Aluminium oxide bin bottom blanking device and method

A technology of alumina and feed port, which is applied in the field of alumina storage and transportation in aluminum smelting, to achieve the effects of increasing fluidity, reducing wear and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

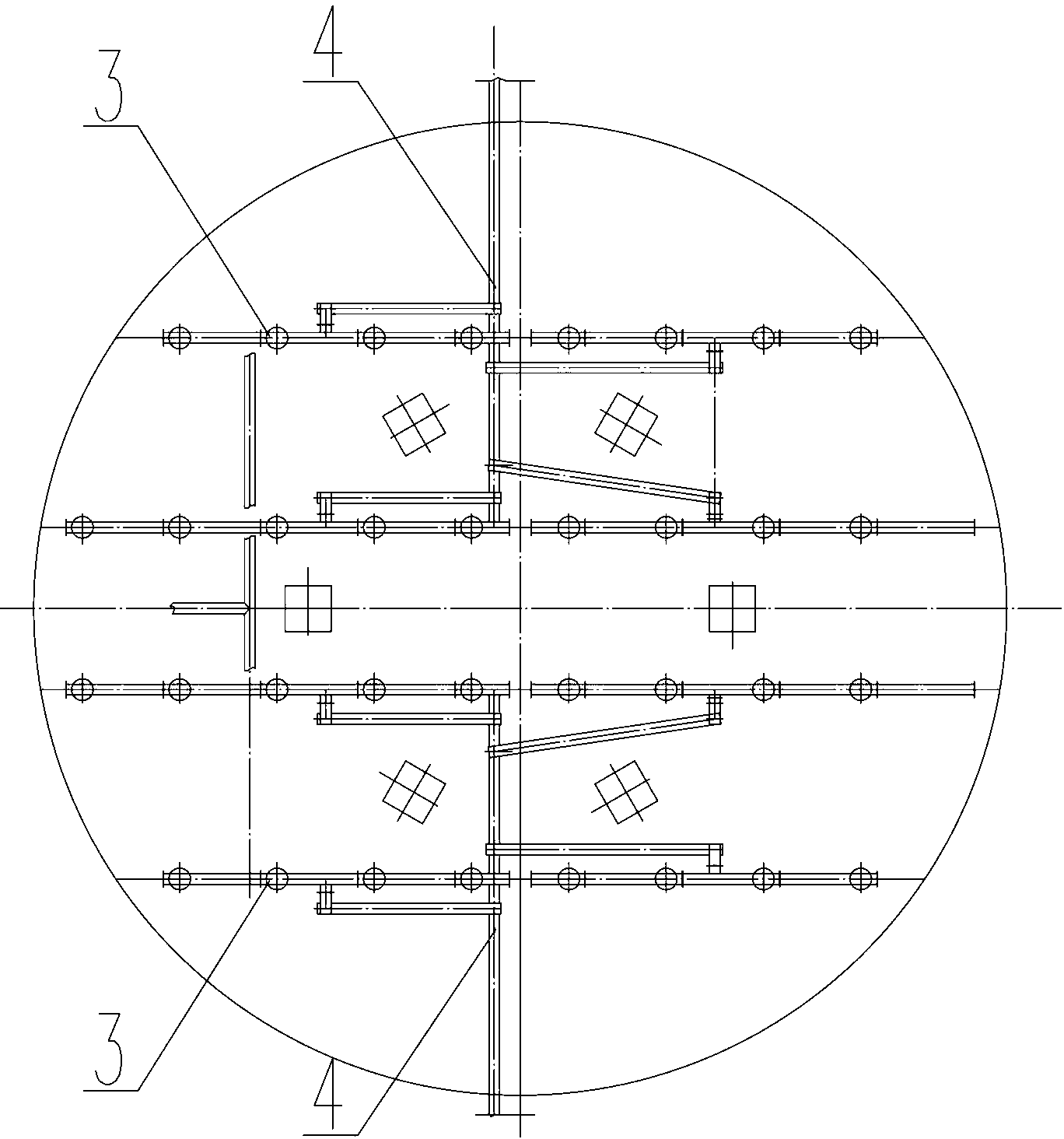

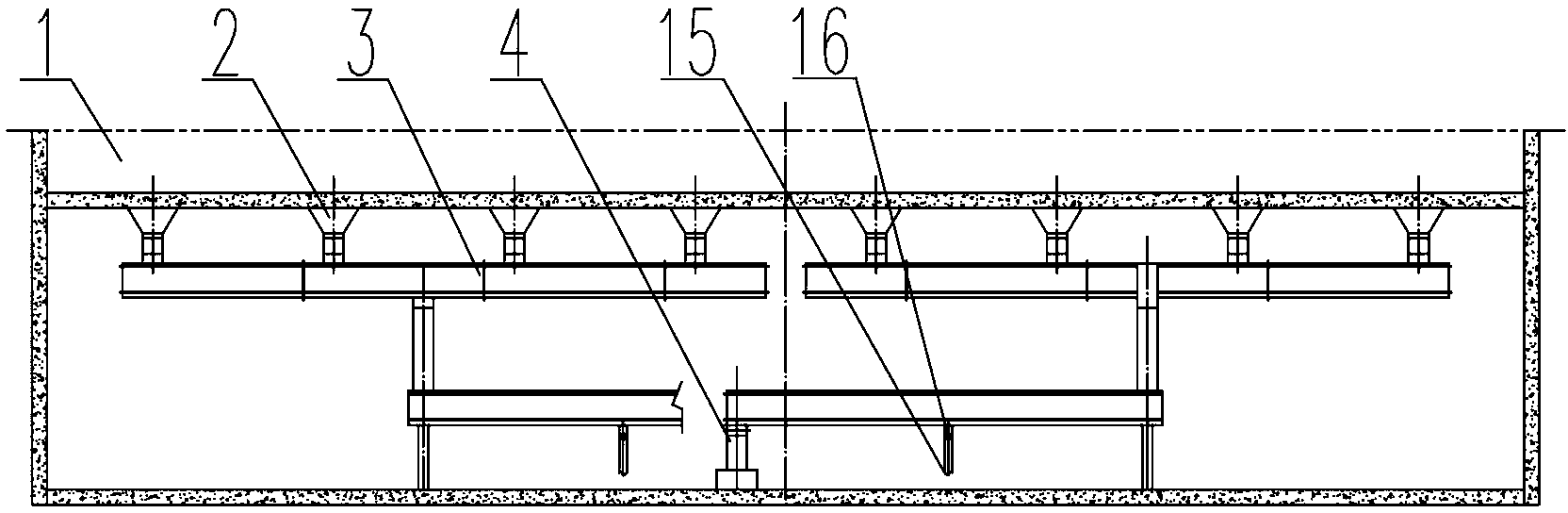

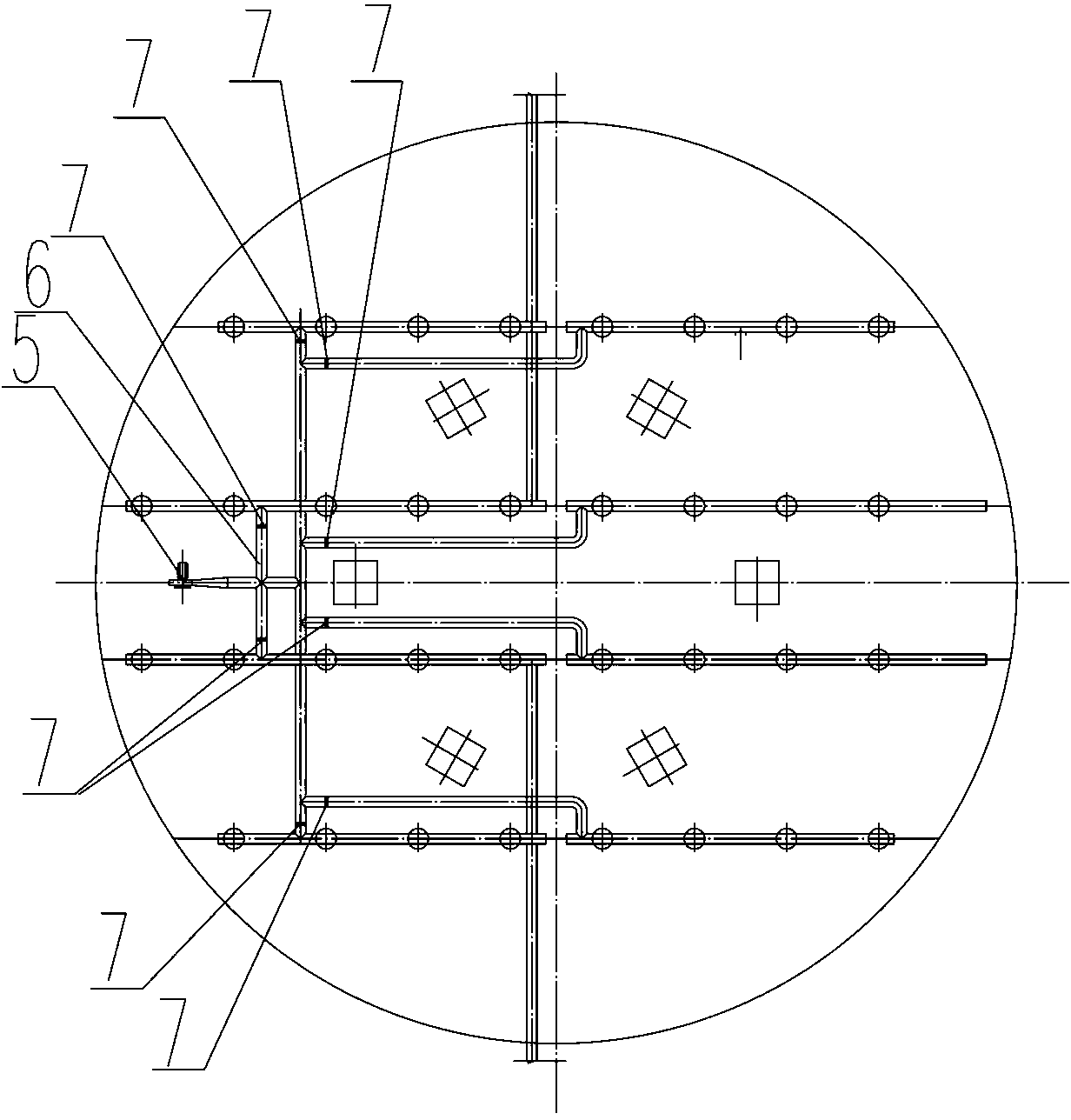

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the schematic diagrams.

[0019] As shown in the figure, the feeding device at the bottom of the alumina silo of the present invention includes a storage bin 1 and a feeding port 2, the feeding port 2 is connected to the feeding chute 3, and the space between the storage bin 1 and the feeding port 2 and the feeding port 2 are cancelled. The valve between the blanking chute 3, the blanking chute 3 is connected with the main chute 4, the blanking chute 3 is supplied with air by the branch air pipe 15, the branch air pipe 15 is connected with the air pipe 6, and the air pipe 6 is connected with the fan 5, An electric valve 7 is arranged on the air pipe 5, and the electric valve 7 is controlled by the computer in the control room. The branch air pipe 15 is provided with a manual valve 16; the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com