Stripping failure detection, alarming and secondary knocking unit for 20kg aluminum ingot continuous caster

A detection device and continuous casting machine technology, applied in the configuration of indicating equipment/measuring equipment, casting equipment, manufacturing tools, etc., can solve the problems of unsmooth production, increased labor intensity of employees, explosion safety, etc., and achieve compact structure, High degree of automation and smooth production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

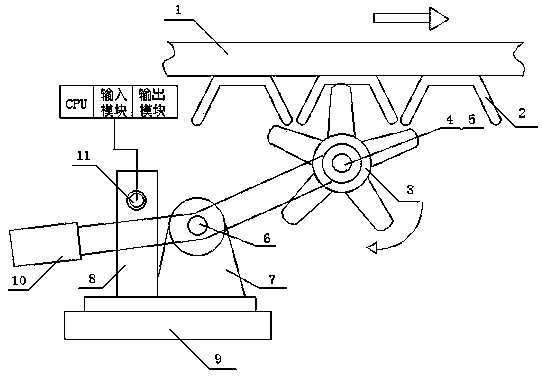

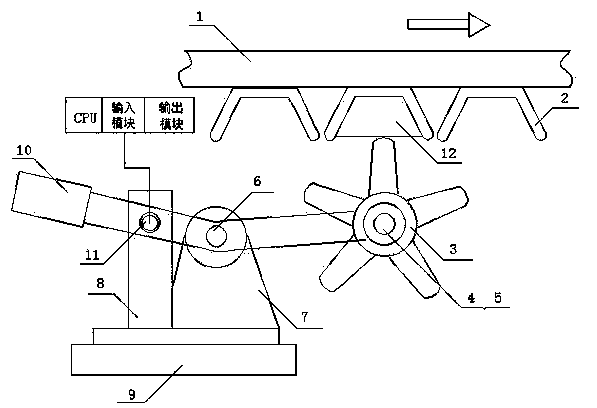

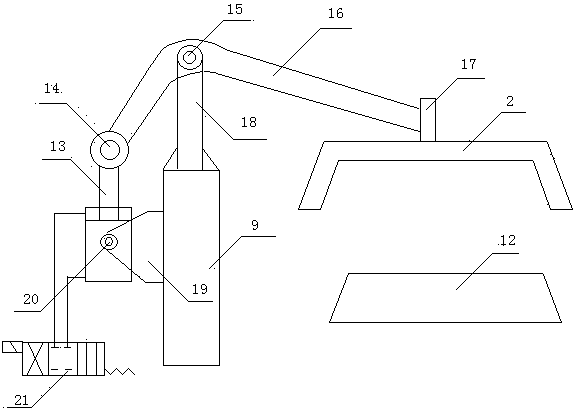

[0034] According to the characteristics of casting machine production, through many on-site analysis, research and multiple tests, it is decided to start from the two aspects of the non-demolding detection alarm device and the second strike system, through the electrical control circuit and PLC automatic control, so that the non-demolding Aluminum ingot demoulding.

[0035] Mechanical part

[0036] The mechanical part is composed of a non-demolding detection device and a secondary strike system. The main function of the non-demolding detection device is that when the aluminum ingot is not demoulded after being struck by the primary strike system, the detection device automatically detects the non-demolding aluminum ingot , and send a signal to the control system; the function of the secondary strike system is that after receiving the signal from the detection device, the PLC electrically executes the original control, and the secondary strike system acts to demould the aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com