A method for linkage recovery of various solid waste materials in the aluminum smelting process

A technology for smelting process and recycling aluminum, which is applied in the field of fluorine-containing and aluminum-containing solid waste materials, and can solve the problems of low product purity and added value, high reagent consumption and energy consumption, and low recovery rate of fluorine and aluminum valuable elements. , to achieve the effect of improving economic and environmental benefits, low reagent consumption and energy consumption, and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

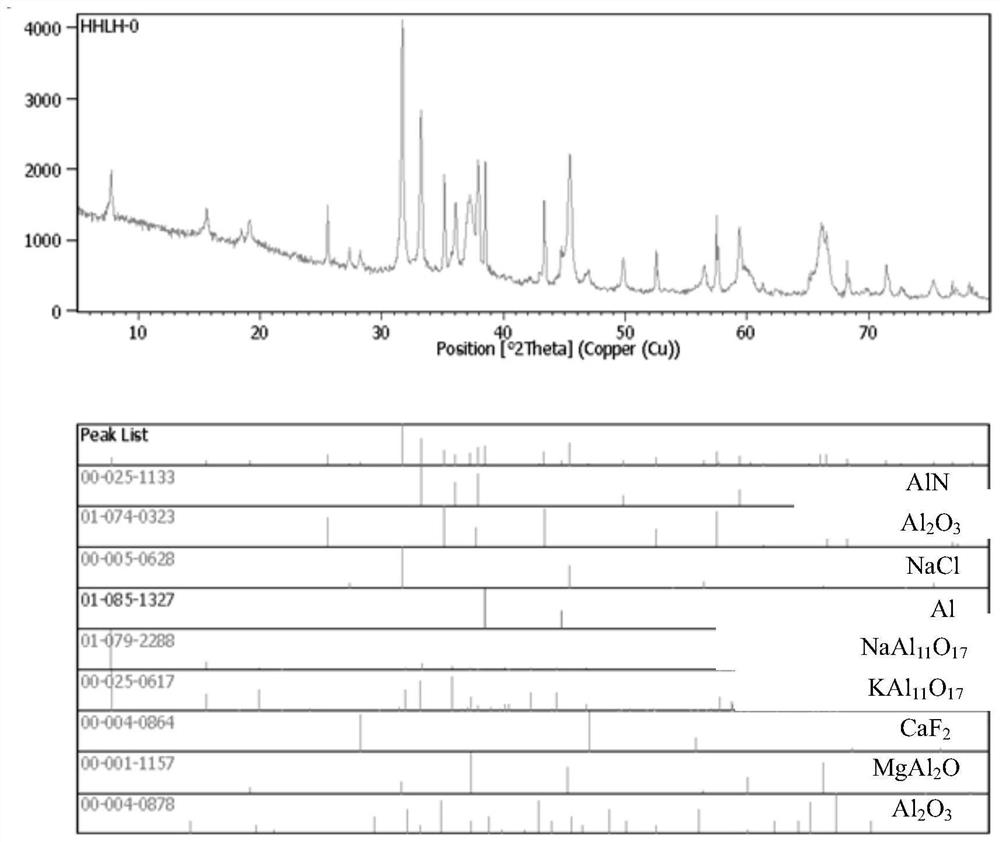

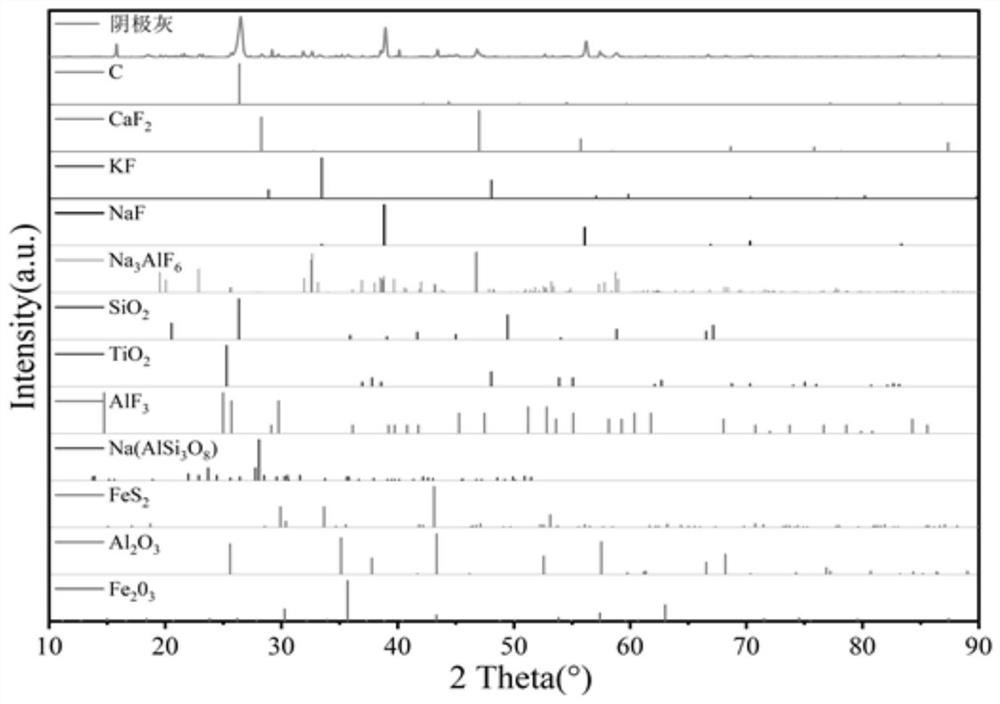

[0101] The raw material of embodiment 1 and embodiment 2

[0102] Taking aluminum ash, cathode ash and carbon slag produced by an aluminum smelter in Yunnan as raw materials, the main components of each substance are as follows after fluorescence spectrum analysis:

[0103] Table 1. Main components of aluminum ash

[0104]

[0105] Table 2. Main components of cathode ash

[0106]

[0107]

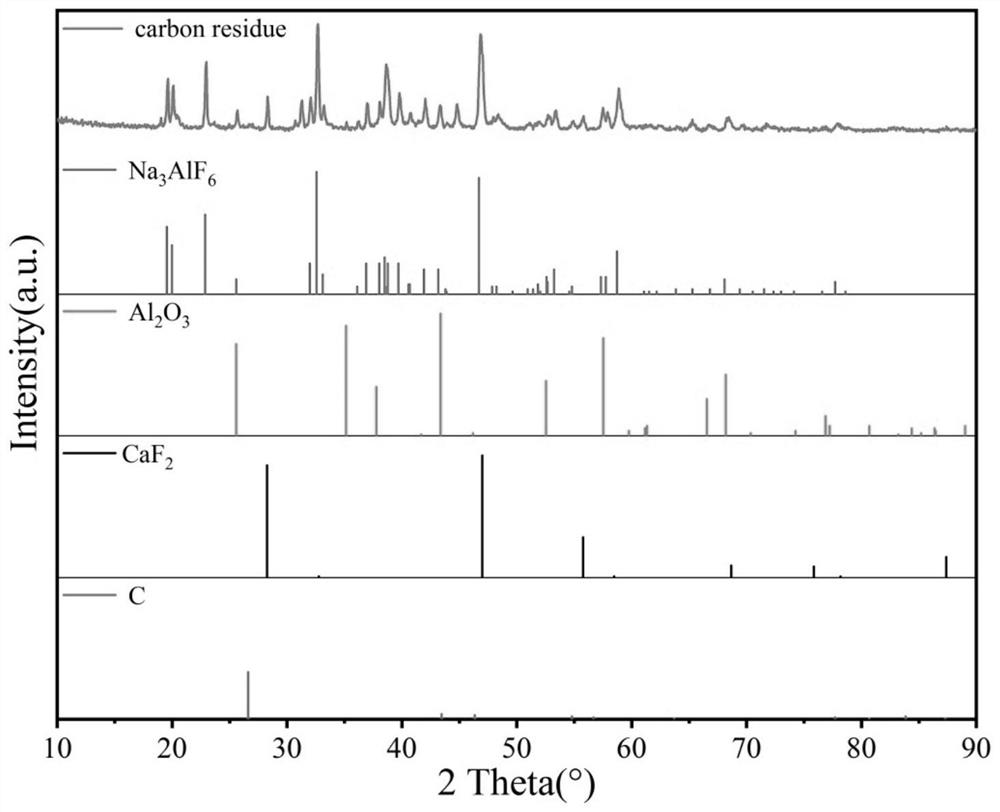

[0108] Table 3. Main components of charcoal residue

[0109] element F Na Al Mg P S Cl K C Content (wt%) 37.11 15.56 8.84 0.27 0.04 3.64 0.15 1.64 26.52 element Ca V mn Fe co Ni Ga Sr O Content (wt%) 3.16 0.08 0.09 0.39 0.04 1.09 0.03 0.04 1.29

[0110] Example 1

[0111] (1) 100g of aluminum ash (composition as shown in Table 1), 10g of cathode ash (composition as in Table 2), and 100g of carbon slag (composition as in Table 3) were respectively crushed to -10mm (materials with a particle size below -10mm ...

Embodiment 2

[0132] (1) 90g of aluminum ash (composition as shown in Table 1), 10g of cathode ash (composition as in Table 2), and 100g of carbon slag (composition as in Table 3) were respectively crushed to -10mm (accounting for 95%) to meet the requirements of grinding Feeding granularity requirements;

[0133] (2) Mix the aluminum ash and cathode ash obtained in step (1) evenly in a mass ratio of 9:1, and dry-grind to -200 mesh by adopting a closed-circuit process of grinding and classification (materials with a particle size below -200 mesh) The mass accounts for more than 95% of the total material mass);

[0134] (3) The charcoal slag obtained in step (1) is wet-ground to -200 mesh (the quality of the material below -200 mesh accounts for more than 95% of the total material mass) with the grinding and classification closed-circuit process, and then adjusted Slurry, control the mass concentration of the slurry to be about 30%, add water glass, kerosene, and 2# oil flotation reagents i...

Embodiment 3

[0150] The raw material of embodiment 3

[0151] Taking aluminum ash, cathode ash and carbon slag produced by an aluminum smelter in Yunnan as raw materials, the main components of each substance are as follows after fluorescence spectrum analysis:

[0152] Table 6. Main components of aluminum ash

[0153] element Al Al 2 o 3

F Cl K Na S MgO CaO SiO 2

content(%) 4.35 66.32 9.14 0.05 0.39 9.49 0.25 0.20 3.36 3.79 element P Ba Sr Zr Cu mn Ni Fe 2 o 3

TiO 2

content(%) 0.02 0.02 0.01 0.01 0.01 0.01 0.01 2.30 0.27

[0154] Table 7. Main components of cathode ash

[0155] element F Na Al Mg P S Cl K C Content (wt%) 24.98 11.04 28.01 0.16 0.03 0.37 0.07 0.38 2.45 element Ca Ti mn Fe Ni Zr Ba Sr O Content (wt%) 2.12 0.22 0.02 3.46 0.02 0.01 0.01 0.01 26.64

[0156] Table 8. Main components of charcoal residue ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com