Suspension type fire-resistant heat preservation assembly for large-capacity oxygen-aluminum co-production electrolytic cell.

A technology of refractory heat preservation and electrolytic cell, which is applied in the direction of electrolysis components, electrolysis process, cells, etc., can solve the problems of cracking of refractory heat insulation materials, etc., and achieve the effect of easy lifting, preventing exposure and heat loss, and convenient moving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

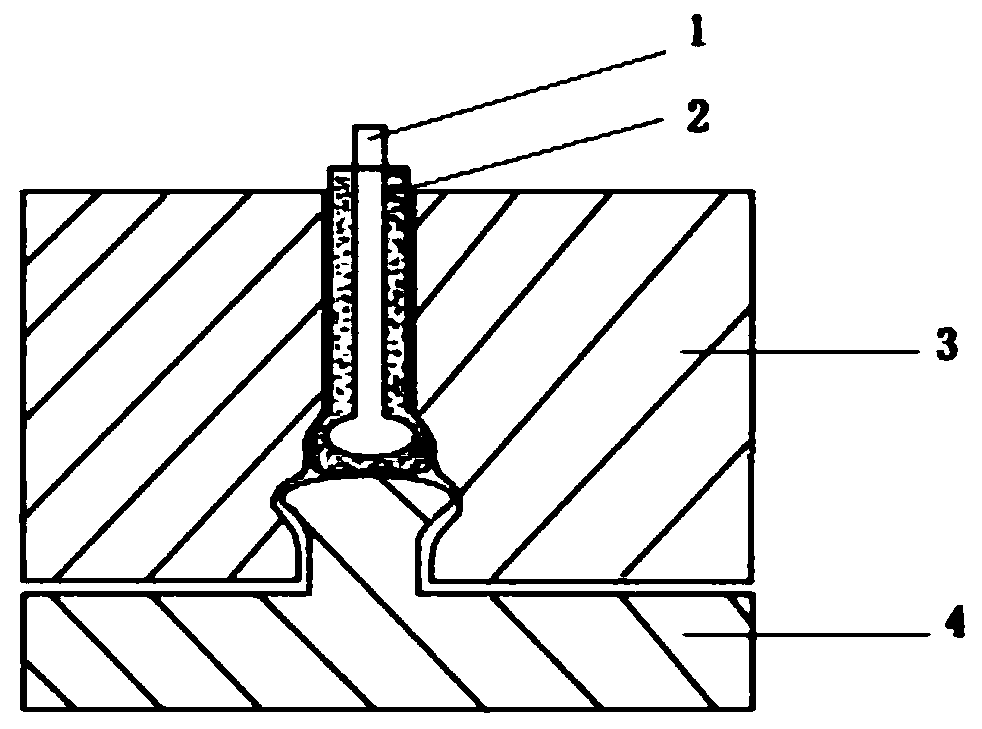

[0039] Such as figure 1 As shown, it is a suspension assembly of a shaped refractory material; it includes a metal rod 1, a hose 2, an insulation layer 3 and a refractory layer 4, and the metal rod 1 is isolated from the aluminum electrolytic cell by the refractory layer 4;

[0040] The metal rod is wrapped with a hose 2, and the space between the metal rod 1 and the hose 2 is filled with an anti-expansion and anti-oxidation buffer powder mixture; the hose 2 is wrapped with an insulation layer 3, and the lower part of the insulation layer is provided with a refractory layer 4, and the insulation layer 3 and The refractory layer 4 is sealed; the metal rod 1 passes through the insulation layer 3 and fits with the insulation layer 3, and the insulation layer 3 and the refractory layer 4 fit together;

[0041] The refractory layer 4 in this design is made of shaped refractory material, the lower part is a high temperature zone and close to the electrolyte, the shaped refractory bl...

Embodiment 2

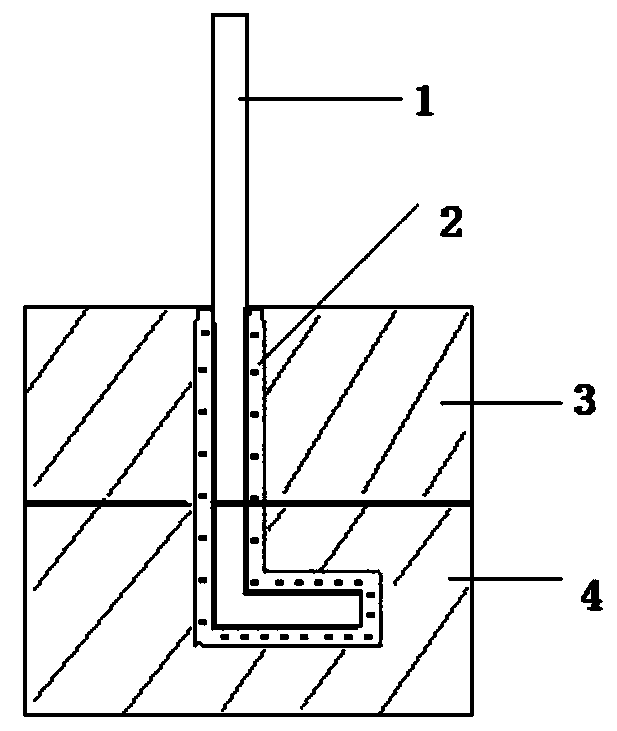

[0046] Such as figure 2 As shown, it is a suspension assembly of an amorphous refractory material; it includes a metal rod 1, a hose 2, an insulation layer 3 and a refractory layer 4, and the metal rod 1 is isolated from the aluminum electrolytic cell by the refractory layer 4;

[0047] The metal rod is wrapped with a hose 2, and the space between the metal rod 1 and the hose 2 is filled with an anti-expansion and anti-oxidation buffer powder mixture; the hose 2 is wrapped with an insulation layer 3, and the lower part of the insulation layer is provided with a refractory layer 4, and the insulation layer 3 and The refractory layers 4 are sealed; the metal rod 1 passes through the insulation layer 3 and extends to the refractory layer 4, and the amorphous refractory material is poured and fixed.

[0048] The refractory layer 4 of this design adopts amorphous refractory material: first fix the metal rod and the anti-expansion and anti-oxidation buffer material in place, and then...

Embodiment 3

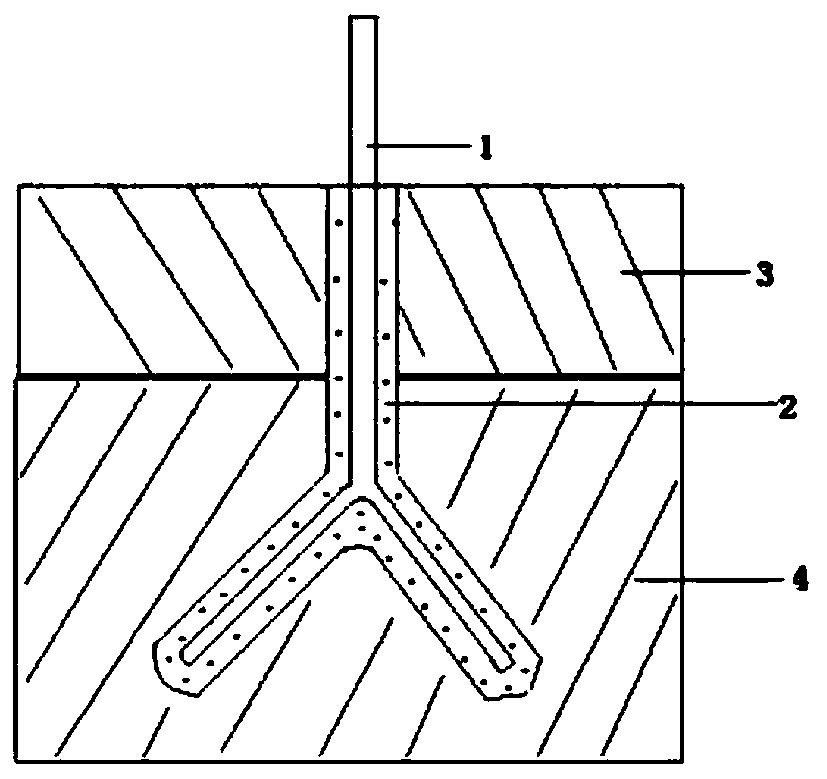

[0054] Such as image 3 Shown is an amorphous refractory suspension assembly.

[0055] It includes a metal rod 1, a hose 2, an insulation layer 3 and a refractory layer 4, and the metal rod 1 is isolated from the aluminum electrolytic cell by the refractory layer 4;

[0056] The metal rod is wrapped with a hose 2, and the space between the metal rod 1 and the hose 2 is filled with an anti-expansion and anti-oxidation buffer powder mixture; the hose 2 is wrapped with an insulation layer 3, and the lower part of the insulation layer is provided with a refractory layer 4, and the insulation layer 3 and The refractory layers 4 are sealed; the metal rod 1 passes through the insulation layer 3 and extends to the refractory layer 4, and the amorphous refractory material is poured and fixed.

[0057] The refractory layer 4 of this design uses amorphous refractory materials: first fix the metal rod and the anti-expansion and anti-oxidation buffer material in place, and then pour the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com