Electrochemical corrosion-resistant reinforced Al-Zr-Er alloy material and preparation method thereof

An alloy material, electrochemical technology, applied in the field of metal alloys, can solve problems such as poor corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0018] Example 1: (1) Alloy castings were prepared by graphite crucible melting and iron mold casting. The raw materials used were pure aluminum and Al-6Er and Al-4Zr intermediate alloys. The melting temperature was 750-780 ° C. After reaching the melting temperature, keep it warm for 30 minutes , cast with an iron mold, and then directly cold-rolled. The cold-rolling process preferably controls the reduction of each pass at 10% to 25%, and the final cold deformation is 75% to 90%. Alloys with 5 different compositions were prepared, and their actual compositions were tested by XRF, as shown in Table 1 below. The S1 and S2 samples are Al-Er and Al-Zr binary alloys, respectively, for comparison.

[0019] Table 1 Experimental alloy composition

[0020]

[0021]

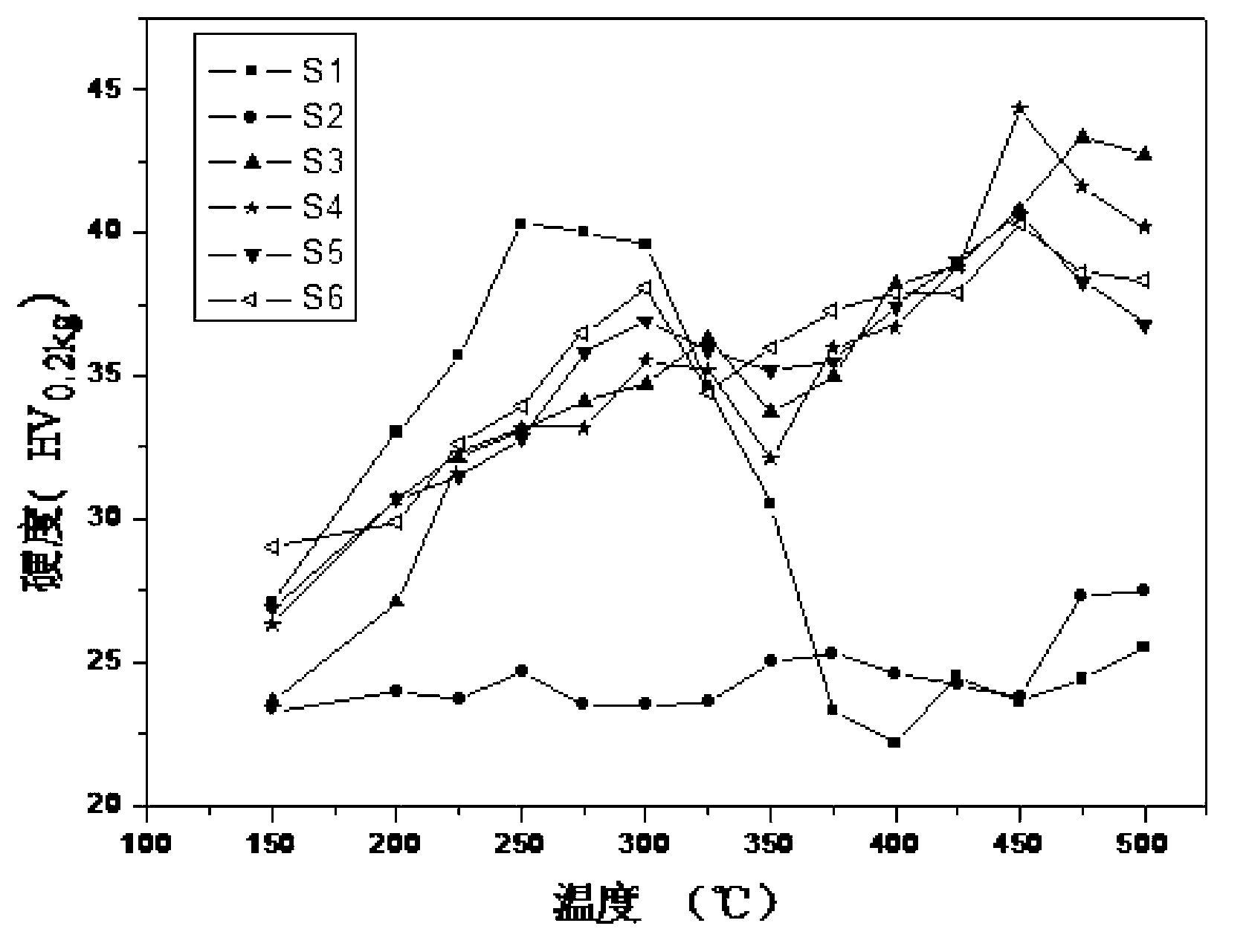

[0022] The alloy in step (1) is then subjected to solution treatment at 640° C. for 20 to 30 hours, and then water quenched to room temperature. Then anneal at intervals of 25°C for 3 hours between 200°C and 500°...

example 2

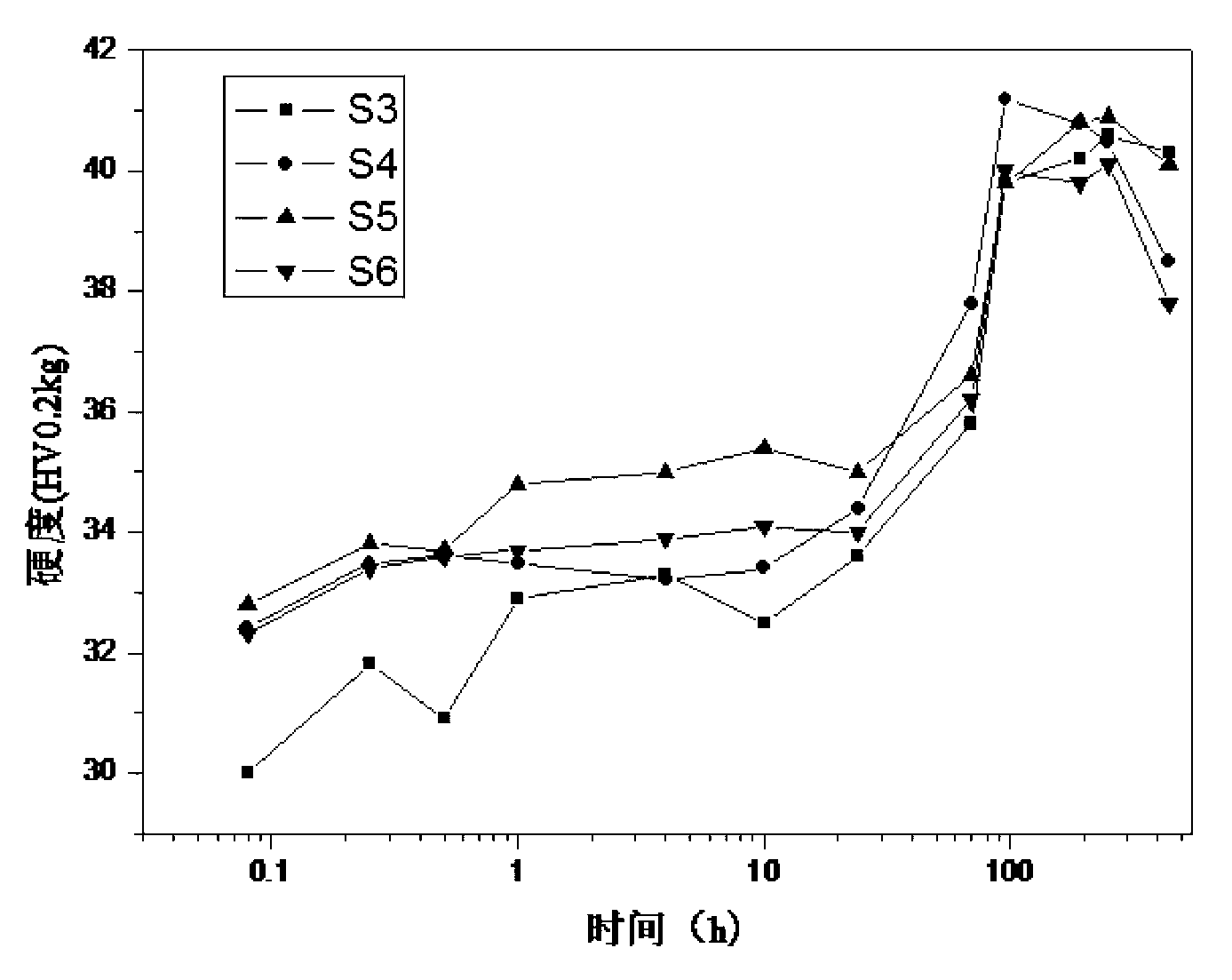

[0023] Example 2: For samples S3-S6 in step (1) of Example 1, solid solution at 640°C for 24 hours, water quenching to room temperature, and then isothermal aging at 375°C. figure 2 The hardness change curves of isothermal aging are given. The hardness peaks of samples S3, S4, S5, and S6 after aging for 96 hours are 40.6HV, 41.2HV, 40.9HV, and 40.1HV, respectively, and all have significant aging strengthening effects .

example 3

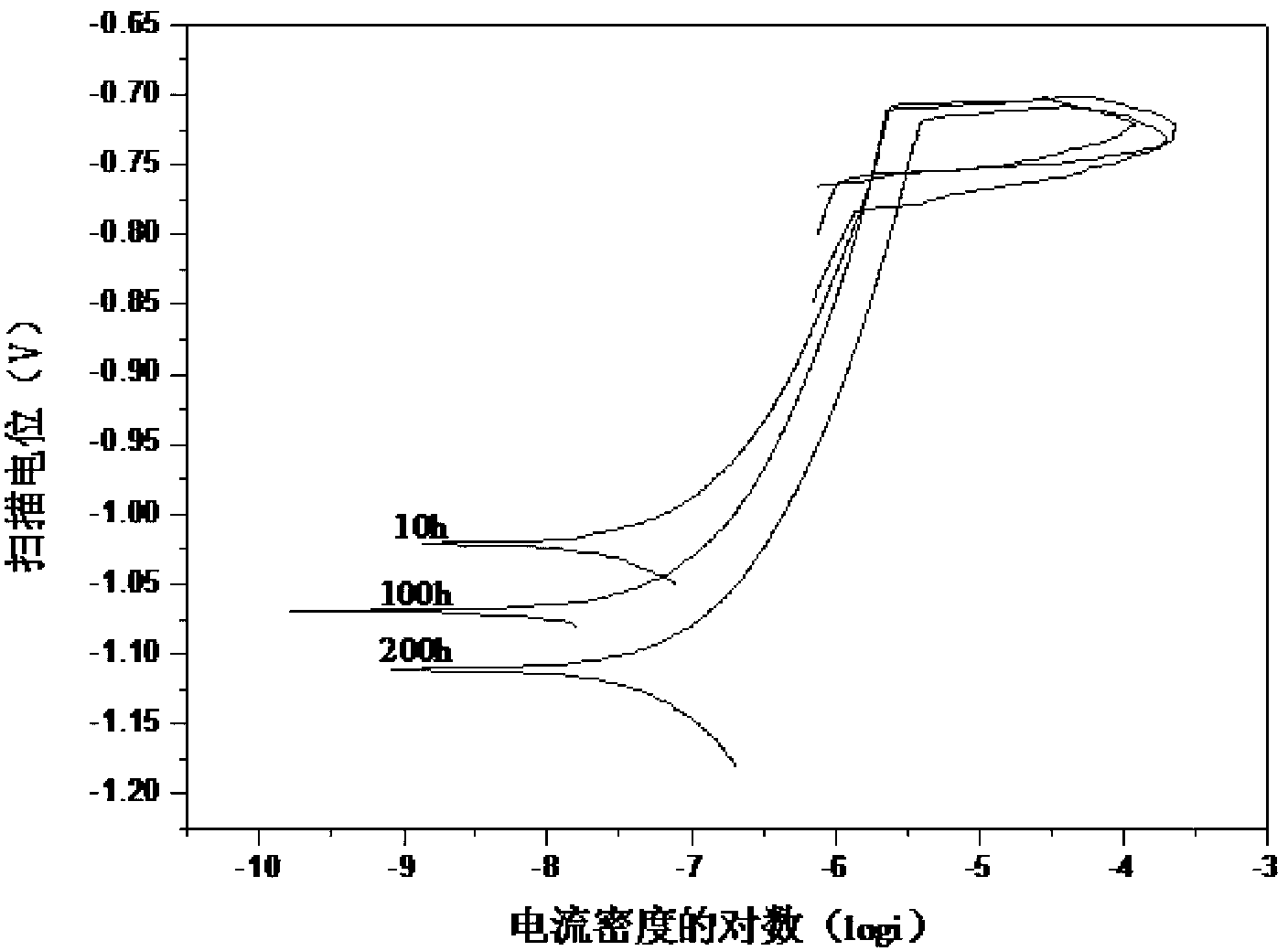

[0024] Example 3: For sample S3 in step (1) of Example 1, solid solution at 640°C for 24 hours, water quenching to room temperature, and then carry out isothermal aging at 375°C, keep warm for 10h, 100h, 200h, and then perform electrochemical corrosion resistance respectively Performance repeatability testing. The device used is a standard three-electrode system, the platinum electrode is used as the auxiliary electrode, the saturated calomel electrode is used as the reference electrode, and is connected by a saturated potassium chloride salt bridge, and the electrolyte solution is 3.5wt.%NaCl. Usually the corrosion potential E corr The magnitude of the thermodynamic driving force for corrosion of the alloy is judged, and the corrosion rate of the alloy is judged by the average corrosion current density i in the passivation zone. Corrosion potential E corr The more negative the corrosion is, the higher the average corrosion current density i is, the faster the corrosion rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com