Vacuum carbon heat reduction aluminium smelting method

A carbothermal and vacuum technology, applied in the field of vacuum metallurgy, can solve problems such as unrealized industrial application, and achieve the effects of low pollution, high recovery rate and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

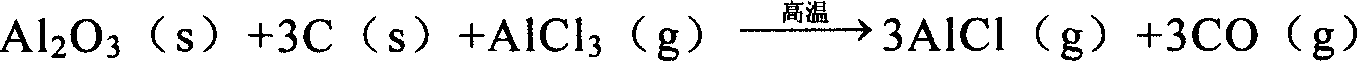

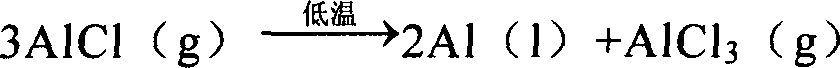

Method used

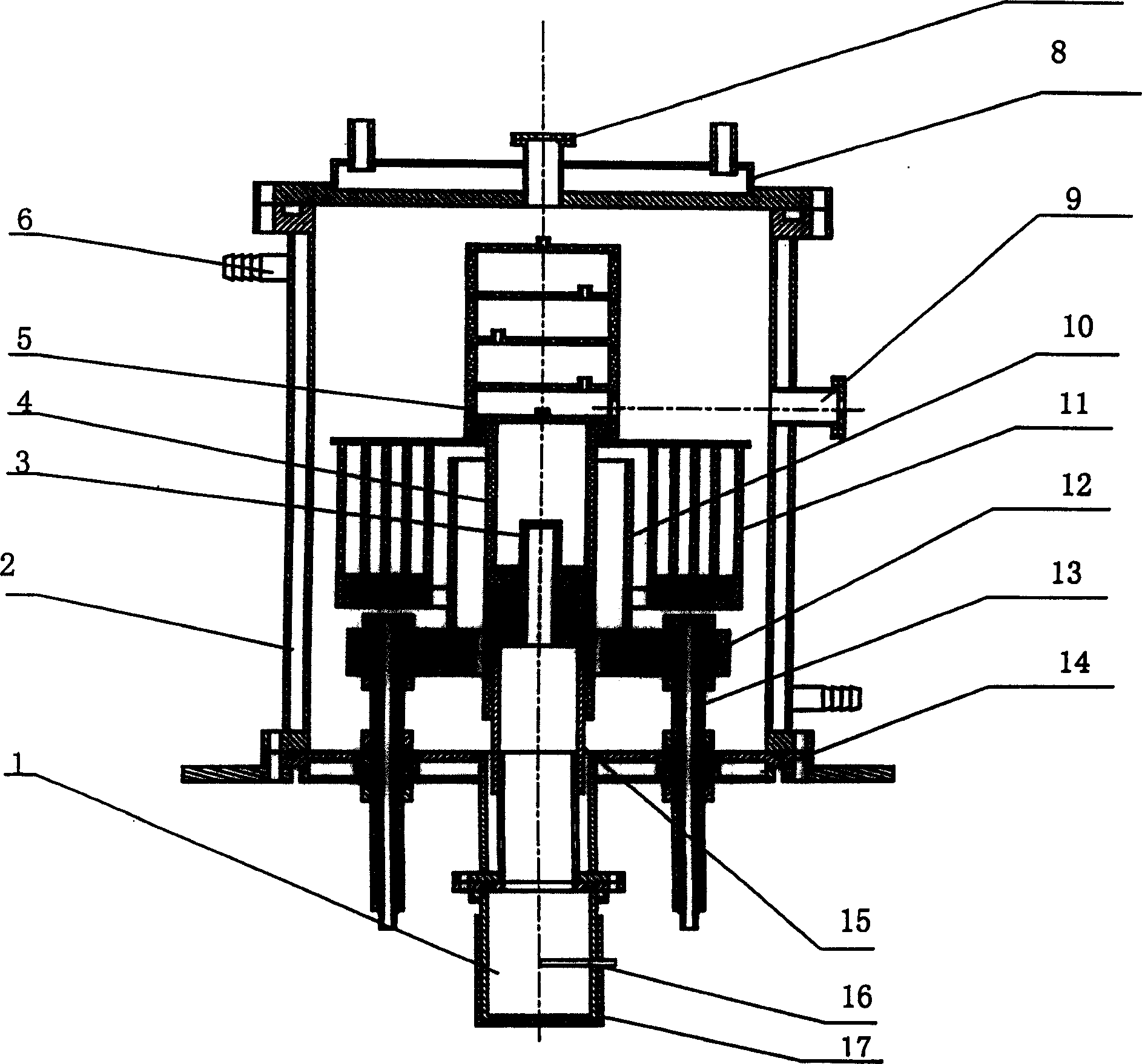

Image

Examples

Embodiment 1

[0030] Using 1.5kg of industrial alumina as raw material, the specific composition is shown in Table 1, using 0.6kg of coal as the reducing agent and 2.3kg of aluminum trichloride as the chlorinating agent, respectively grinding the alumina and coal into fine powders of 100±20 mesh, Mix evenly and make spherical particles with a diameter of less than 0.1-0.5mm. Put the material particles in a sintering furnace and sinter at a temperature of 300±50°C for 30 minutes. Take out the particles and put them in a vacuum furnace. The pressure in the vacuum furnace is 5-40Pa. When the temperature reaches 1300°C, the measured aluminum trichloride in the sublimator will let the aluminum trichloride escape in gaseous state and enter the reaction zone containing alumina and coal. The three reacted for 100 minutes to obtain AlCl gas, which entered the condensation pan under the condition of vacuuming the top of the vacuum furnace, and was condensed. When the temperature of the gas was cooled ...

Embodiment 2

[0034] Using 2kg of bauxite as raw material, the specific composition is shown in Table 3, using 0.9kg of charcoal as the reducing agent, and 3.kg of aluminum trichloride as the chlorinating agent, respectively grinding alumina and charcoal into fine powders of 100±20 mesh, Mix evenly and make spherical particles with a diameter of less than 0.1-0.5mm. Put the material particles in a sintering furnace and sinter at a temperature of 300±50°C for 35 minutes. Take out the particles and put them in a vacuum furnace. The pressure in the vacuum furnace is 50-100Pa, and the temperature is raised. When the temperature reaches 1500°C, the gas of aluminum trichloride is passed into the reaction zone, and the three react for 120 minutes to obtain AlCl gas, which enters the condensation tray and is condensed. The temperature of the gas is cooled below 900°C, and it condenses and decomposes into metallic aluminum and gaseous aluminum trichloride. Condensate down in the condensing pan, obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com