Aluminum-based sandwich panel for construction industry and preparation method thereof

A sandwich panel, aluminum-based technology, applied in the field of sandwich panels, can solve the problems of lack of heat insulation and noise reduction functions of aluminum composite panels, short service life of gypsum panels, etc. The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

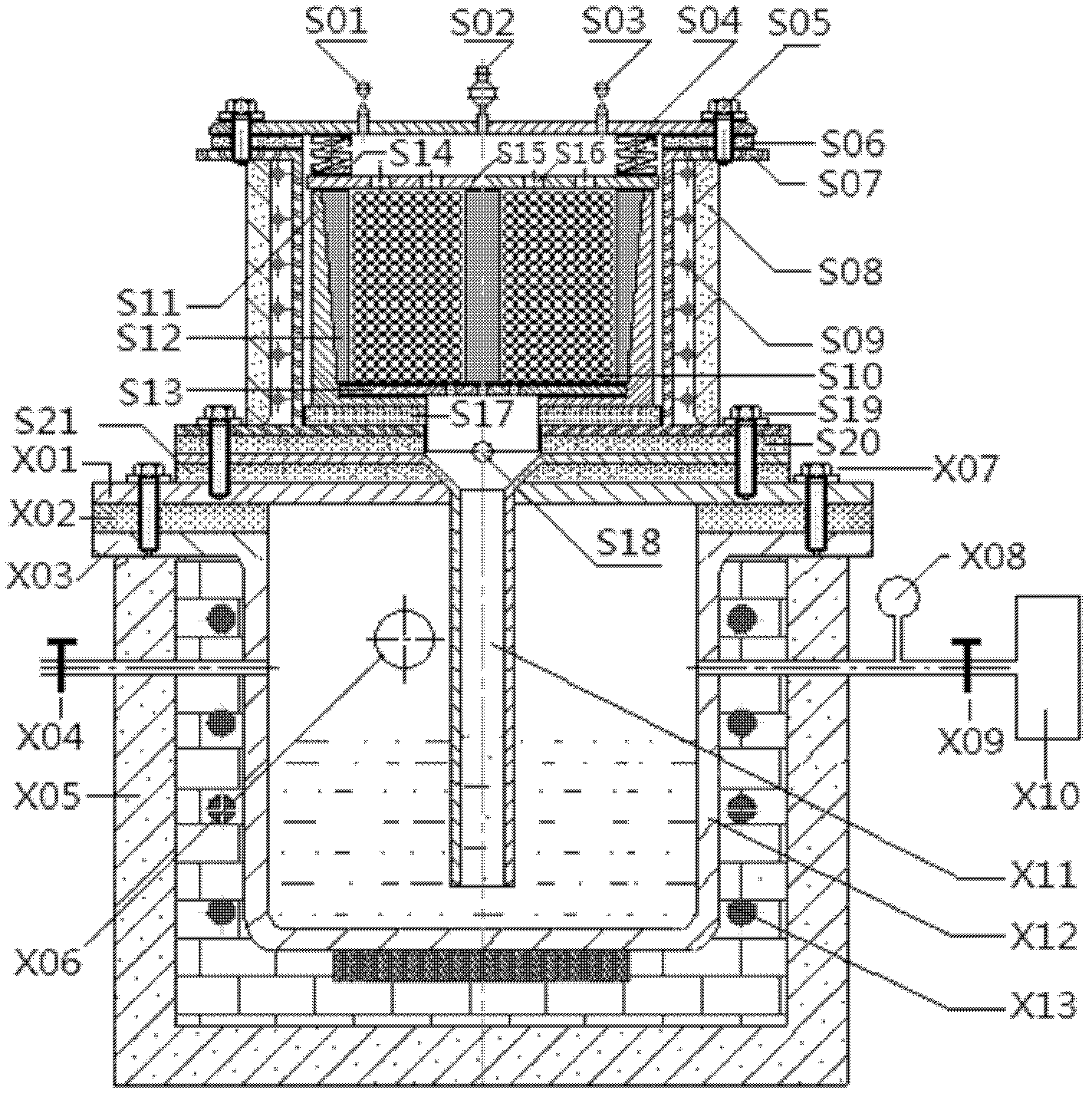

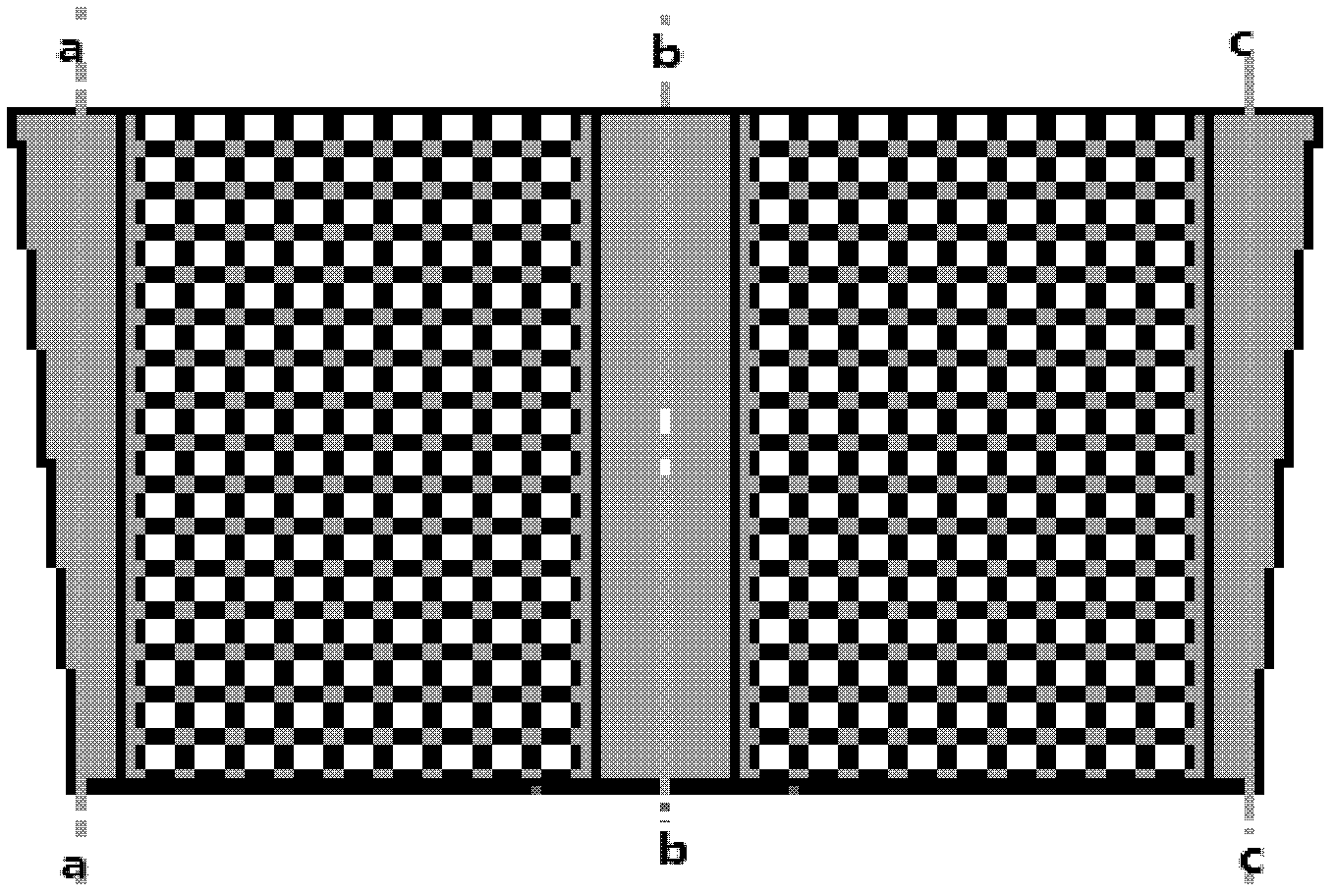

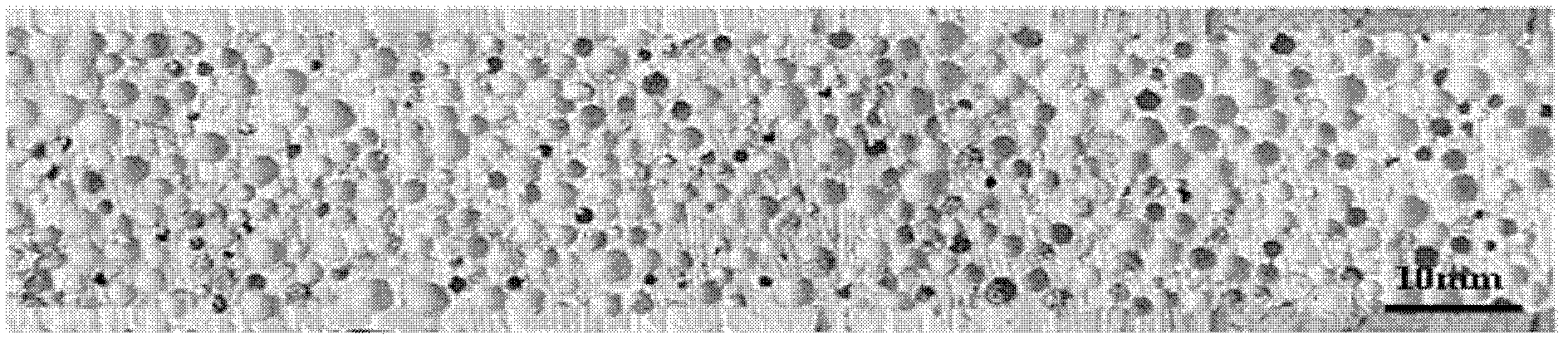

[0027] With aluminum panel / / aluminum oxide hollow sphere-aluminum composite material core / / aluminum panel structural material and its preparation process In this embodiment, alumina hollow spheres with a particle size of 1.6-2.0mm, LY12 plates with a thickness of 1.26mm and 6063 aluminum are used Alloys as raw materials; figure 1 Schematic of the equipment used to prepare the materials for this example. The concrete implementation of present embodiment 1 comprises the following steps:

[0028] (1) Grind the surface of the aluminum panel S12 with coarse sandpaper to remove the scale, and use a coarse steel wire wheel to grind out irregular lines with a depth of 0.1-0.3mm;

[0029] (2) The mold S11 is hoisted into the casting chamber S09, and a graphite paper gasket S17 is placed between the bottom of the mold and the casting chamber; a breathable partition S13 is placed on the bottom of the mold S11;

[0030] (3) Fix the aluminum panel with surface roughening treatment in the...

Embodiment 2

[0039] With aluminum panel / / fly ash-aluminum composite material core / / aluminum panel structural material and its preparation process

[0040] In this embodiment, fly ash with a particle size of 1.6-2.0 mm and 6063 aluminum alloy are used as raw materials. The specific implementation of this embodiment includes the following steps:

[0041] (1) Prepare the prefabricated block of the fly ash particle precursor according to the following process: ① uniformly mix the fly ash particles and silica sol at a mass ratio of 10:1; ② pack the mixed particles into an effective thickness of 30mm prefabricated mold for uniform molding; ③Then put the prefabricated mold in a drying furnace and dry it at 120°C for 2 hours to obtain a prefabricated block of fly ash particle precursor.

[0042] (2) Press Figure 4 As shown, the floating bead precursor preform was loaded into the mold; however Figure 4 S12 in is blank, and S10 is the prefabricated block of fly ash particle precursor.

[0043]...

Embodiment 3

[0046] With aluminum panel / / aluminum oxide ball-aluminum composite material core / / aluminum panel structural material and its preparation process

[0047] In this embodiment, alumina balls with a particle size of 0.8-2.0 mm, LY12 plates with a thickness of 1.26 mm, and 6063 aluminum alloys are used as raw materials; the specific implementation of Embodiment 3 includes the following steps:

[0048] (1) Grind the surface of the aluminum panel S12 with coarse sandpaper to remove the scale, and use a coarse steel wire wheel to grind out irregular lines with a depth of 0.1-0.3mm;

[0049] (2) Mold S11 is hung in the casting chamber S09, graphite paper gasket S17 is placed between the bottom of the mold and the casting chamber; a breathable partition S13 is placed on the bottom of the mold S11;

[0050] (3) Fix the aluminum panel with surface roughening treatment in the mold S11, and simultaneously fill the aluminum oxide ball S10 into the interval between the aluminum plates;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com