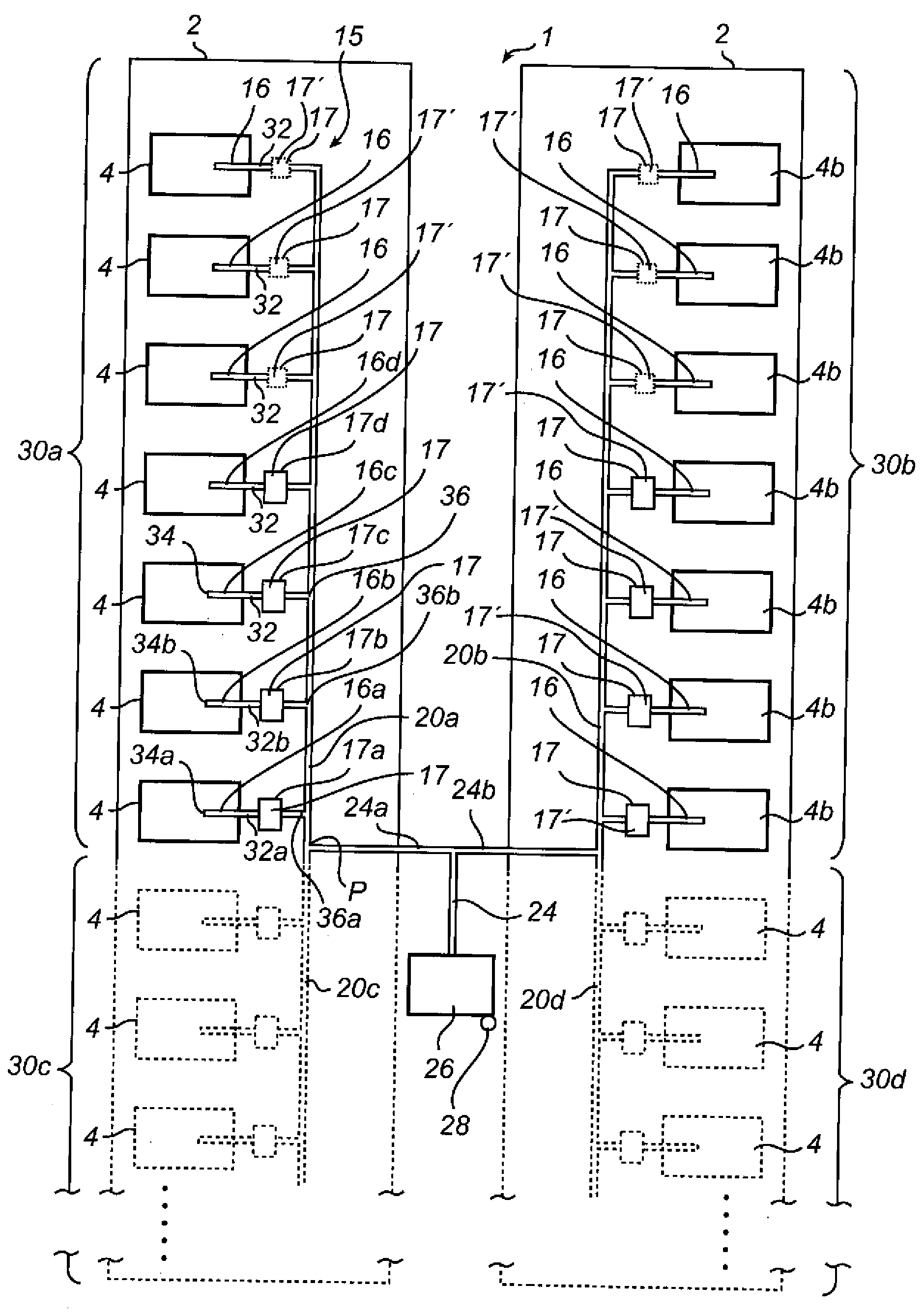

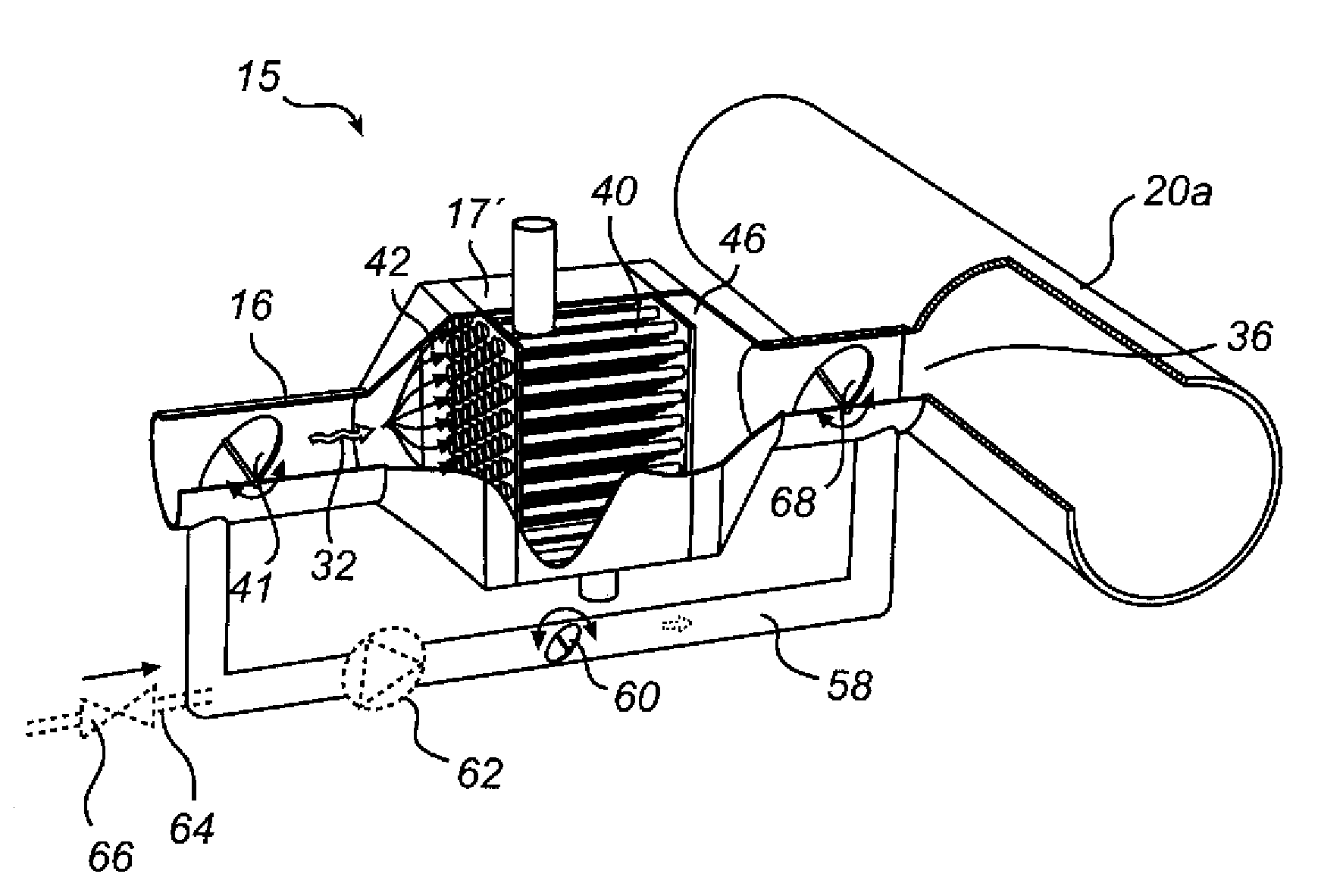

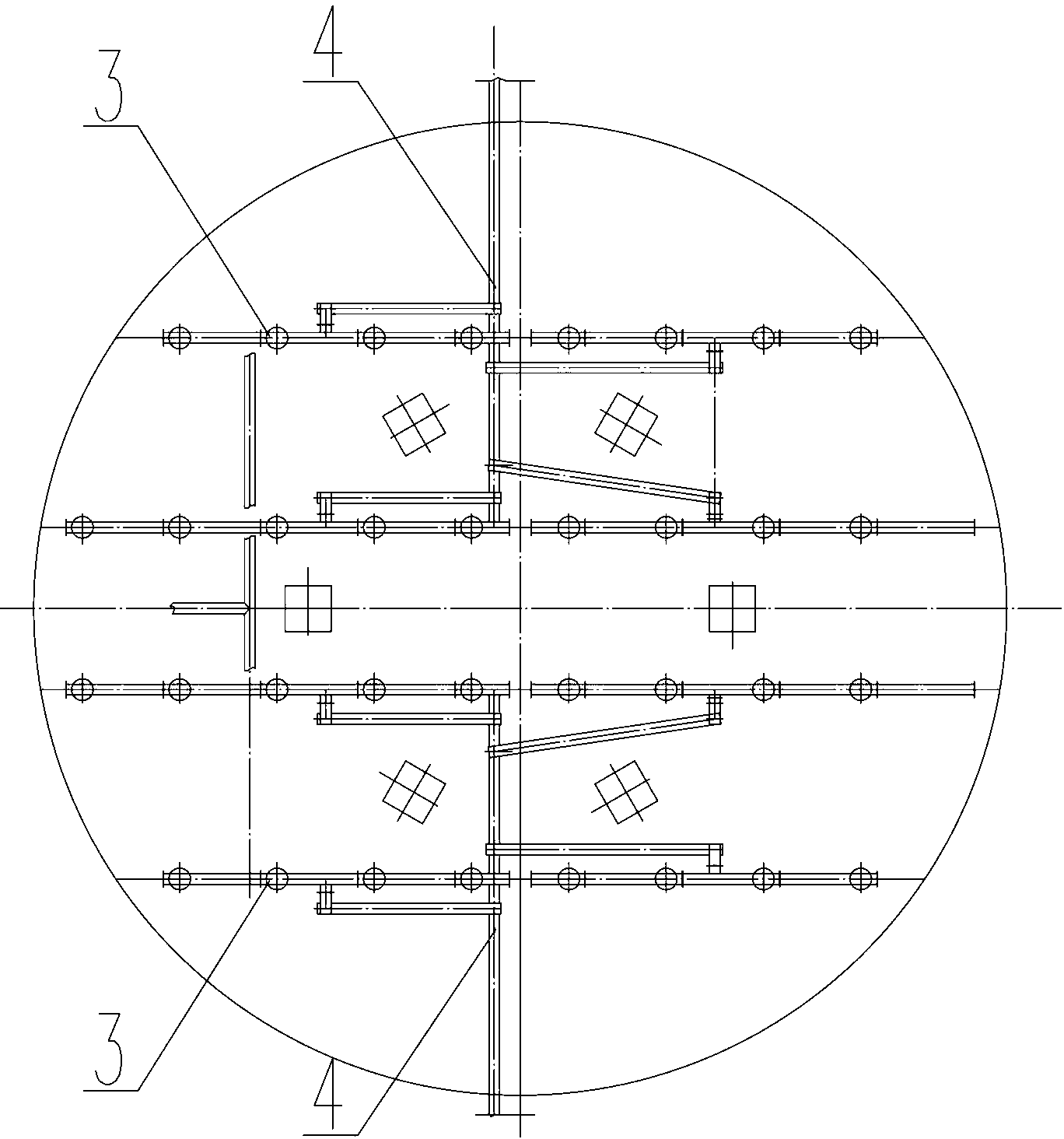

Raw gas collection system

ActiveCN103261487AReduce consumptionOvercome or alleviate shortcomingsCouplings for rigid shaftsIncreasing energy efficiencyCollection systemProcess engineering

Owner:GENERAL ELECTRIC TECH GMBH

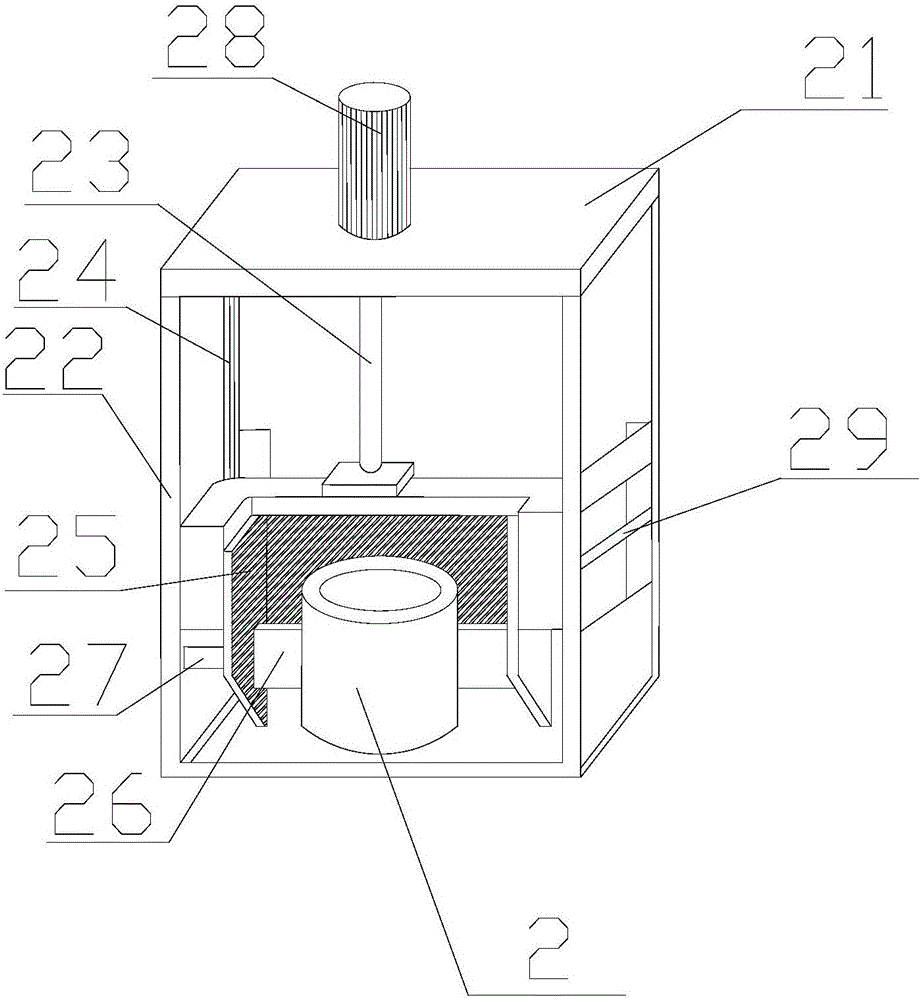

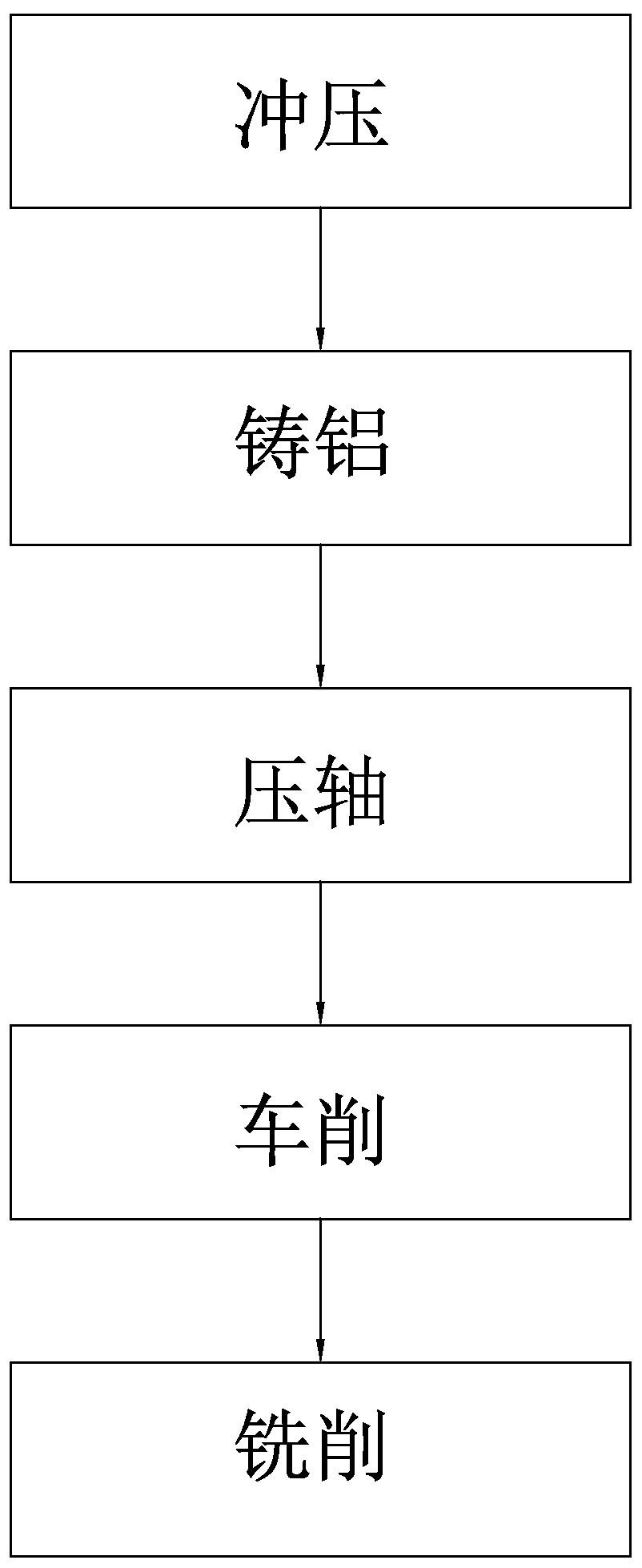

Production technology and production equipment for motor rotor of UAV camera

InactiveCN111558667AEvaluation is objective and accurateQuality assuranceShaping toolsNon-rotating vibration suppressionElectric machineryAluminium casting

The invention relates to a production technology and production equipment for a motor rotor of a UAV camera. The motor rotor meeting the using requirement is obtained through stamping of a punch, melting of pure aluminium by a dump-type aluminium smelting furnace, aluminium casting by an aluminium casting hydraulic machine, shaft pressing by an oil press, turning by a lathe and milling by a milling machine. Compared with the prior art, the production technology is perfected and clear in flow path, can lower the labor intensity of a worker, and is safe, high in obtained product quality and production efficiency.

Owner:衢州市迈德电子有限公司

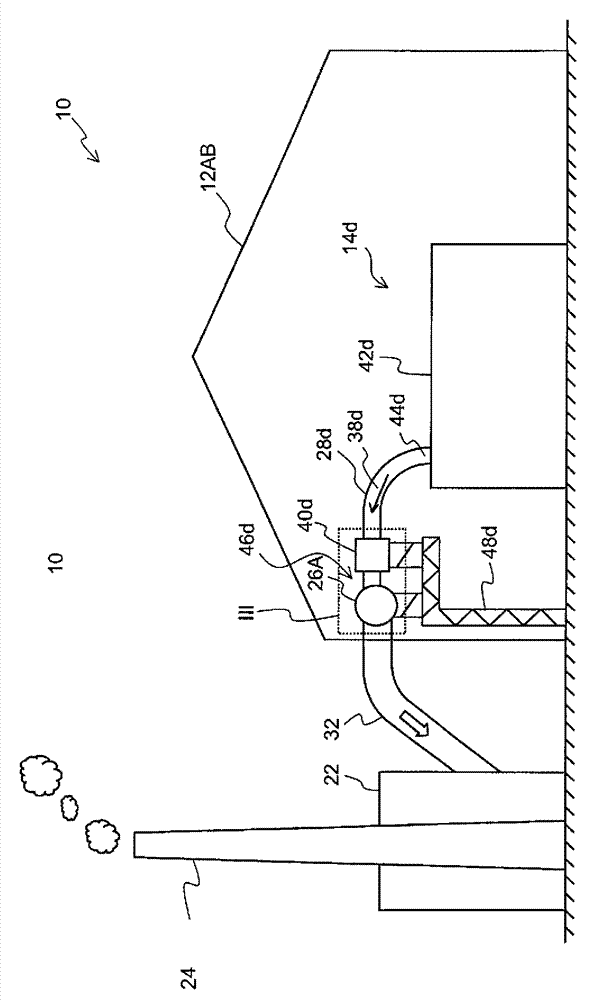

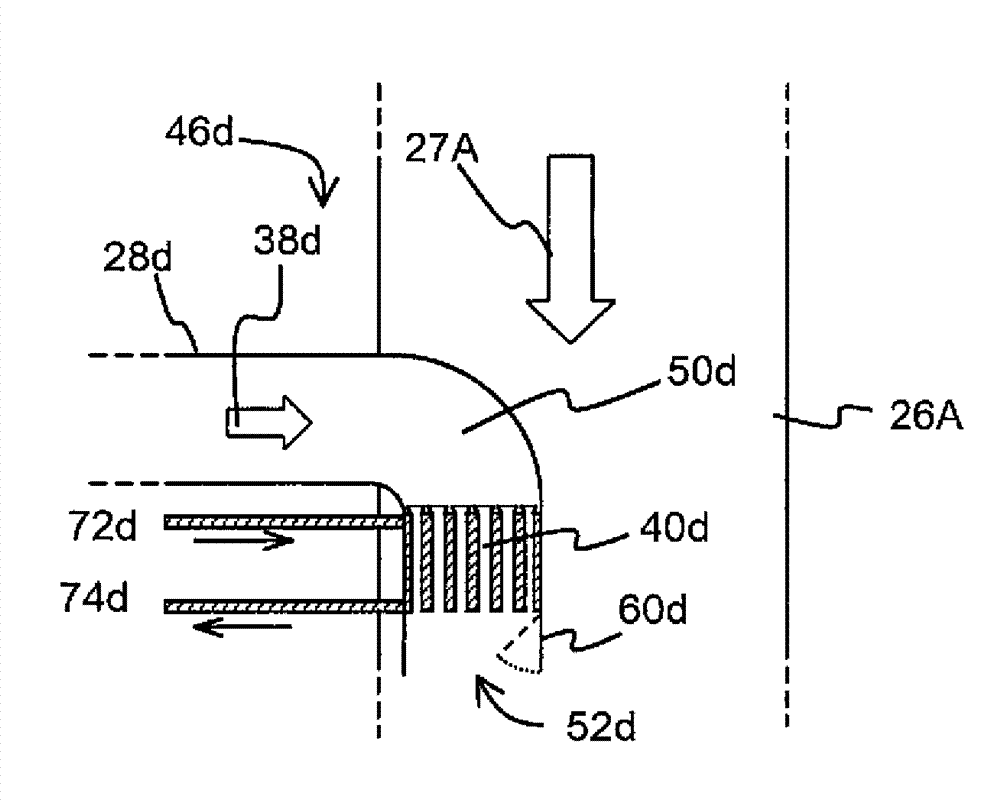

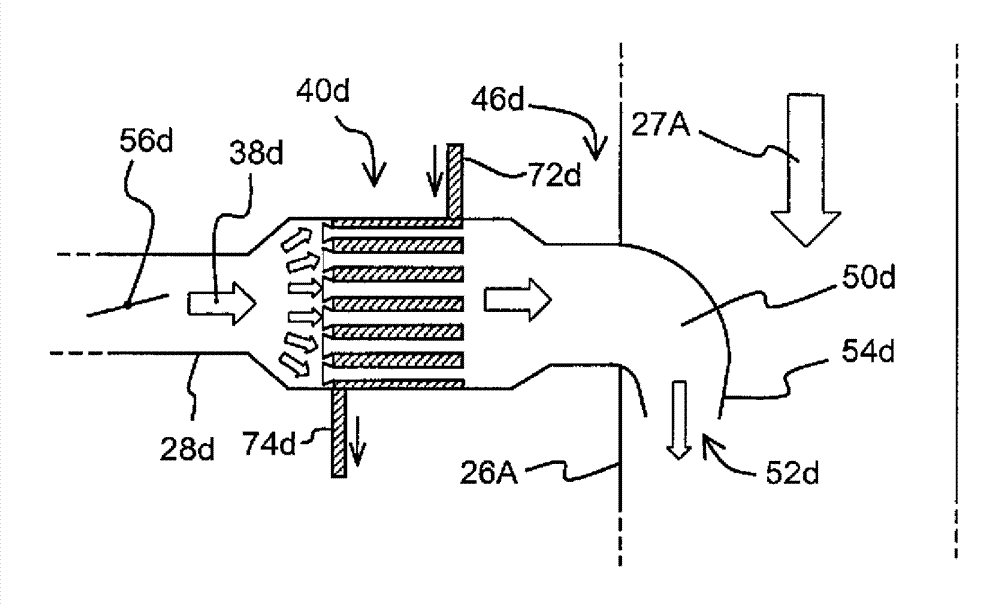

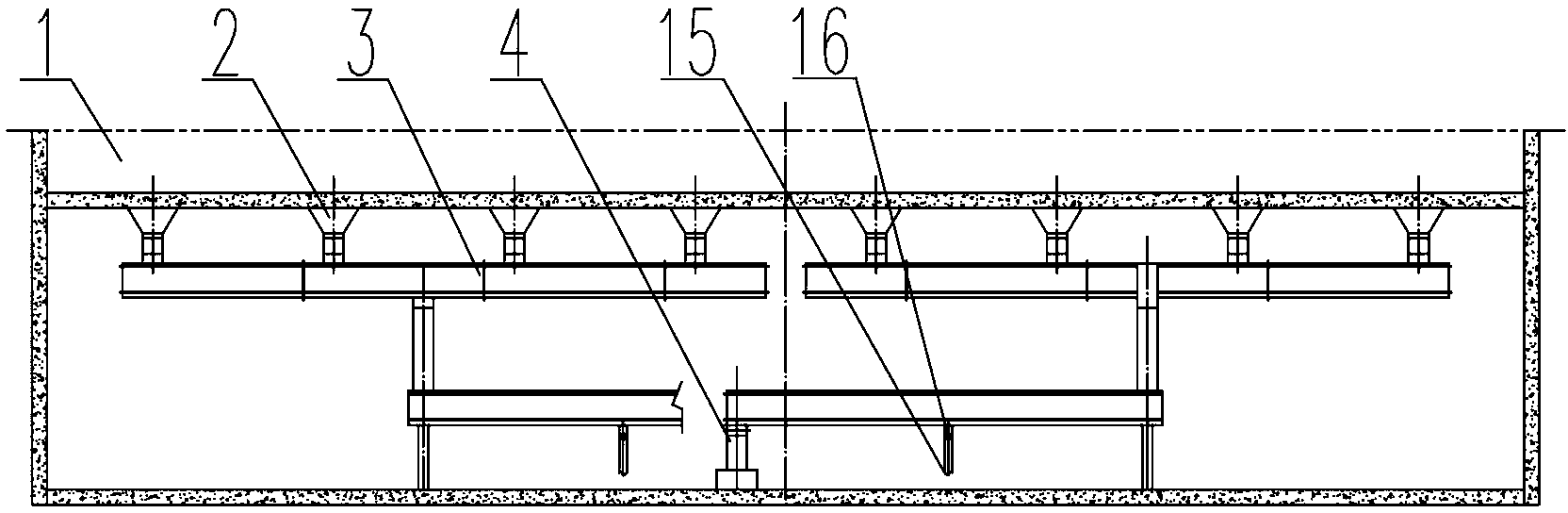

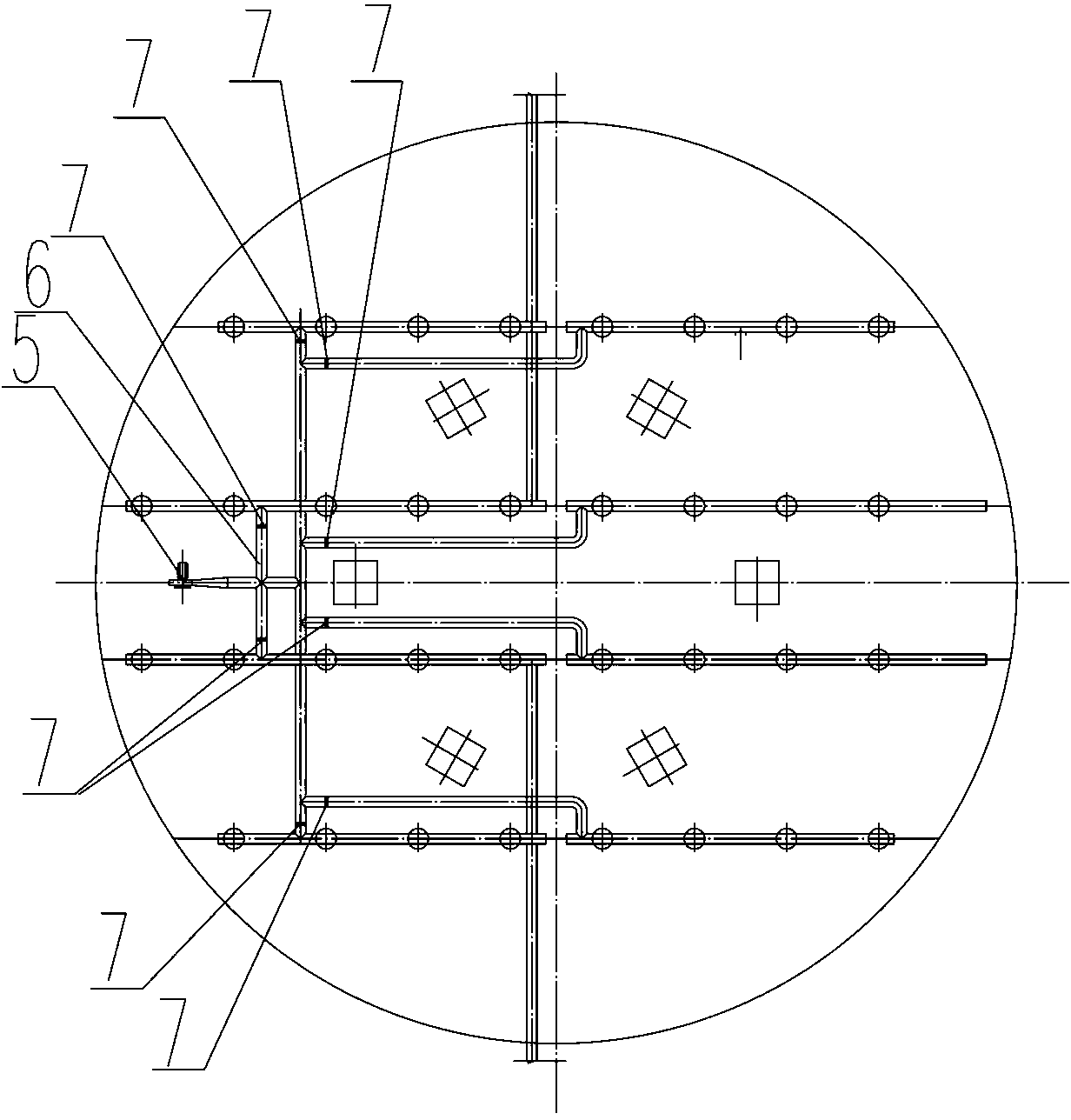

Pot heat exchanger

ActiveCN103201414ASufficient pressure dropReduce foulingElectrolysis componentsRecuperative heat exchangersPlate heat exchangerCollection system

A raw gas collection system for collecting raw gas from a plurality of aluminium smelting pots is equipped with a plurality of branch ducts (28d), each of which is arranged to channel a respective branch flow (38d) of raw gas from an aluminium smelting pot to a collection duct (26A), which is common to and shared by the branch ducts (28d). Each of said branch ducts (28d) is, near an outlet (52d) thereof, equipped with a curved section (50d) for aligning the branch flow (38d) with a flow direction of raw gas (27A) already present in the common collection duct (26A), and a constriction (54d) for accelerating the branch flow (38d) through the branch duct outlet (52d) into the common collection duct (26A). Furthermore, each of said branch ducts (28d) is equipped with a heat exchanger (40d) for removing heat from the respective branch flow (38d) of raw gas.; The combined flow resistance of the constriction (54d) and the heat exchanger (40d) reduces the need for adjusting the respective branch flows (28d) using dampers, thereby reducing the power required to transport the raw gas.

Owner:GENERAL ELECTRIC TECH GMBH

Energy-saving and cost-reducing technology for directly utilizing smelting of aluminium scraps

InactiveCN103614561AImprove qualityTake advantage ofProcess efficiency improvementAlloyAluminium smelting

The invention relates to the field of waste metal recovery, and particularly relates to an energy-saving and cost-reducing technology for directly utilizing smelting of aluminium scraps. Two smelting procedures of smelting and utilizing secondary aluminium are replaced by one smelting procedure by virtue of changing the traditional secondary aluminium smelting technology, so as to finish the overall process from smelting to utilizing. Energy conservation and consumption reduction are greatly achieved by reducing two smelting procedures, and purifying and adding alloying components. The method provided by the invention not only is simple in flow, but also can be used for saving energy source, and reducing emission of wastes.

Owner:ANHUI JINYING ALUMINUM

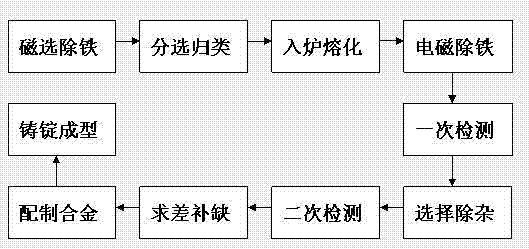

Secondary aluminium smelting technology and processing technology

The invention provides a secondary aluminium smelting technology and processing technology and relates to the technical field of aluminium alloys. The secondary aluminium smelting technology comprises the steps that a pretreated aluminium strip and an industrial pure aluminium ingot are melted at the temperature of 680-760 DEG C; then the melted aluminium liquid with industrial pure silicon, industrial pure copper, industrial pure iron, pure metals and rare-earth metals are added in a smelting furnace, nanometer carbonates are added, meanwhile inert gas is injected from the bottom of the smelting furnace, and the temperature is raised to 1680-1800 DEG C till complete melting is achieved and kept for 40-60 min; and then filtering is conducted through a foam ceramic filtering plate. The technology is simple, the impurity removing and purifying effects in the smelting progress are good, and the technology is suitable for preparing an automobile body aluminium alloy. The secondary aluminium processing technology including the secondary aluminium smelting technology is easy to operate and environmentally friendly, and the prepared finished product is good in quality.

Owner:重庆顺博铝合金股份有限公司

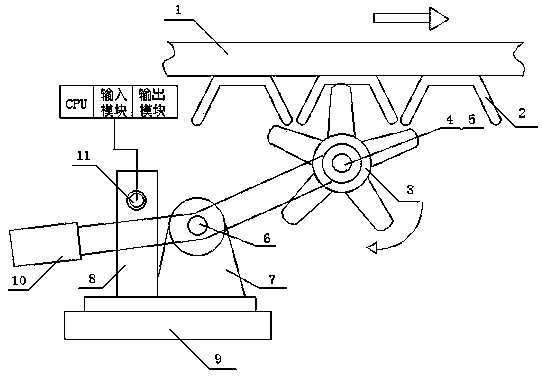

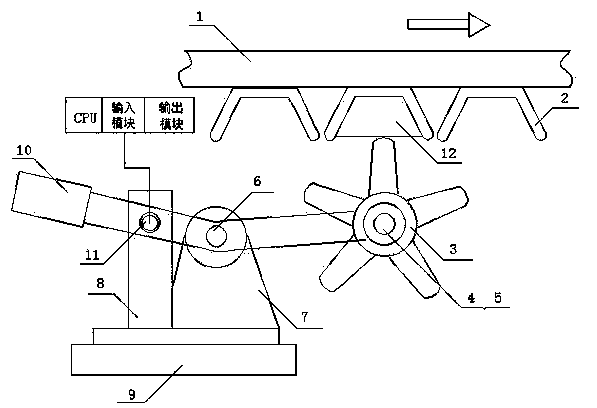

Stripping failure detection, alarming and secondary knocking unit for 20kg aluminum ingot continuous caster

InactiveCN104174828AExquisite designCompact structureCasting parameters measurement/indication devicesProduction lineElectrical control

The invention relates to the technical field of aluminum smelting, in particular to a stripping failure detection, alarming and secondary knocking unit for a 20kg aluminum ingot continuous caster. The stripping failure detection, alarming and secondary knocking unit comprises a secondary knocking device, a stripping failure detector and an electrical control device. The stripping failure detection, alarming and secondary knocking unit has the advantages that the unit is capable of accurately knocking an aluminum ingot failed to be stripped, the unit is ingeniously designed, compactly structured and highly automated in the limited space of the 20kg aluminum ingot continuous caster, the unit allows accurate stripping by knocking, the major safety hazard that stripping failure of the aluminum ingot causes explosion of molten aluminum is eliminated, and the unit is applicable to a production line of 20kg aluminum ingot continuous casters in the industry of aluminum electrolysis.

Owner:QINGHAI QIAOTOU ALUMINUM & POWER CO LTD

Dealkalization method of Bayer process red mud

ActiveCN110127725BImprove solubilityHigh activityTransportation and packagingSolid waste disposalEngineeringSlurry

The invention relates to the field of aluminum smelting, in particular to a dealkalization method of red mud by the Bayer process, comprising: a, taking red mud; b, taking calcium oxide-containing materials, strong oxidants, and fluorides and putting them into enhanced diffusion of red mud slurry In the container, control the CaO in the calcium oxide-containing material and the Na in the solid phase of the red mud 2 The weight ratio of O is 2 to 6, the addition of strong oxidant is 0 to 0.1% of the content of sodium oxide in red mud, and the addition of fluoride is 0 to 0.1% of the content of sodium oxide in red mud to obtain mixed pulp residue; c, Atmospheric pressure dealkalization reaction, put the mixed pulp slag obtained in step b into a stirred atmospheric pressure dealkalization reactor for dealkalization reaction, the reaction temperature is 50-102°C, the liquid-solid ratio is 3-8, and the reaction time is greater than 3h ; d, separation and washing, the separated alkali-containing solution is returned to the alumina production process, and the separated low-alkali red mud is sent to the storage yard for storage, which can reduce the alkali content in the discharged red mud to less than 1%, and does not produce other hazardous waste.

Owner:河南镁联铝基材料有限公司

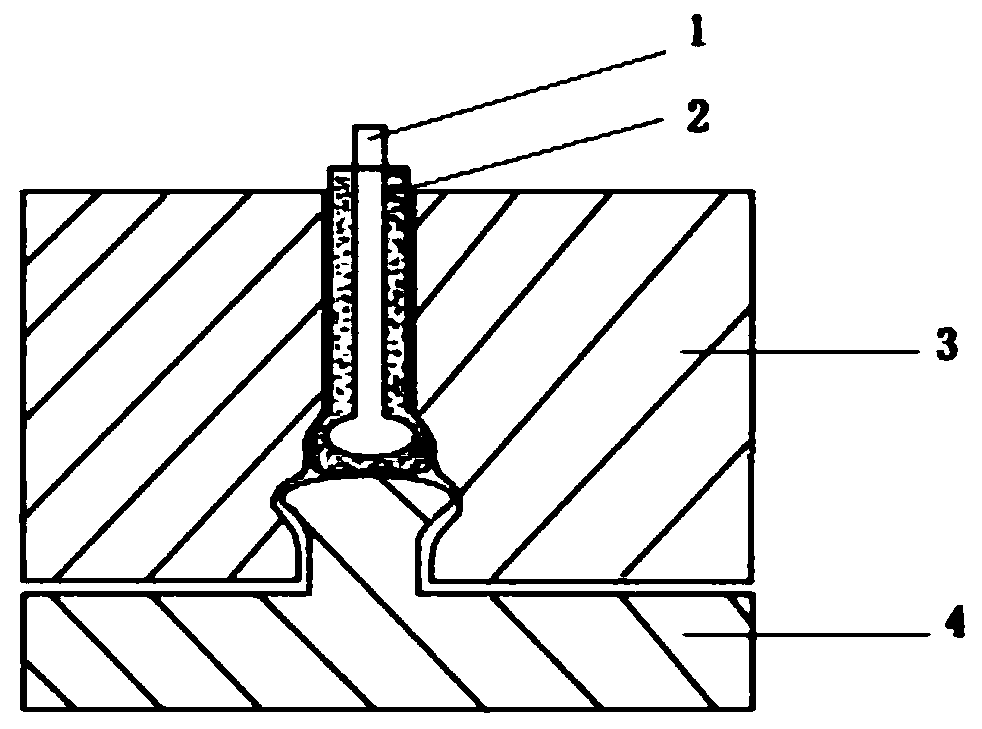

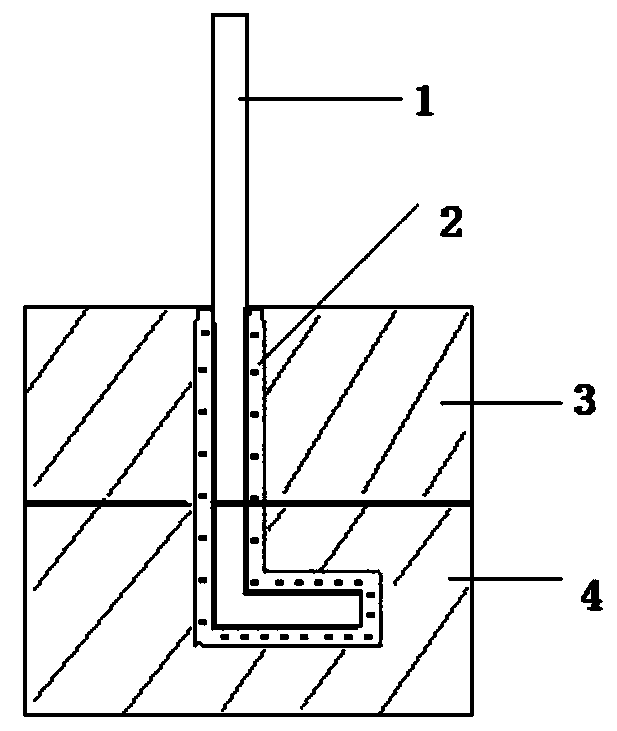

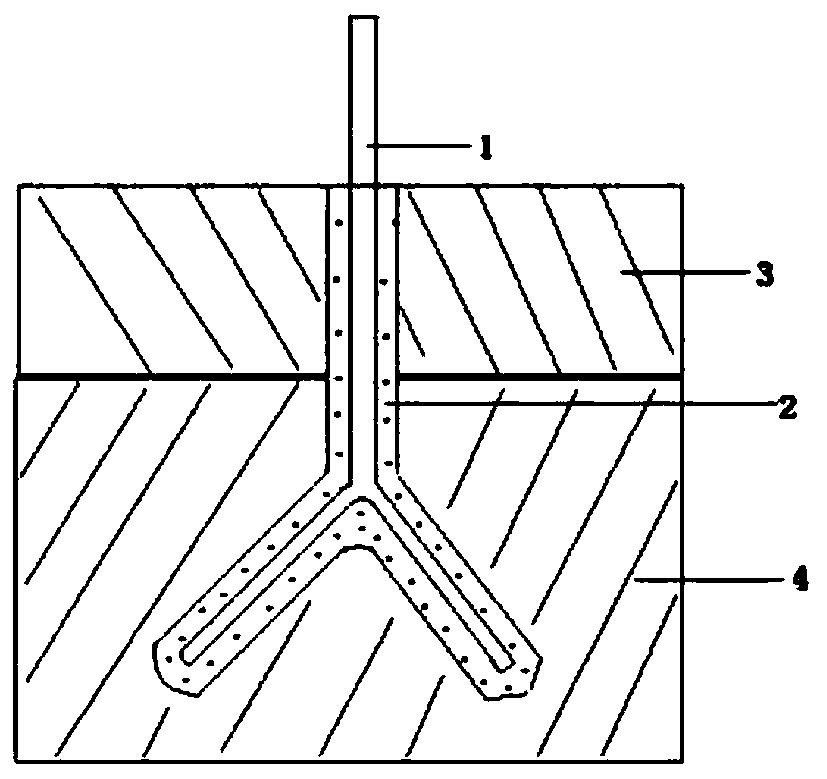

Suspension type fire-resistant heat preservation assembly for large-capacity oxygen-aluminum co-production electrolytic cell.

The invention belongs to the technical field of aluminum smelting, and particularly relates to a suspension type fire-resistant heat preservation assembly for a large-capacity oxygen-aluminum co-production electrolytic cell. The assembly comprises a metal rod, a hose, a heat preservation layer and a fire-resistant layer, wherein the metal rod and the aluminum electrolytic cell are isolated throughthe fire-resistant layer; the metal rod is wrapped with the hose, and the space between the metal rod and the hose is filled with an anti-expansion and anti-oxidation buffer powder mixture; the hoseis wrapped with the heat preservation layer, the fire-resistant layer is arranged at the lower part of the heat preservation layer, and the heat preservation layer and the fire-resistant layer are sealed; and the metal rod, the heat preservation layer and the fire-resistant layer are fixedly connected. The invention provides the fire-resistant heat preservation assembly which can be freely combined, is easy to lift and convenient to move for the large-capacity non-carbon anode vertical electrolytic cell, and the problem that the fire-resistant heat preservation material is broken due to thermal expansion or oxidation of the metal when the fire-resistant heat preservation material is connected with the metal is well solved.

Owner:浙江睿曦绿业新材料科技有限公司

Aluminium oxide bin bottom blanking device and method

The invention relates to a blanking device and a method, particularly relates to an aluminium oxide bin bottom blanking device and a method, and is mainly applied to the aluminium oxide storage and transportation field in aluminium smelting. The blanking device comprises a storage bin and a blanking port, wherein the blanking port is connected with a blanking chute, a valve arranged between the storage bin and the blanking port and a valve arranged between the blanking port and the blanking chute are saved, the blanking chute is connected with a main chute, and a branch air pipe supplies air for the blanking chute, the branch air pipe is connected with an air pipe, the air pipe is connected with a fan, the air pipe is provided with an electric valve, and the electric valve is controlled by a computer of a control chamber. The blanking device and the method provided by the invention have the beneficial effects that hardening of aluminium oxide in the storage bin is reduced, and thus blocking of the blanking port is avoided.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

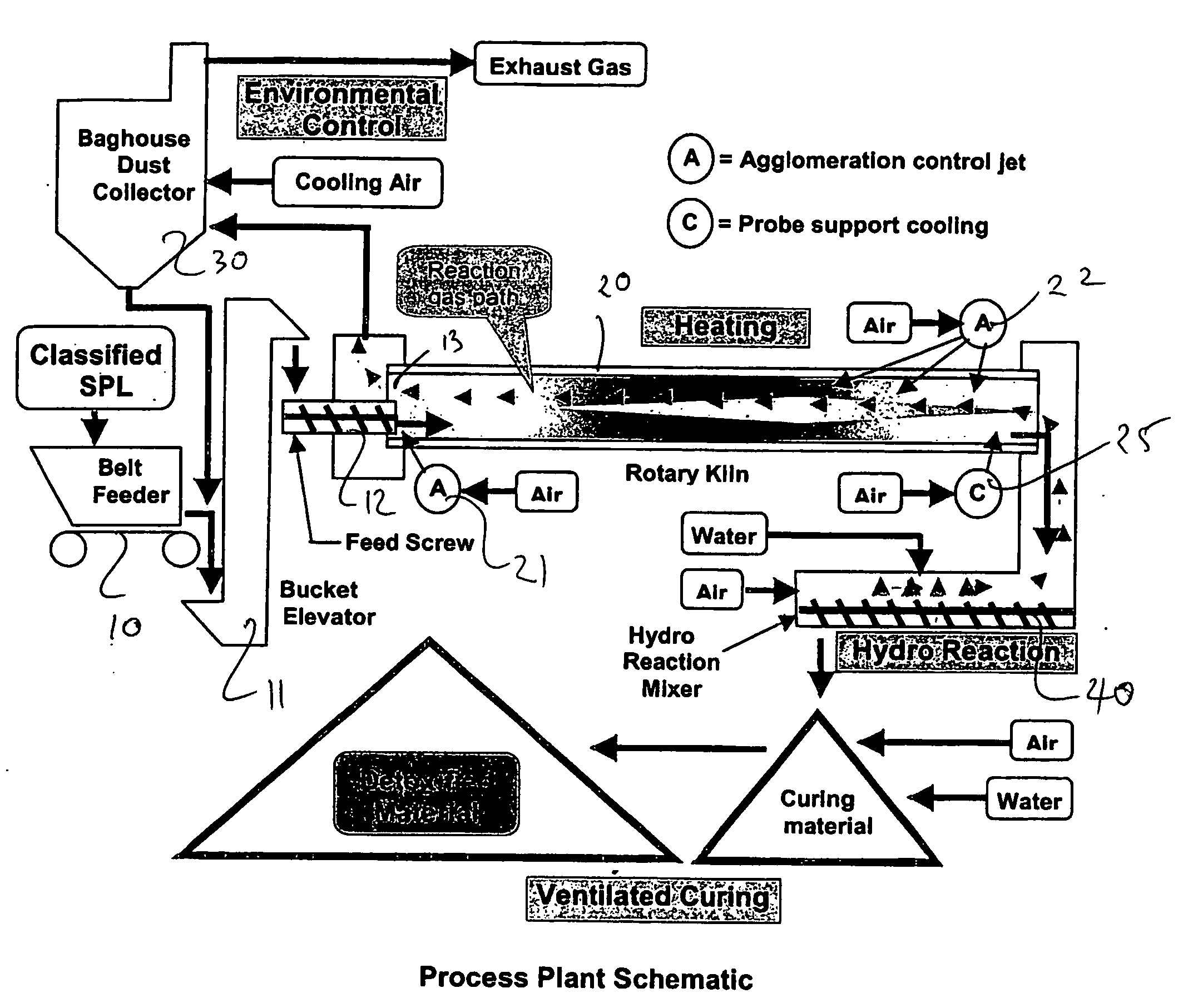

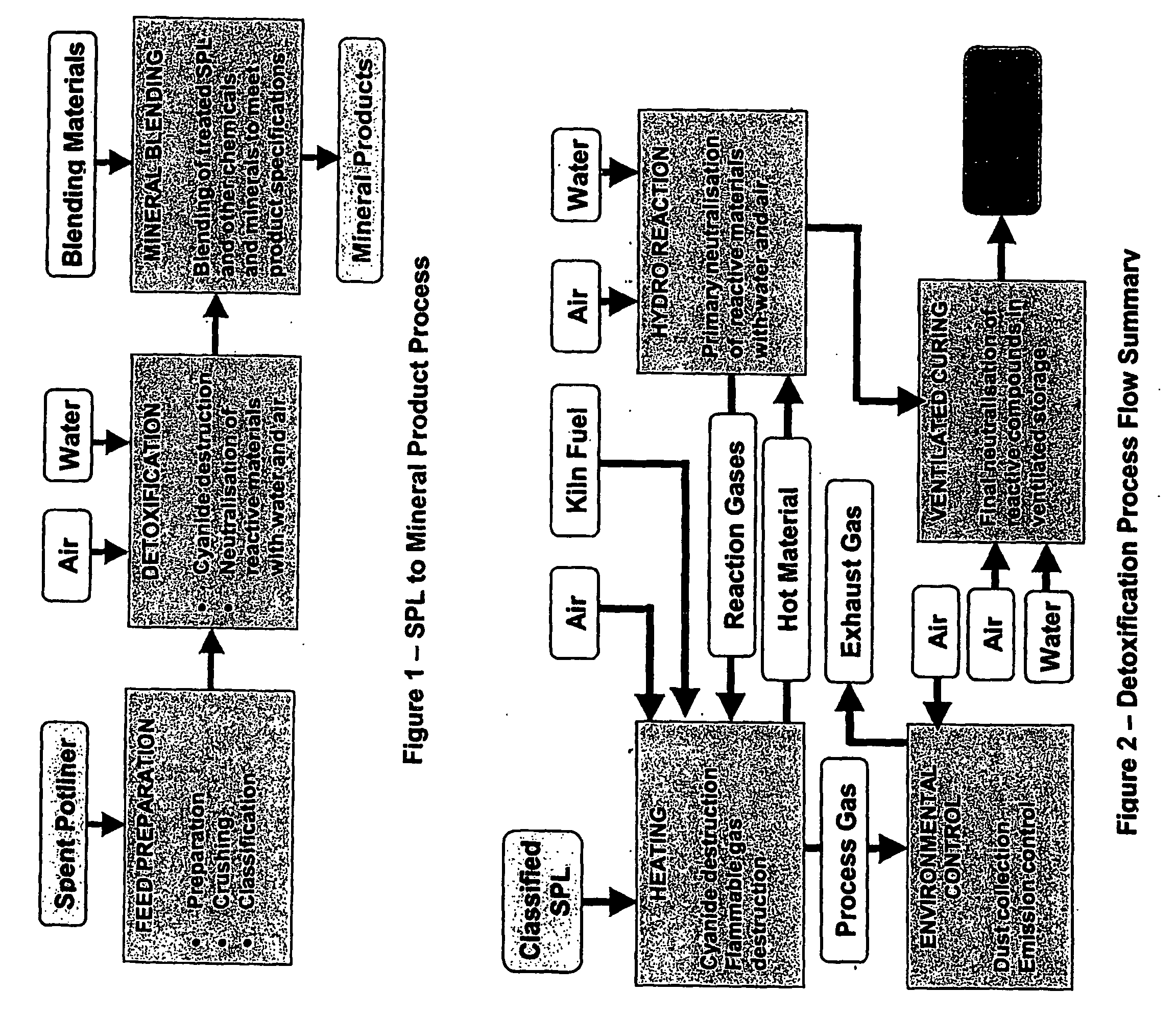

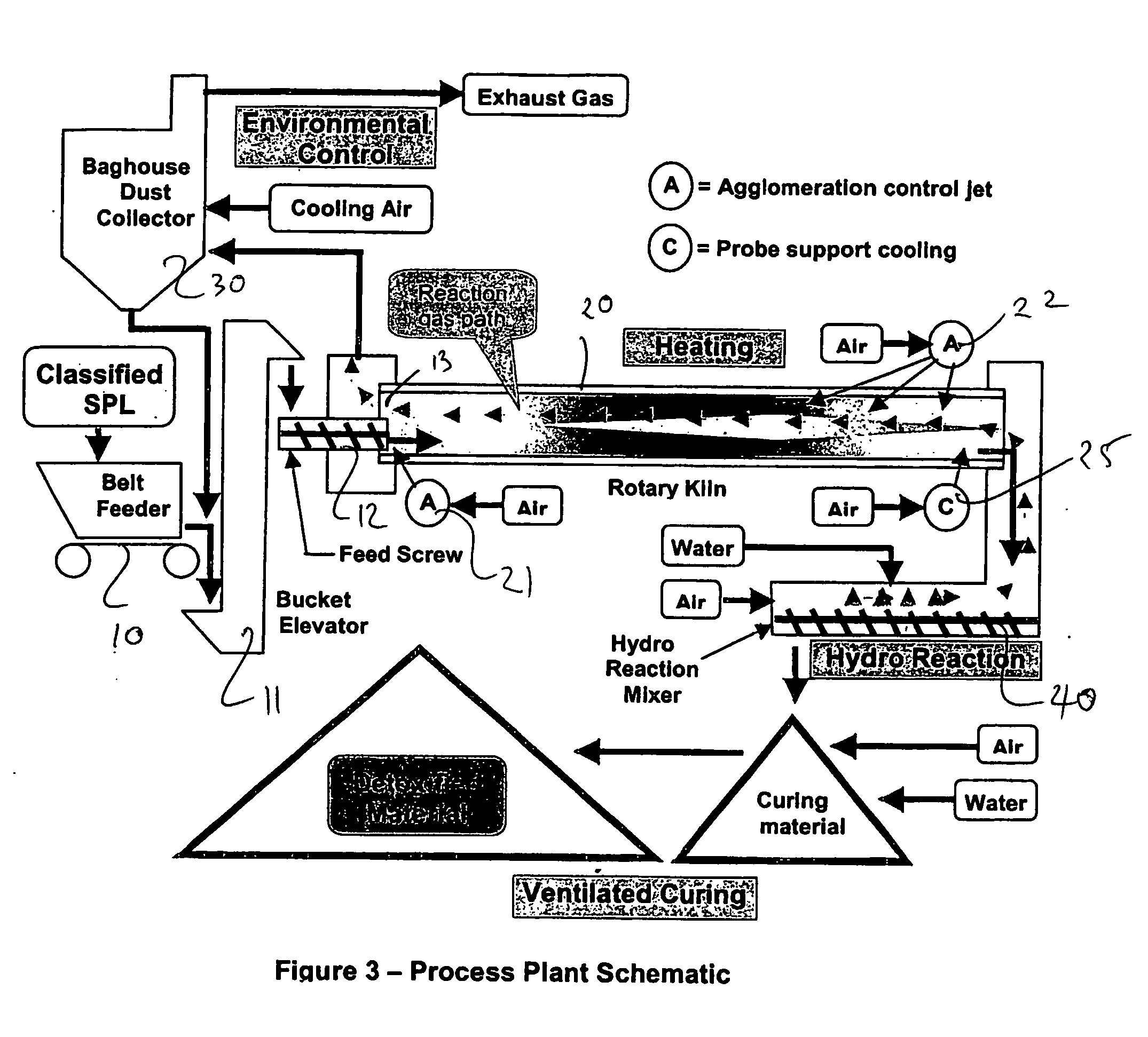

Treatment of smelting by-products

A method of treating a spent potliner after use in an aluminium smelting process, the method comprising crushing and classifying the spent potliner, placing the classified and crushed spent potliner in a furnace at a temperature greater than 450° C., heating the spent potliner to a temperature greater than 450° C., mixing the heated spent potliner with water to produce reaction gases and residue, burning the reaction gases, mixing the residue with water in a well ventilated area for a period of weeks to cure the residue. The method also embraces blending the cured residue with other chemicals and minerals to provide specific mineral products.

Owner:REGAIN TECH

A method for preheating and starting a vertical electrode aluminum electrolytic cell

Owner:浙江睿曦绿业新材料科技有限公司

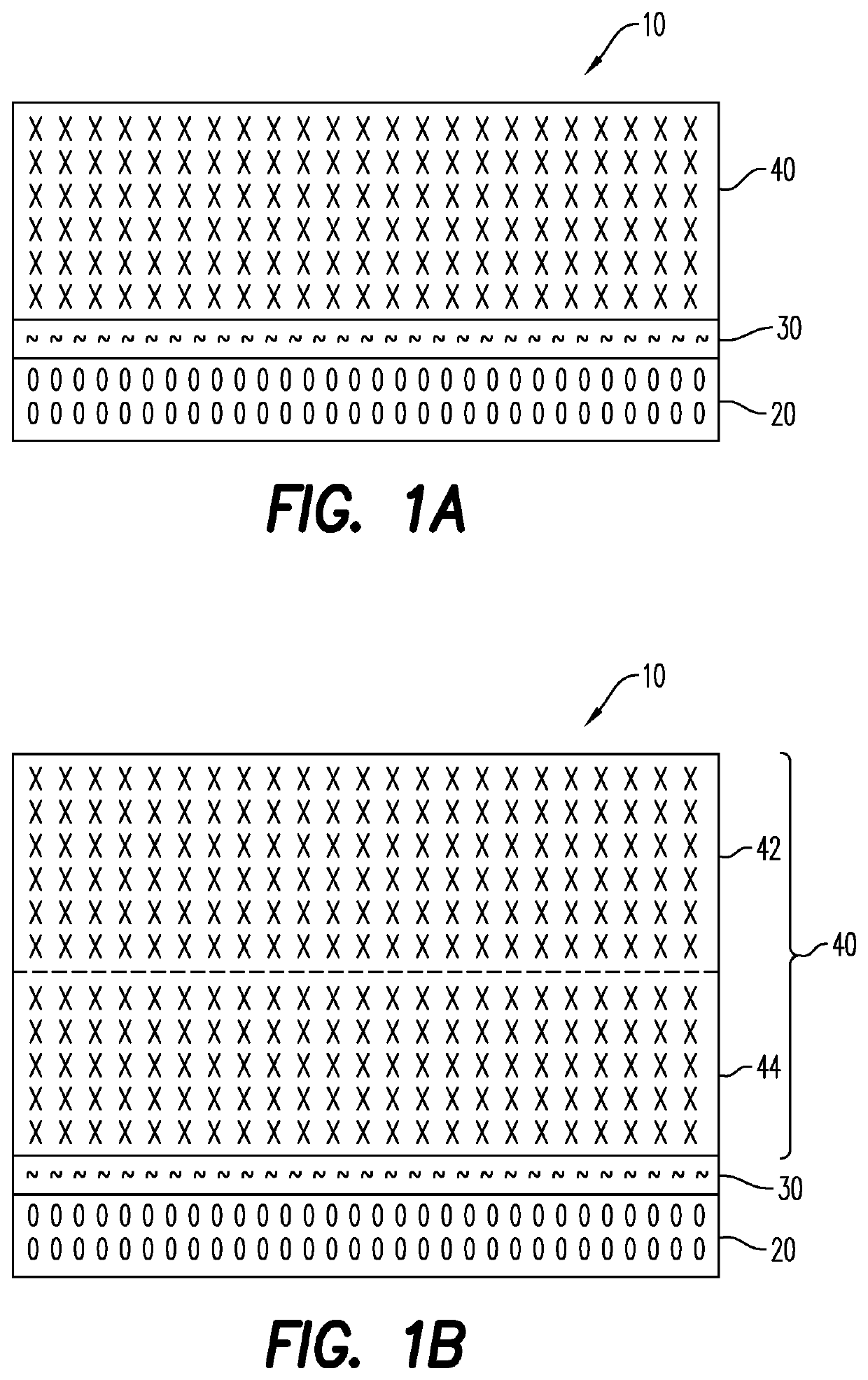

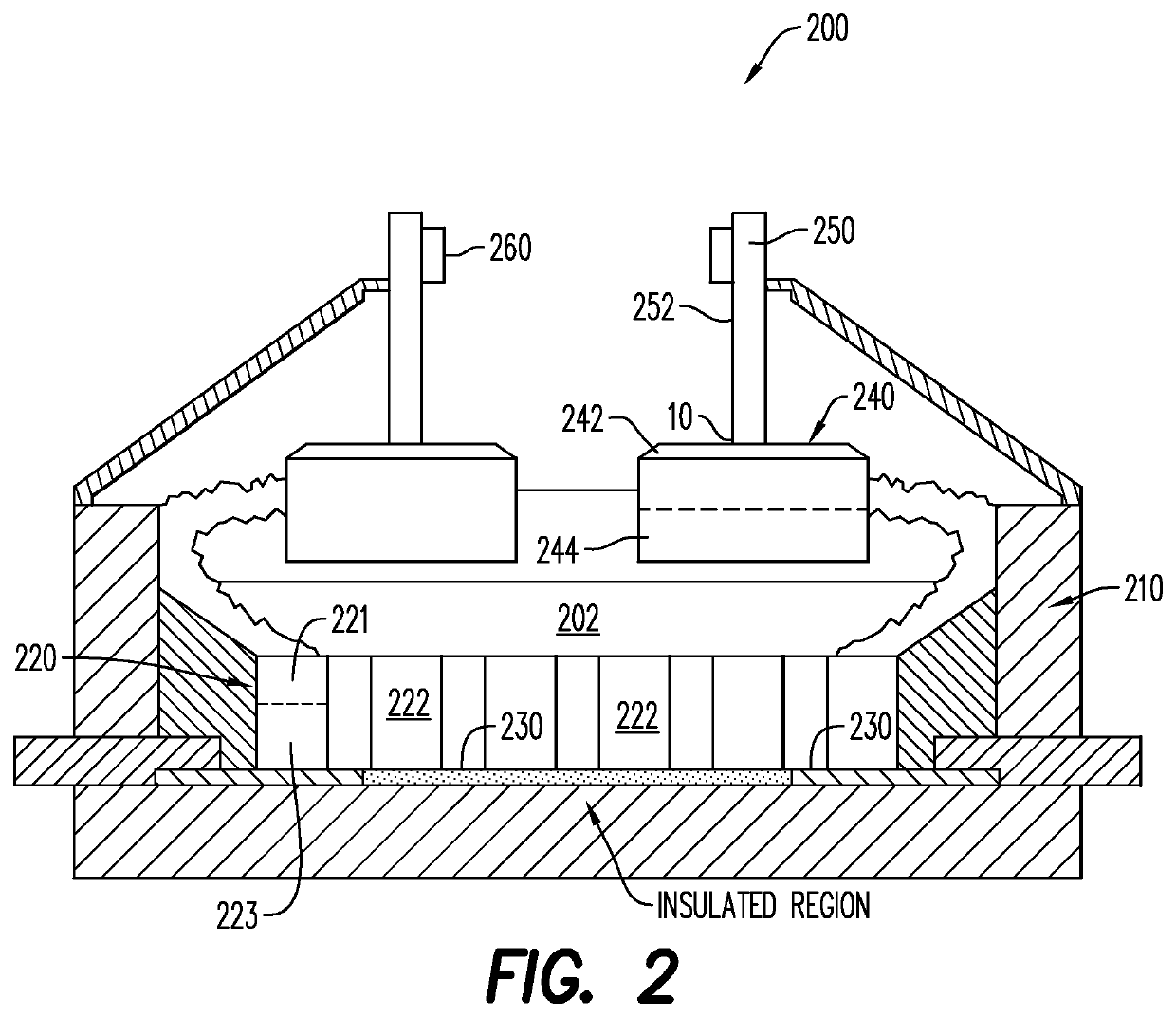

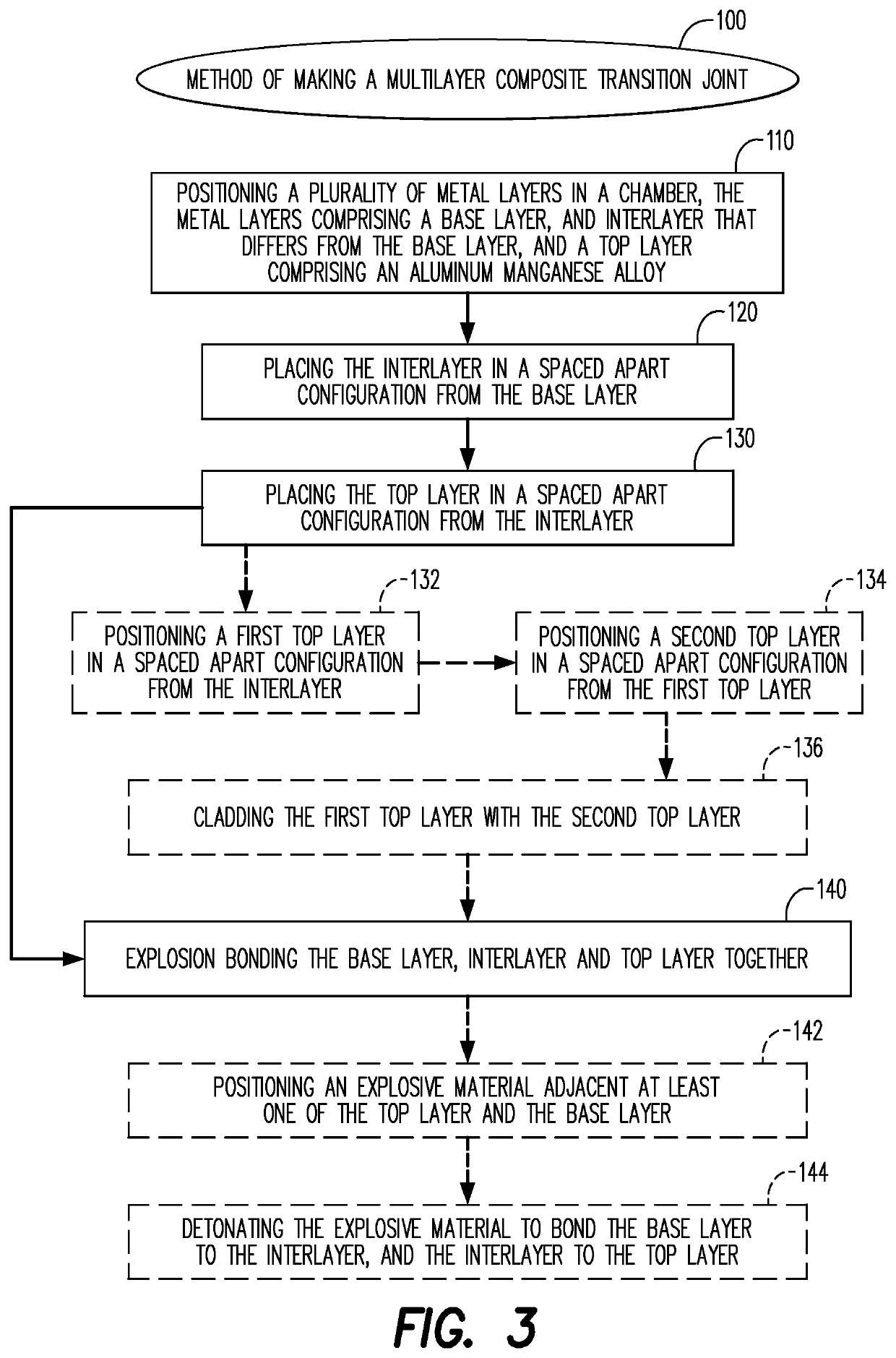

Multilayer transition joint for aluminum smelter and method of making

PendingUS20210363652A1Increasing the thicknessReduce replacement frequencyWelding/soldering/cutting articlesMetal working apparatusManganeseAlloy

A composite transition joint is described. The transition joint includes a plurality of metal layers that are metallurgically bonded together. The metal layers include a base layer, an interlayer bonded to the base layer, and a top layer bonded to the interlayer. The top layer includes an aluminum manganese alloy and includes a thickness of at least 15 mm. The composite transition joint may bond a current stem to an anode of an aluminum smelter. The transition joint increases the length of the current stem, without impacting electrical conductivity of the current stem.

Owner:DMC GLOBAL INC

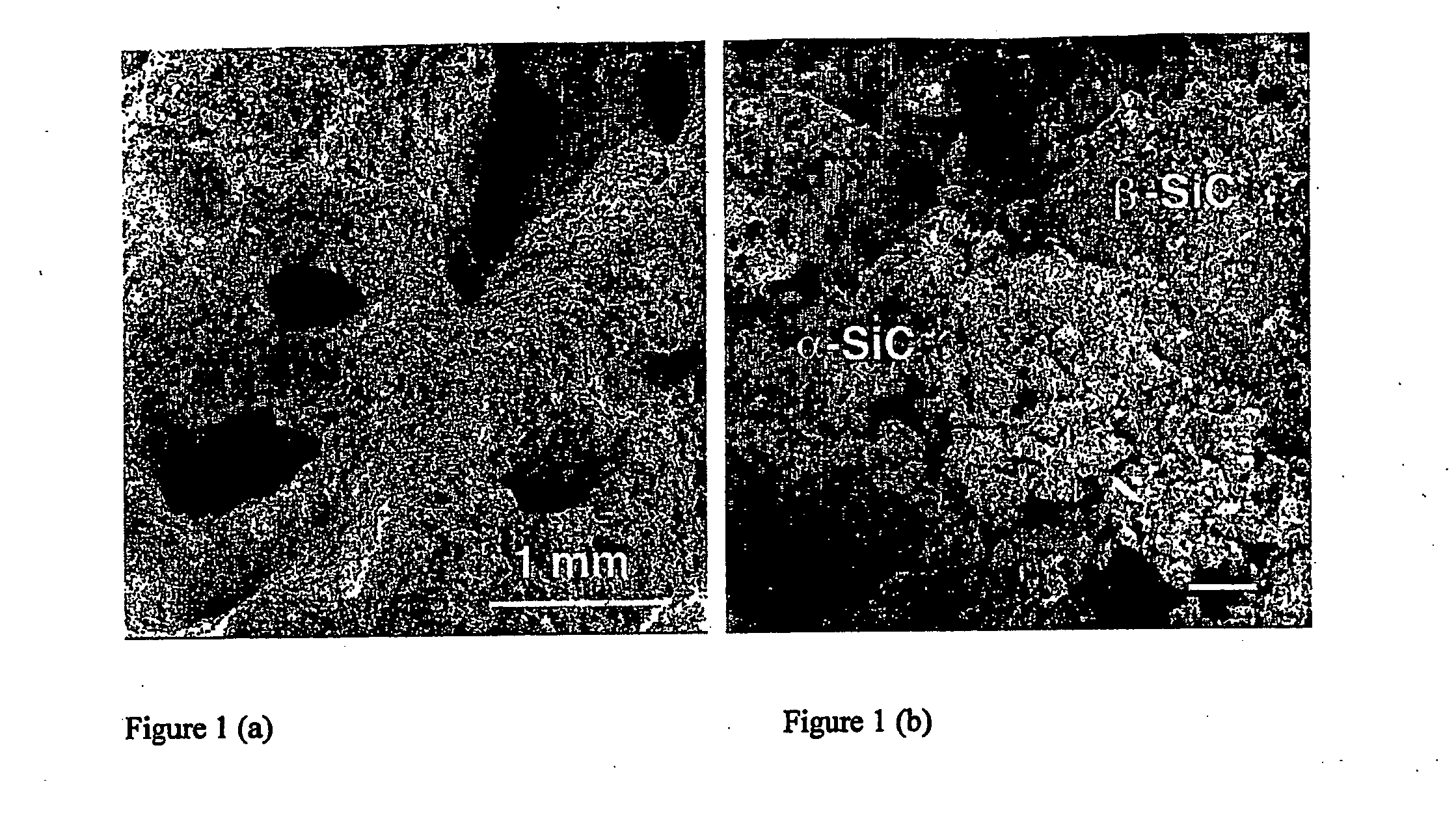

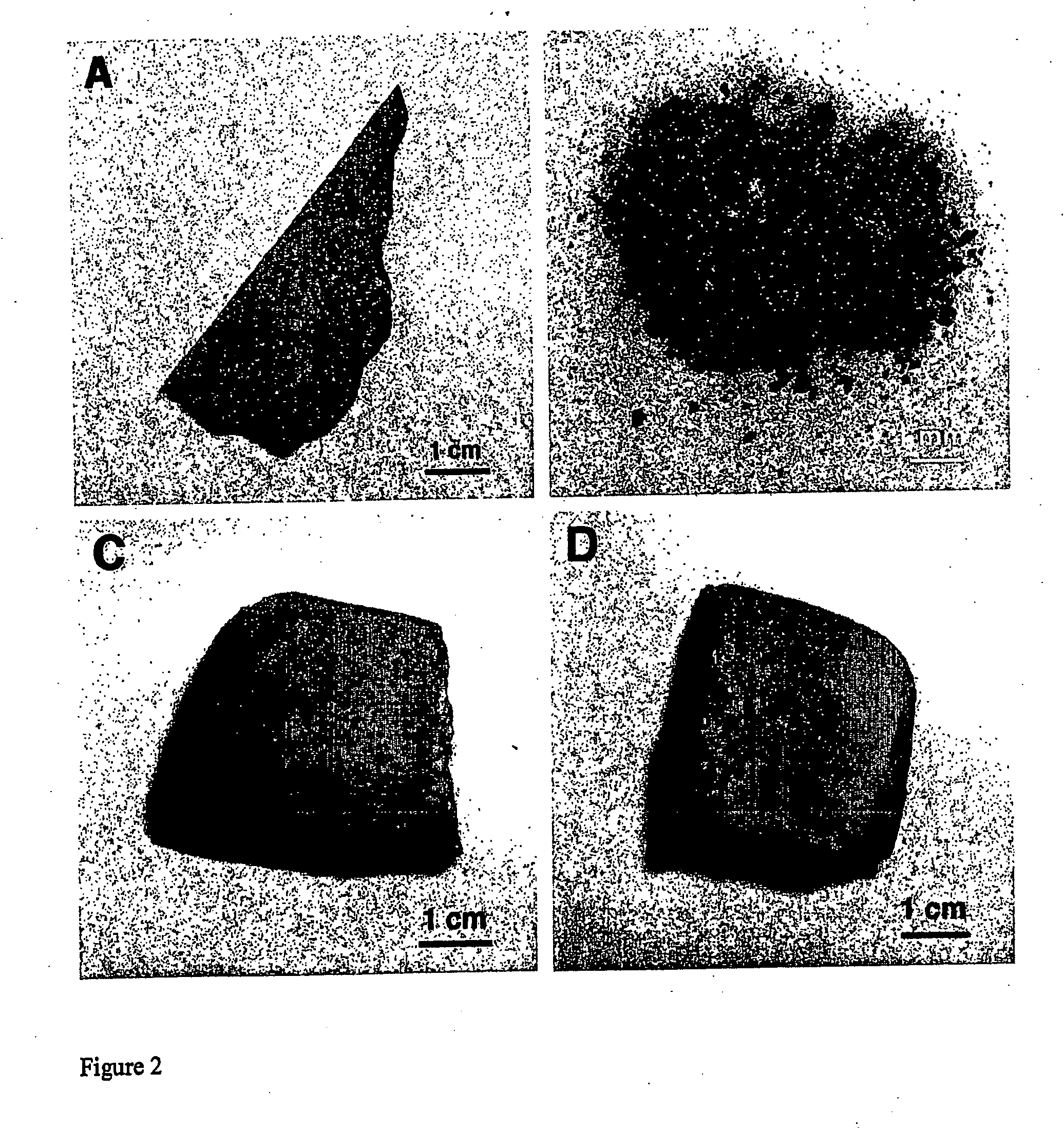

Use of a silicon carbide-based ceramic material in aggressive environments

A SiC-based composite material capable of use as an inner coating for an aluminium smelting furnace or as an inner coating for a fused salt electrolytic cell, wherein said composite material has been prepared from a precursor mixture comprising at least one β-SiC precursor and at least one carbonated resin, and wherein said composite material contains inclusions, and wherein at least one part thereof comprises α-SiC, in a β-SiC matrix.

Owner:LOUIS PASTEUR DE STRASBOURG UNIV +2

A method for linkage recovery of various solid waste materials in the aluminum smelting process

ActiveCN113278808BHigh recovery rateImprove protectionSulfate/bisulfate preparationAluminium fluoridesAluminium electrolysisSmelting process

The invention discloses a method for linked recovery of various solid waste materials in the aluminum smelting process, specifically making full use of the composition characteristics of aluminum ash, cathode ash and carbon slag, and comprehensively considering the linked recovery of various solid waste materials in the aluminum smelting process, fluorine and aluminum High recovery rate of valuable elements (≥90%), high product purity (main product AlF 3 and Al 2 o 3 Mixing purity ≥ 98%), can be used in the aluminum electrolysis process, the overall technical profit is high in added value, reagent consumption and energy consumption are small, which is conducive to protecting the ecological environment, effectively reducing material consumption and cost, and improving the economic benefits of solid waste recycling and environmental benefits.

Owner:YUNNAN RUNXIN ALUMINUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com