Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85 results about "Fugitive emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fugitive emissions are emissions of gases or vapors from pressurized equipment due to leaks and other unintended or irregular releases of gases, mostly from industrial activities. As well as the economic cost of lost commodities, fugitive emissions contribute to air pollution.

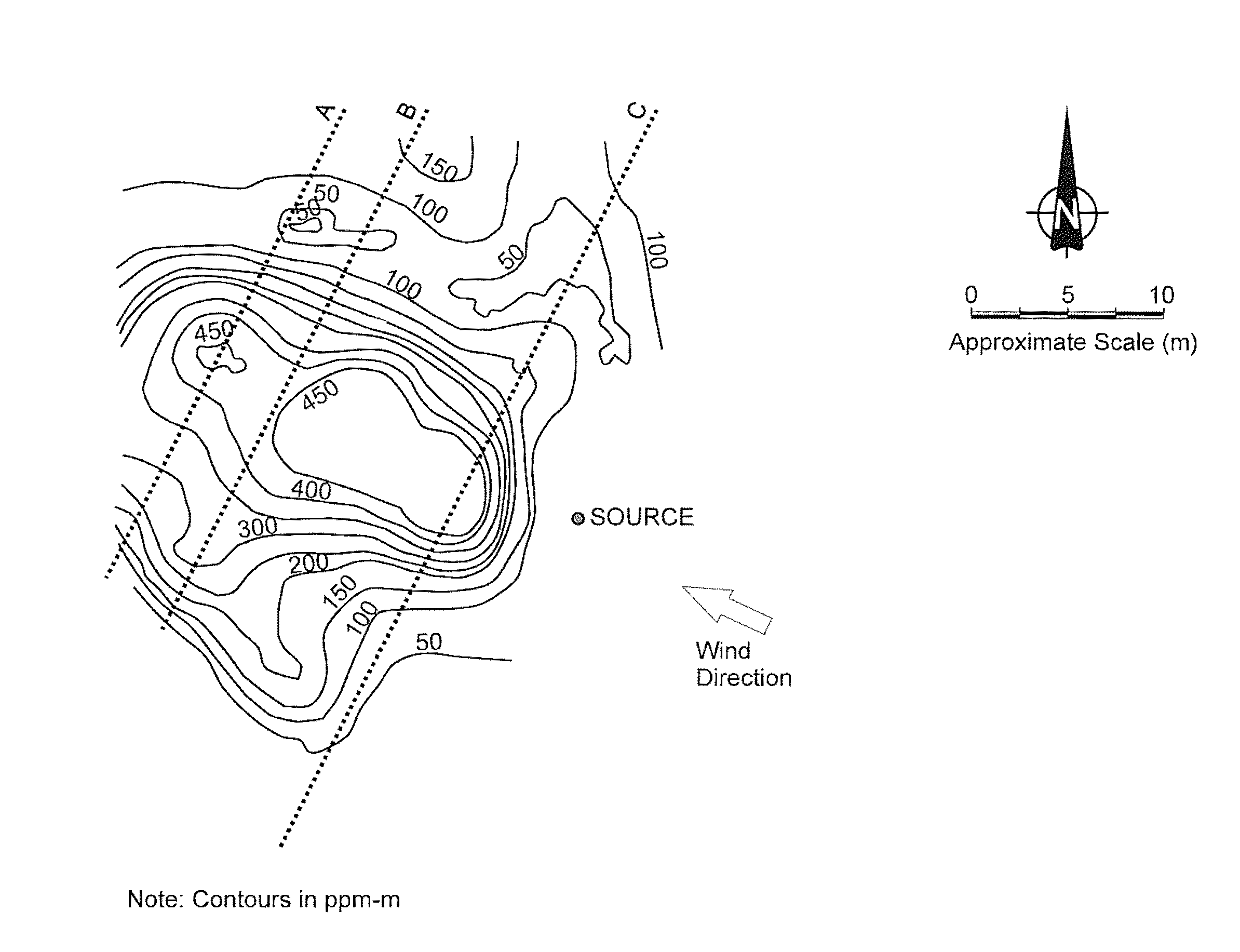

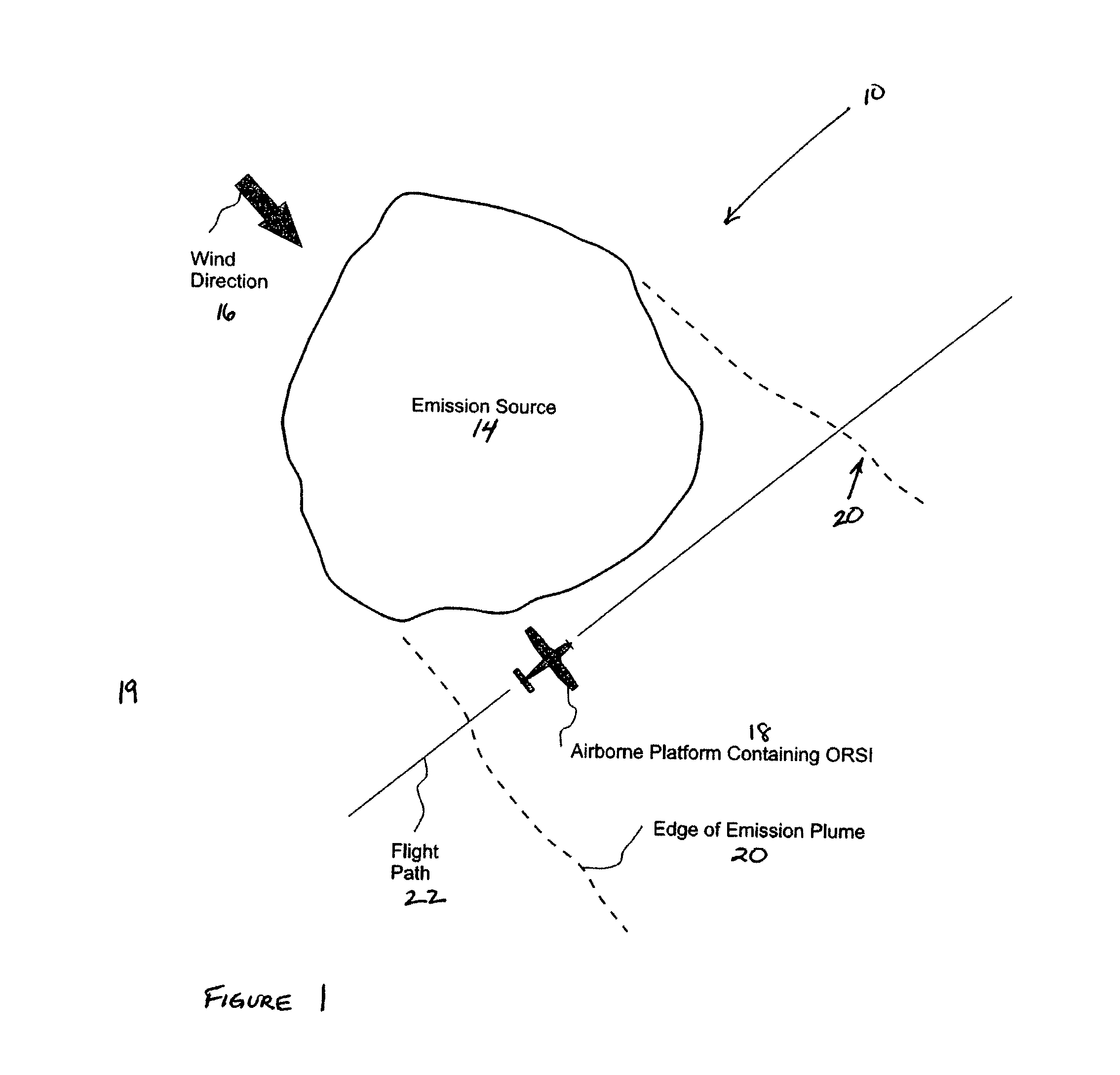

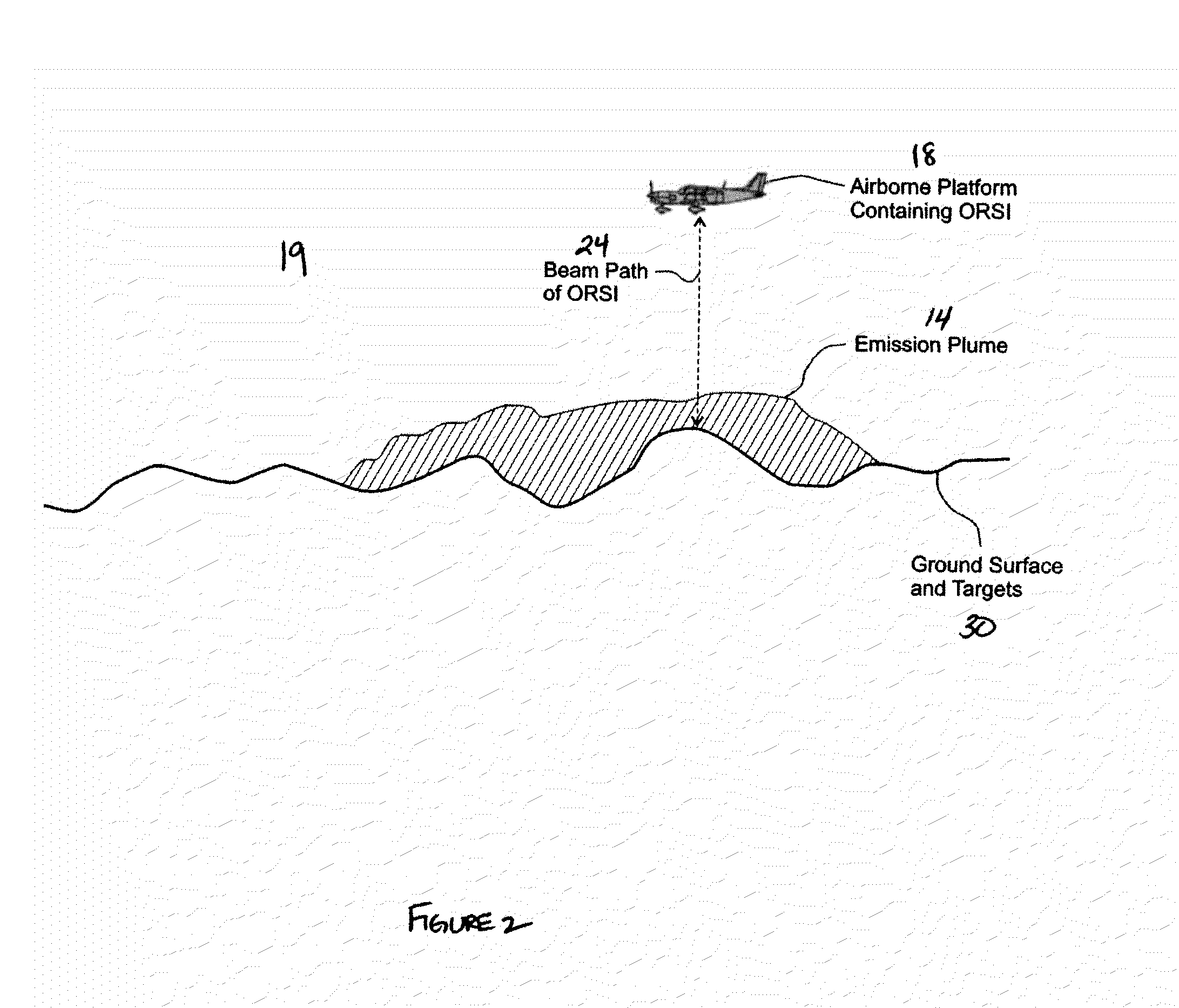

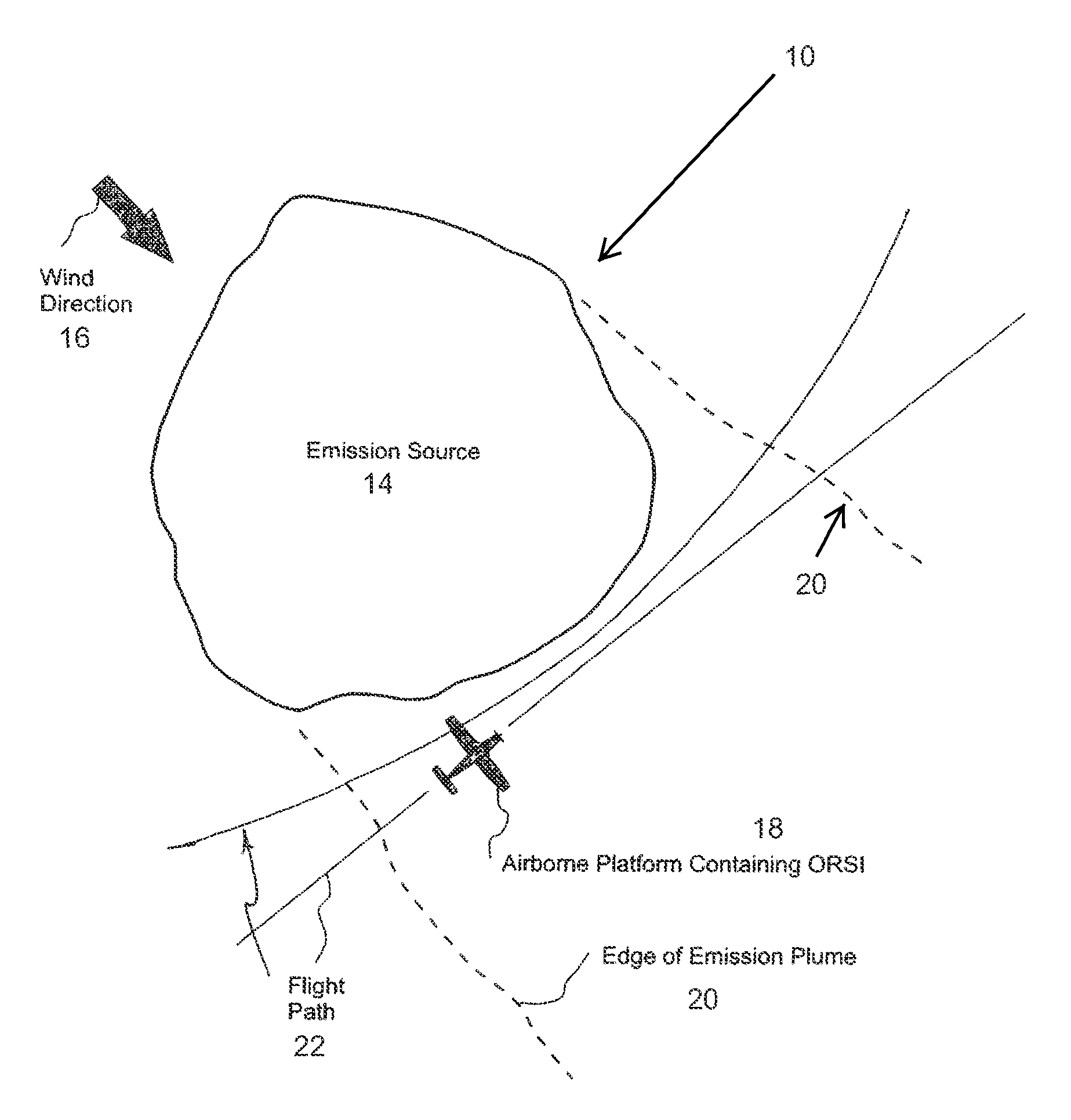

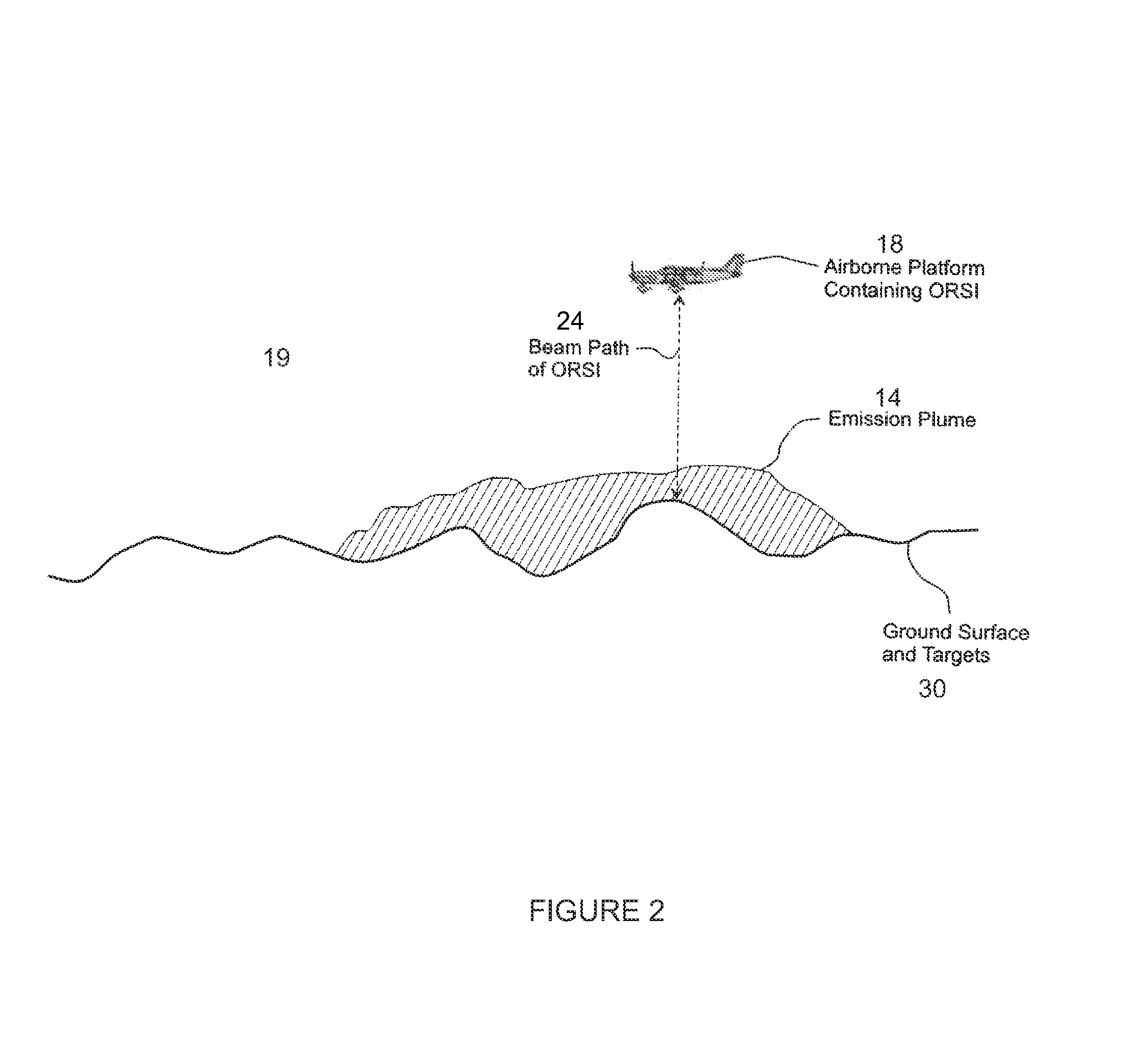

Fugitive emission flux measurement

A method of obtaining a fugitive emission flux measurement of airborne matter is provided. The method involves measuring the airborne matter along one or more than one measurement plane that spans the fugitive emission using two or more than two measurement beam paths where each of the two or more than two measurement beam paths are parallel to each other, or substantially parallel to each other, and determining a mass per unit length measurement for the measurement plane, determining a representative wind velocity at or near the one or more than one measurement plane, and calculating the fugitive emission flux of the airborne matter in mass per unit time using the mass per unit length determination and representative wind velocity.

Owner:GOLDER ASSOCIATES

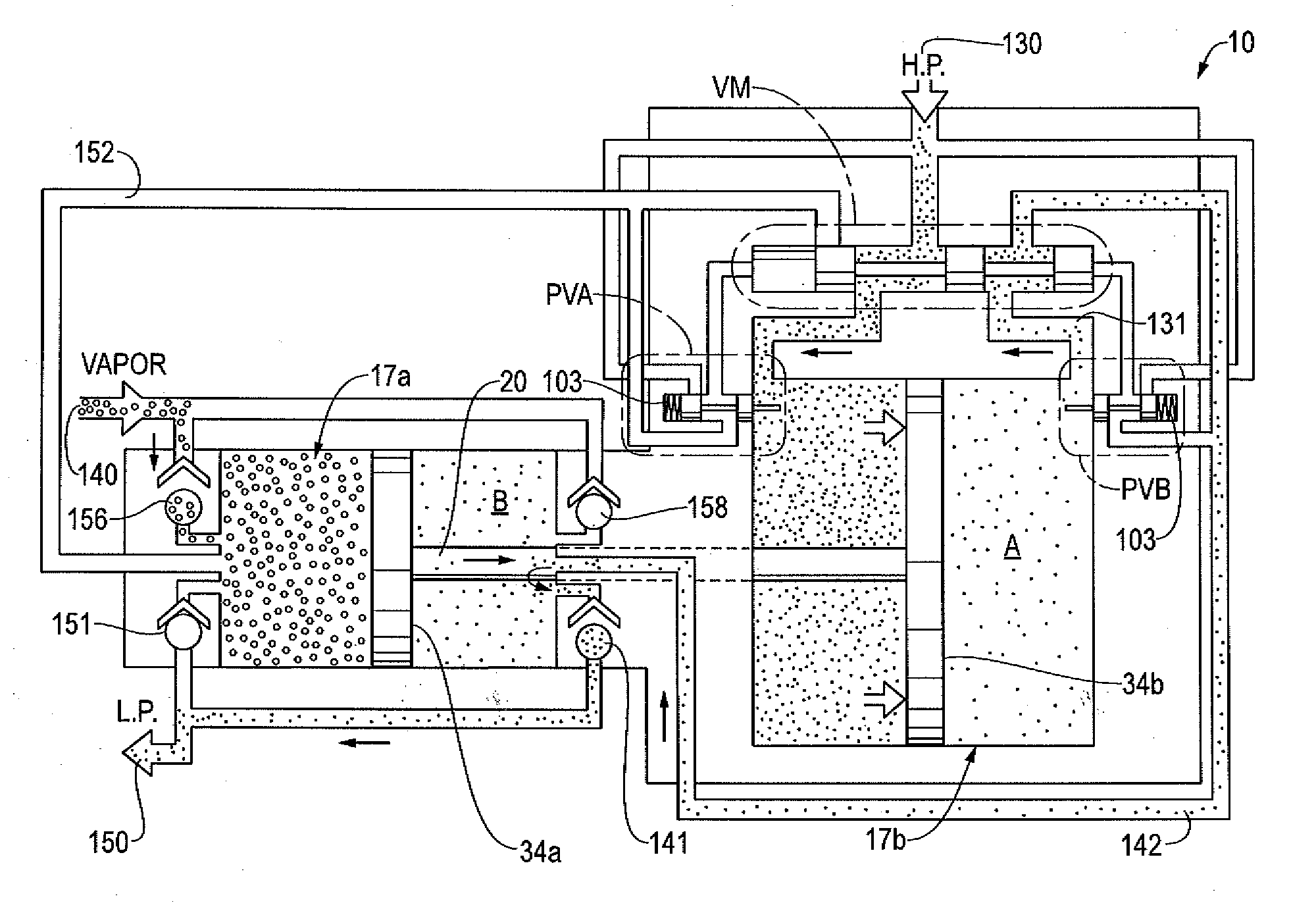

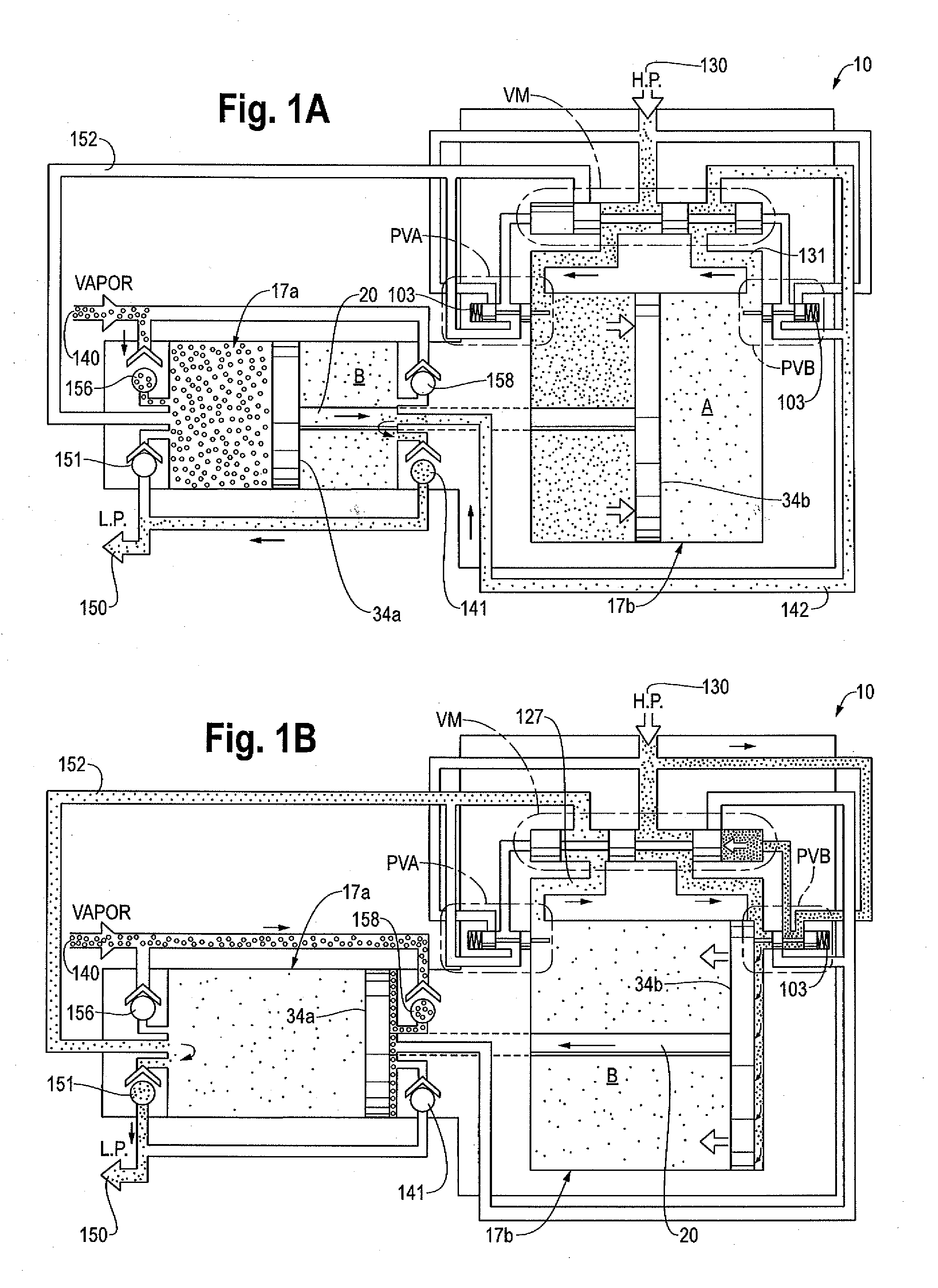

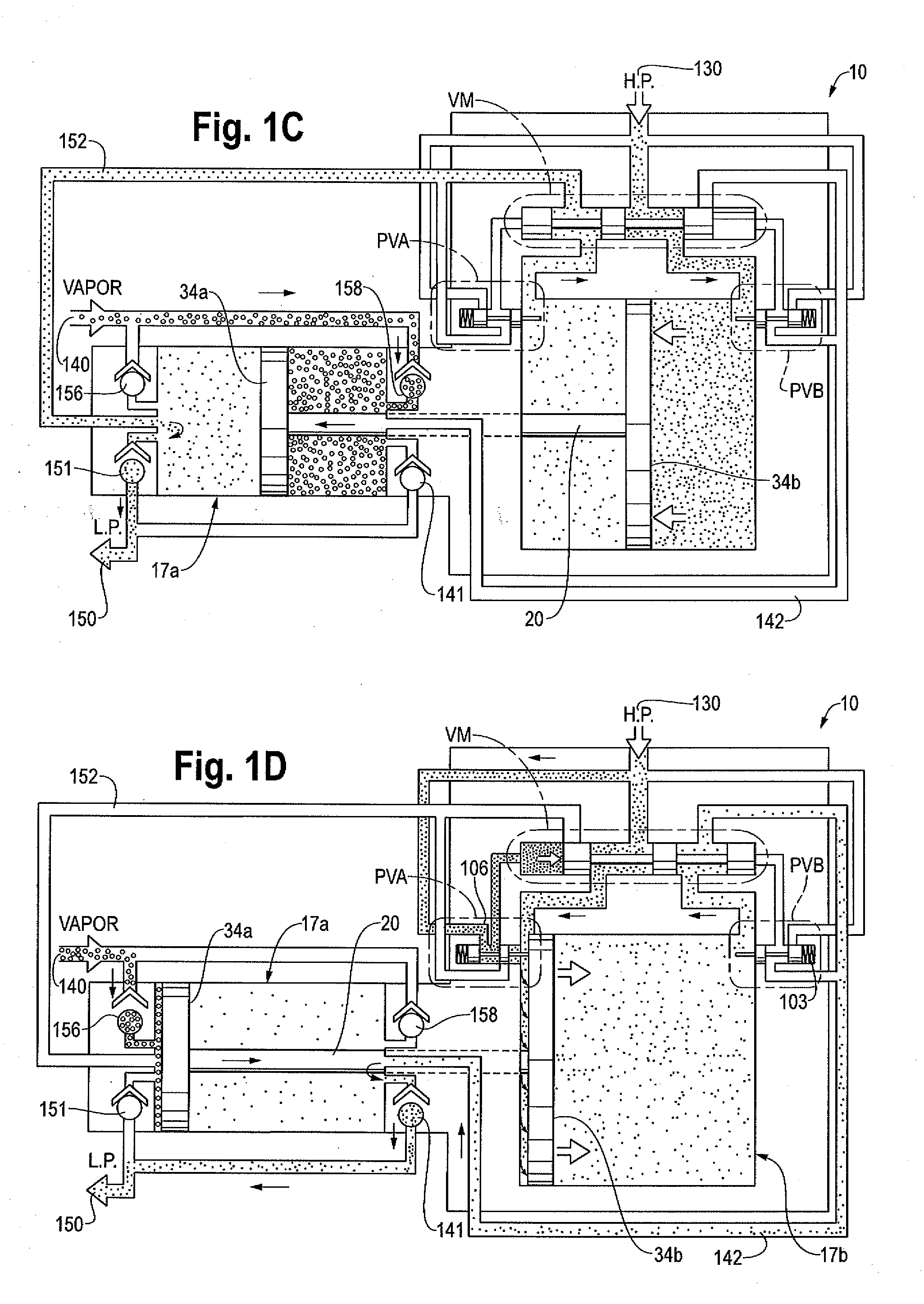

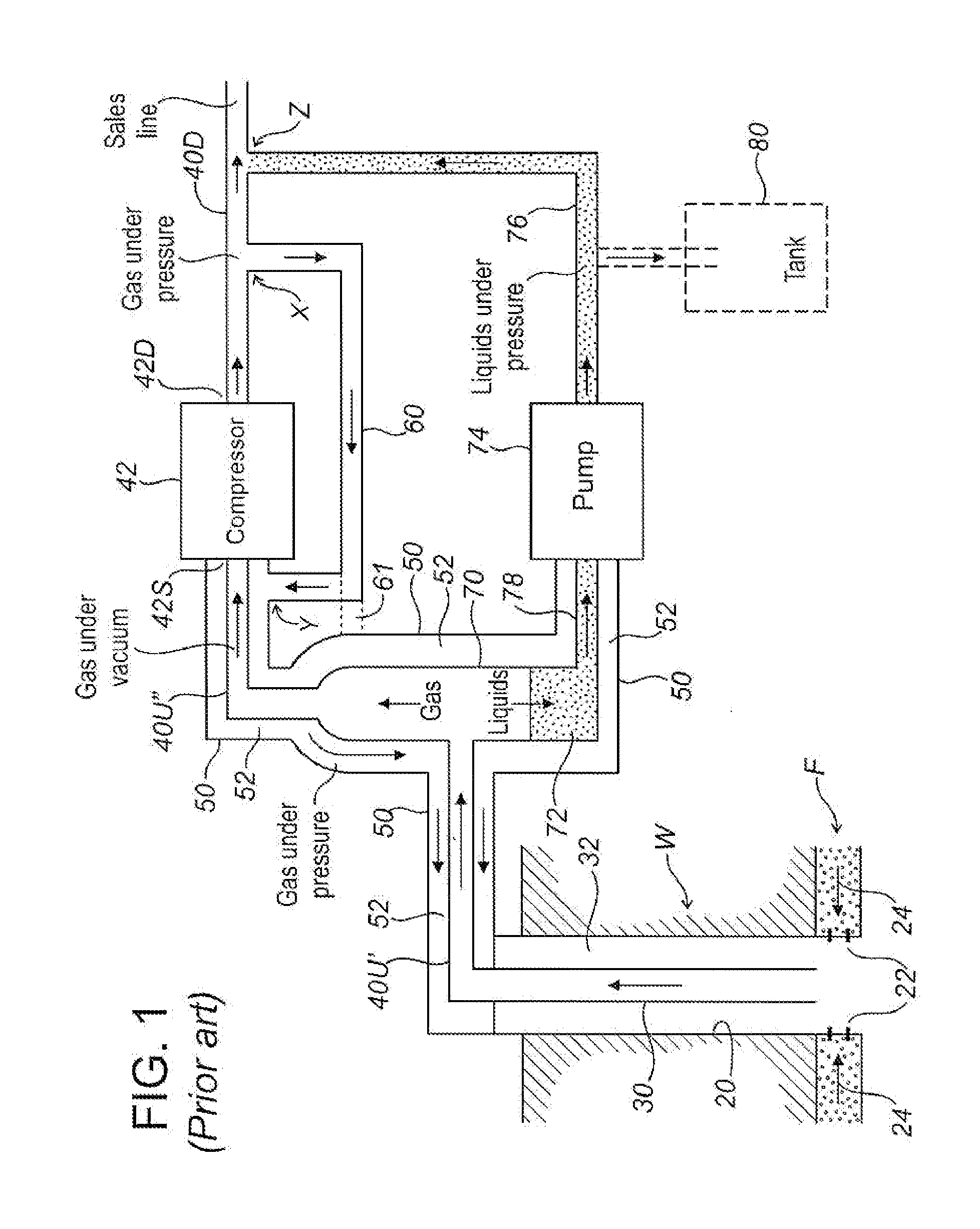

Vapor recovery gas pressure boosters and methods and systems for using same

A gas pressure booster and a method for using it, which recovers fugitive gas emissions such as at atmospheric pressure, boosts them such as to the pressure level of the low pressure gas sink, and returns them to, e.g., the low pressure gas sink, in a single stage of compression. No electricity or cooling water is required. All gas used to drive the vapor recovery booster may be recovered and vented to the low pressure gas sink.In one preferred embodiment, the gas pressure booster includes a drive cylinder and a boost cylinder interconnected by reciprocating drive and boost pistons. The drive piston supplies force powered by a first gas stream within the drive cylinder which exhausts to a second gas stream at a lower pressure. Fugitive gas emissions may be captured and transported to the lower pressure second gas stream to eliminate gas discharged to atmosphere. The need for boosting a gas multiple ratios is eliminated, as the pressure of the fugitive emission vapor is equalized to the low pressure gas sink at the end of the piston suction stroke. Preferably, a four-way valve operating on differential gas pressure may be used to automatically actuate the reciprocating piston.

Owner:MIDWEST PRESSURE SYST

Fugitive emission flux measurement

A method of obtaining a fugitive emission flux measurement of airborne matter is provided. The method involves measuring the airborne matter along one or more than one measurement surface that spans the fugitive emission using two or more than two measurement beam paths where each of the two or more than two measurement beam paths are parallel to each other, or substantially parallel to each other, and determining a mass per unit length measurement for the measurement surface, determining a representative wind velocity at or near the one or more than one measurement surface, and calculating the fugitive emission flux of the airborne matter in mass per unit time using the mass per unit length determination and representative wind velocity.

Owner:GOLDER ASSOCIATES

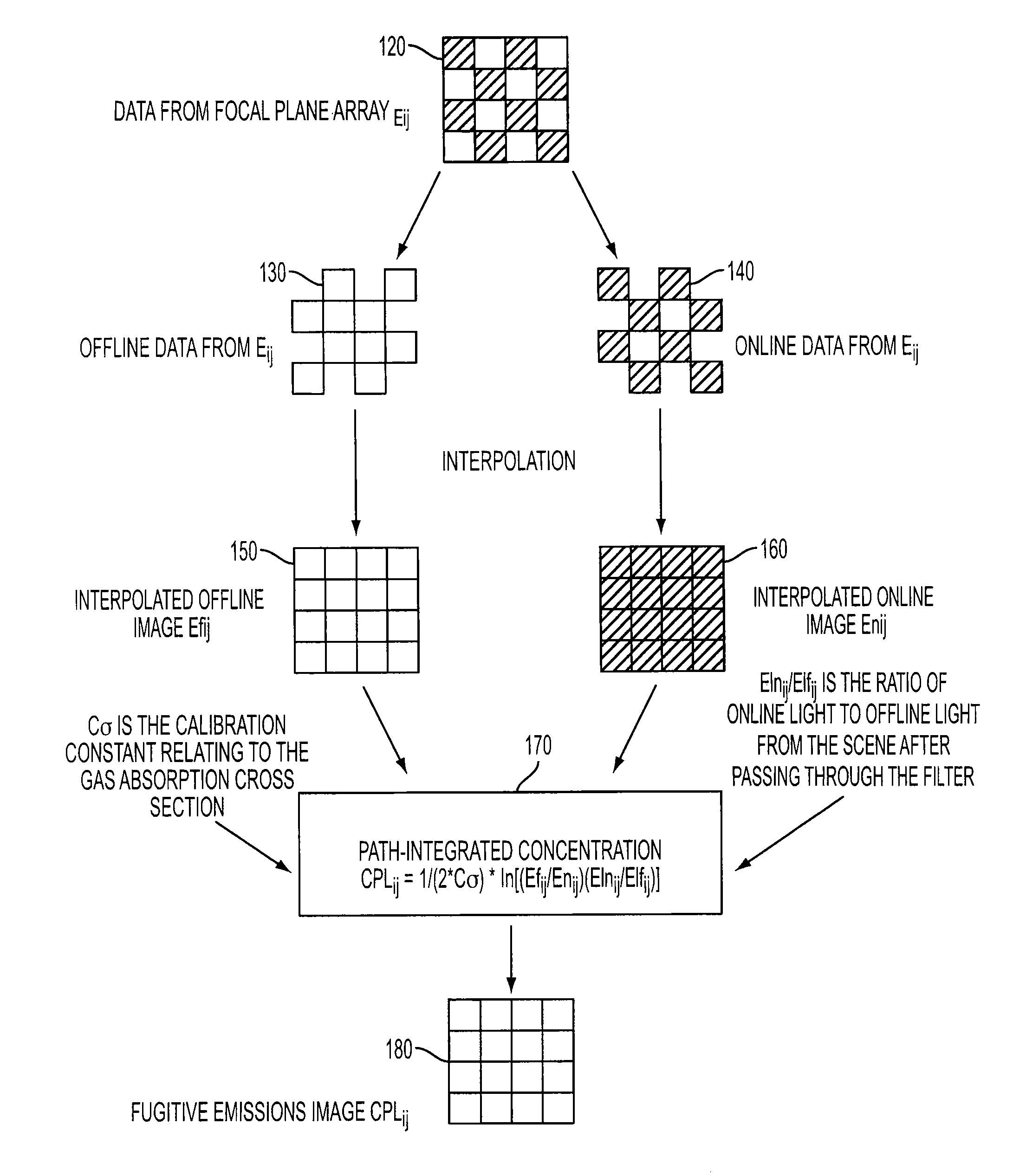

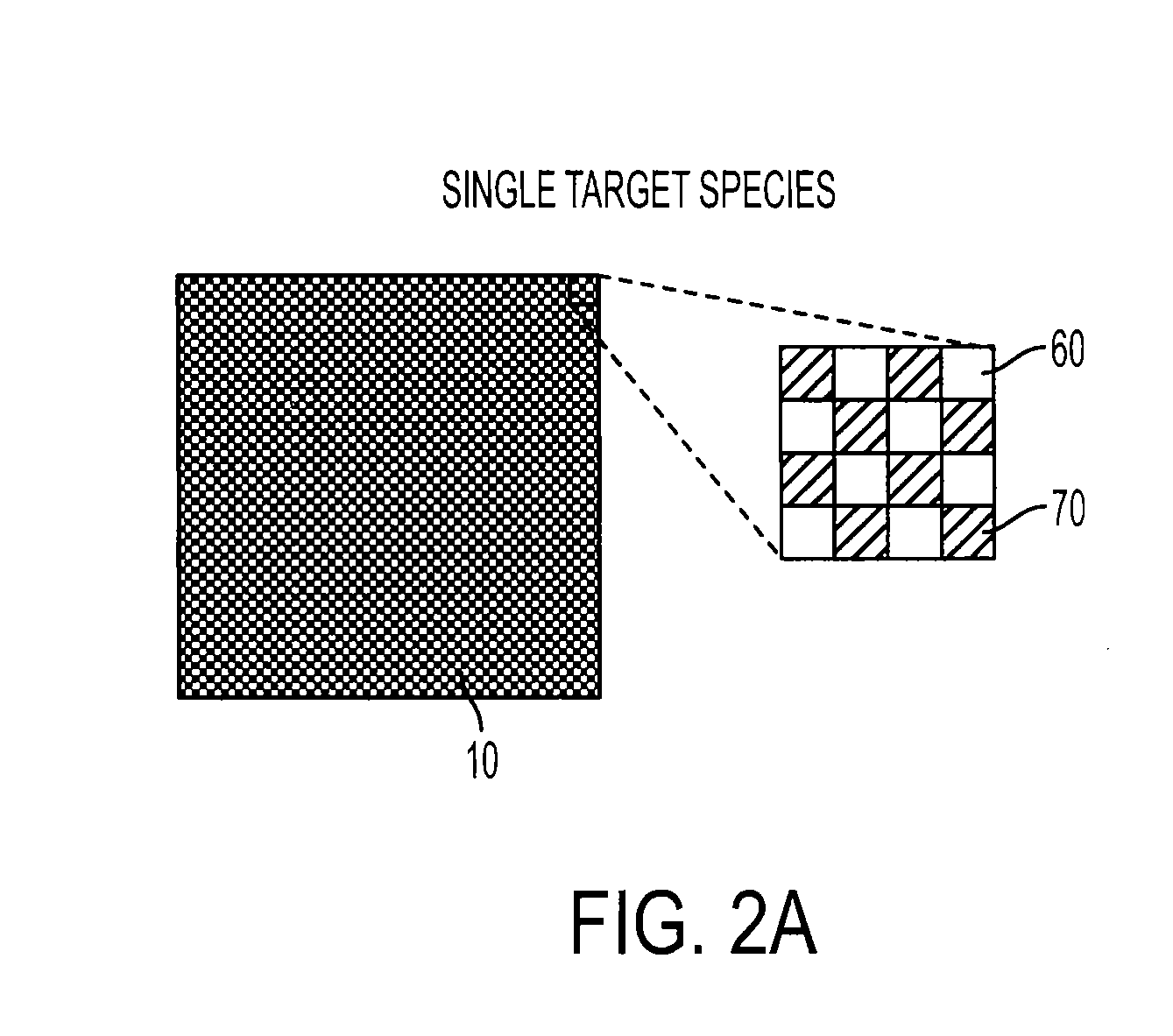

Filter mosaic for detection of fugitive emissions

A method and apparatus for quantitative and qualitative imaging of fugitive emissions of gas, vapors, or fumes are described. The apparatus includes a filter mosaic for placement in registration over an imaging focal plane array (FPA). The filter mosaic includes at least two filter elements providing transmission response functions for transmitting wavelengths of light corresponding to an absorption wavelength (online wavelength) and a non-absorption wavelength (offline wavelength) of the targeted fugitive emission. Also described is an image processing method for transforming a filtered image into an image of the targeted fugitive emission.

Owner:HARRIS CORP

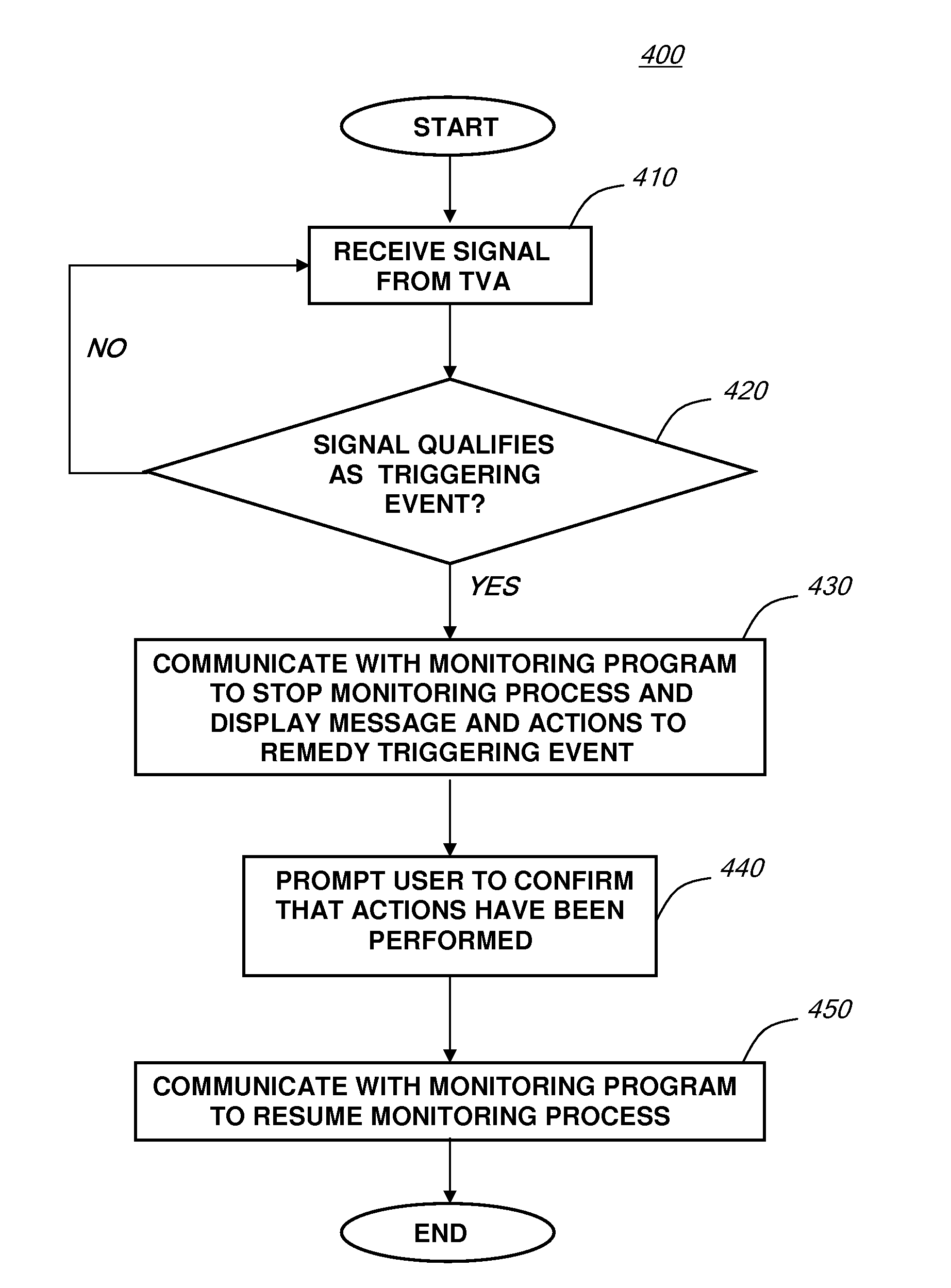

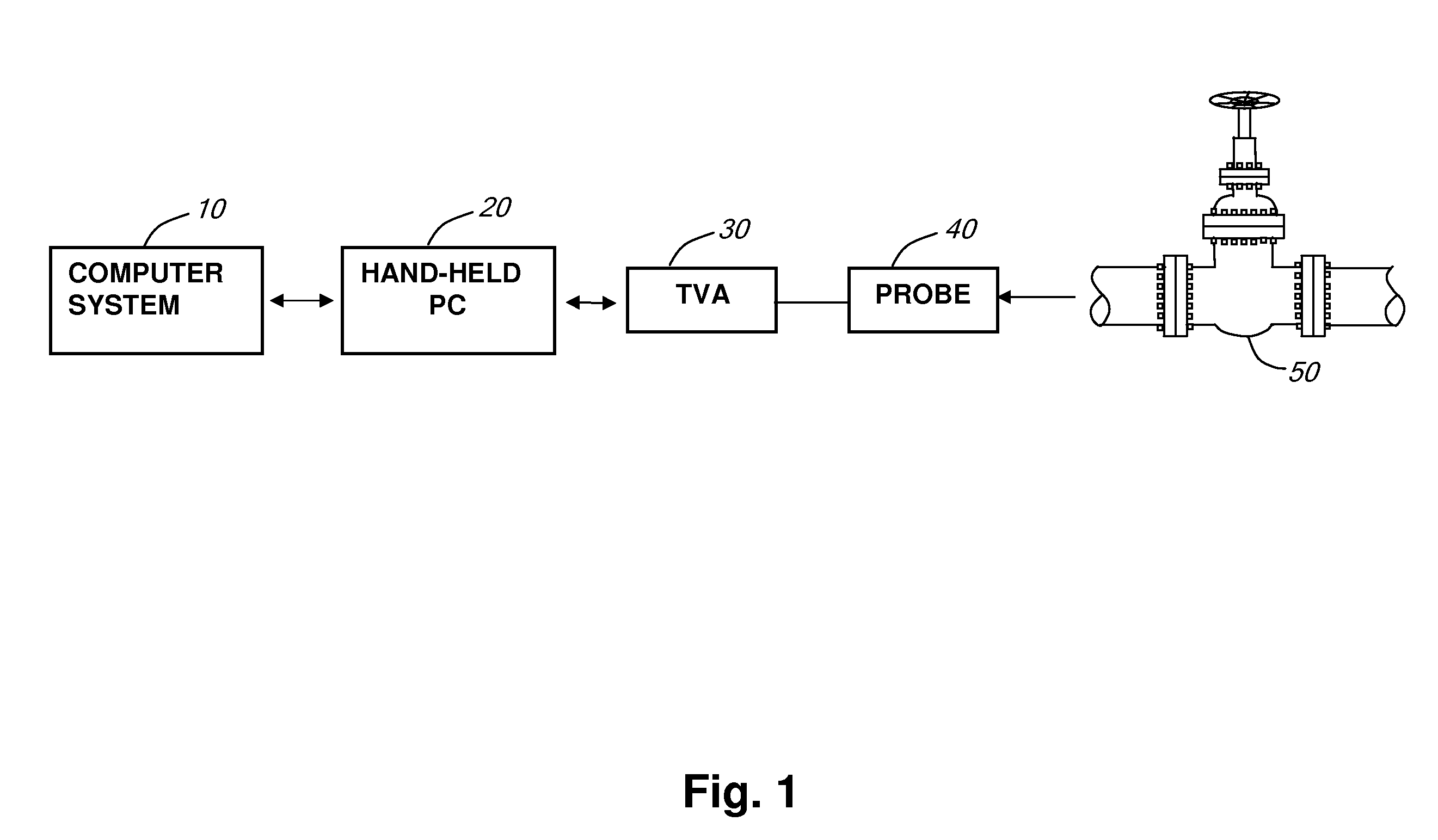

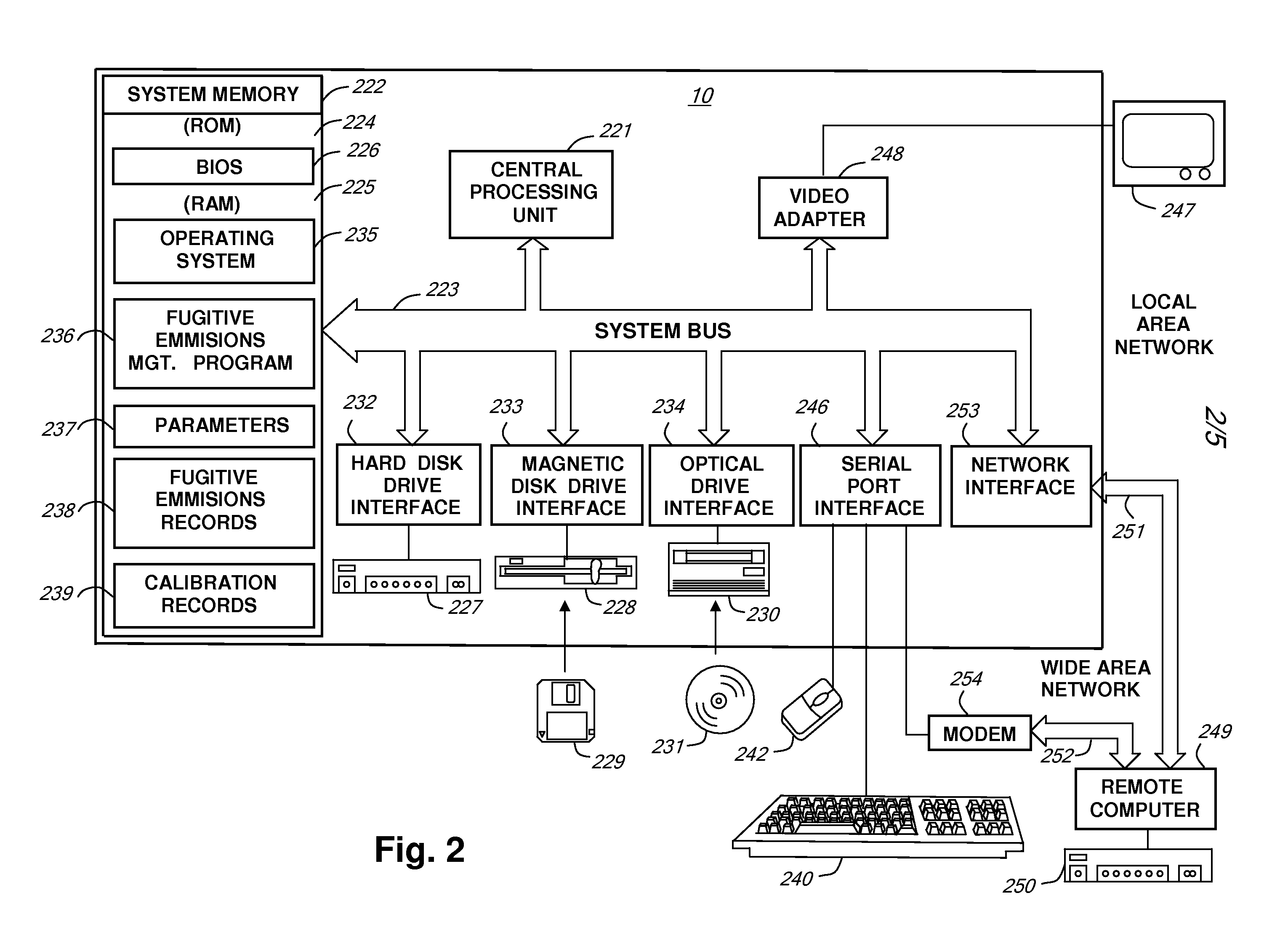

Management of response to triggering events in connection with monitoring fugitive emissions

InactiveUS7657384B1Chemical analysis using combustionComponent separationReal-time computingFugitive emissions

Method for managing a response to a triggering event in connection with a fugitive emissions monitor of a component. In one implementation, the method may include determining whether an input is a triggering event. If the input is a triggering event, then a message regarding the triggering event and one or more actions to remedy the triggering event may be displayed. The method may further include displaying one or more queries to confirm that the actions have been completed.

Owner:LDARTOOLS

Fugitive emission flux measurement

A method of obtaining a fugitive emission flux measurement of airborne matter is provided. The method involves measuring the airborne matter along one or more than one measurement surface that spans the fugitive emission using two or more than two measurement beam paths where each of the two or more than two measurement beam paths are parallel to each other, or substantially parallel to each other, and determining a mass per unit length measurement for the measurement surface, determining a representative wind velocity at or near the one or more than one measurement surface, and calculating the fugitive emission flux of the airborne matter in mass per unit time using the mass per unit length determination and representative wind velocity.

Owner:GOLDER ASSOCIATES

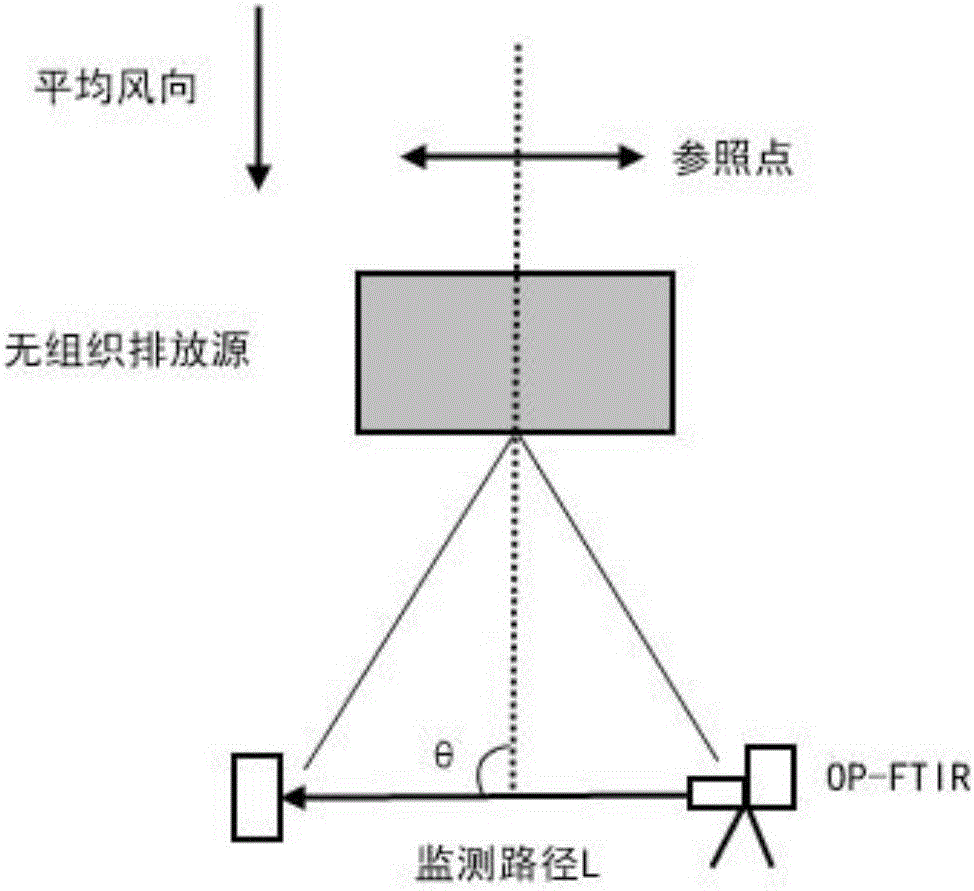

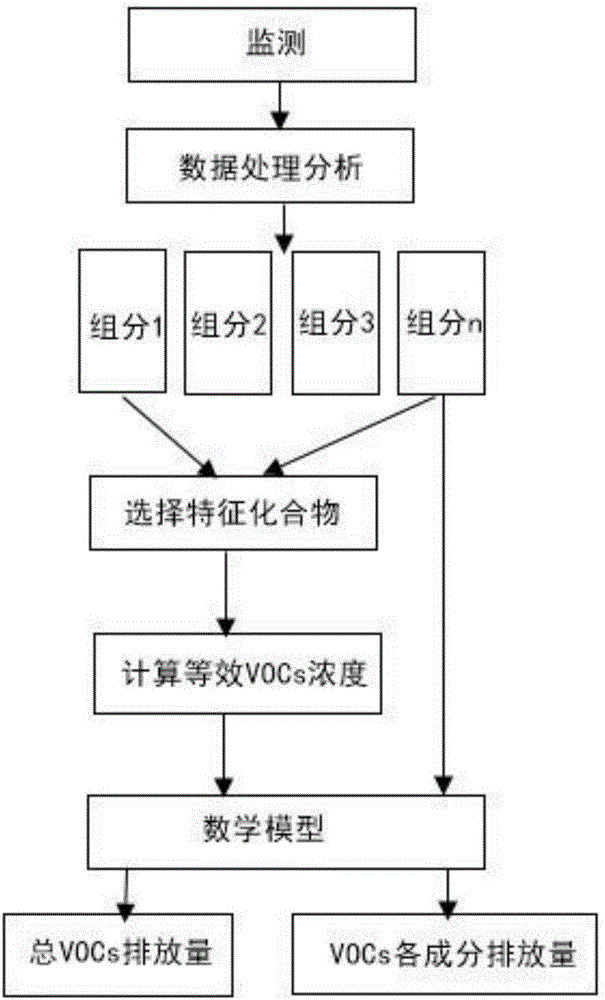

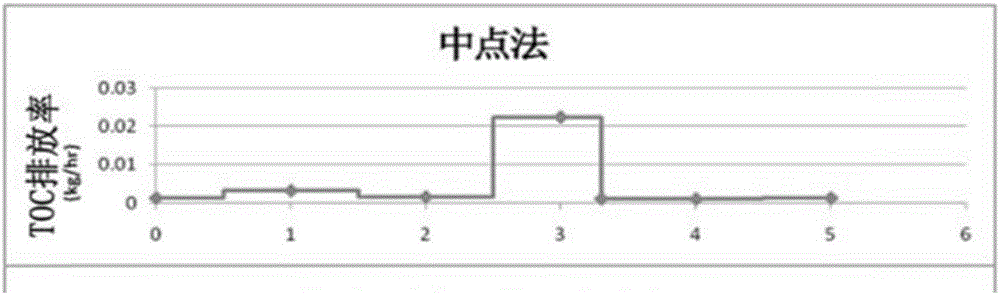

Method for measuring and calculating discharge amount of petrochemical enterprise fugitive emission source VOCS

ActiveCN106841087AThe result is accurateTrue reactionMaterial analysis by optical meansAir quality improvementMathematical modelAdditive ingredient

The invention relates to a method for measuring and calculating a discharge amount of petrochemical enterprise fugitive emission source VOCS. The method mainly solves the problem of poor calculating accuracy of the prior art. The method comprises setting a monitoring route along a fugitive emission source down wind direction through combination of an open-circuit infrared monitoring technology and meteorological conditions, carrying out continuous real-time monitoring, carrying out analysis and processing on the monitoring data result, selecting a characteristic compound, calculating a VOCs equivalent concentration, building a mathematical model and a calculation formula and acquiring a fugitive emission source total VOCs discharge amount and discharge amounts of ingredients of VOCs. The method solves the above problem and can be used for measuring and calculating the discharge amount of petrochemical enterprise fugitive emission source VOCS.

Owner:CHINA PETROLEUM & CHEM CORP +1

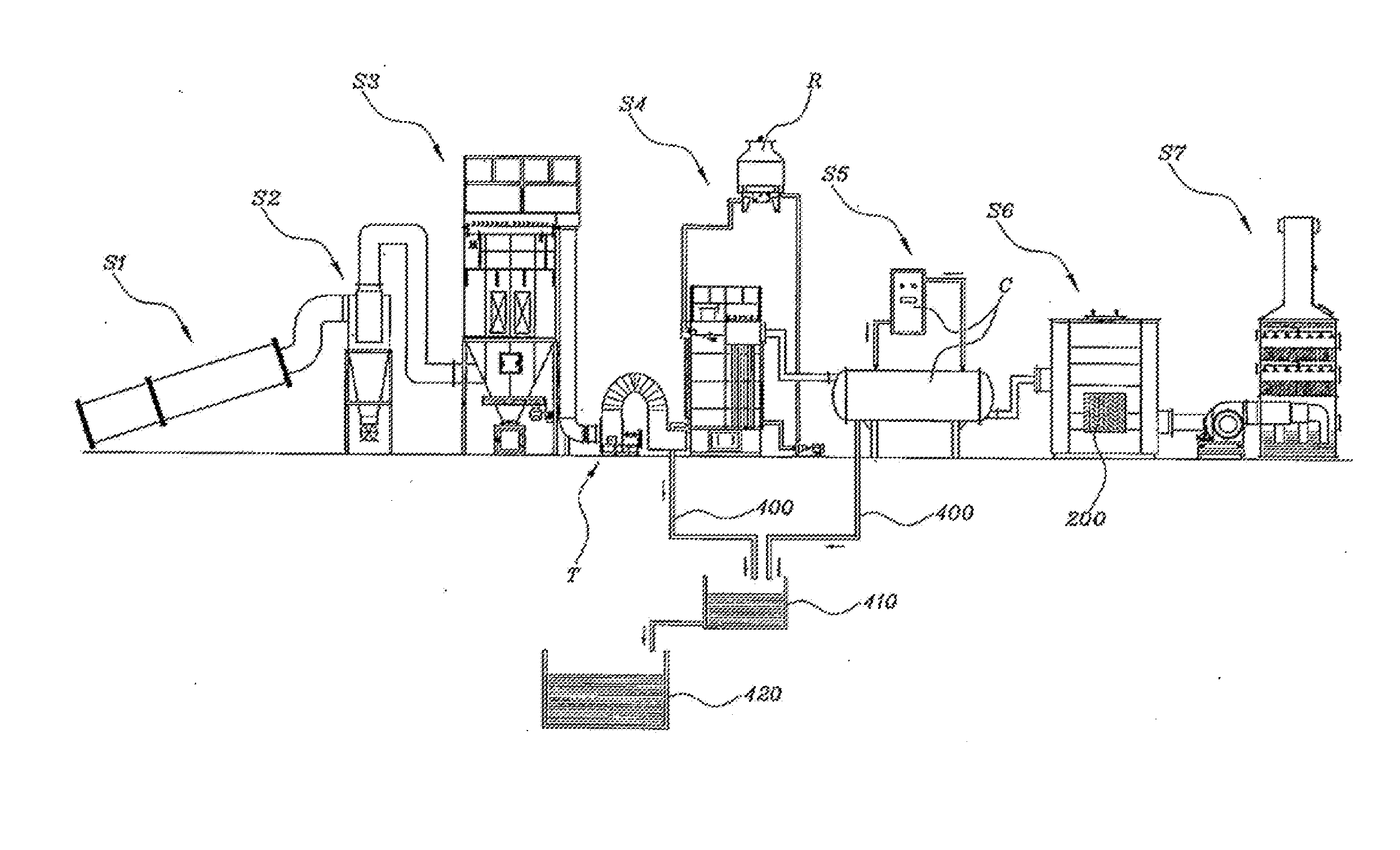

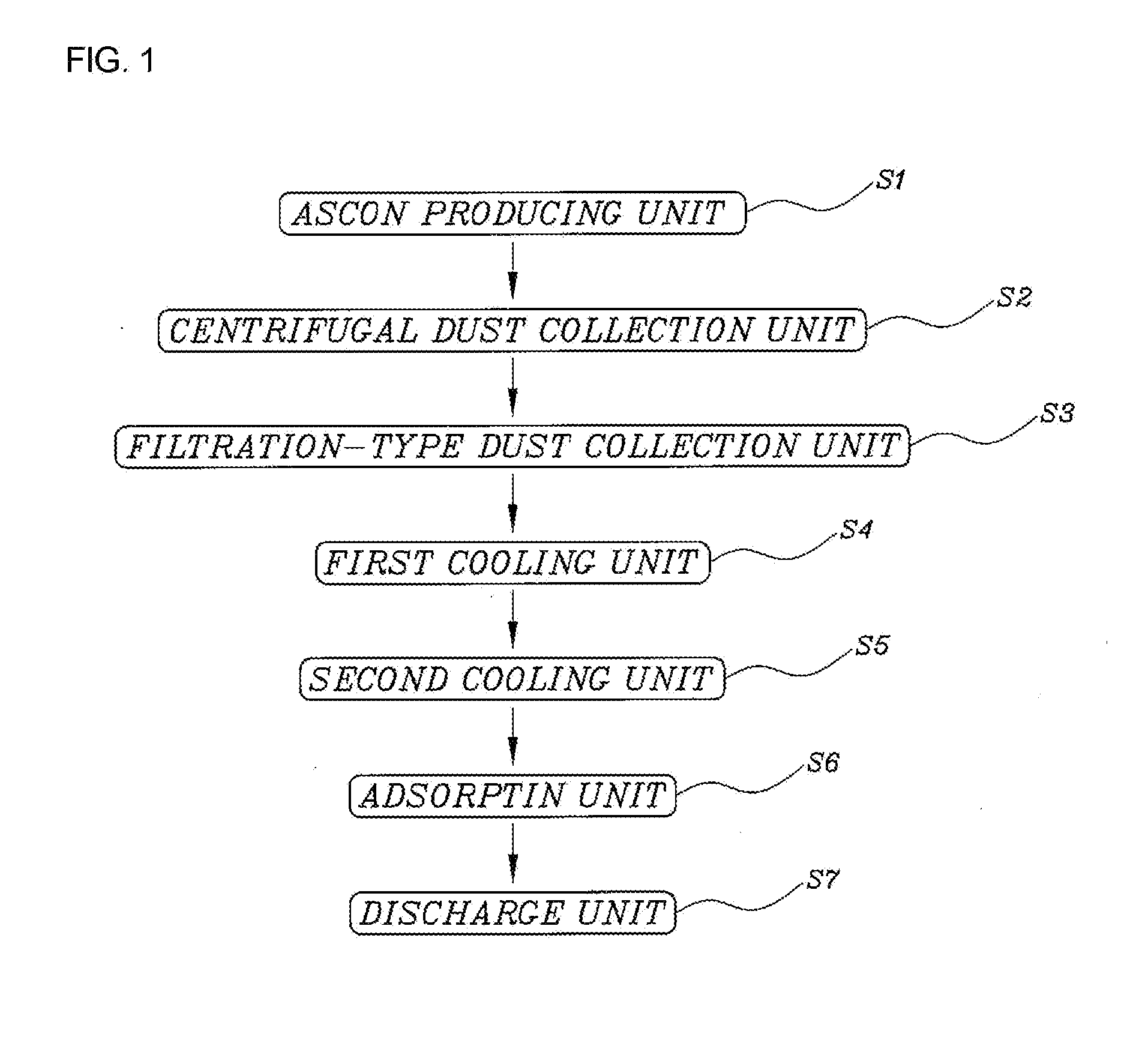

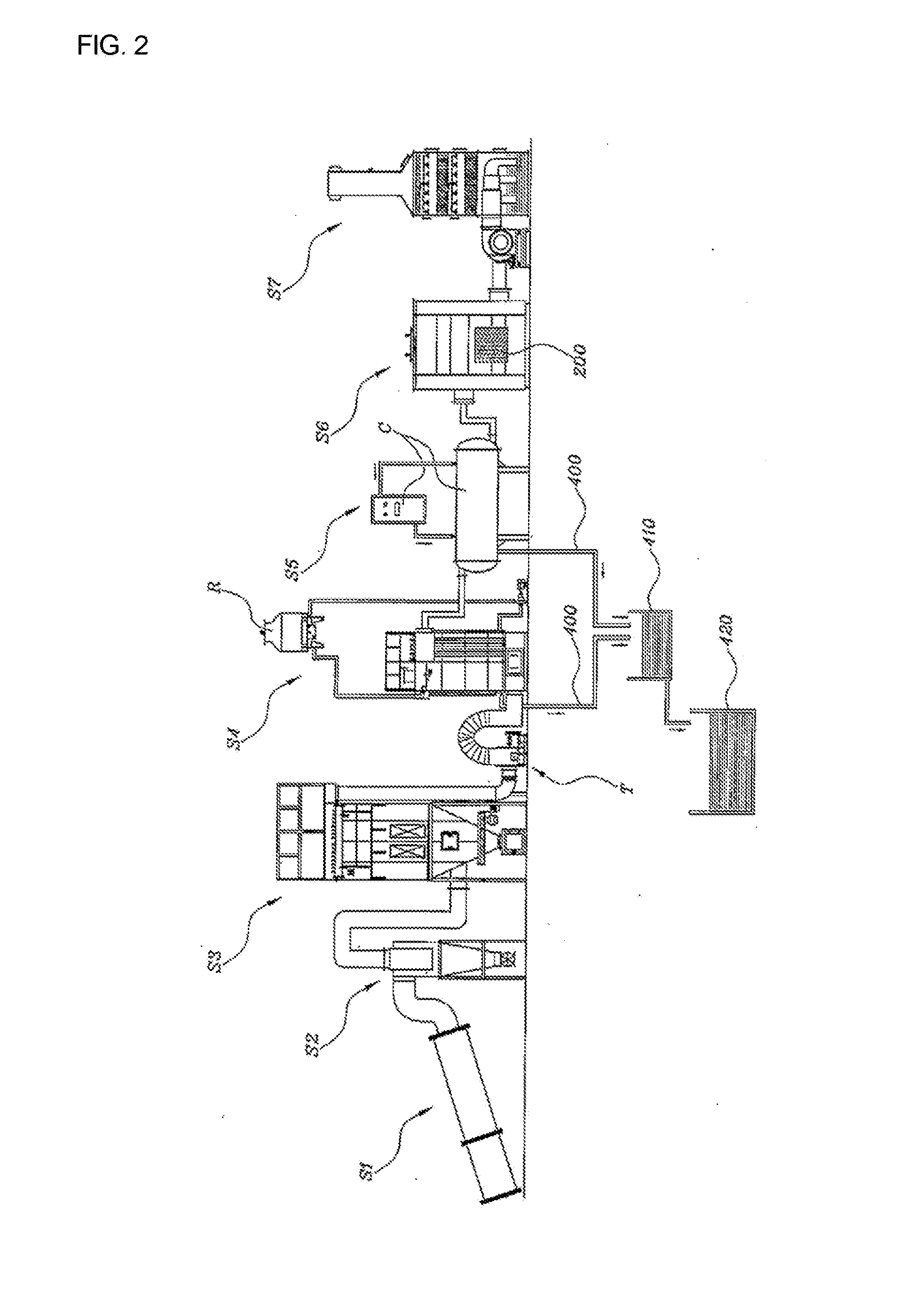

Apparatus for removing dust and offensive odor generated from ascon

InactiveUS20150075382A1Avoid environmental pollutionMinimizes and removeCombination devicesGas treatmentCooling towerFiltration

An apparatus for removing dust and offensive odor generated from ascon includes: a centrifugal dust collection unit which forcibly sucks offensive odor-causing materials, harmful gas and dust generated from the ascon, produced in an ascon producing unit, via a pipe so as to discharge the dust having a relatively large particle size via a hopper provided at the lower end thereof to the outside by means of a rotary valve while conveying air and relatively fine dust to a filtration-type dust collection unit via a pipe provided at the upper side thereof; the filtration-type dust collection unit for filtering the offensive odor-causing materials, harmful gas and fine dust having passed through the centrifugal dust collection unit by means of a filter while discharging the remaining fine dust or the like to the outside by a screw provided at the lower end of the hopper; a first cooling unit for condensing the harmful gas and offensive odor-causing materials of 150° C., supplied from the filtration-type dust collection unit, by cooling the same to 40˜50° C. using a cooling tower and thus removing and separating the moisture and the offensive odor-causing materials; a second cooling unit for condensing the offensive odor-causing materials and harmful gas of 40˜50° C., having passed through the first cooling unit, by re-cooling the same to 20° C. or lower by a condenser and thus removing and separating the moisture and offensive odor-causing materials so as to prevent a white plume phenomenon; an adsorption unit for removing volatile organic compounds (VOCs) by adsorbing and filtering the offensive odor-causing materials and harmful gas of 20° C., having passed through the second cooling unit, using a active carbon filter; and a discharge unit configured such that spray pipes are provided therein in stages so as to remove water-soluble offensive odor-causing materials in the air, from which the volatile organic compounds (VOCs) have been removed via the adsorption unit, by spraying water via a plurality of spray nozzles provided at each of the spray pipes, and a discharge pipe is provided at the upper side thereof so as to discharge fresh air, wherein a turbo fan is provided between the filtration-type dust collection unit and the first cooling unit, and wherein an oil-water separation tank and a water collection tank are additionally provided between the first cooling unit and the second cooling unit such that the oil-water separation tank separates harmful oil and water from each other by discharging the cooled and condensed moisture and offensive odor-causing materials via pipes, and the water collection tank collects only water separated from the oil-water separation tank. The apparatus of the present invention can prevent environmental pollution by removing or minimizing the offensive odor and dust by a batch system, wherein air pollutants or any other harmful dust generated in the ascon producing unit is removed or minimized regardless of ducted emission and fugitive emission. Particularly, according to the offensive odor prevention plan, the step for mixing AP oil and heated aggregate and the step for loading the ascon onto a truck, which are considered to be the main steps for generating the offensive odor, are preformed when producing the ascon by using a new aggregate, while the AP oil vapor is condensed so as to be removed by the first cooling unit, and untreated materials are removed by the second cooling unit in consideration of the physical and chemical properties of the AP oil during re-generation of the waste ascon. Therefore, the apparatus of the present invention is mounted at the rear end of an existing asphalt plant collection facility such that the moisture which is evaporated in the step for drying the AP oil vapor and the aggregate is first condensed and collected, and the volatile organic compounds (VOCs) and the moisture are secondarily condensed and collected by the condenser, the untreated offensive odor-causing materials are collected in the adsorption unit and the discharge unit. Thus, effects of decreasing offensive odor and preventing a white plume phenomenon are exhibited.

Owner:JEONG CHOONG EUI

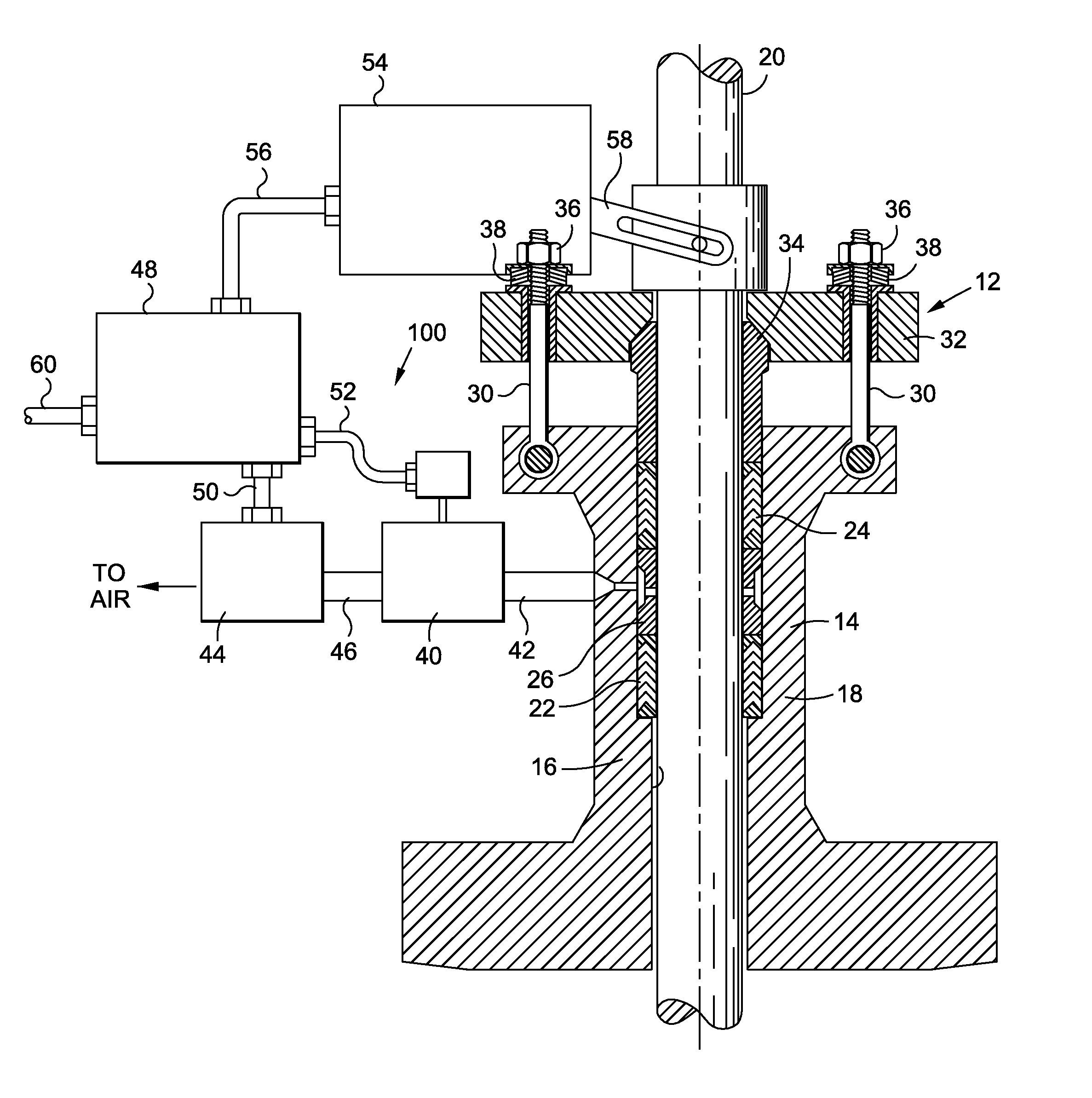

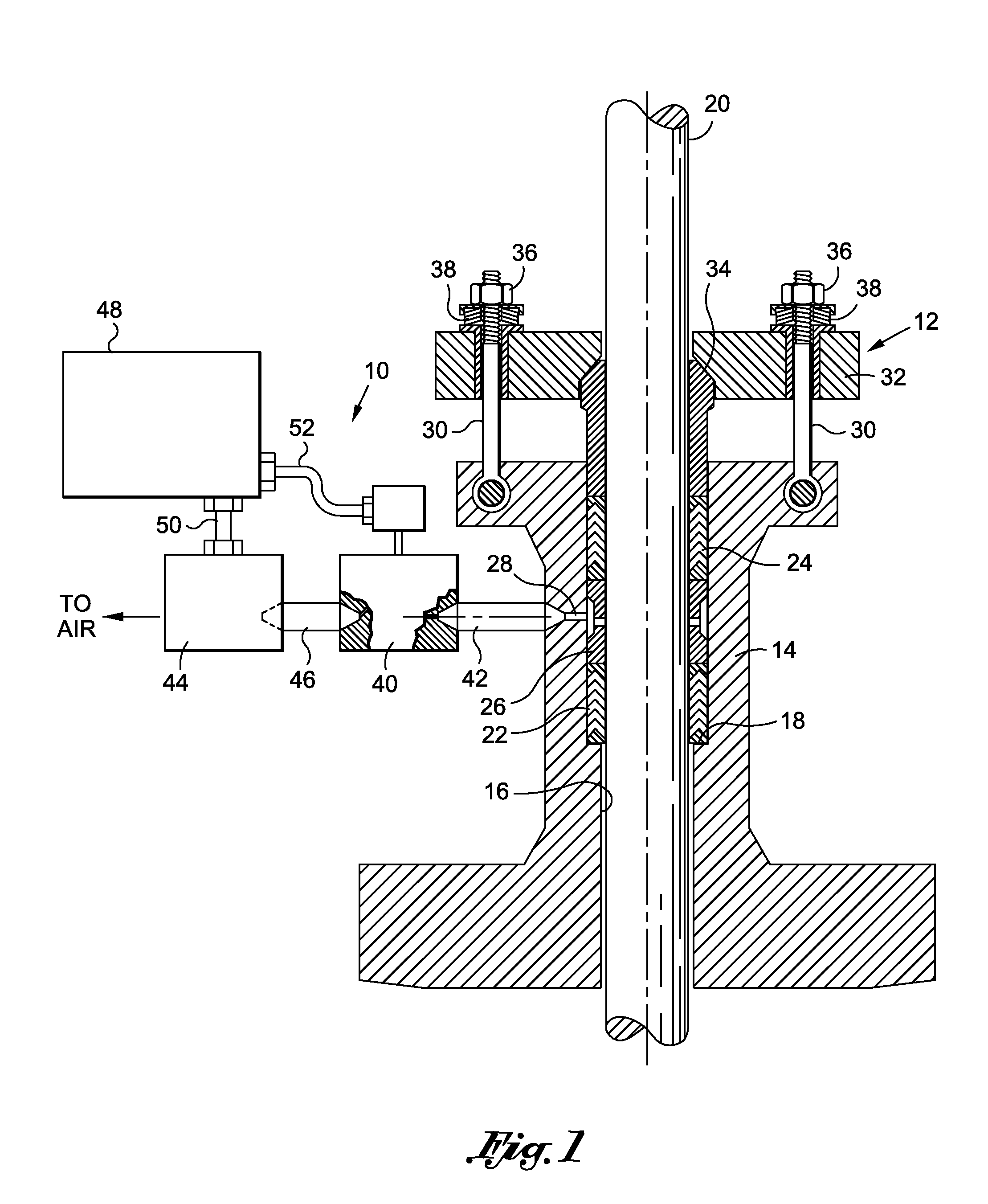

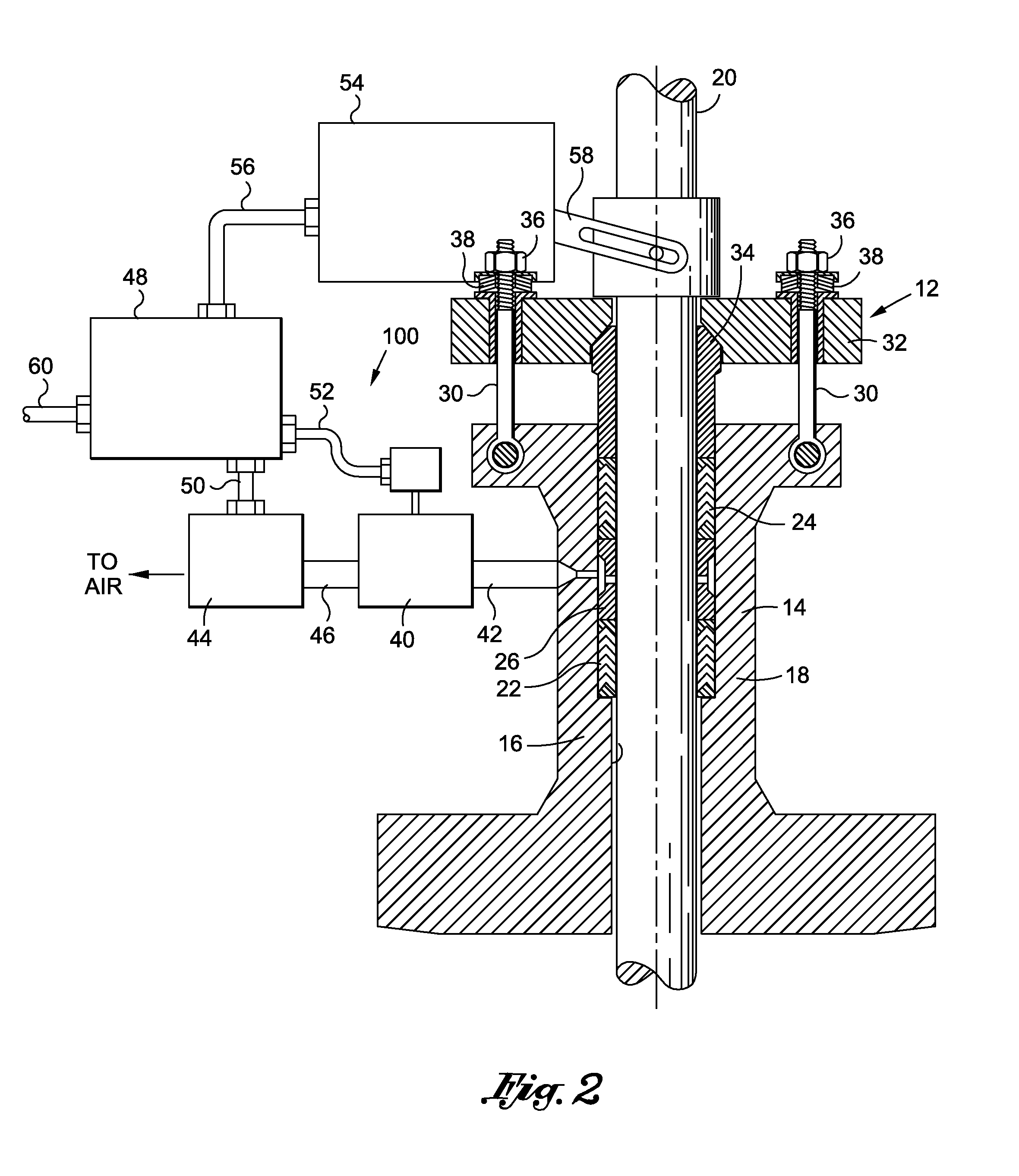

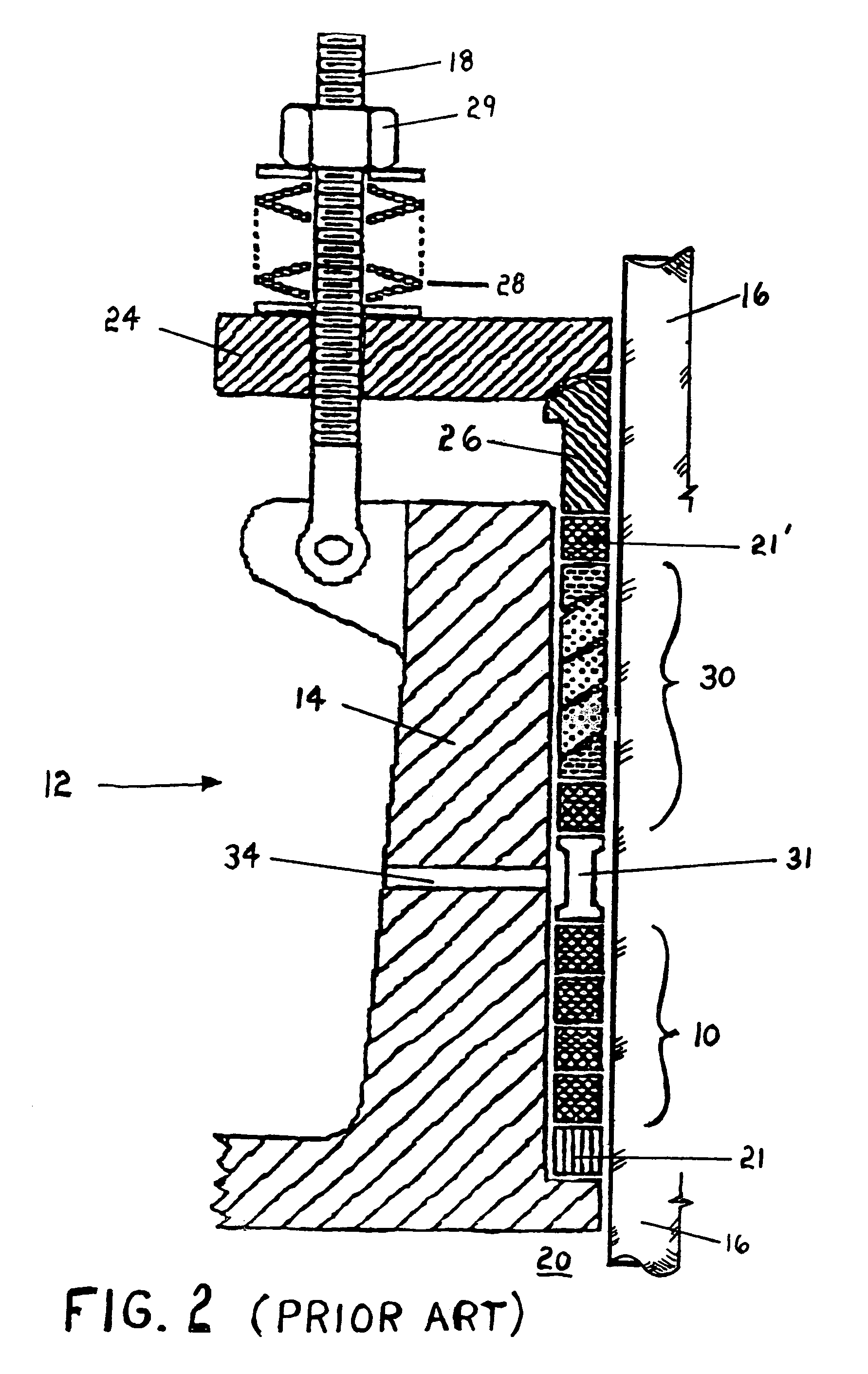

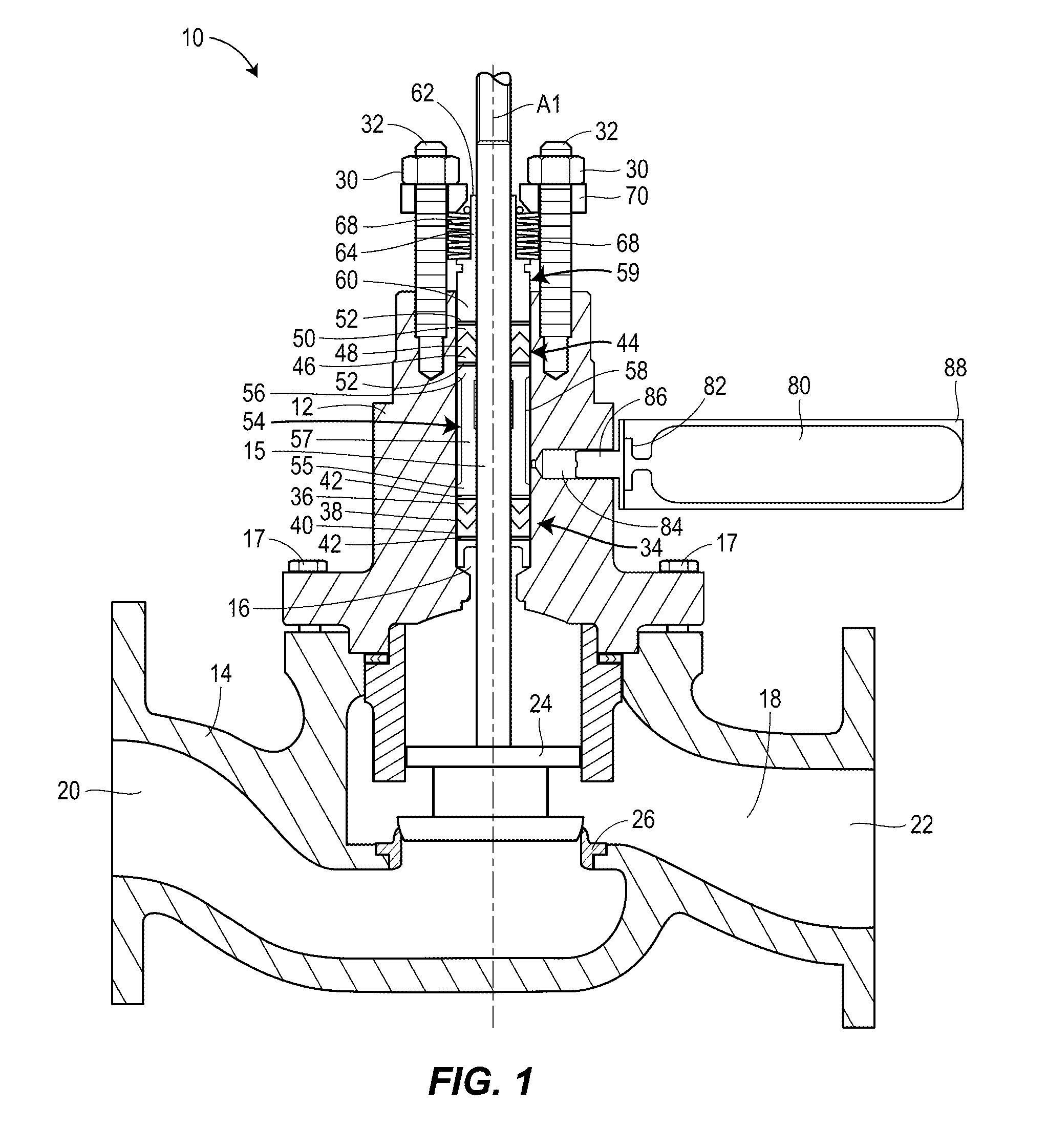

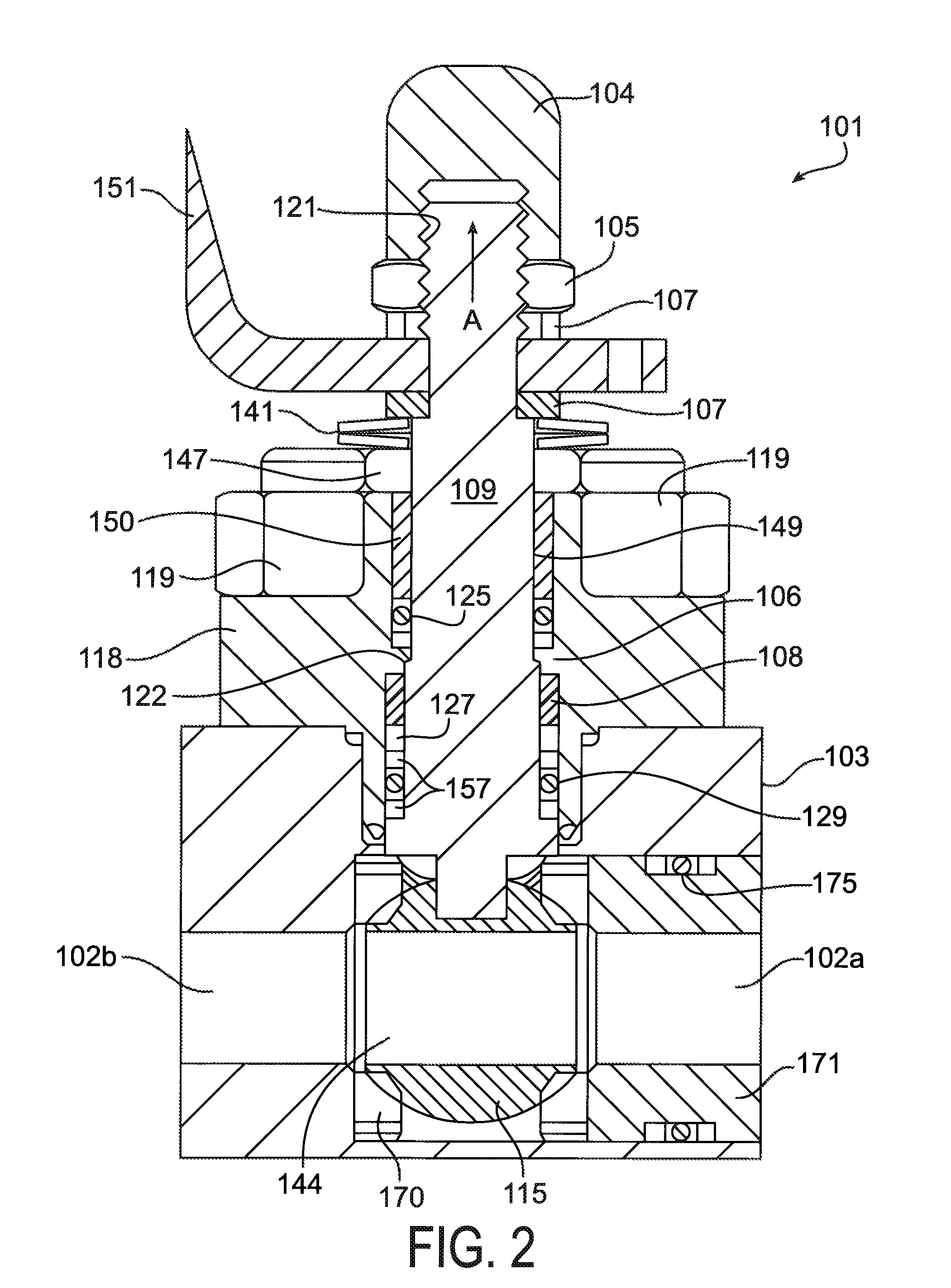

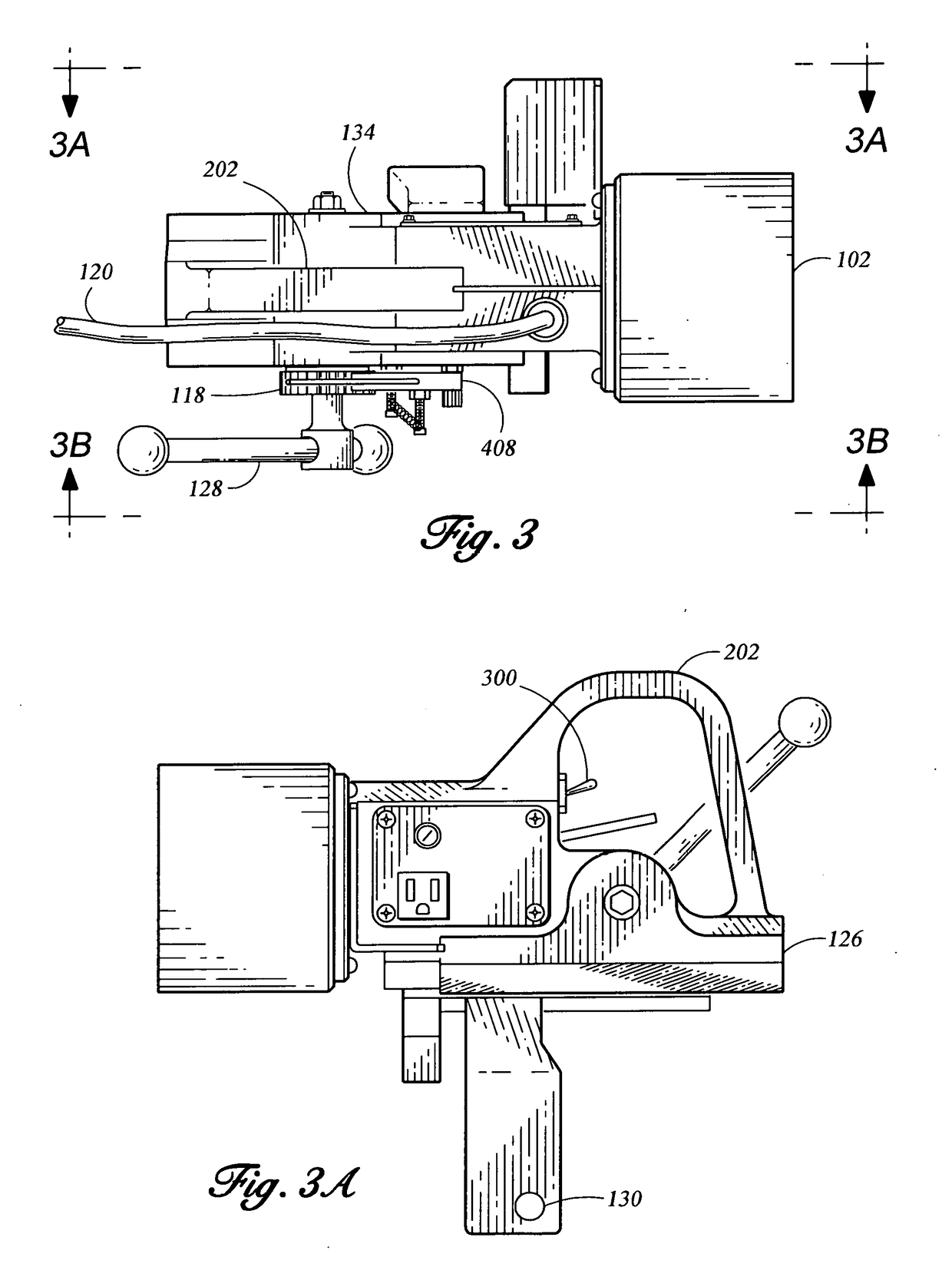

Valve packing fugitive emission detection system

ActiveUS20130061954A1Easy to pressurizeMaximize efficacySpindle sealingsEngine sealsCombined useEngineering

In accordance with the resent invention, there is provided a fugitive emission detection system for use in conjunction with a valve having a packing deign which includes a primary packing and a secondary packing. The valve further includes a leak port which is disposed within the valve bonnet between the primary and secondary packings. The detection system is operative to maintain the leak port in a normally open state. As a result, any fluid leakage past the primary packing is normally sent to the detection system, as opposed to being applied to and thus pressurizing the secondary packing. In the event of that a prescribed level of fluid leakage beyond the primary packing is detected, the leak port will be closed. The closure of the leak port facilitates the pressurization of the secondary packing.

Owner:CONTROL COMPONENTS INC

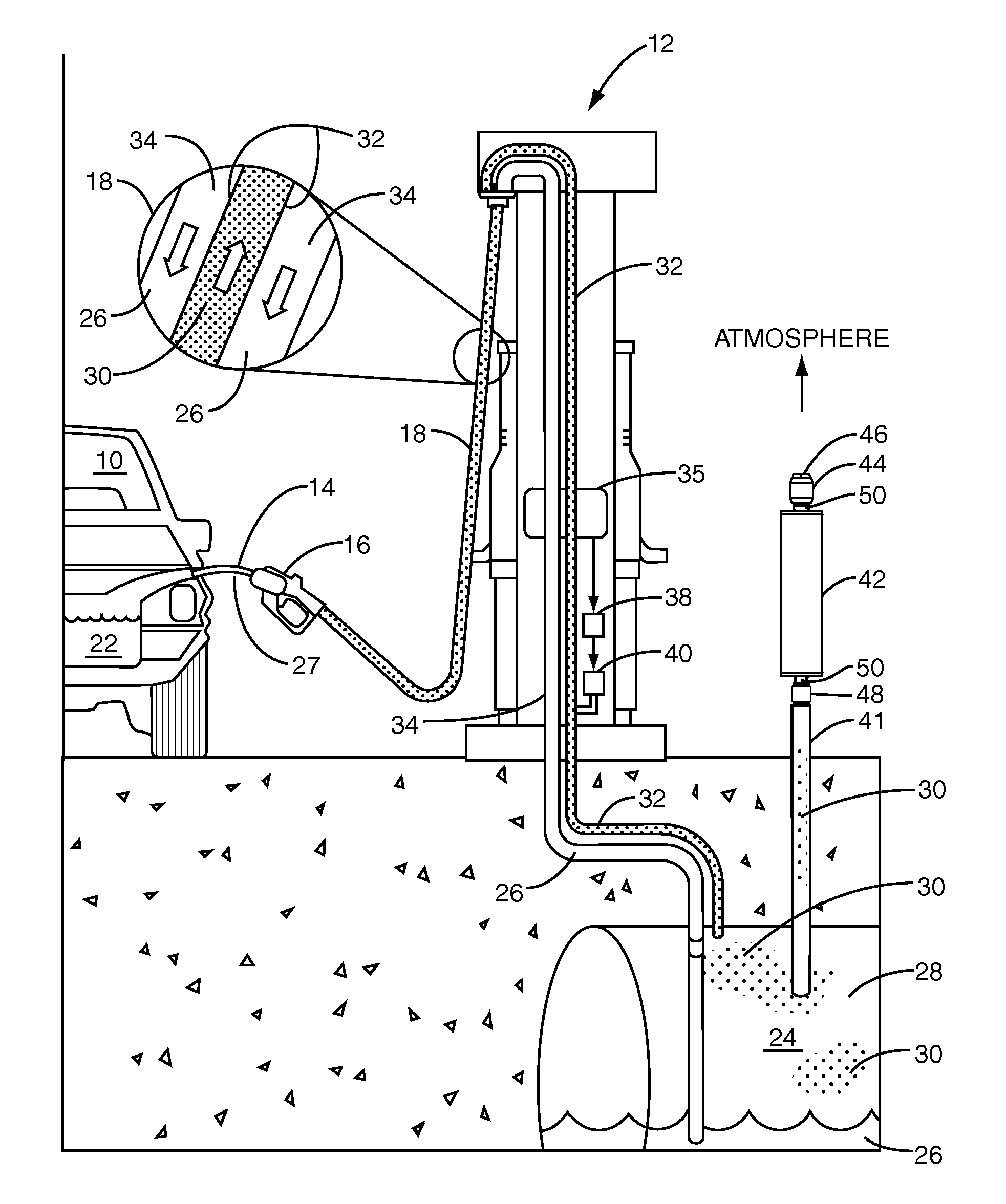

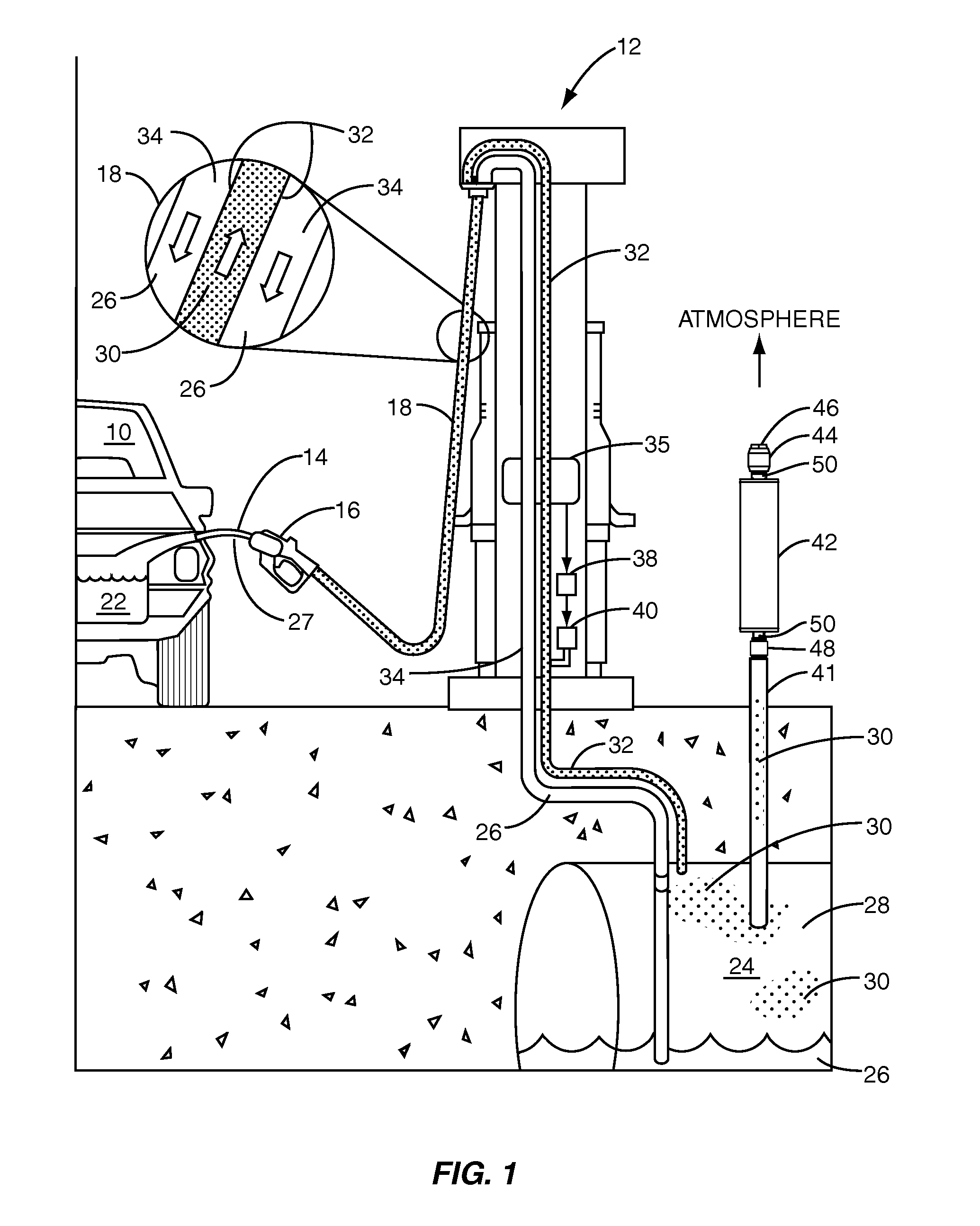

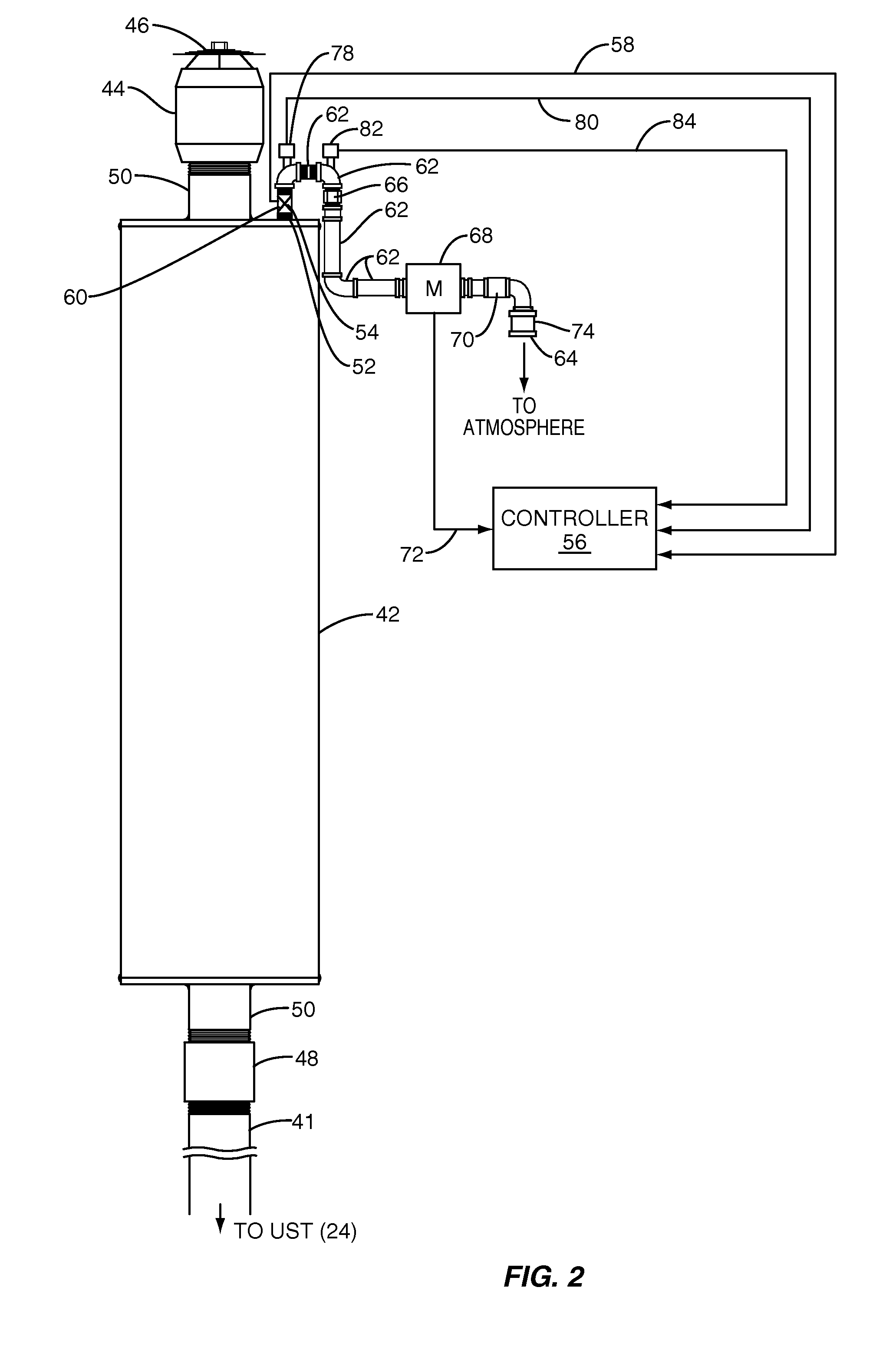

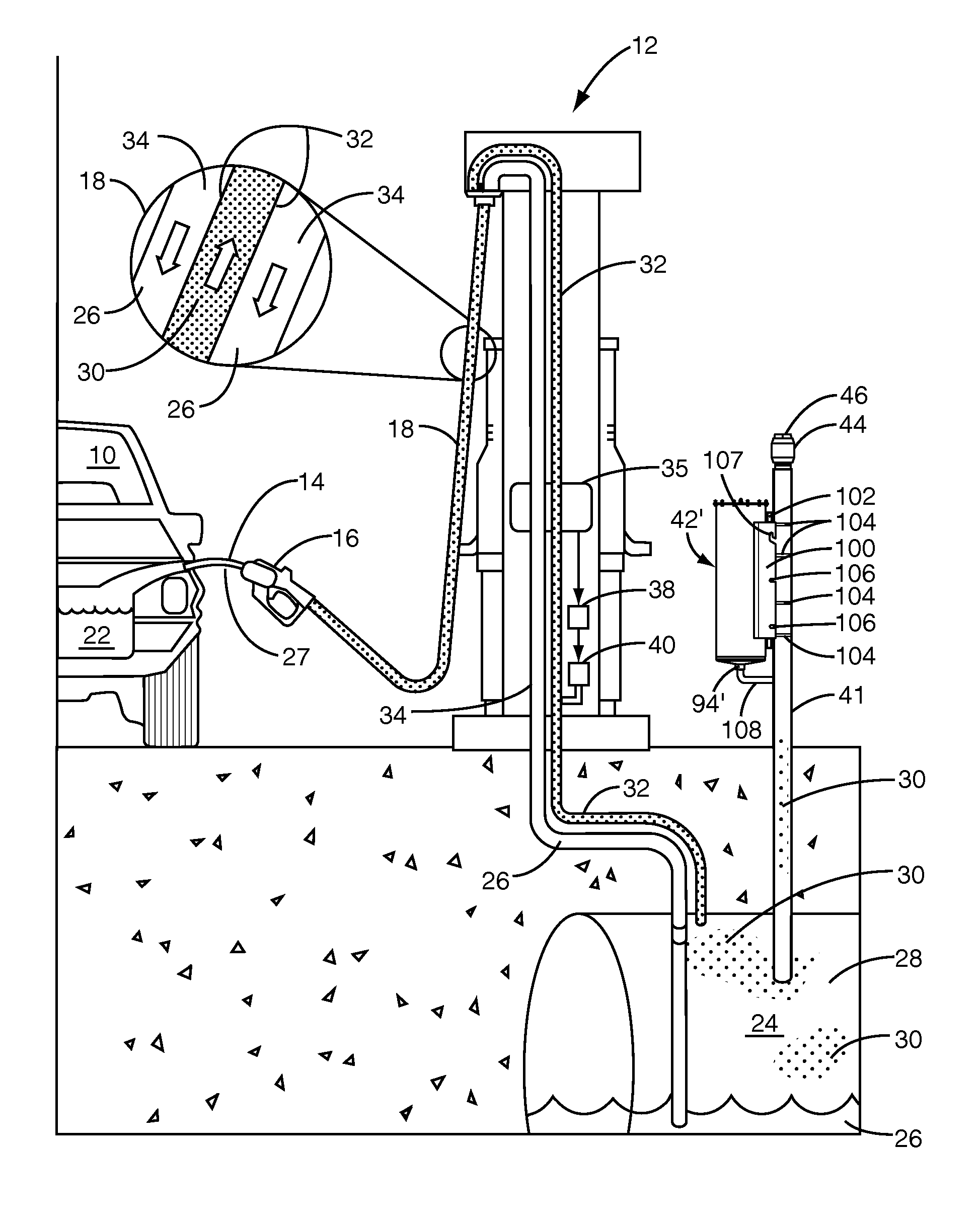

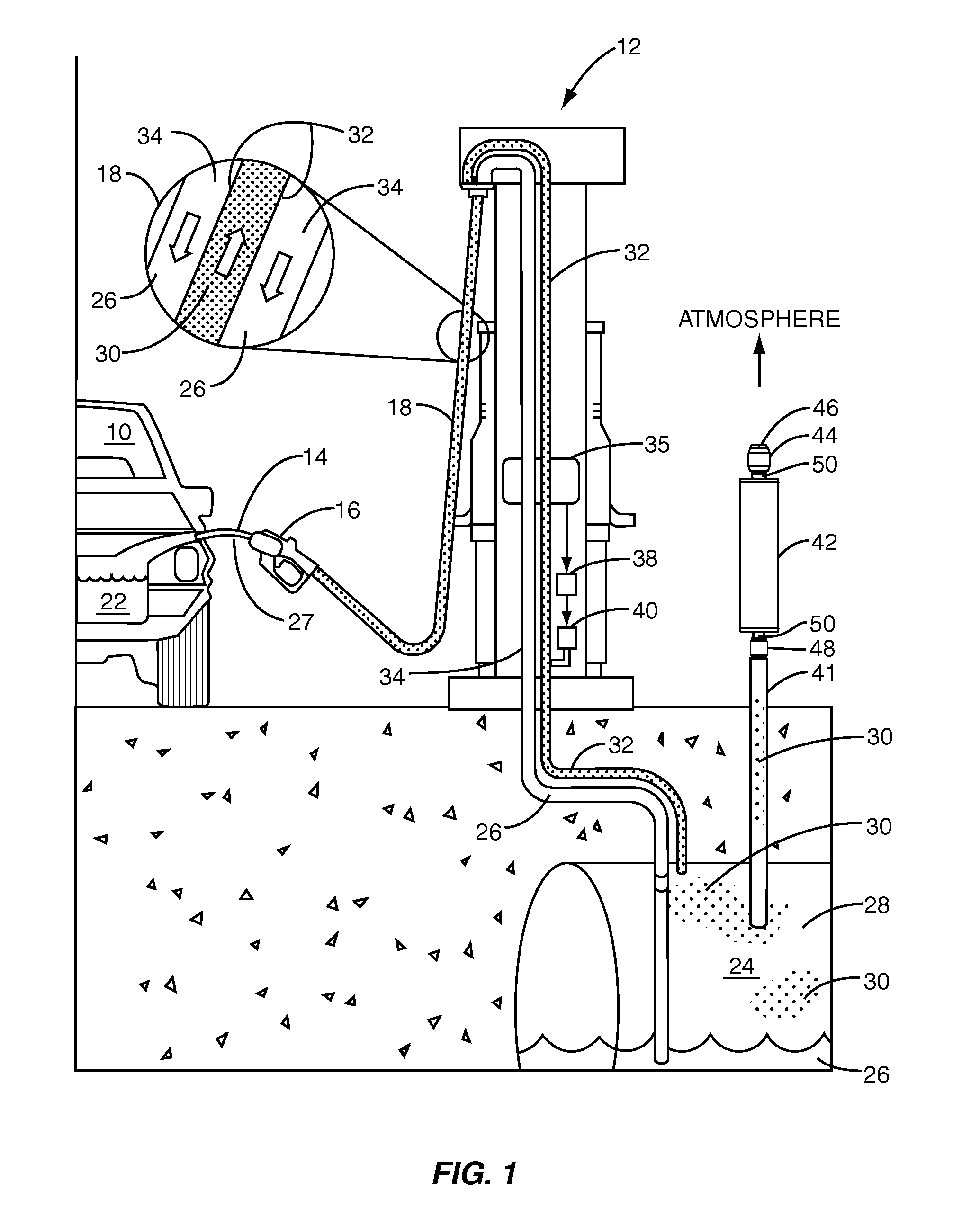

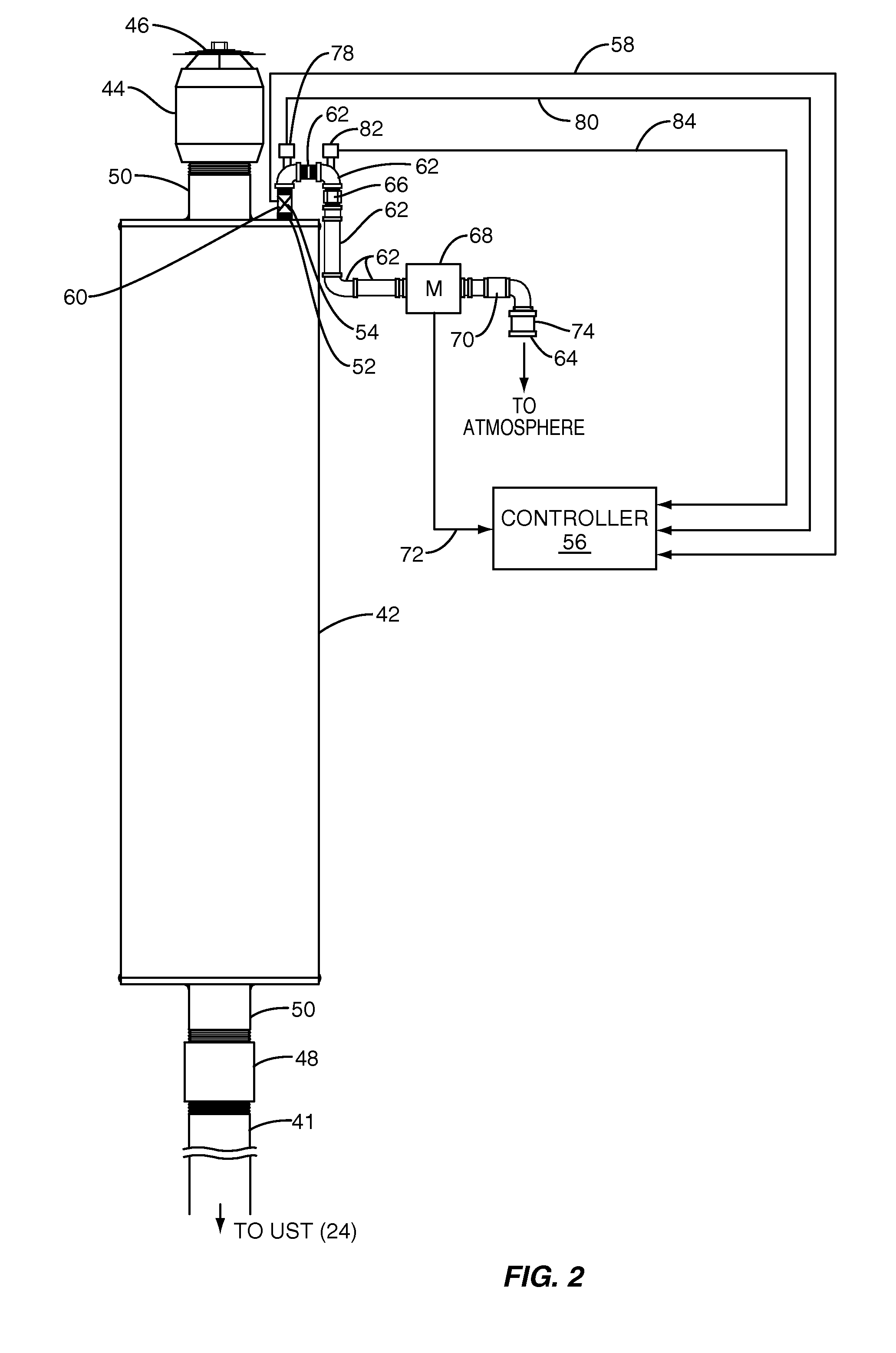

Fuel storage tank pressure management system and method employing a carbon canister

ActiveUS7566358B2Prevents excessive positive pressureAvoid emissionsCombination devicesGas treatmentPressure risePositive pressure

A carbon canister to adsorb hydrocarbons from a hydrocarbon air mixture in a UST system to prevent fugitive emissions due to overpressurization. The carbon canister has an inlet port at one end coupled to the UST system. An outlet port on the opposite end of the canister is connected to a flow-limiting orifice with a known calibrated flow rate that vents in a controlled fashion to the atmosphere. When UST pressure rises slightly above ambient pressure, fuel vapors and air from the UST system enters, via the inlet port, into the canister, where hydrocarbons are adsorbed onto the surface of the activated carbon. The cleansed air vents through the controlled flow outlet port to atmosphere, thereby preventing excessive positive pressure from occurring in the UST system. The activated carbon is purged of hydrocarbons by means of reverse air flow caused by negative UST pressures that occur during periods of ORVR vehicle refueling.

Owner:VEEDER ROOT

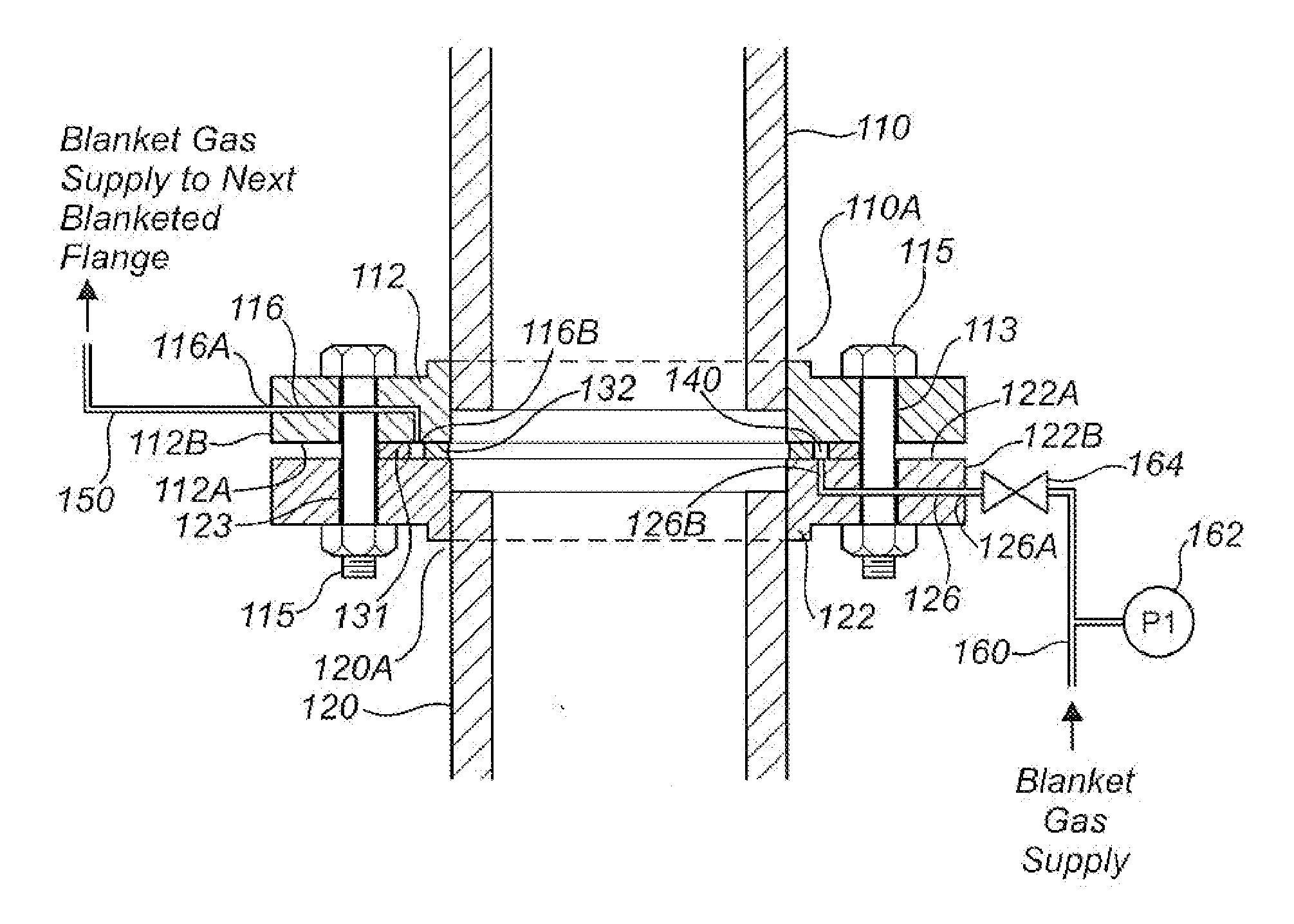

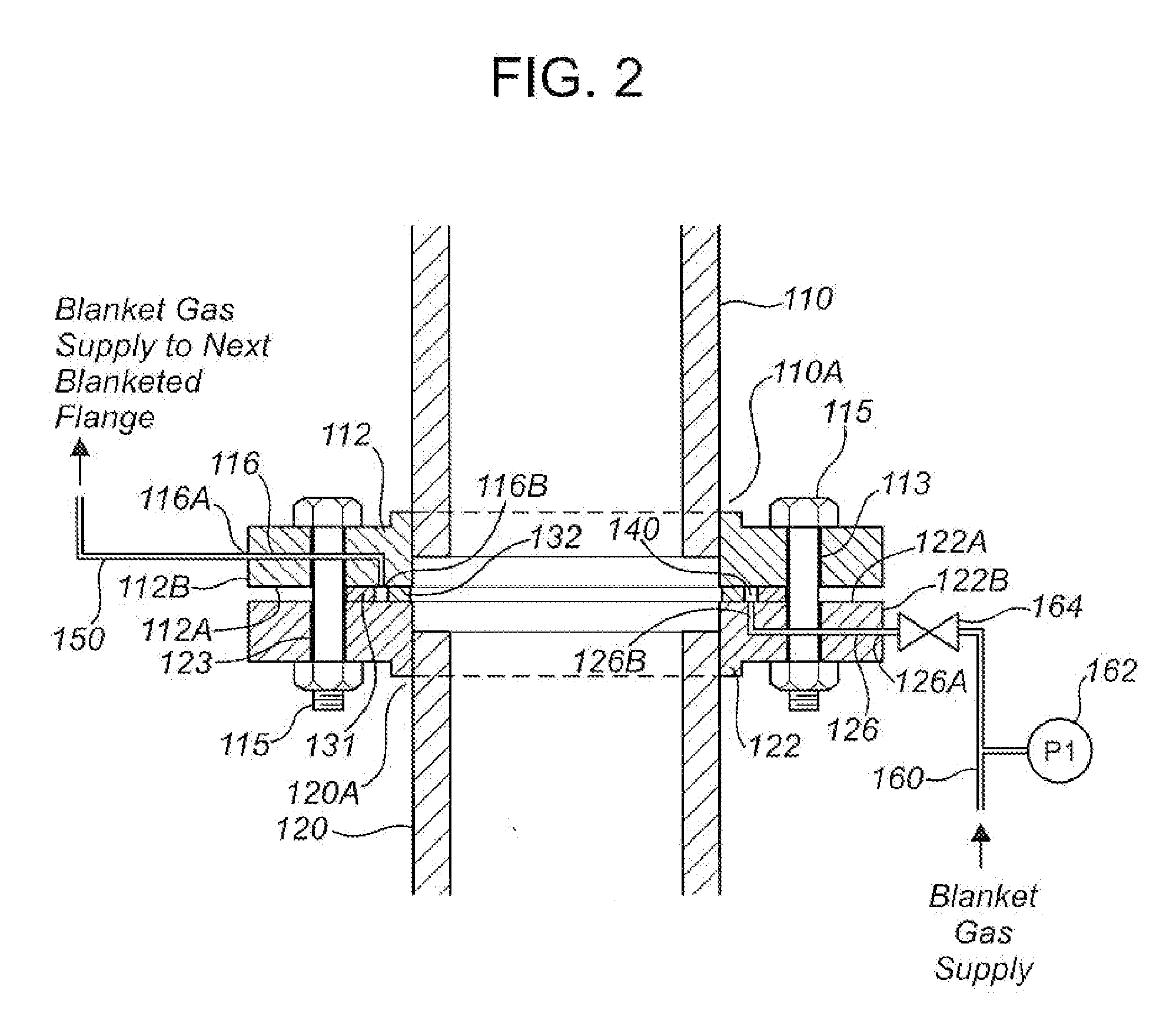

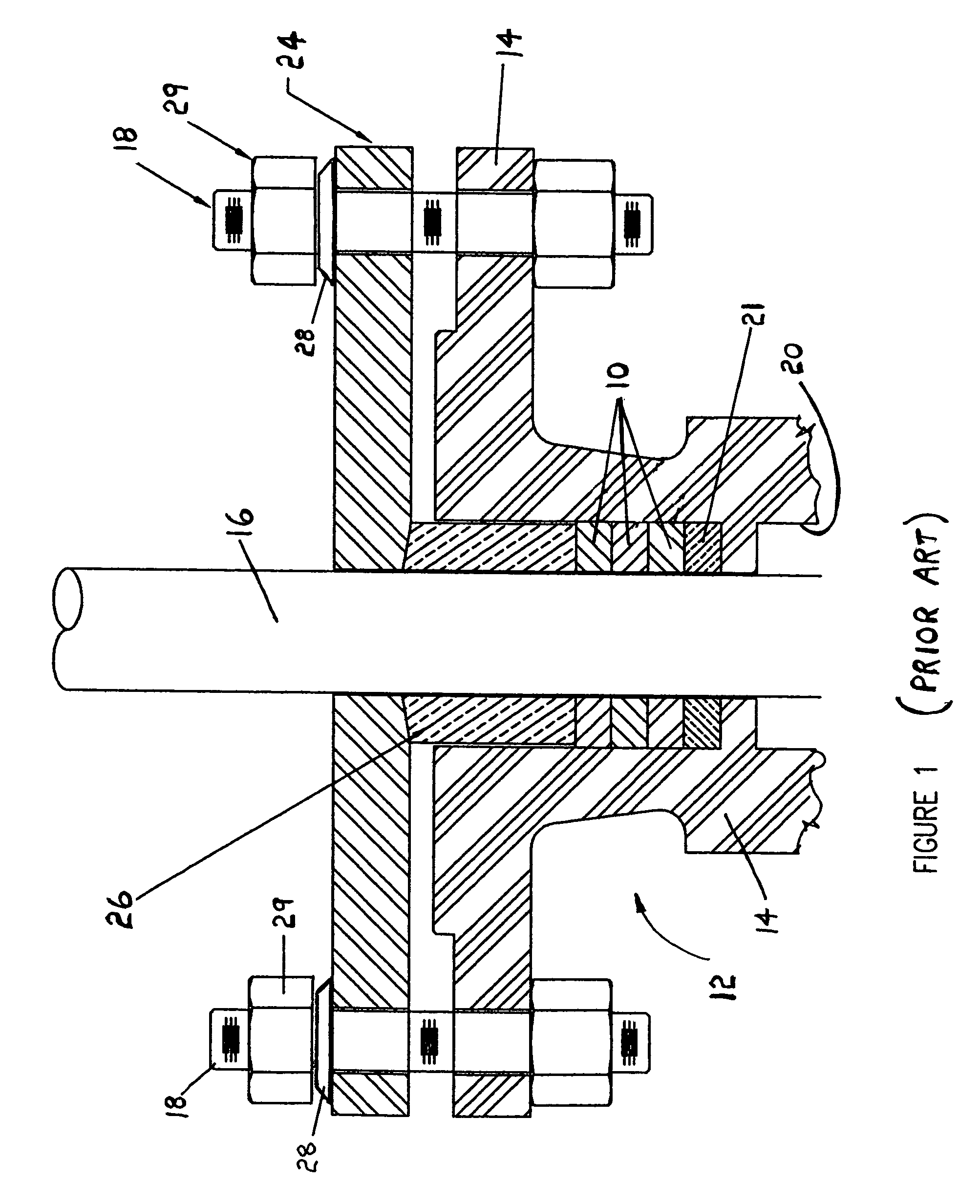

Gas-blanketed piping connections

InactiveUS20110186305A1Inhibit migrationAdvantageous and beneficialSleeve/socket jointsFlanged jointsAtmospheric airEngineering

Migration of air through a flanged connection into piping containing a gas under negative pressure is prevented by disposing concentric inner and outer gaskets between the flange faces, so as to form an annular chamber into which a blanketing gas is introduced at a pressure higher than atmospheric. Air tending to migrate through the outer gasket is blocked by the higher-pressure blanketing gas in the annular chamber. The blanketing gas pressure is maintained at a level higher than atmospheric notwithstanding any fugitive emissions through the outer gasket. The annular chambers of multiple flanged connections may be interconnected to blanket multiple flanged connections using a single source of blanketing gas. The blanketing gas may be the same type as the gas under negative pressure. In sour service applications, an inert blanketing gas may be used to prevent leakage of sour gas to atmosphere through flanged connections. In alternative embodiments, the principles of the invention may be adapted for use with other types of connections including threaded piping connections, and for use with piping carrying liquids.

Owner:OPTIMUM PROD TECH INC

Mobile multi-stage hydraulic-drive pneumatic spray dust-settling truck

ActiveCN103786628AImprove spray distanceIncrease speedSpraying vehiclesLiquid spraying apparatusWater storage tankGear wheel

The invention relates to a mobile multi-stage hydraulic-drive pneumatic spray dust-settling truck, mainly solving technical problems of high investment caused by individual use of spray dust-settling devices and poor effect caused by common use of the spray dust-settling devices due to far distance on conditions of multiple and dispersed dust source points, variable dust source locations and complicated conditions of dust sources. The technical scheme includes that a water storage tank is connected with a high-pressure water pump through a water pipe and high-pressure water is pumped to a spraying assembly; a hydraulic station is connected to a hydraulic motor of a mist spraying device through a high-pressure oil pipe to drive an impeller of axle-flow fans to generate high-pressure air flows, the high-pressure air flows send mist to a dust working face, and high-pressure oil of a hydraulic station is connected to a hydraulic cylinder; the mist spraying device is lifted and then is driven to oscillate around a rotating bearing by a motor and a reduction gearbox via a rotational driving gear; a carriage engine drives a power generator through a double-output transmission in a gear shifting manner so that power required for system running is obtained. The mobile multi-stage hydraulic-drive pneumatic spray dust-settling truck is mainly used for far-distance large-range dust settling and removing and firefighting in fugitive emission fields such as tunnel heading, blast mining, loading, crushing and unloading.

Owner:PINGAN ELECTRICAL

Fuel storage tank pressure management system and method employing a carbon canister

ActiveUS20070131111A1Prevents excessive positive pressureAvoid emissionsCombination devicesGas treatmentPressure risePositive pressure

A carbon canister to adsorb hydrocarbons from a hydrocarbon air mixture in a UST system to prevent fugitive emissions due to overpressurization. The carbon canister has an inlet port at one end coupled to the UST system. An outlet port on the opposite end of the canister is connected to a flow-limiting orifice with a known calibrated flow rate that vents in a controlled fashion to the atmosphere. When UST pressure rises slightly above ambient pressure, fuel vapors and air from the UST system enters, via the inlet port, into the canister, where hydrocarbons are adsorbed onto the surface of the activated carbon. The cleansed air vents through the controlled flow outlet port to atmosphere, thereby preventing excessive positive pressure from occurring in the UST system. The activated carbon is purged of hydrocarbons by means of reverse air flow caused by negative UST pressures that occur during periods of ORVR vehicle refueling.

Owner:VEEDER ROOT

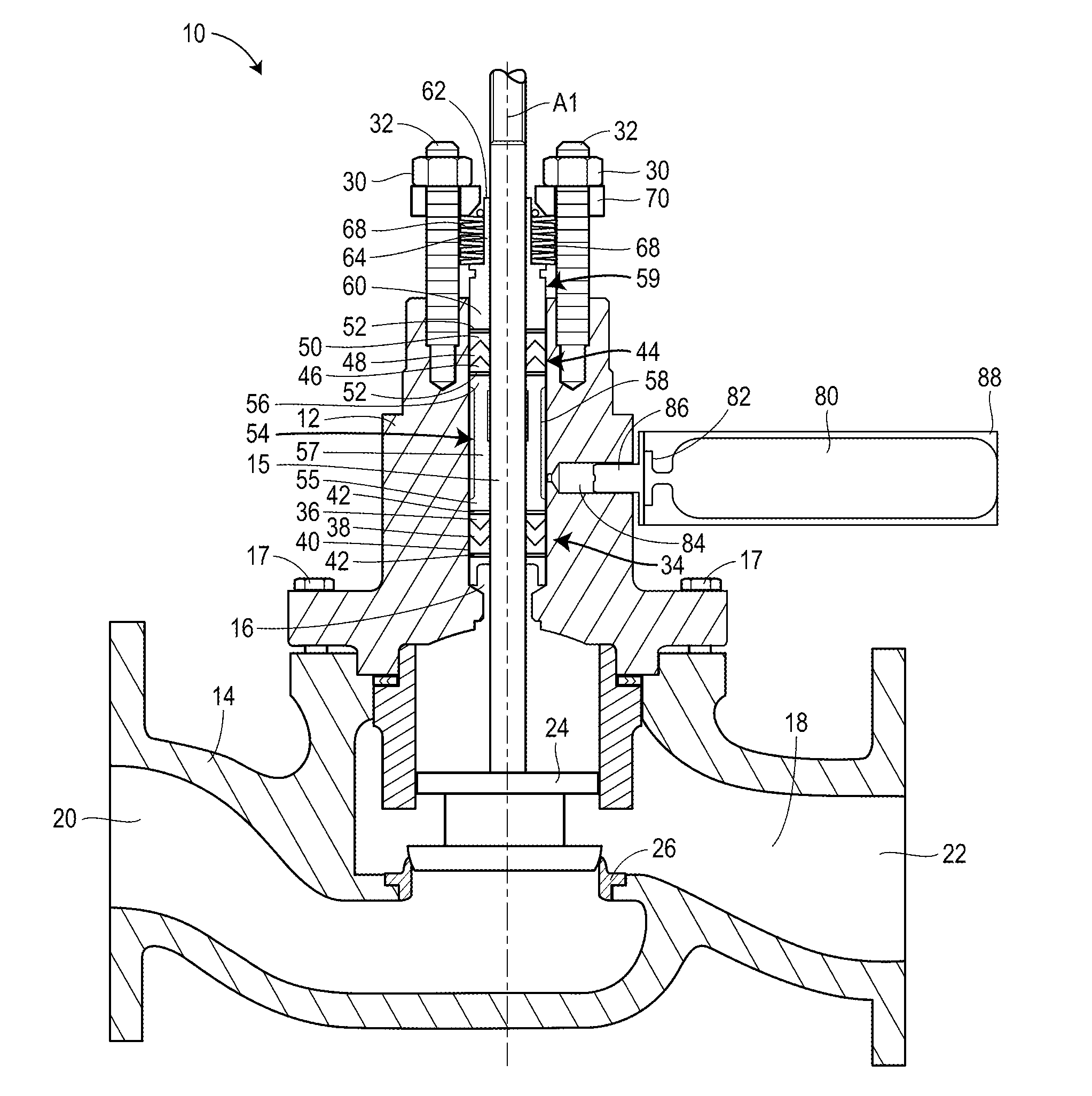

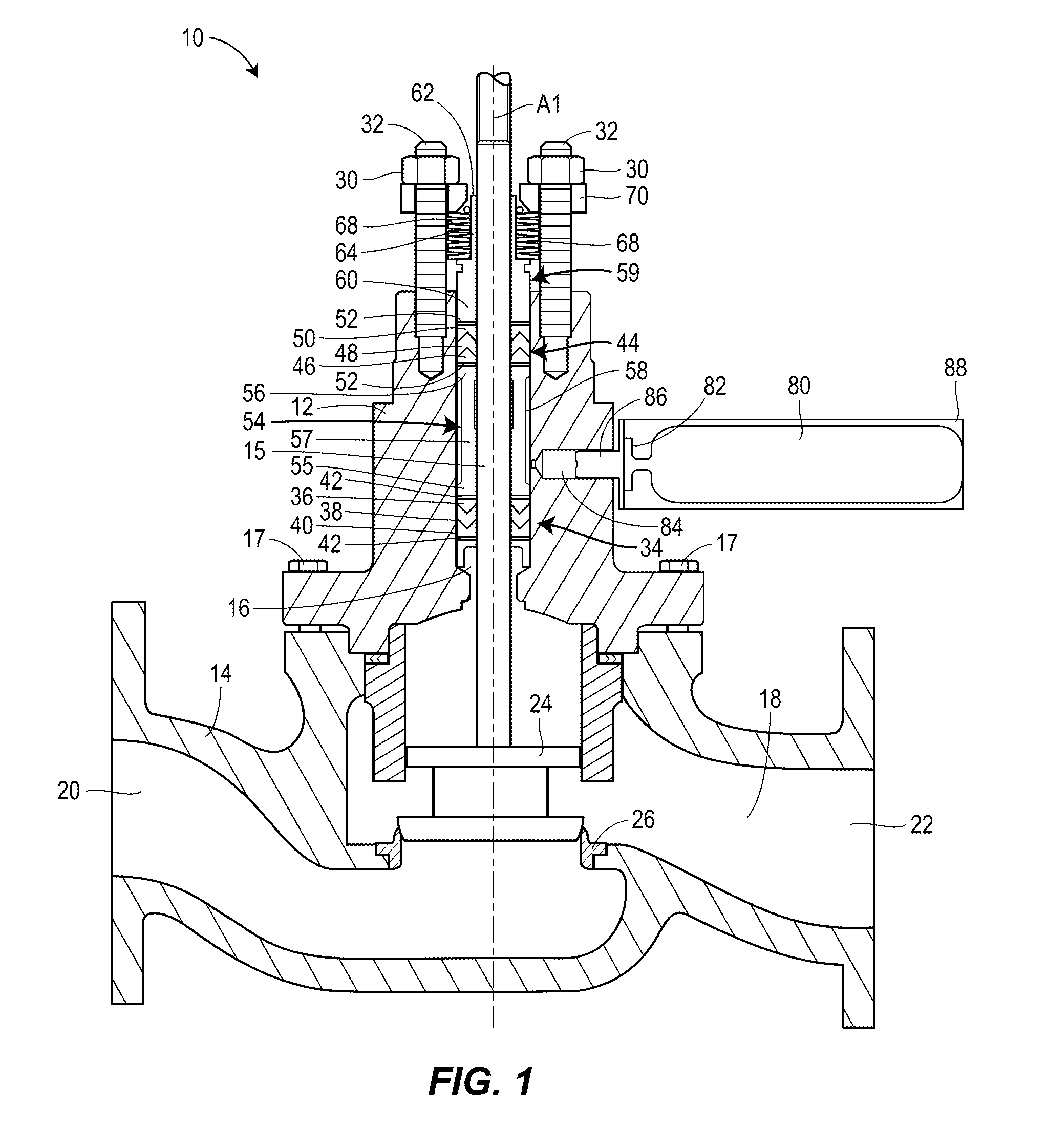

Gas pressurized packing system for control valves

Owner:FISHER CONTROLS INT LLC

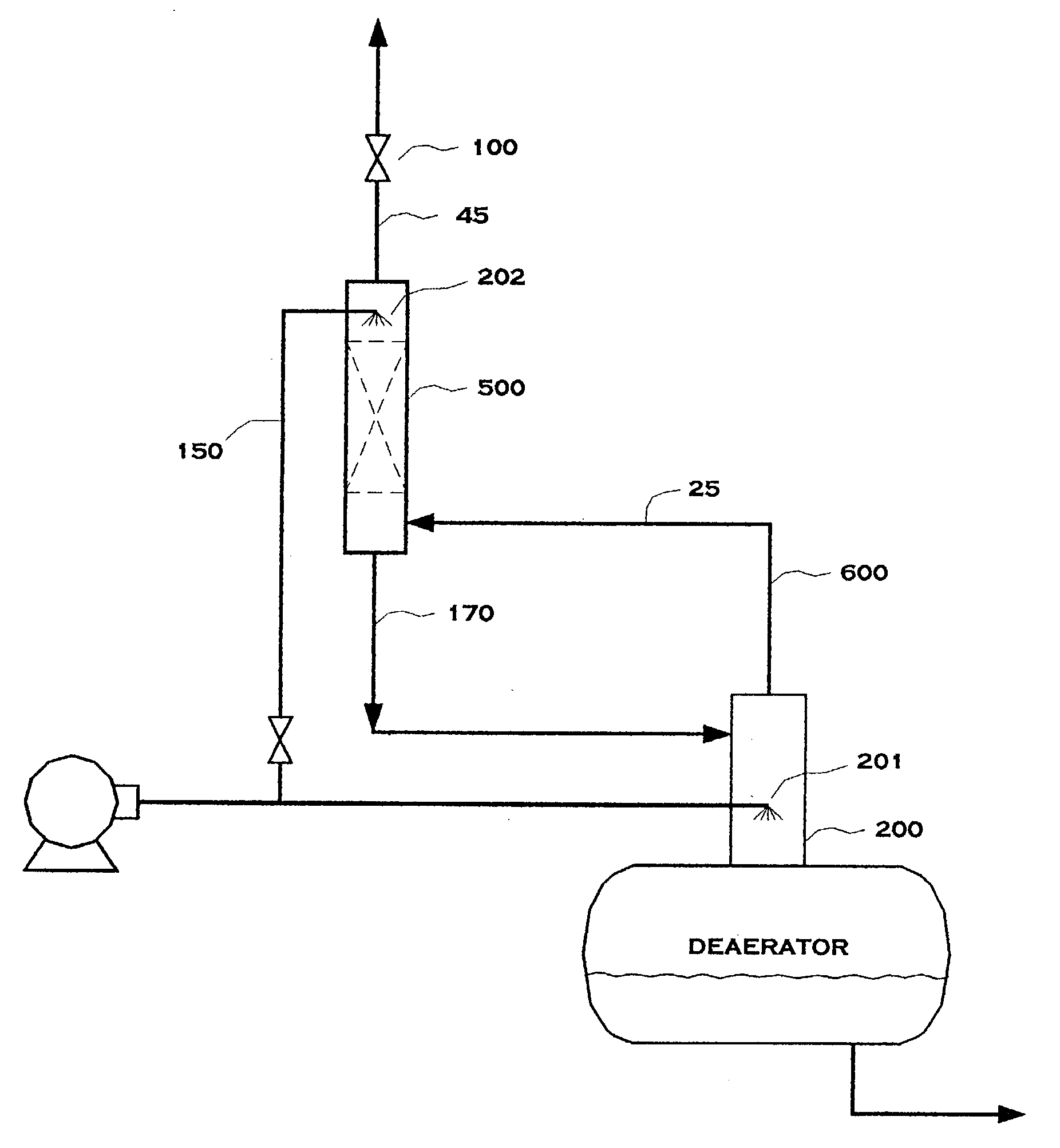

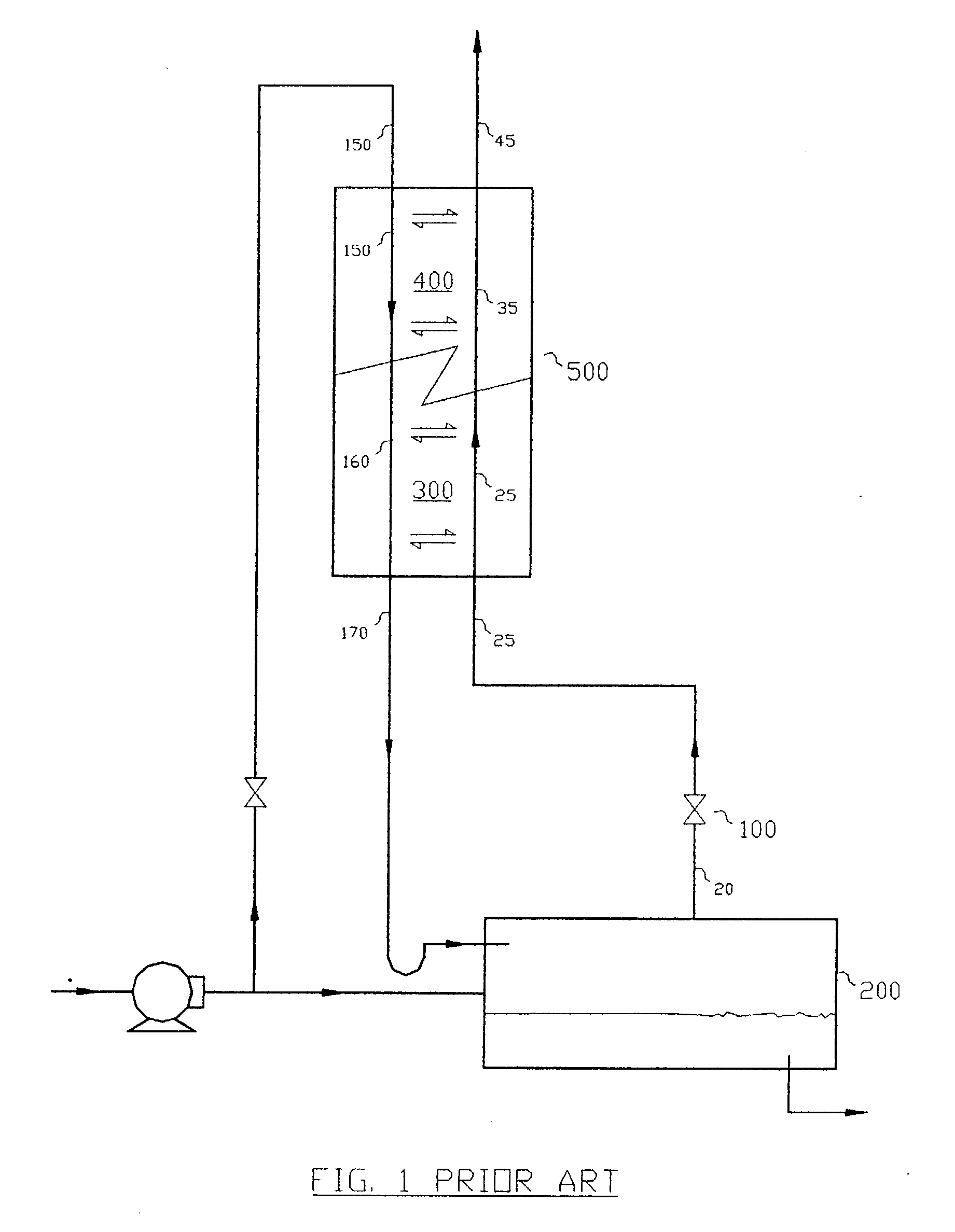

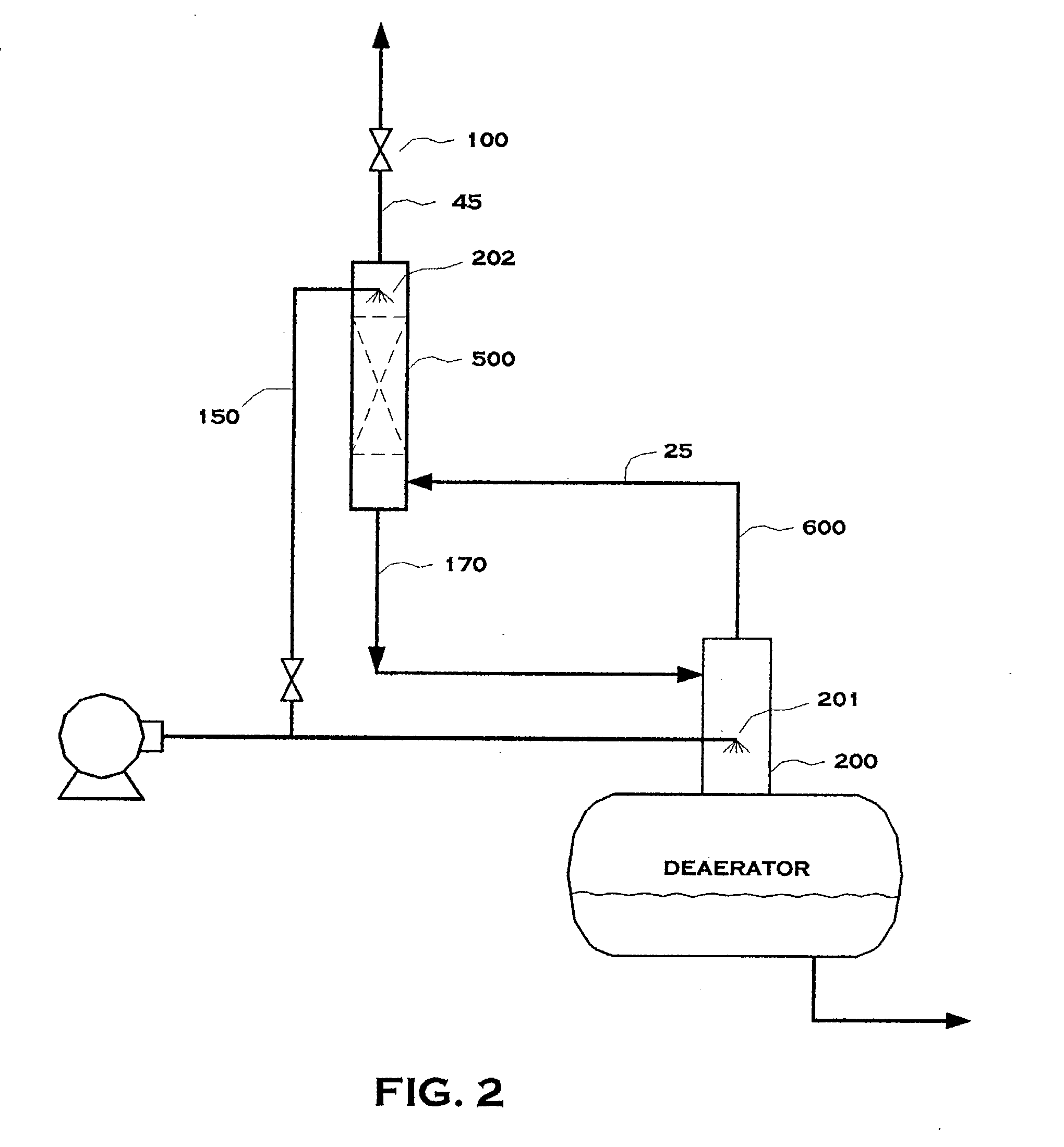

Staged heat and mass transfer applications

InactiveUS20040168900A1Easy to operateImprove reliabilityDistillation regulation/controlDistillation in boilers/stillsParticulatesSteam condensation

This invention exploits the concept of Staged Heat and Mass Transfer (SHMT) to enhance operability, control robustness and intrinsic safety in preventing corrosion while recovering material, and energy if desirable, in process waste streams. Two applications illustrating the improvements based on the SHMT concept are given. One application illustrates novel design features to recover vent from a steam boiler deaeration system, positively eliminating the risk of oxygen and carbon dioxide accumulation in deaerator. The other application illustrates process adaptations of the same SHMT concept to recover steam, steam condensate, and fugitive emissions involving particulate materials if desirable, from any process vents from vessels that are opened to the atmosphere. Again, without the risk of corrosion by atmospheric oxygen.

Owner:TUNG PETER

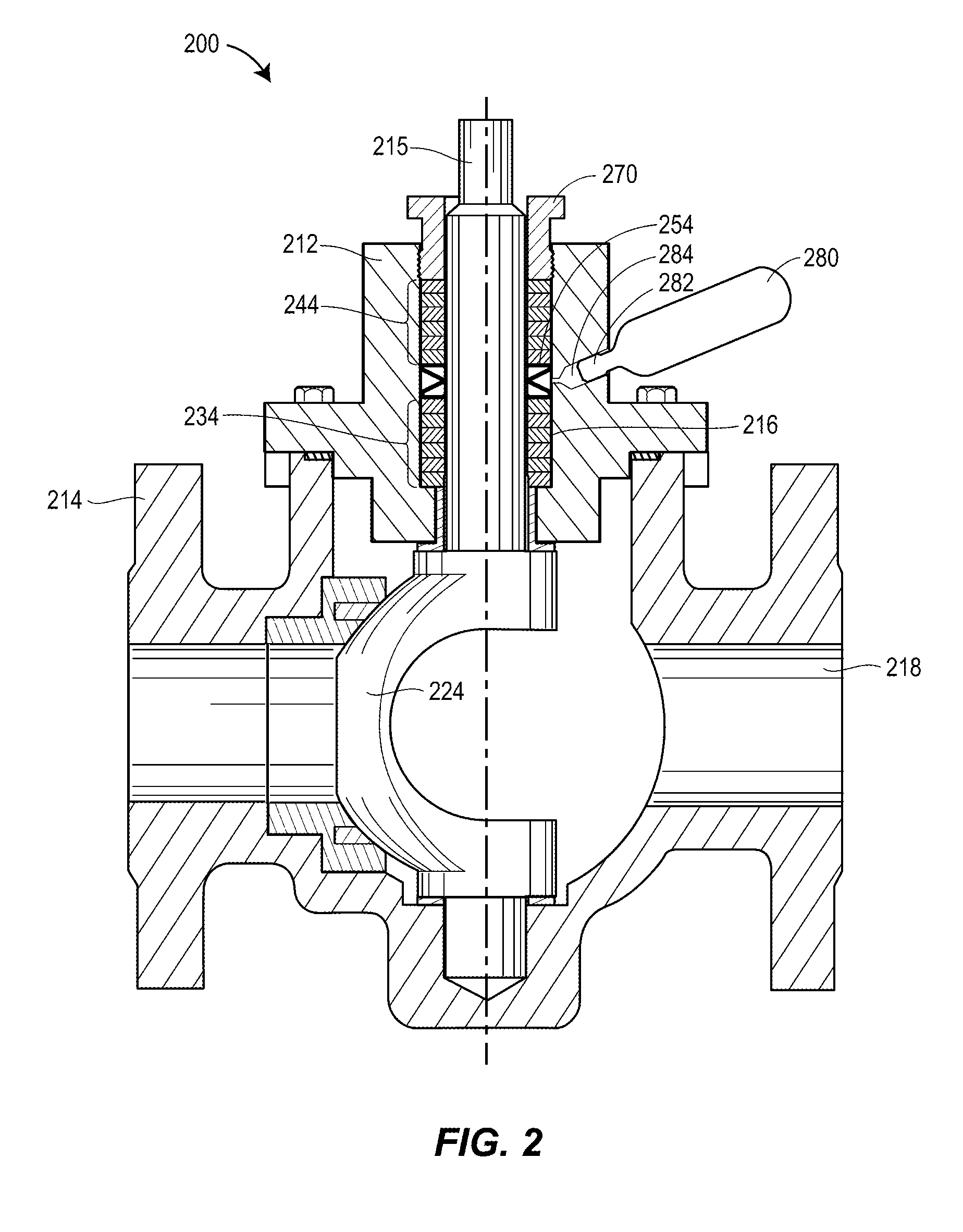

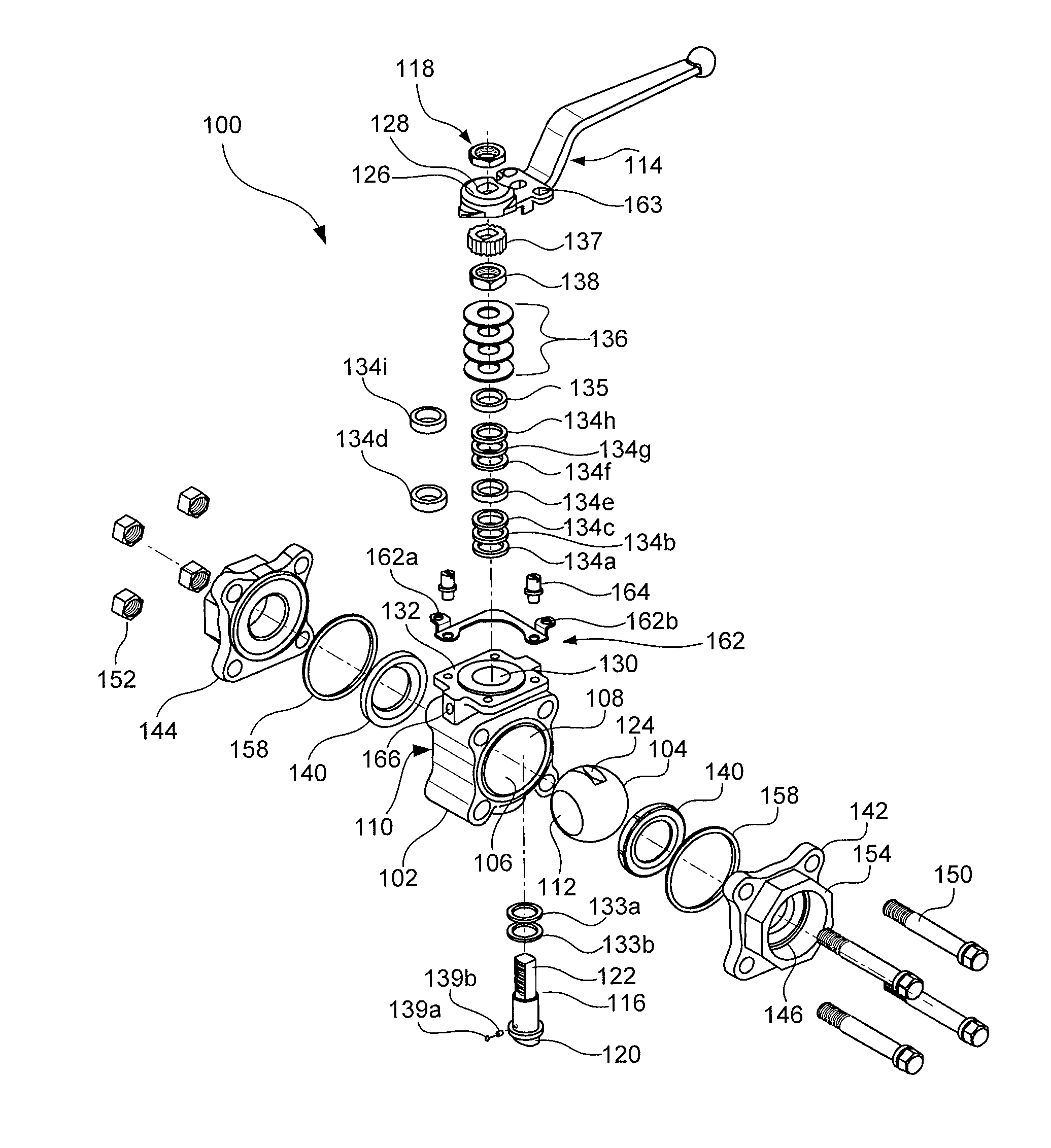

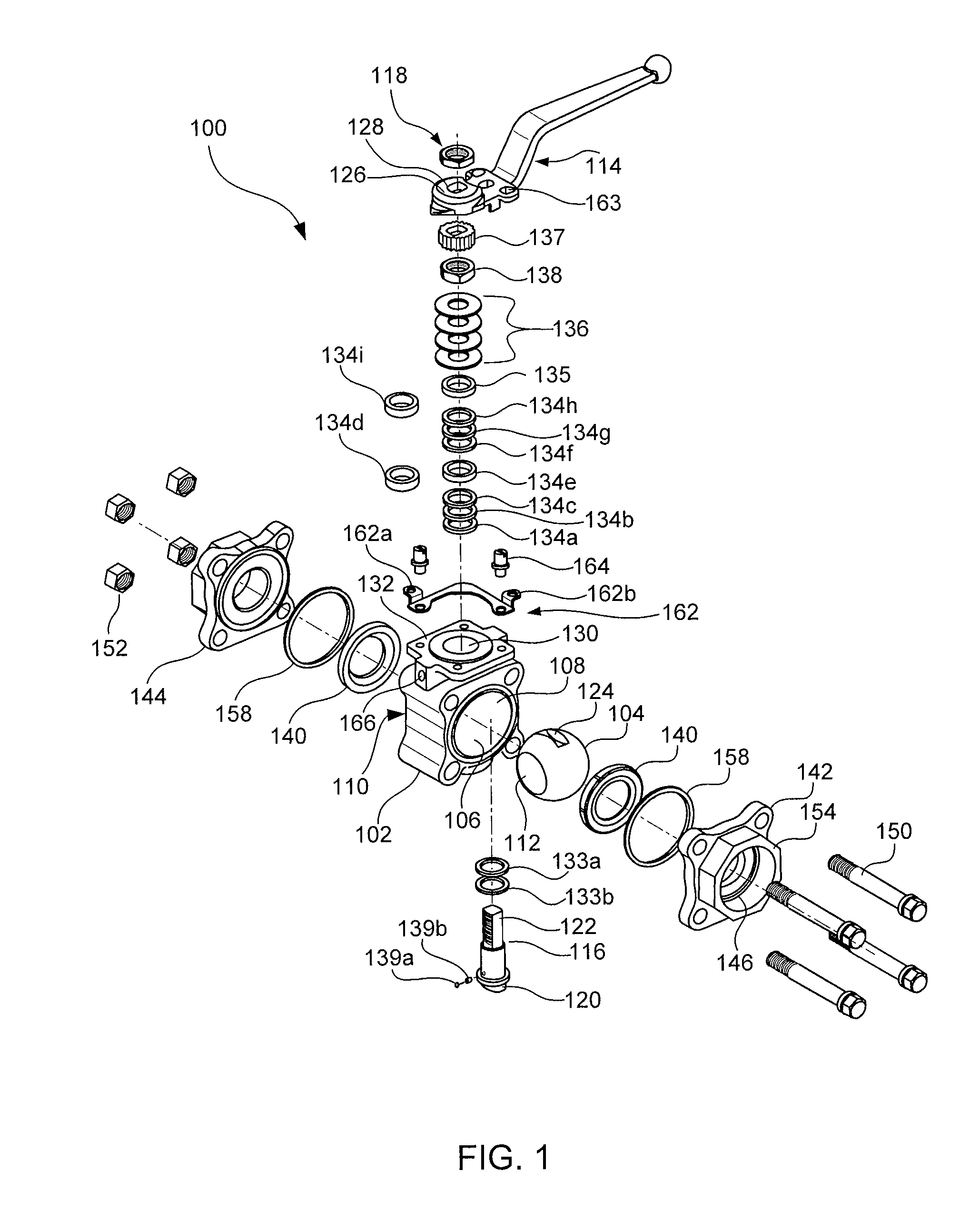

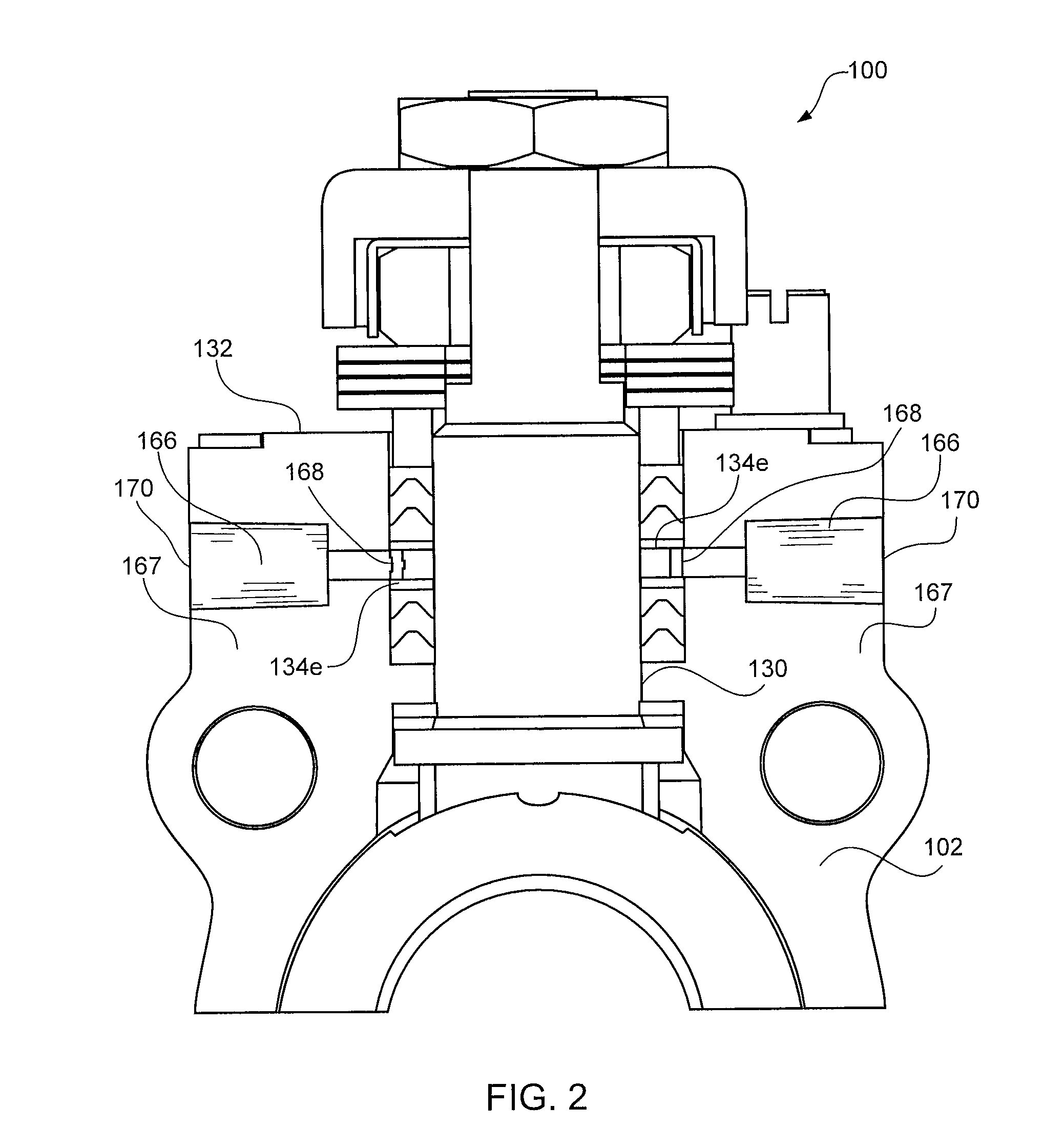

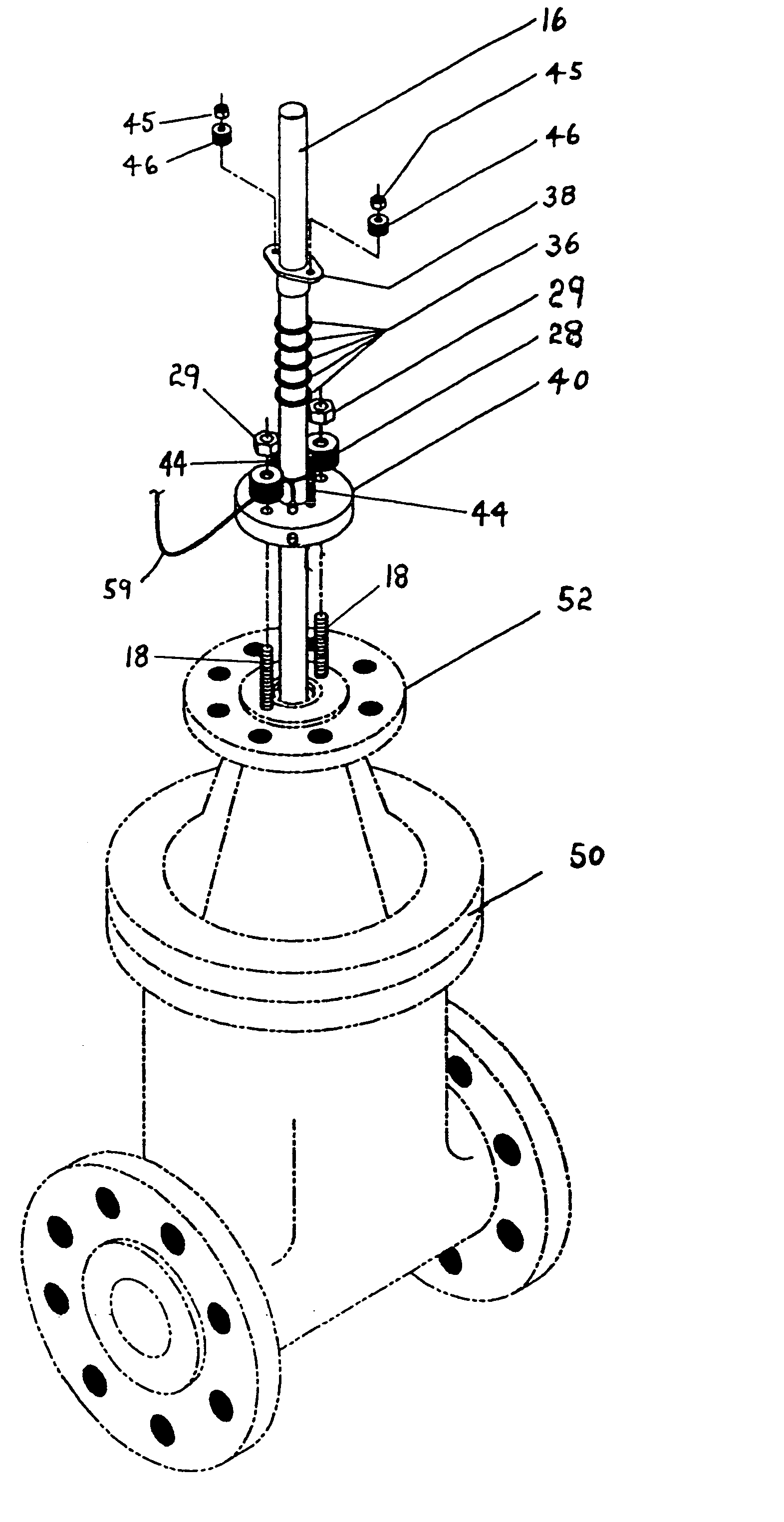

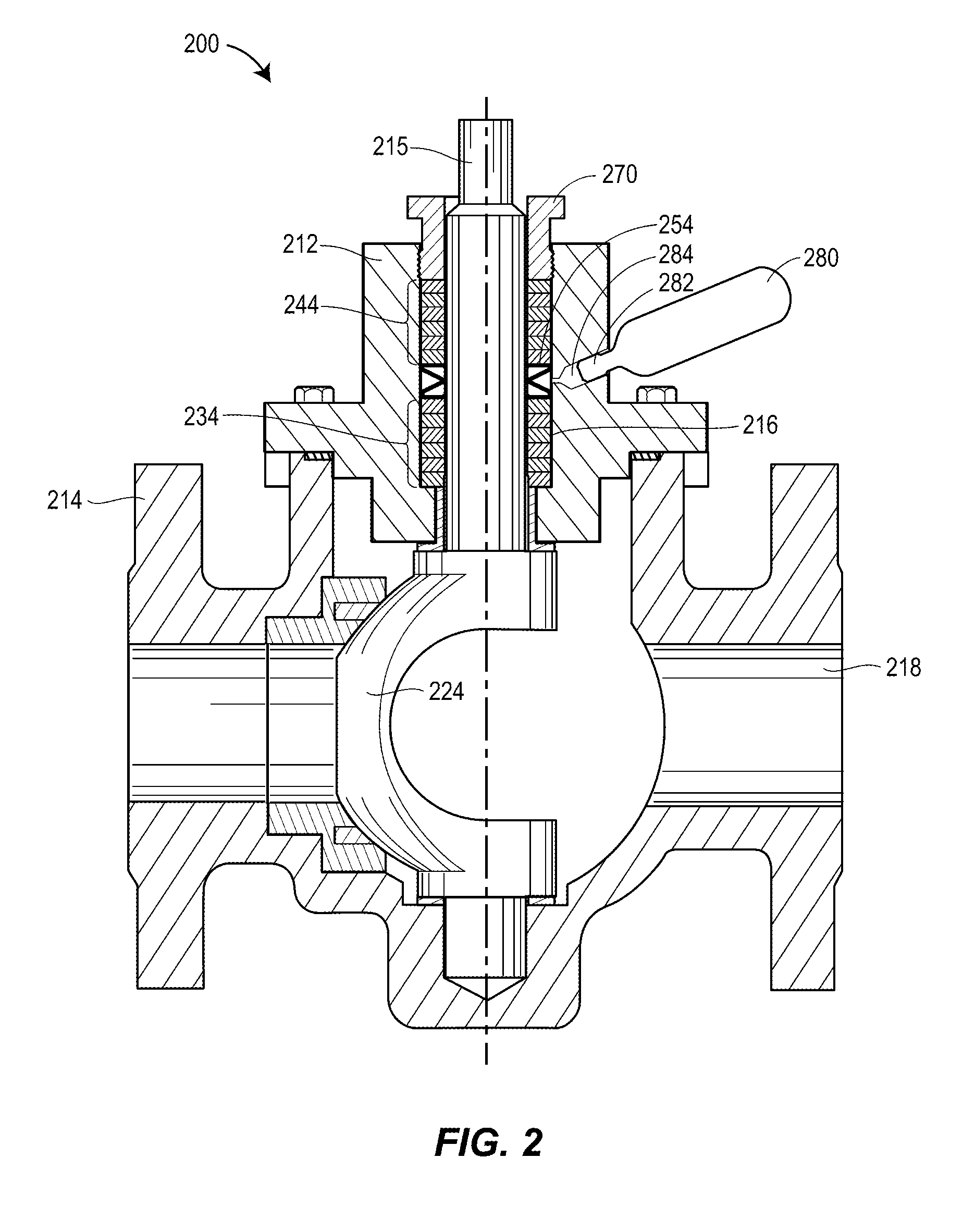

Ball valve with integrated fugitive emission assembly

A valve includes a body that has an inner cavity configured to house a ball. The ball has a hole that allows fluid to pass through the inner cavity when the hole is aligned with a longitudinal axis of the cavity and prevents the fluid to pass through the inner cavity when the hole is misaligned with the longitudinal axis of the cavity. The valve includes a fugitive emission assembly that is integral to or a unitary part of the body.

Owner:FLO RITE PROD COMPANY

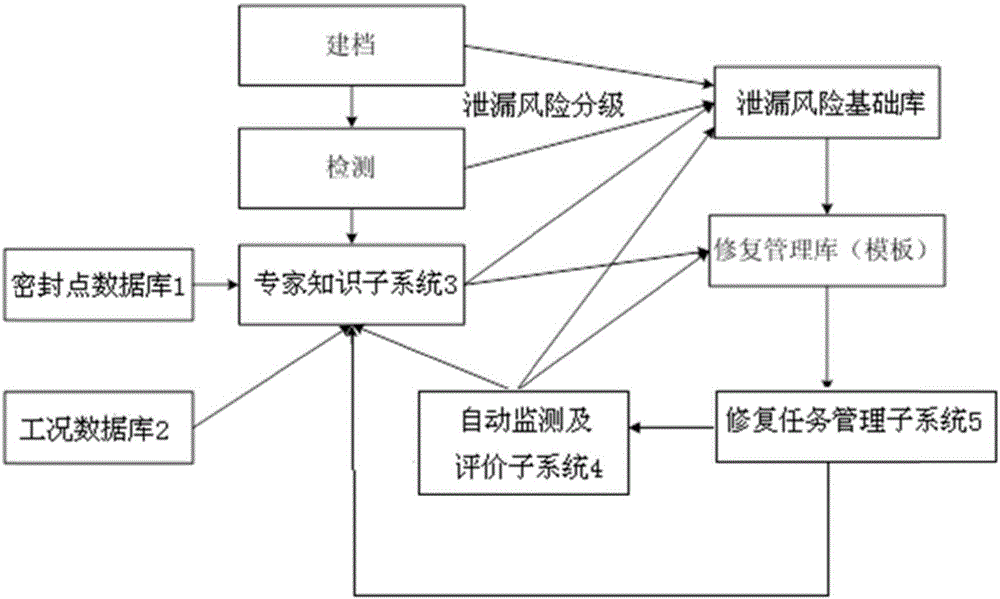

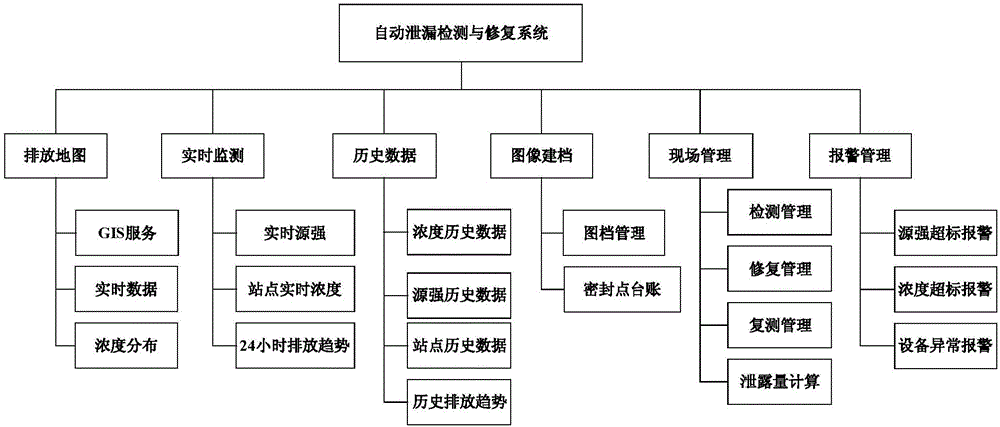

Automatic leakage monitoring and repair system for chemical plant device

ActiveCN106644284ALow costIncrease costData processing applicationsManufacturing computing systemsTask completionNormal values

The invention provides an automatic leakage monitoring and repair system for a chemical plant device. The system comprises a seal point database, a working condition database, an expert knowledge subsystem, a leakage risk database, an automatic monitoring and evaluation subsystem and a repair task management subsystem, wherein the repair task management subsystem receives a task instruction, transmits the task instruction to a corresponding repair worker, and after a repair task is completed, sends a task complete instruction to the automatic monitoring and evaluation subsystem around a device corresponding to the repair task; the automatic monitoring and evaluation subsystem acquires monitoring data of a surrounding environment of the device, and automatically estimates a fugitive emission amount of the device area; if the fugitive emission amount exceeds a normal value, a new seal point repair task is further increased; and if the estimated emission amount is smaller than the normal value, there is no serious leakage point. The system reduces the leakage risk, effectively reduces the emission, realizes all-weather real-time online monitoring, and timely generates a repair task to remind an enterprise of quick repair.

Owner:BEIJING VIREADY TECH CO LTD +1

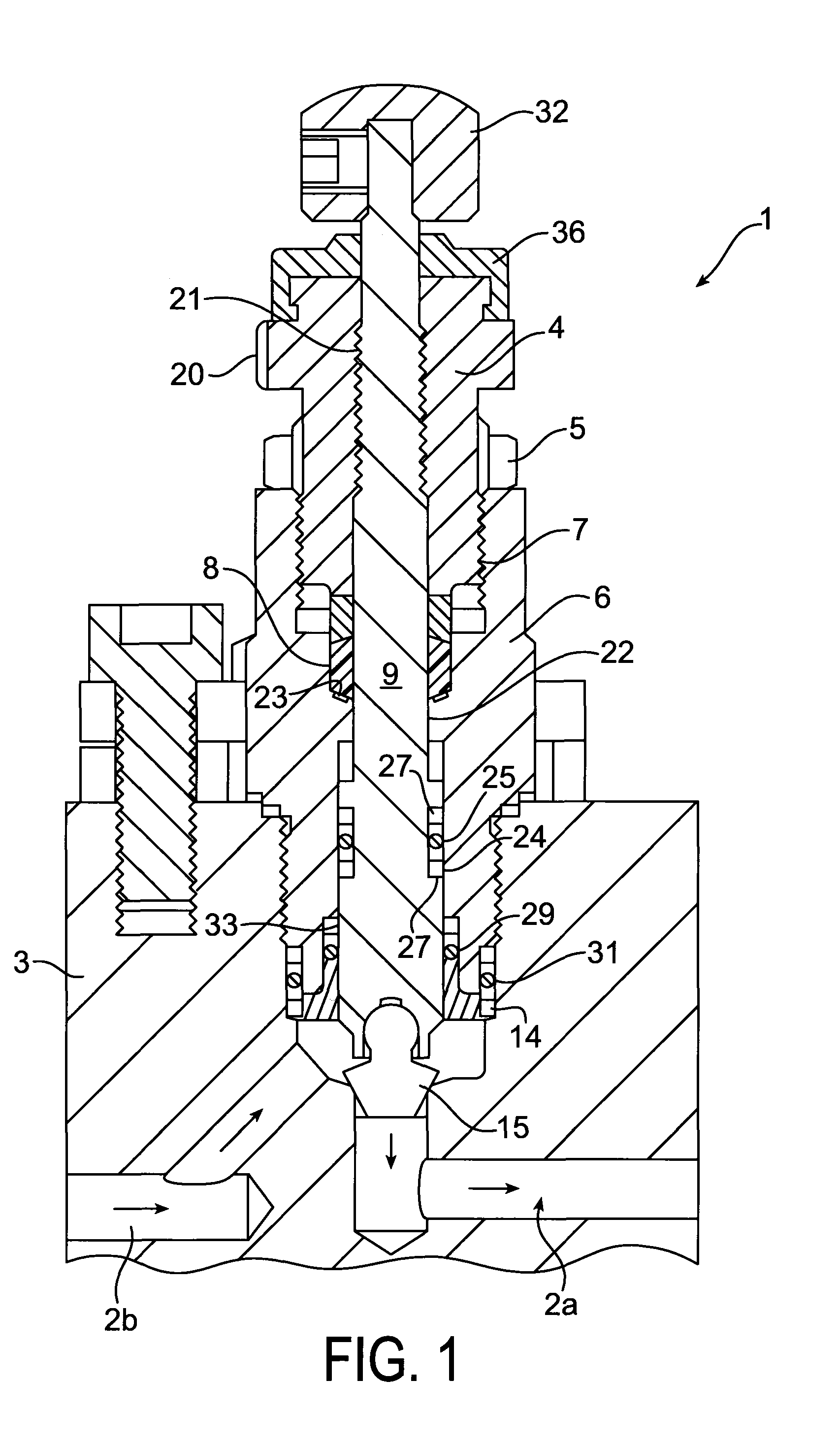

Low-leakage valve apparatus

A low-leakage valve apparatus which reduces fugitive emissions from valves to the ambient atmosphere. A secondary packing chamber or gland is installed on an existing valve to intercept leakage past the valve's original primary packing gland, which otherwise would escape past the valve stem to the atmosphere.

Owner:WESTERN REFINING SOUTHWEST

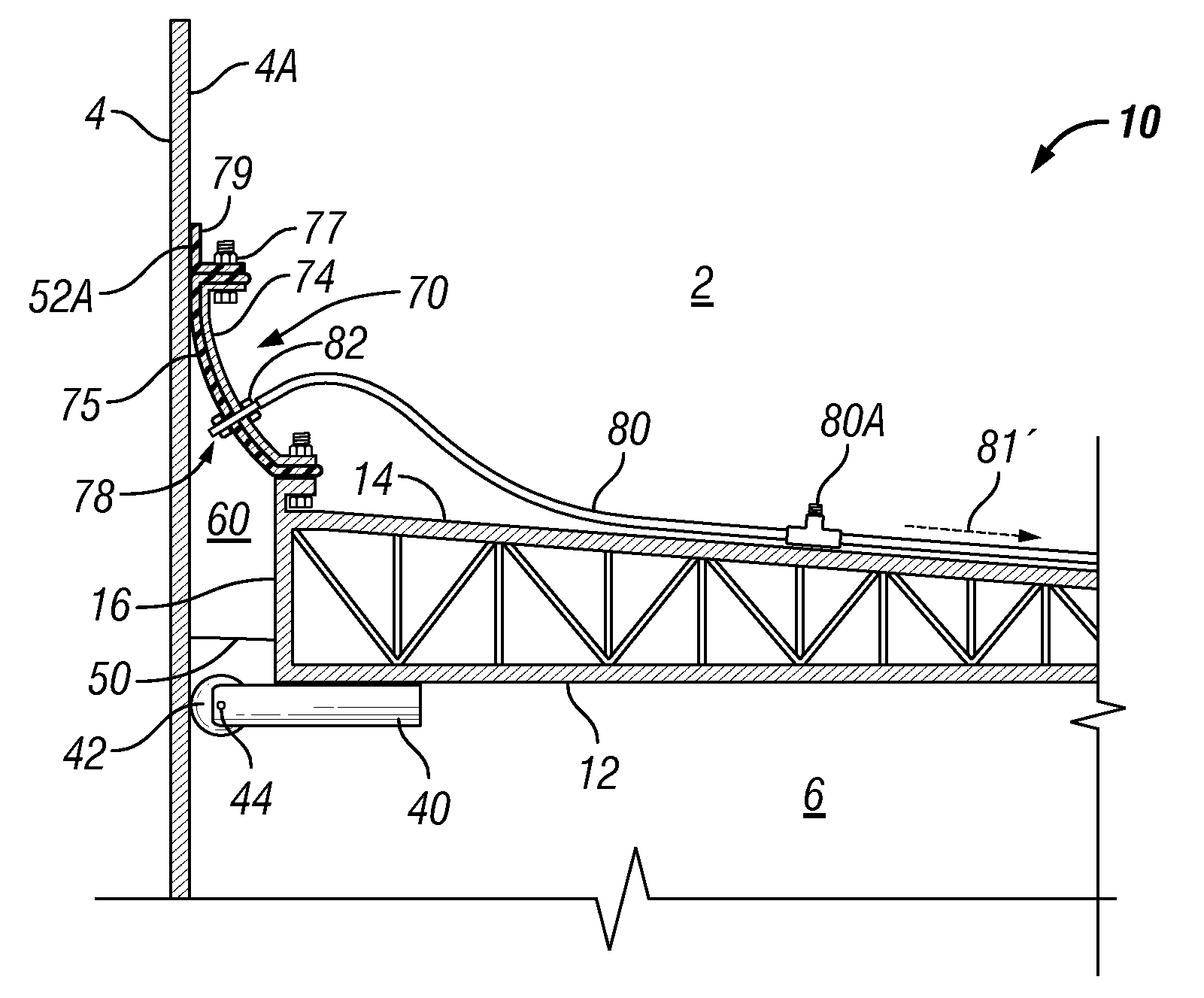

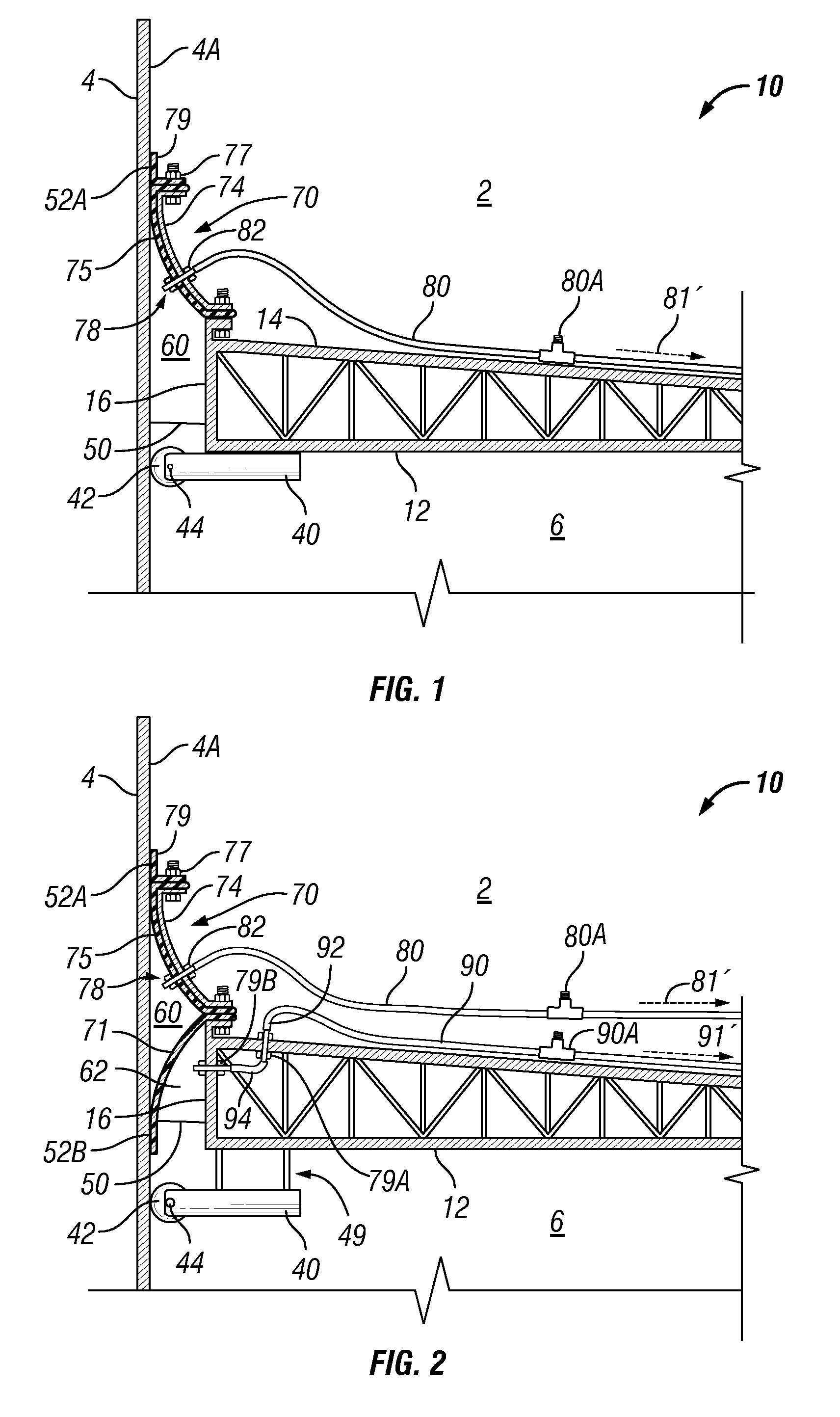

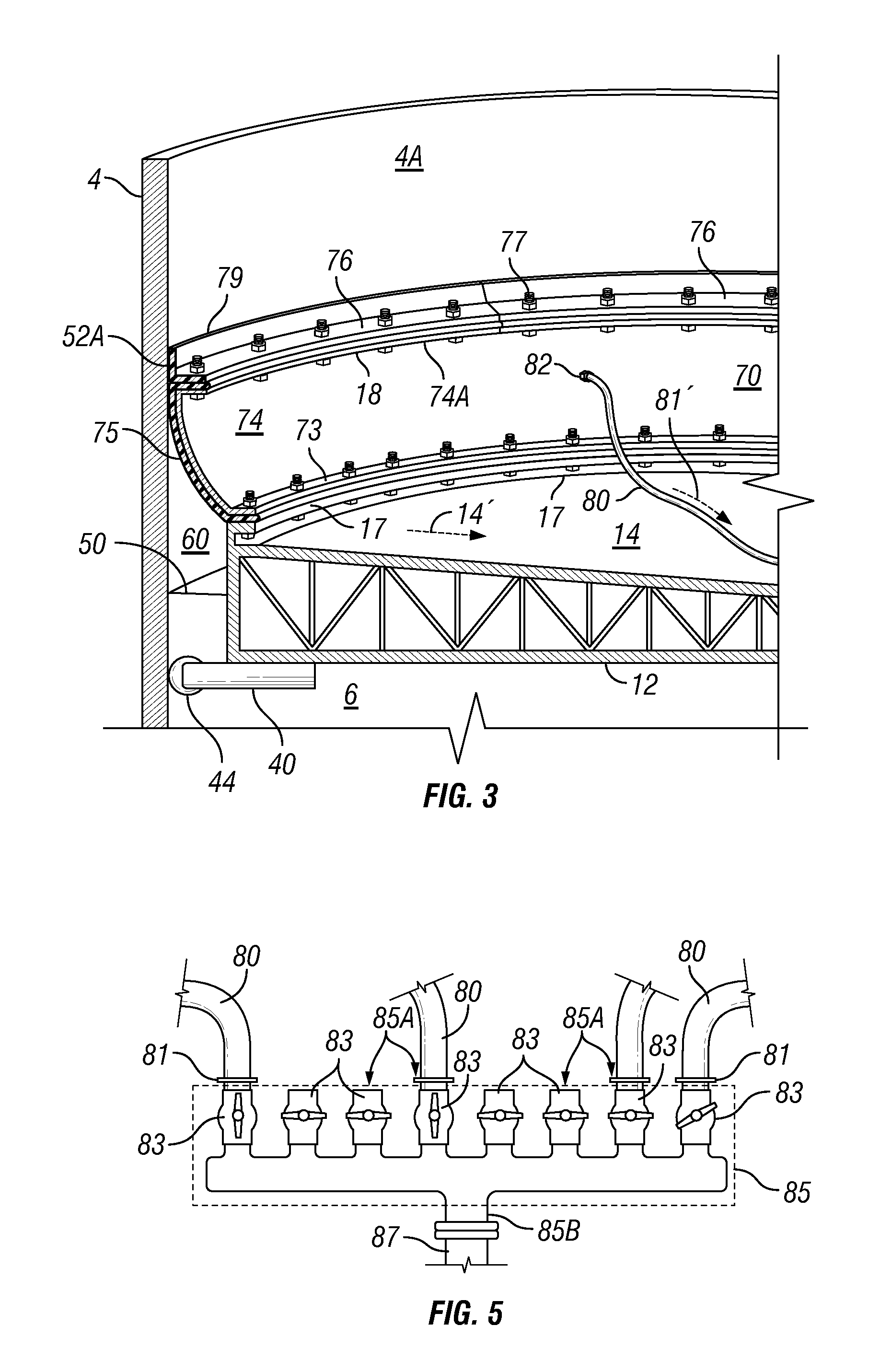

Method And Apparatus For Abating Fugitive Emissions From A Volatile Liquid Storage Tank

A fugitive emissions abatement system for use a storage tank 4 with a floating roof assembly 10 comprises a roof structure 12, a first peripheral seal 70 slidably engaging an interior surface 4A of the tank 4 to form an annular gas chamber 60 intermediate the first peripheral seal 70 and the liquid level 50 within the tank 4, and an aperture 78 in the first peripheral seal 70 coupled to the first end 82 of a fluid conduit 80. The second end 81 of the fluid conduit 80 may be coupled to the inlet of a gas mover 88 so that operation of the gas mover 88 draws gas from the annular gas chamber 60 through the fluid conduit 80 so that it can be delivered to a processing apparatus that may include, but is not limited to, a compressor, a vessel, a heat exchanger and / or an incinerator.

Owner:HILLIARD EMISSION CONTROLS

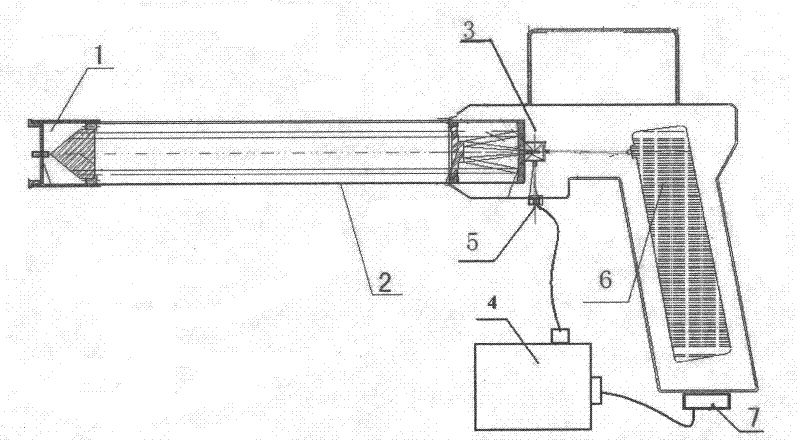

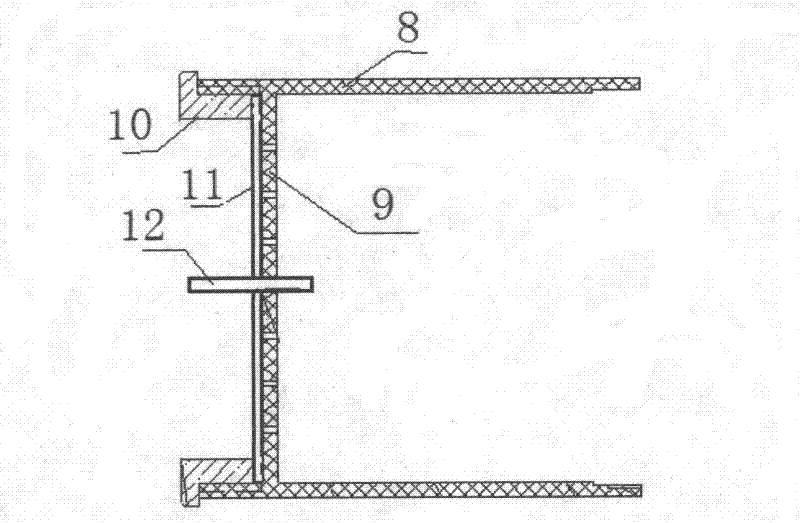

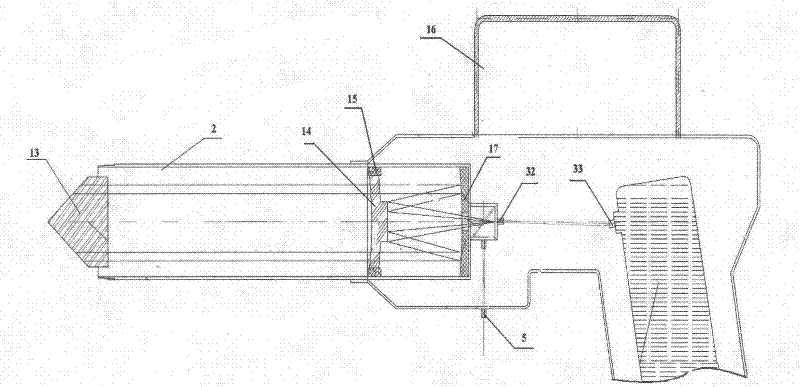

Novel monitor

InactiveCN102359945AReduce labor intensityAvoid damagePreparing sample for investigationColor/spectral properties measurementsData displayDirect test

The invention relates to a novel monitor, comprising a dust filter, a long-path gas adsorption cell, a light source emitter and a host machine. Specifically, the dust filter and the long-path gas adsorption cell are in rotational connection, the long-path gas adsorption cell is connected to the light source emitter through a fixation device, a triangular-pyramid total reflection mirror is arranged in the front of the long-path gas adsorption cell, and the light source emitter is in connection with the host machine by a communication link. The host machine of the monitor consists of a gas extraction and control module, a data display module and a wireless sending and receiving module. The invention discloses a monitor for odor gases of fugitive emission sources like dimethyl sulfide, methyl mercaptan, ammonia gas, hydrogen sulfide, methylamine, dimethyl disulfide, styrene, carbon disulfide, etc. With a portable structural design, the monitor of the invention can be used for direct on-site tests, and can avoid complex processes like gas extraction sampling, transportation, dilution, olfactory discrimination, etc., as well as can reduce the labor intensity of the staff.

Owner:郭振铎

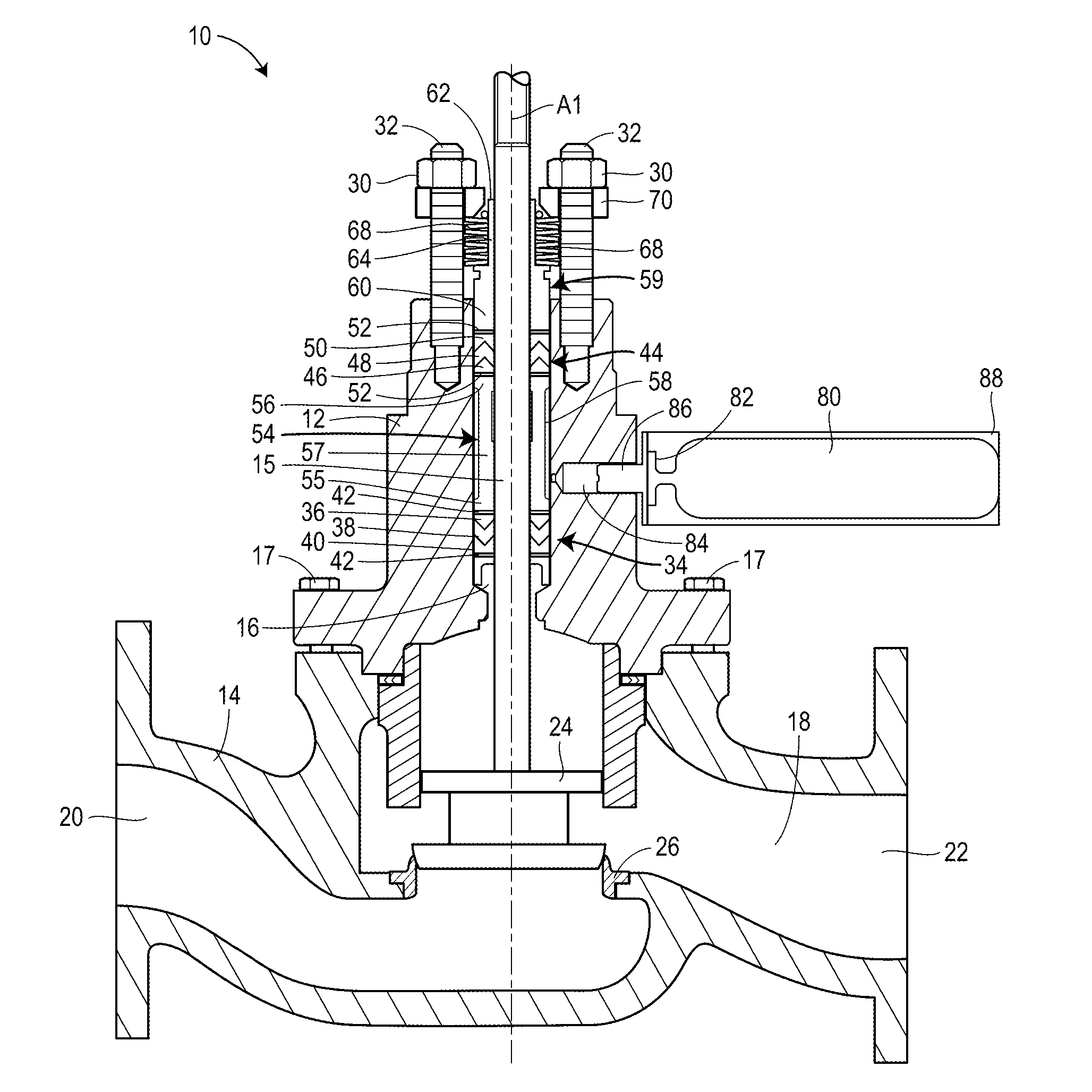

Gas pressurized packing system for control valves

A gas pressurized packing system for use in a control valve is disclosed. The gas pressurized packing system may include a first packing member, a second packing member and a pressurized gas supply. The first and second packing members may be arranged about, respectively, lower and upper portions of an operating member that extends through a bore in the control valve. The pressurized gas supply may be configured to pressurize a portion of the bore arranged between the first and second packing members. Also disclosed are a low fugitive emission control valve and a low fugitive emission control valve system.

Owner:FISHER CONTROLS INT LLC

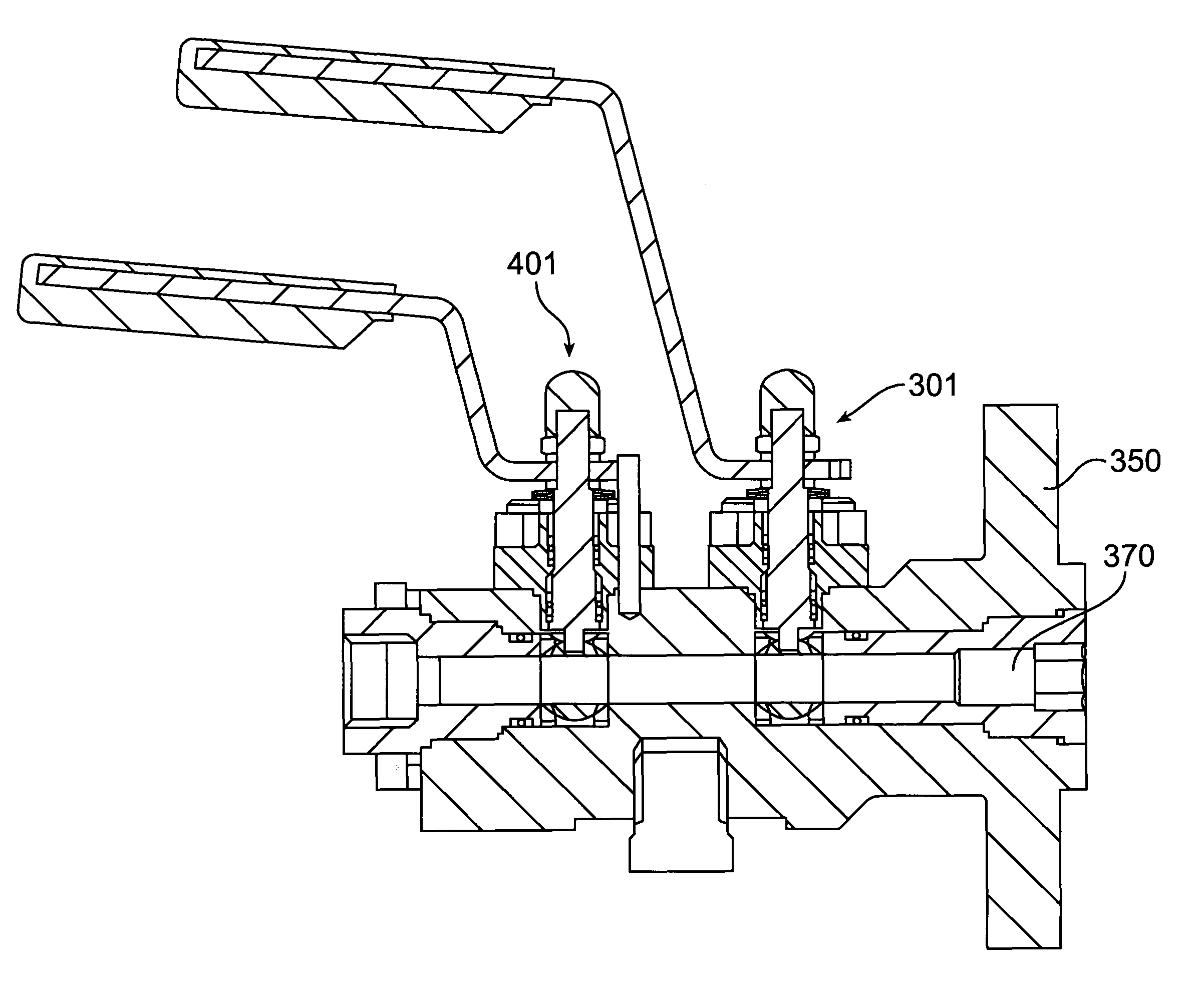

Fugitive emission reducing valve arrangement

ActiveUS8453676B2Improve performanceEmission reductionSpindle sealingsPlug valvesMechanical engineeringFugitive emissions

Owner:PARKER HANNIFIN LTD HEMEL HEMPSTEAD

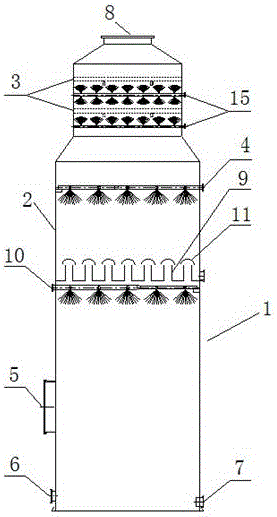

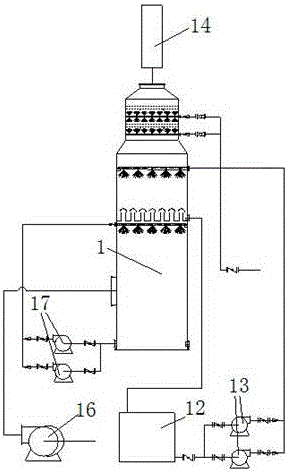

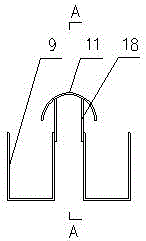

Treatment device and method for smelting flue gas collected from fugitive emission

ActiveCN106345259ASolve the problem of meeting emission standardsAchieve recyclingCombination devicesGas treatmentLiquid slagDust control

The invention particularly relates to a treatment device and method for smelting flue gas collected from fugitive emission. The treatment device comprises a desulfurizing tower; the desulfurizing tower comprises a tower body, and a demister and an alkaline liquid spraying device which are sequentially arranged in the tower body from top to bottom; a flue gas inlet, an acid water outlet and a drain outlet are formed in the side wall of the tower body; a flue gas outlet is formed in the top of the tower body; an alkaline liquid receiving device and an acid water spraying device are also sequentially arranged below the alkaline liquid spraying device; the alkaline liquid spraying device comprises a plurality of U-shaped grooves; and a gas-liquid separation cover supported by a supporting plate is arranged between two adjacent U-shaped grooves. On one hand, the treatment device realizes the dedusting and desulfurization treatment to flue gas to recover heavy metals in the flue gas and prevent the heavy metals from entering alkaline liquid and being absorbed to change the absorbed liquid slag to dangerous waste slag to increase the treatment difficulty and cost of the absorbed liquid; on the other hand, the recycling of the alkaline liquid can be realized, two functions with one tower can be realized, the equipment investment, alkali consumption and running cost can be effectively lowered, and the up-to-standard emission problem of the flue gas collected from fugitive emission can be solved.

Owner:JINCHUAN GROUP LIMITED

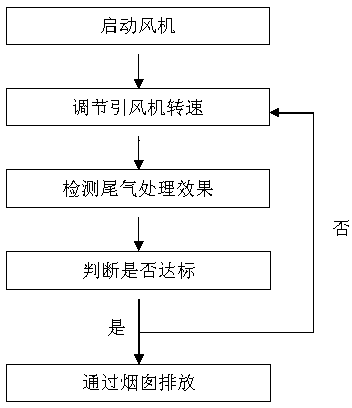

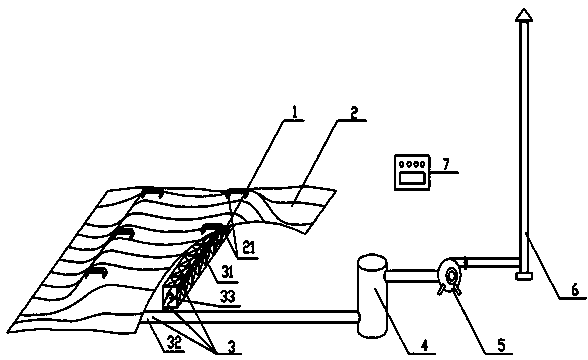

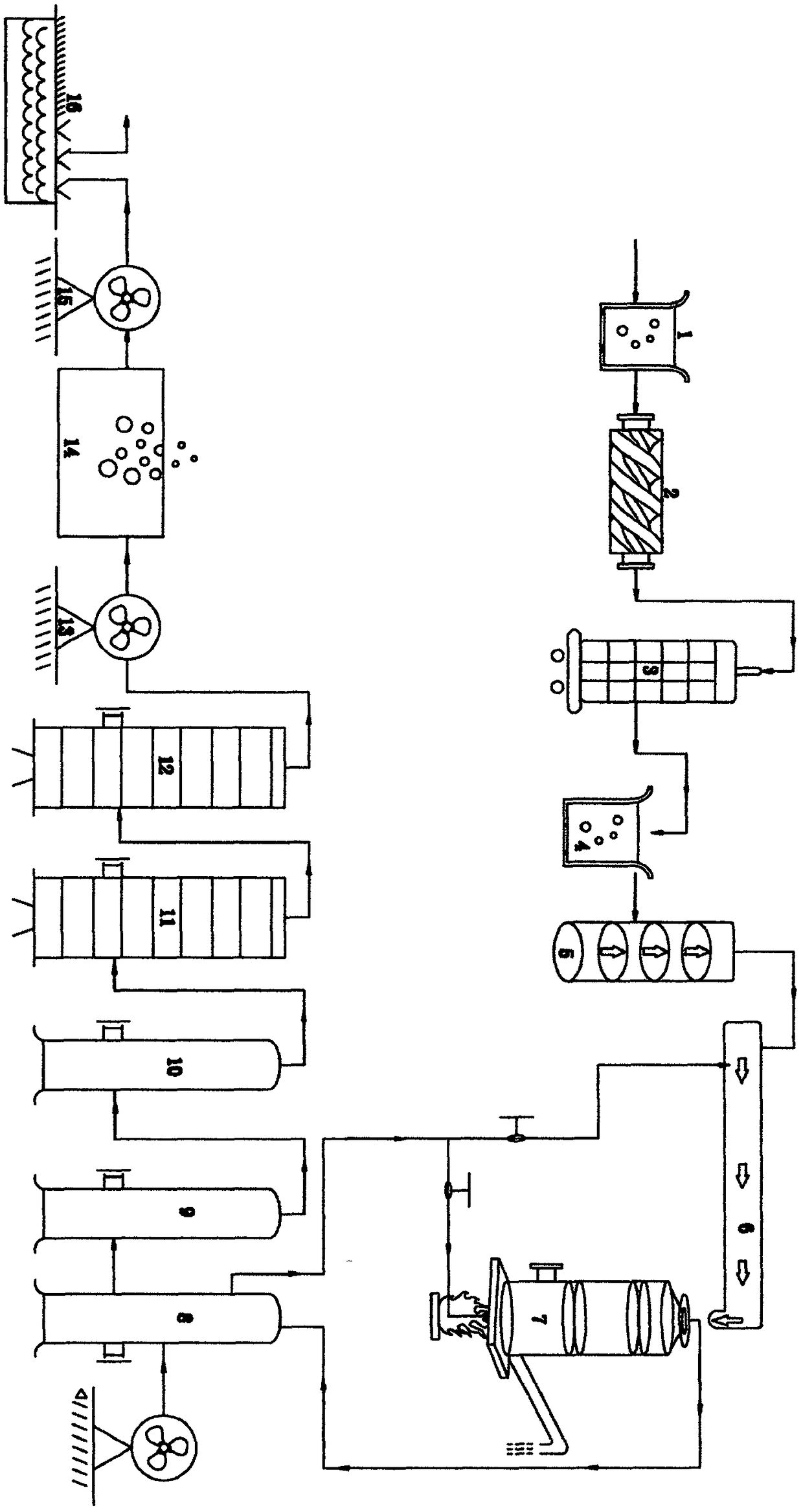

Device for collecting and disposing fugitive-emission volatile/semi-volatile gas in contaminated site

ActiveCN103349884AEffective control of diffusionLow costDispersed particle separationGas collecting tubeAutomatic control

The invention discloses a device for collecting and disposing fugitive-emission volatile / semi-volatile gas in a contaminated site. The device comprises support brackets, a cover material, gas collection and delivering pipelines, a tail gas processing system, an induced draft fan, an emission chimney and an automatic control system, wherein the support brackets are used for supporting the cover material; the gas collection and delivering pipelines comprise gas collection pipelines and gas delivering pipelines, the gas collection pipelines are arranged in the support brackets, and each gas collection pipeline is connected to each gas delivering pipeline through a soft connector; the gas delivering pipelines, the tail gas processing system, the induced draft fan and the emission chimney are connected in sequence, and the automatic control system can ensure the normal operation of the device through controlling the induced draft fan and the tail gas processing system. According to the device, the fugitive-emission volatile / semi-volatile gas on the surface of the contaminated site can enter the tail gas processing system through the gas collection and delivery pipelines to be processed, and then is emitted after the processed gas meets standards, so that the problem of collection and disposal of the fugitive-emission and volatilized volatile / semi-volatile gas in the reparation and construction process in the contaminated site is solved.

Owner:ZHEJIANG ZONE KING ENVIRONMENTAL SCI&TECH CO LTD

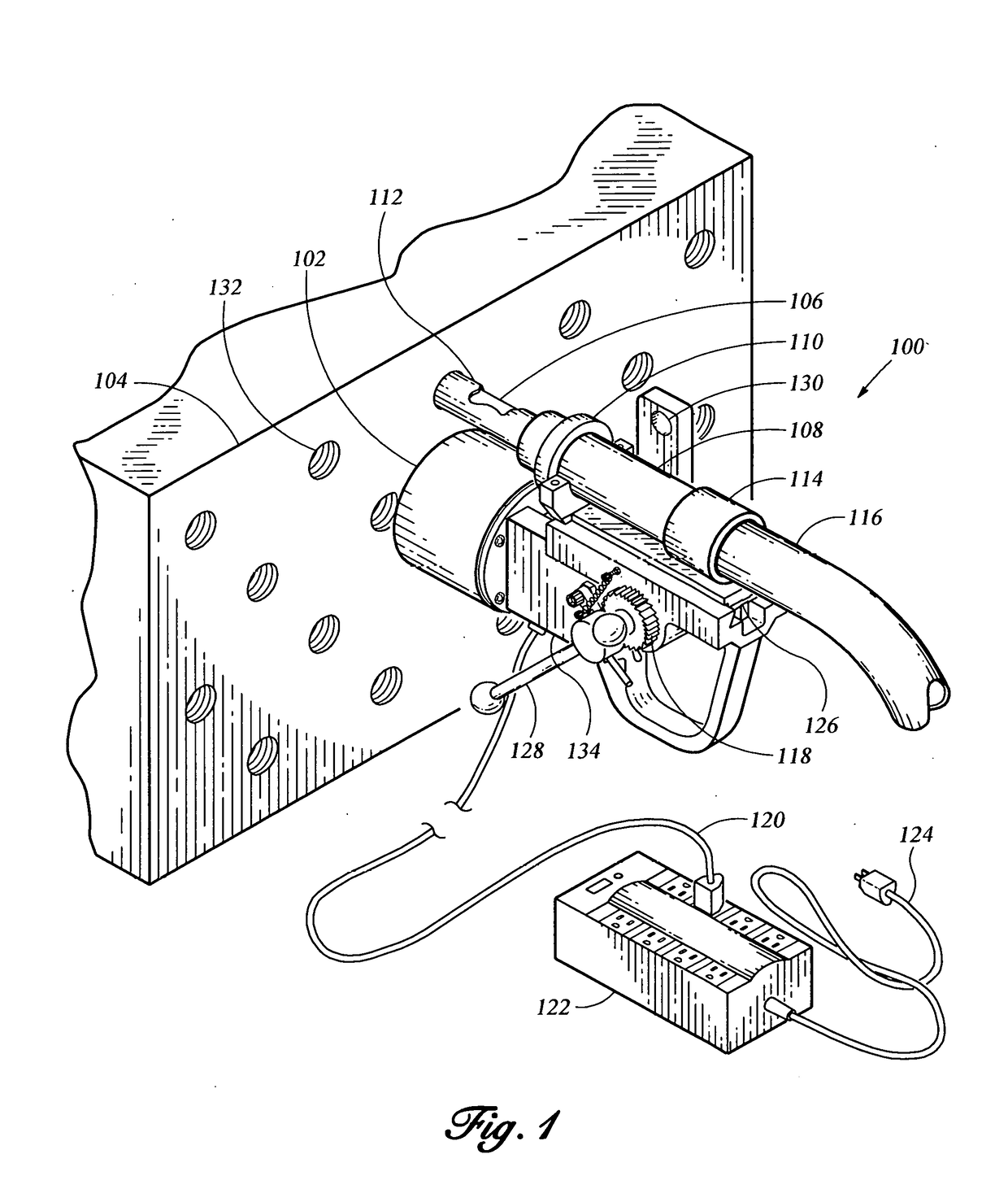

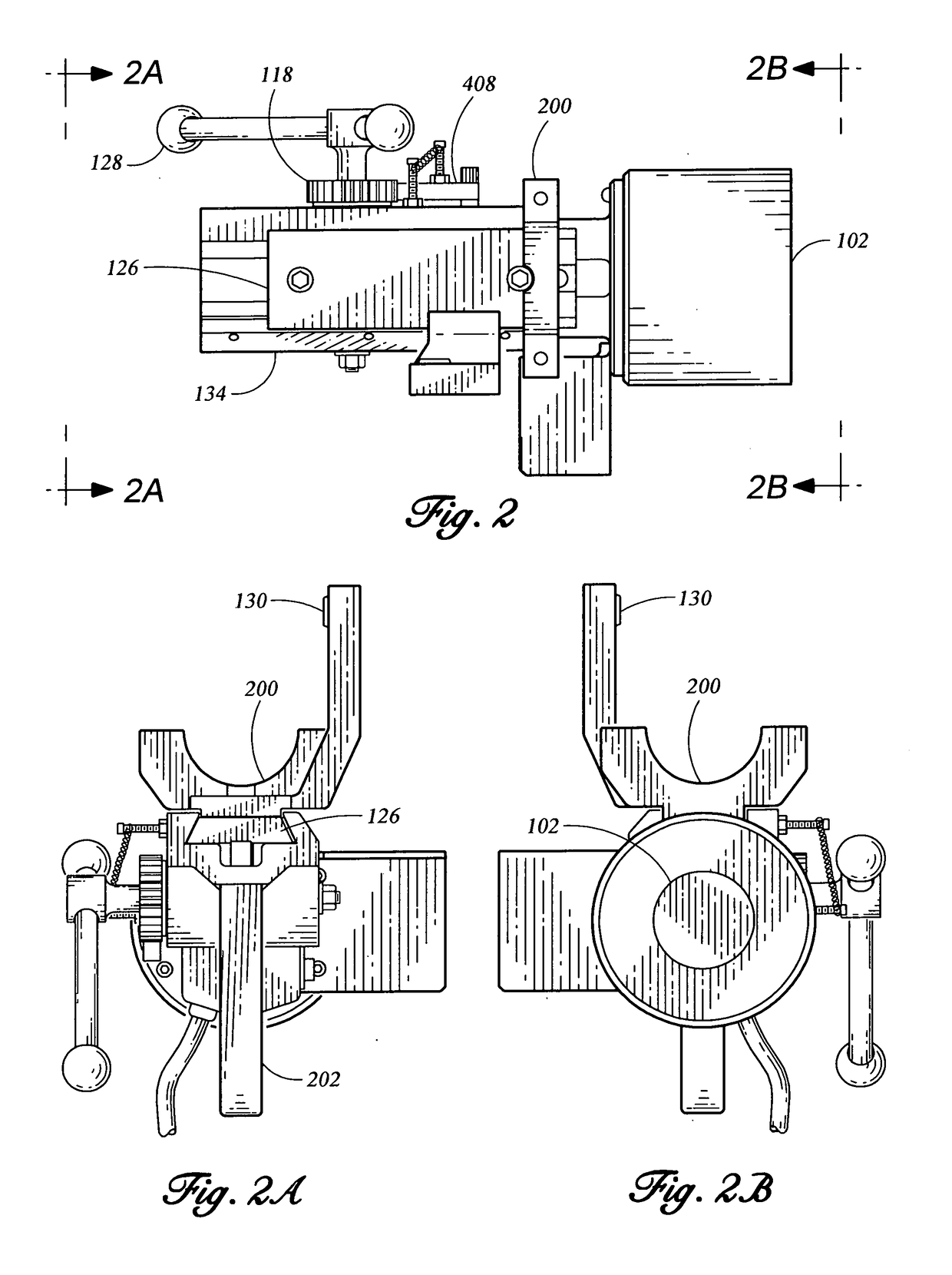

Device, system, and method for cleaning the interior of the tubes in air-cooled heat exchangers

ActiveUS20190039209A1Safely and efficiently and economically and protectiveEnvironmental efficiencyBlast gunsAbrasive feedersAbrasive blastingInternal rotary inspection system

A device, system, and method is disclosed for cleaning the interior of the tubes in air-cooled heat exchangers. The tubes are cleaned using dry finely divided abrasive entrained in high pressure air blasted through the tube to remove any accumulation in the tube or on the tube walls resulting in a bright metal condition suitable for inspection by the Internal Rotary Inspection System, or application of a corrosion-resistant coating, or a lesser level of cleanliness appropriate for return to service. The device is electromagnetically attached to the outside of a ferromagnetic tube header, or to a ferromagnetic plate secured to the outside of a non-ferromagnetic plug-type header or a plate-type header of any material, to temporarily secure a grit-resistant nozzle assembly and position the nozzle for proper application of the high pressure air and entrained abrasive to facilitate cleaning, avoid tube damage, and provide for operator safety. The disclosure still further relates to a system and a method, both employing the device, to clean the interior of the tubes with dry abrasive blasting using high pressure air, and at the other end of the tube, capturing the air, spent abrasive, and material removed from the tube, separating the spent abrasive and removed material from the waste air, filtering the waste air, and exhausting the now filtered air to the environment; all without fugitive emissions.

Owner:CURRAN EDWARD LAWRENCE +1

Device used for high-efficiency processing and fugitive emission of VOCs

PendingCN108722104AEfficient governanceGuaranteed uptimeGas treatmentDispersed particle separationLiquid wasteDesorption

The invention discloses a device used for high-efficiency processing and fugitive emission of VOCs. The device comprises a buffer tank, a blower fan, a condenser, a gas-liquid separation tank, and anadsorption tower unit which are connected successively; the adsorption tower unit and a vacuum pump are connected through a desorption pipeline; the desorption pipeline is provided with a desorption valve; the vacuum pump is connected with the buffer tank; the vacuum pump is used for conveying desorption gas from the desorption tower unit into the buffer tank from bottom to top; a presser sensor is arranged in the buffer tank; the condenser and the gas-liquid separation tank are connected with a liquid storage tank; and the liquid storage tank is provided with a waste liquid outlet. The devicecomprises the advantages of condensing method and adsorption method, a high efficiency stable operation comprehensive treatment technology process is formed, the newest national emission standards are achieved at relatively low investment and operation cost, and no secondary pollution is caused.

Owner:GUANGDONG J TECH ENVIRONMENT SCI CO LTD

Desulfurization and denitrification method of desulfurization and denitrification system

ActiveCN105749716AIngenious structural designReasonable structural designGas treatmentDispersed particle separationFlue gasEngineering

The invention discloses a desulfurization and denitrification method of a desulfurization and denitrification system. The system comprises a tower body, wherein a flue gas inlet is formed in the lower part of the tower body; an oxidizing section is arranged at a lower position, corresponding to the flue gas inlet, in the tower body; a concentrating section, an absorbing section, a purifying and water washing section and a defogging section are sequentially arranged from bottom to top at an upper position, corresponding to the flue gas inlet, in the tower body. The invention also discloses a desulfurization and denitrification method of the desulfurization and denitrification system. The desulfurization and denitrification system provided by the invention is ingenious and reasonable in structural design, effectively solves the problem of high operation cost, and is stable in process; absorption, concentration and crystallization are carried out integrally, no any waste liquid is discharged, ammonia fugitive emission is limited, and the problems of ammonia escape and aerosol are thoroughly solved. The desulfurization and denitrification method provided by the invention is simple and easy in process steps, not only realizes the effects of desulfurization and denitrification, but also has the characteristics of high desulfurization and denitrification efficiency, energy conservation and environment protection, low cost and stable operation safety, and can make waste profitable.

Owner:SHANDONG MINGSHENG CHEM ENG CO LTD

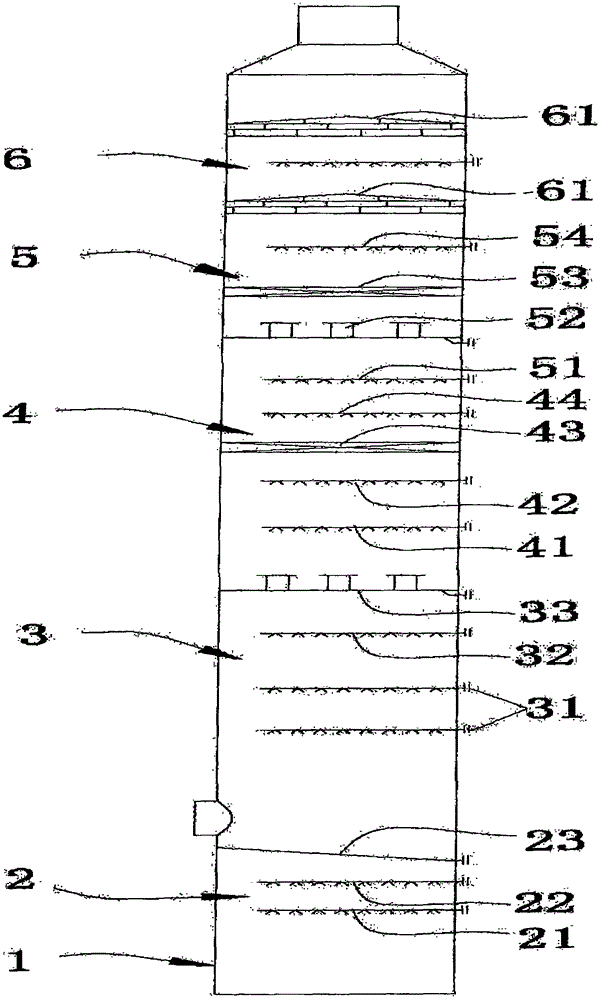

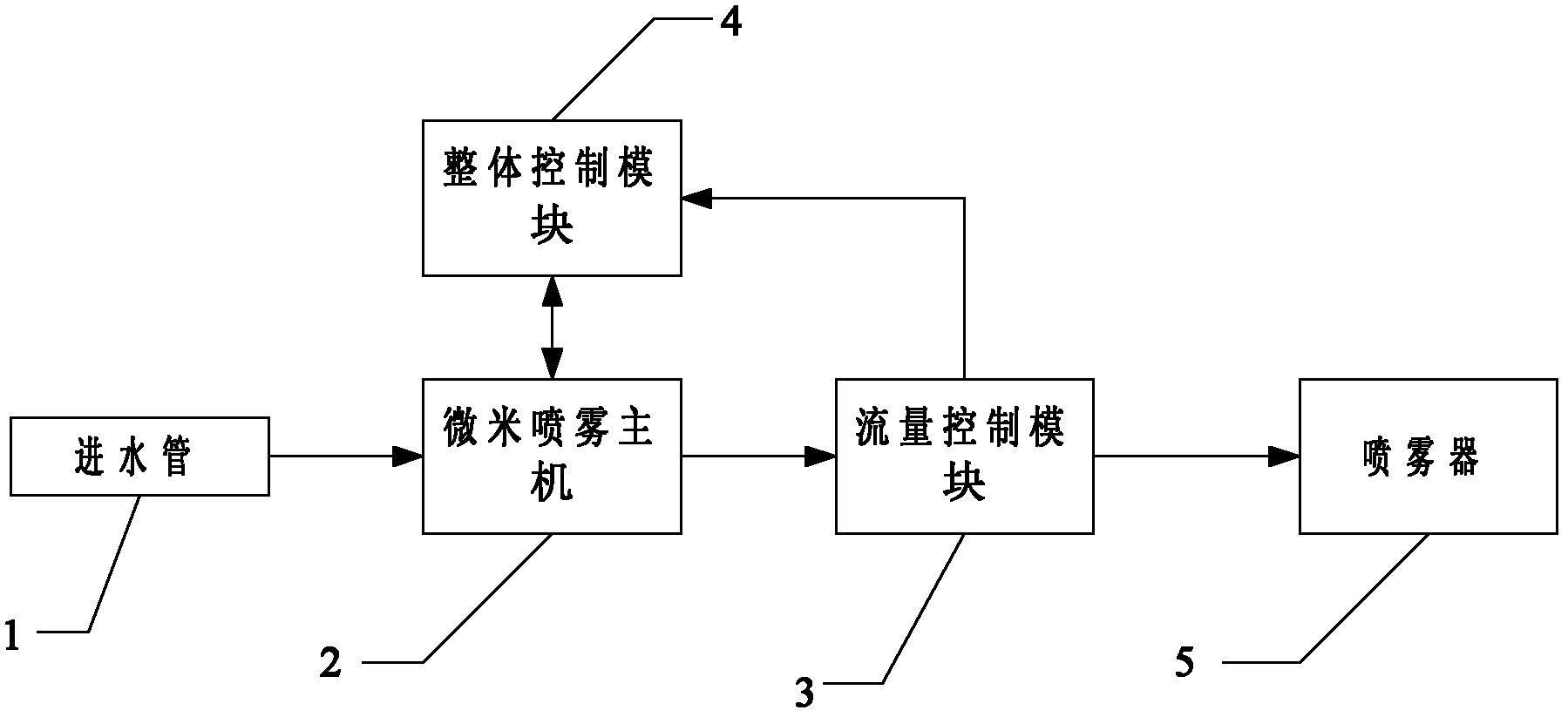

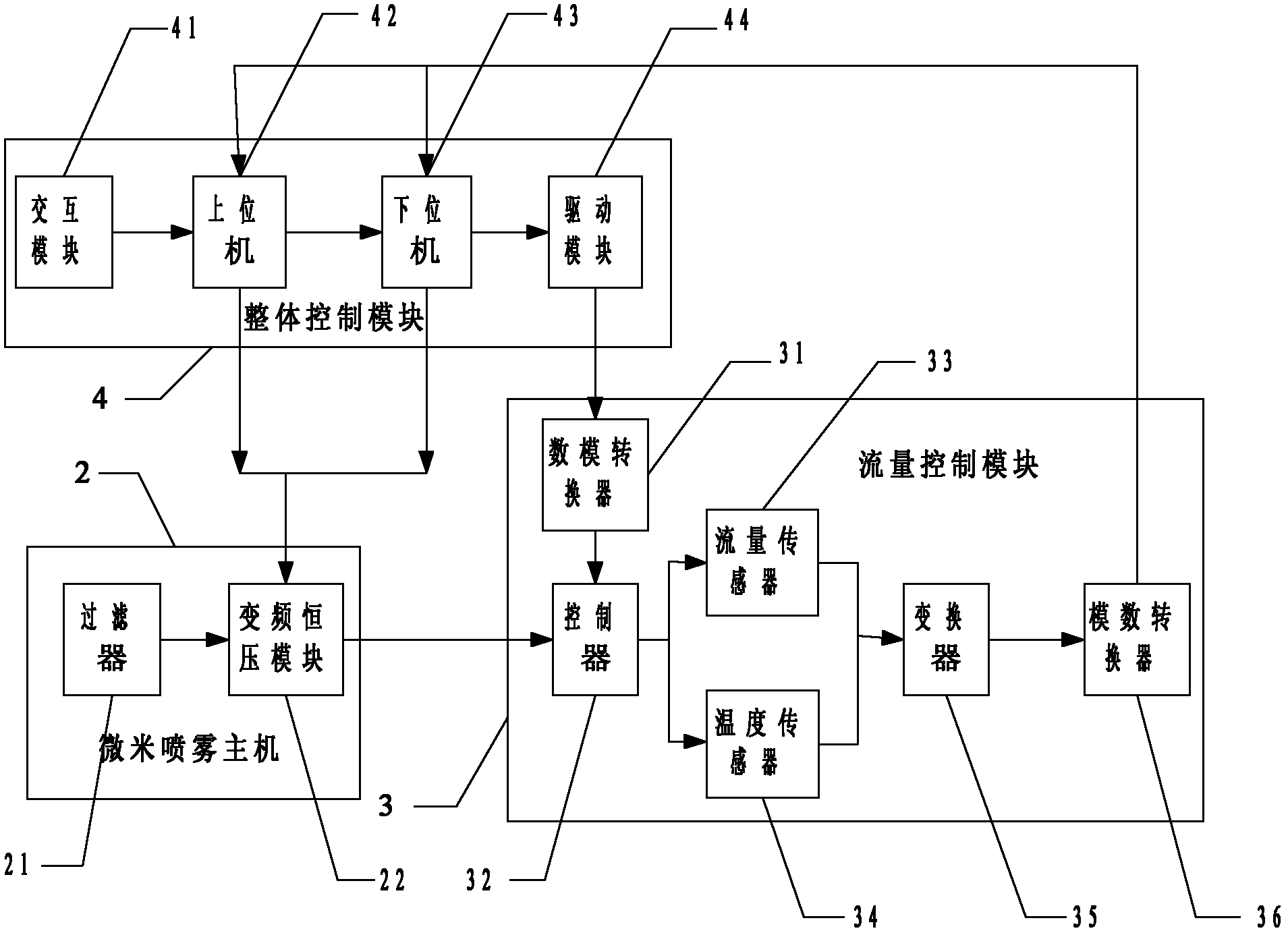

High-pressure micron-sized atomizing dust suppression system

InactiveCN102671491AControl Surface MoistureReduce maintenanceUsing liquid separation agentAutomatic controlControl signal

The invention relates to a high-pressure micron-sized atomizing dust suppression system, which comprises a water inlet pipe, an integral control module, a micron atomizing main machine and at least one atomizer; the water inlet pipe is connected with the micron atomizing main machine and is used for conveying the liquid to the micron atomizing main machine; the integral control module transmits a control signal to the micron atomizing main machine and controls the micron atomizing main machine to work through the control signal; and the atomizer is connected with the micron atomizing main machine and is used for spraying mist particles. The high-pressure micron-sized atomizing dust suppression system has high dust suppression efficiency and good effect for controlling the dust with the size being less than 10 micrometers and can avoid the harm of the pneumoconiosis; the size of the mist particle is 3 to 20 micrometers, and a thick and dense mist pool is formed on a dust suppression place; the water consumption is small, the material humidity is increased, the material has no heat loss, and no secondary pollution exists; the land occupation area is small, convenience in operation is achieved, and automatic control can be realized; the running and maintenance expense is low; the dust suppression system is suitable for the pollution source with fugitive emission and a closed or a semi-closed space; the dust explosion possibility is reduced, and the investment on the firefighting equipment can be reduced; and the high-pressure micron-sized atomizing dust suppression system can be used normally in winter.

Owner:陈勇

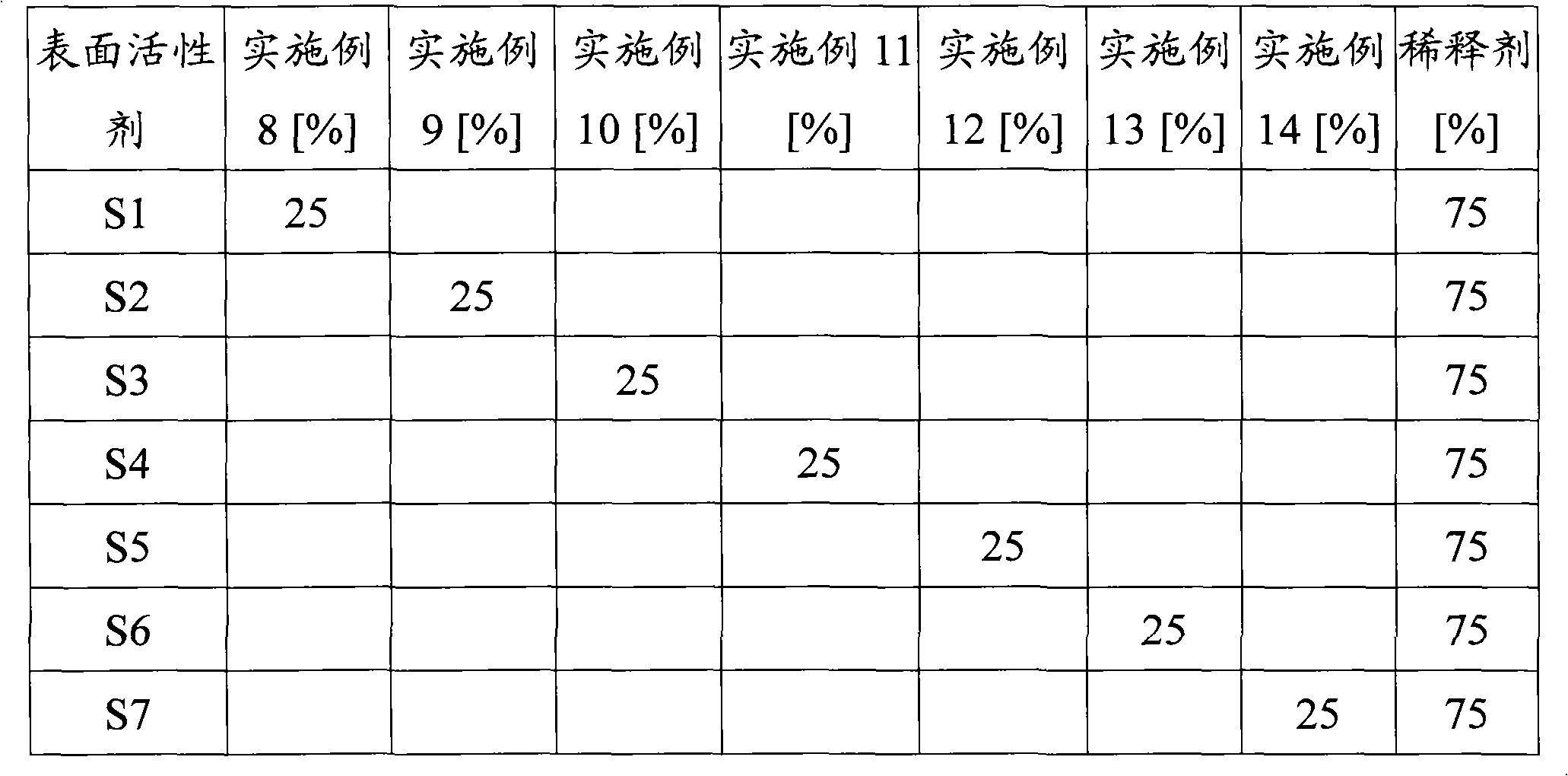

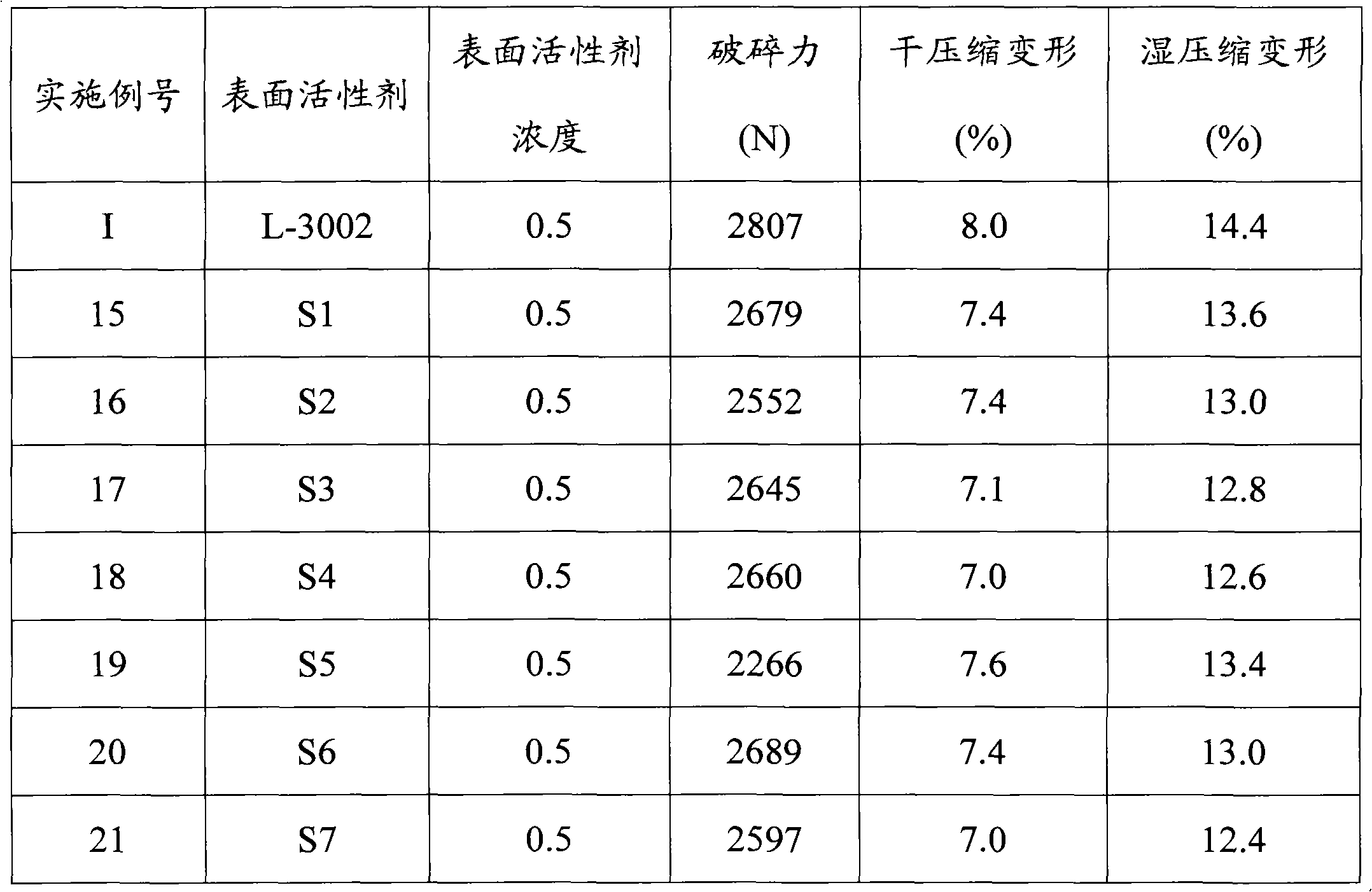

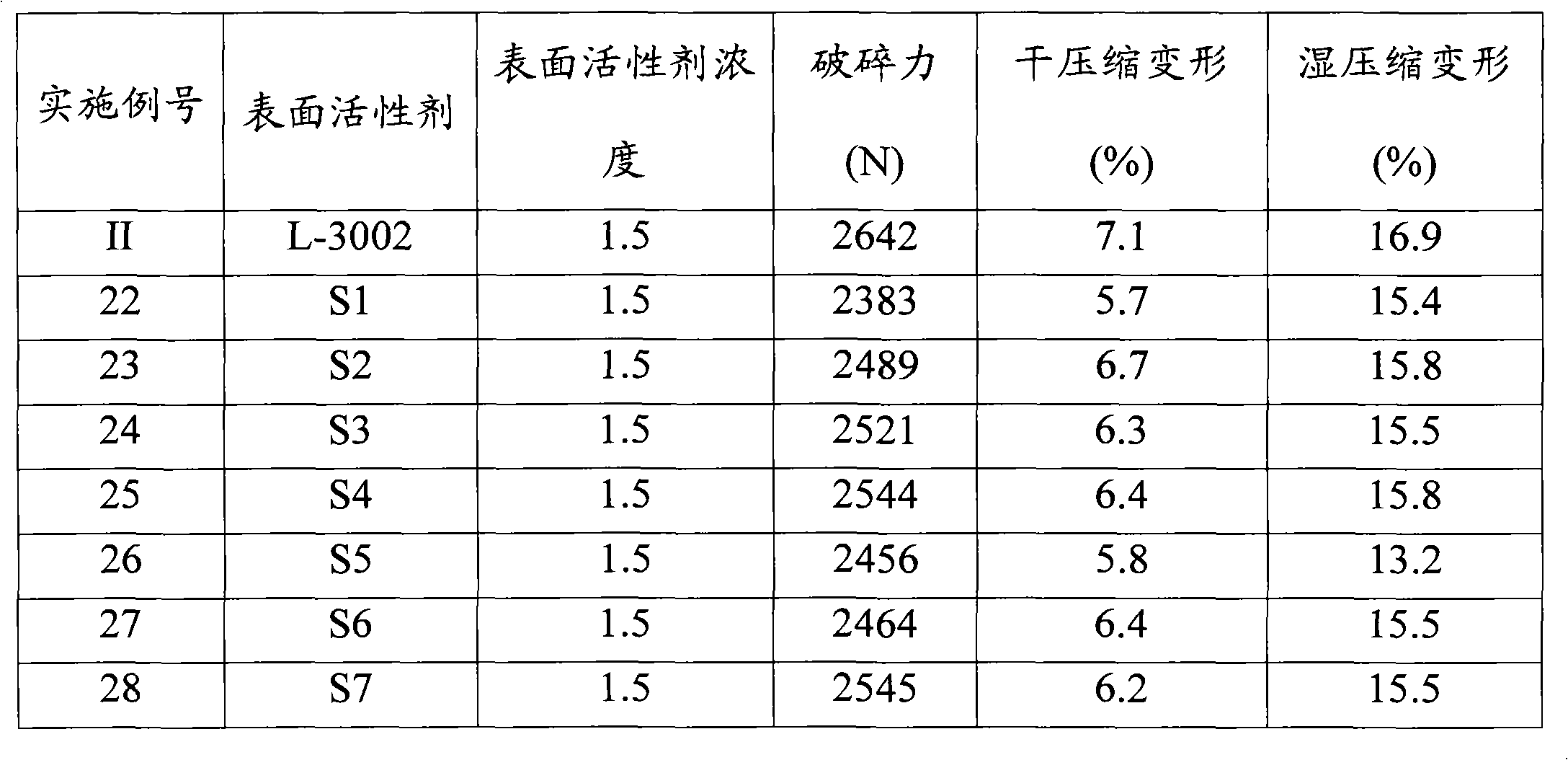

Organosilicone surfactant for producing flexible foam

The invention provides a polyurethane foam forming composition of a surfactant with general formula R13Si(OSiR2G)xOSiR33, wherein each of R1, R2 and R3 is an alkyl group with 1-10 carbon atoms; G is a group with general formula -R4(OR5)yA; R4 is a bivalent alkyl group with 2-4 carbon atoms; R5 is ethylidene or propylidene; A is a hydroxyl group; x is a number from 1 to 5; and y is a number from 0 to 10. The composition can be used for generating polyurethane foam with high concentration of open pores, improved dry / wet compressive deformation and low fugitive emission.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

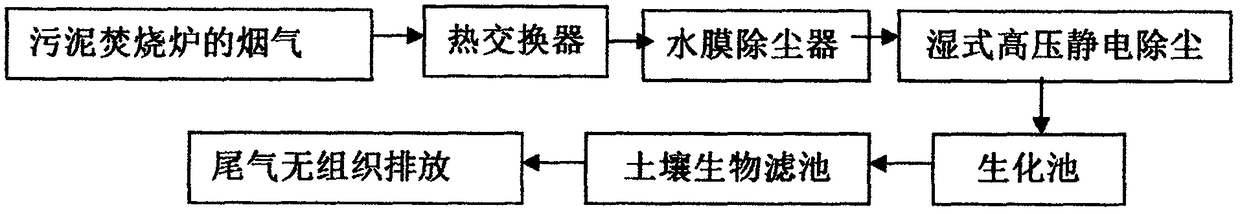

Sludge incineration flue gas treatment process

InactiveCN108613198AMeeting timeEmission preventionIncinerator apparatusIndustrial waste waterEngineering

The invention discloses a sludge incineration flue gas treatment process, and relates to the technical field of sludge and industrial waste water treatment. The process comprises following steps thatwet sludge is lifted to a direct pressing sludge deep water removal process device through a screw rod pump to be subjected to water removal; then, the sludge is lifted to a sludge drying machine; then, the sludge enters an incinerator to be subjected to preheating, drying and incineration; flue gas out of the incinerator passes through a heat exchanger, heat energy is absorbed, the sludge entersa water-film separator, large-particle dust is removed, and continuous cooling is achieved; flue gas passes through the water-film separator and then sequentially enters a condenser, a first-stage electrostatic precipitator and a second-stage electrostatic precipitator, and dust in the flue gas is reduced to 10 mg and below per cubic meter; and through a high-pressure draught fan, the flue gas ispressed into a biochemical reaction basin, gas in the biochemical reaction basin is pressed into a biological soil filter through a collection draught fan, and the flue gas passes through the biological soil filter for fugitive emission. Reduction, stabilization, harmlessness and resource needs of sludge disposal and treatment in a sewage treatment plant are met.

Owner:刘学琳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com