Preparation and using methods for slurry type iron-based red mud arsenic removing agent

An application method and technology of red mud, applied in chemical instruments and methods, water/sludge/sewage treatment, other chemical processes, etc., can solve the problems of poor separation ability between floc and water body, difficulty in engineering application, low arsenic removal efficiency, etc. problem, to achieve the effect of not easy to dissolve again, stable form of arsenic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

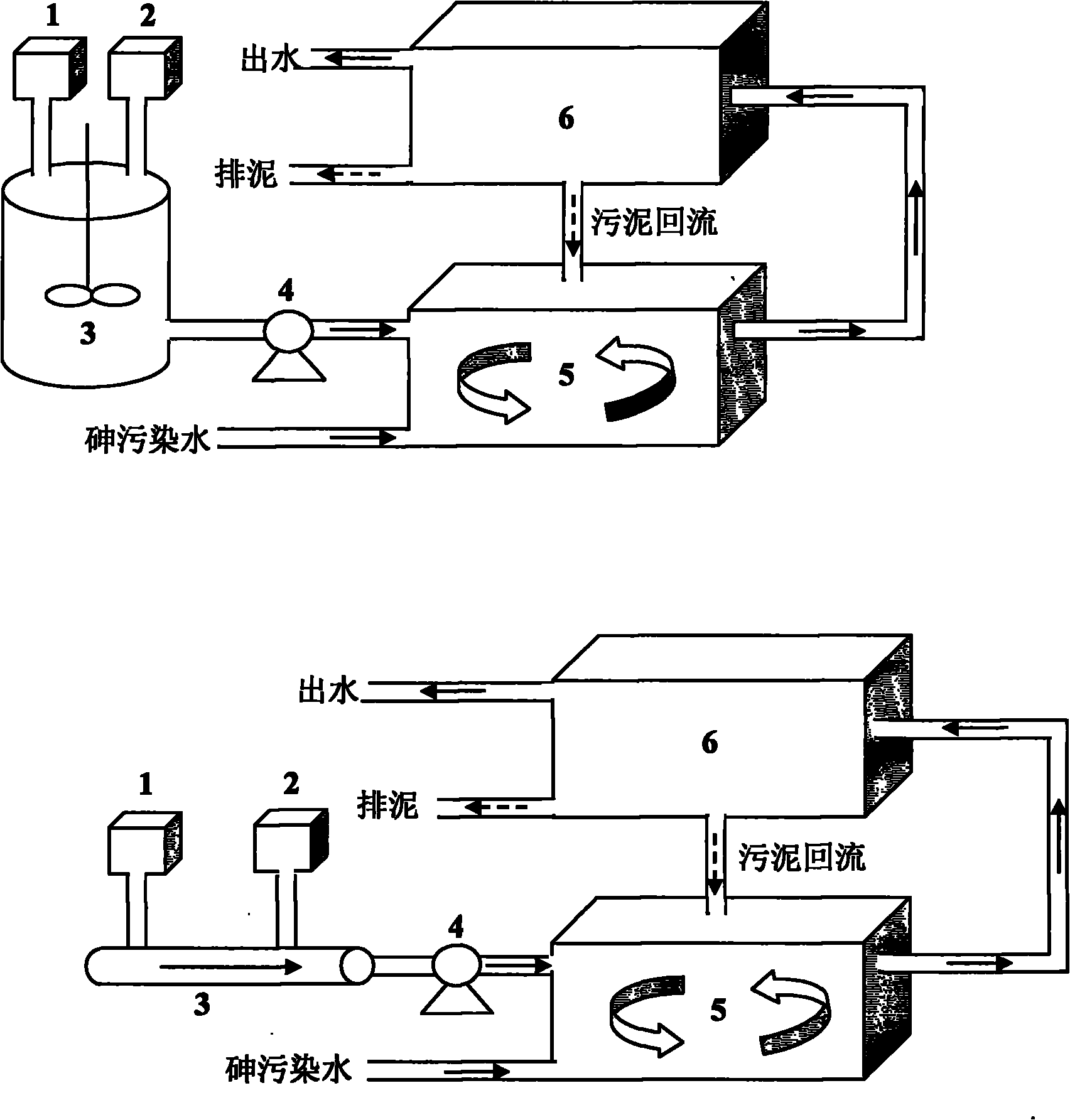

[0017] The preparation method and application process example of the "slurry-type iron-based red mud arsenic adsorption agent" of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] figure 1 with figure 2 Respectively are the process flow diagrams of embodiment 1 and embodiment 2 of the present invention.

[0019] Present embodiment 1 and example 2 are made of ferrous solution dosing tank 1, red mud dosing tank 2, medicament mixing tank 3 ( figure 1 ) or drug mixing tube 3 ( figure 2 ), a mud pump 4, a reaction mixing tank 5, a settling tank 6 and pipelines connected to each other. Among them, the solid arrows in the pipeline indicate the direction of chemical agent and water flow, and the dotted arrows indicate the direction of sludge reuse and flow.

[0020] The working process of this embodiment is:

[0021] Through the medicine adding tank 1 and the medicine adding tank 2 to the medicament mixing tank 3 ( fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com