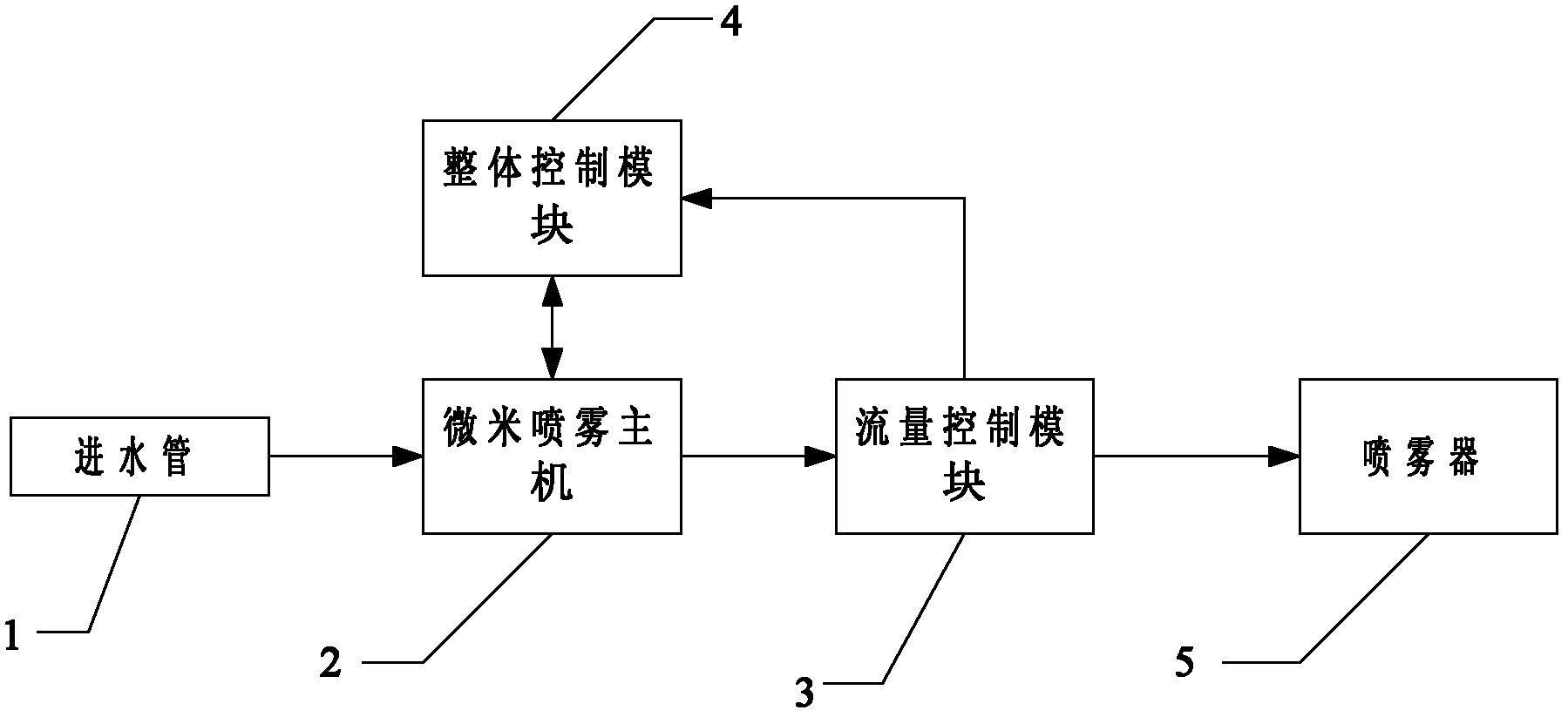

High-pressure micron-sized atomizing dust suppression system

A micron-level, high-pressure technology, which is applied in the direction of dispersed particle separation, chemical instruments and methods, and the use of liquid separating agents, can solve the problems of inhalable dust that cannot be treated, reduce the investment in fire-fighting equipment, prolong equipment life, and water consumption. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

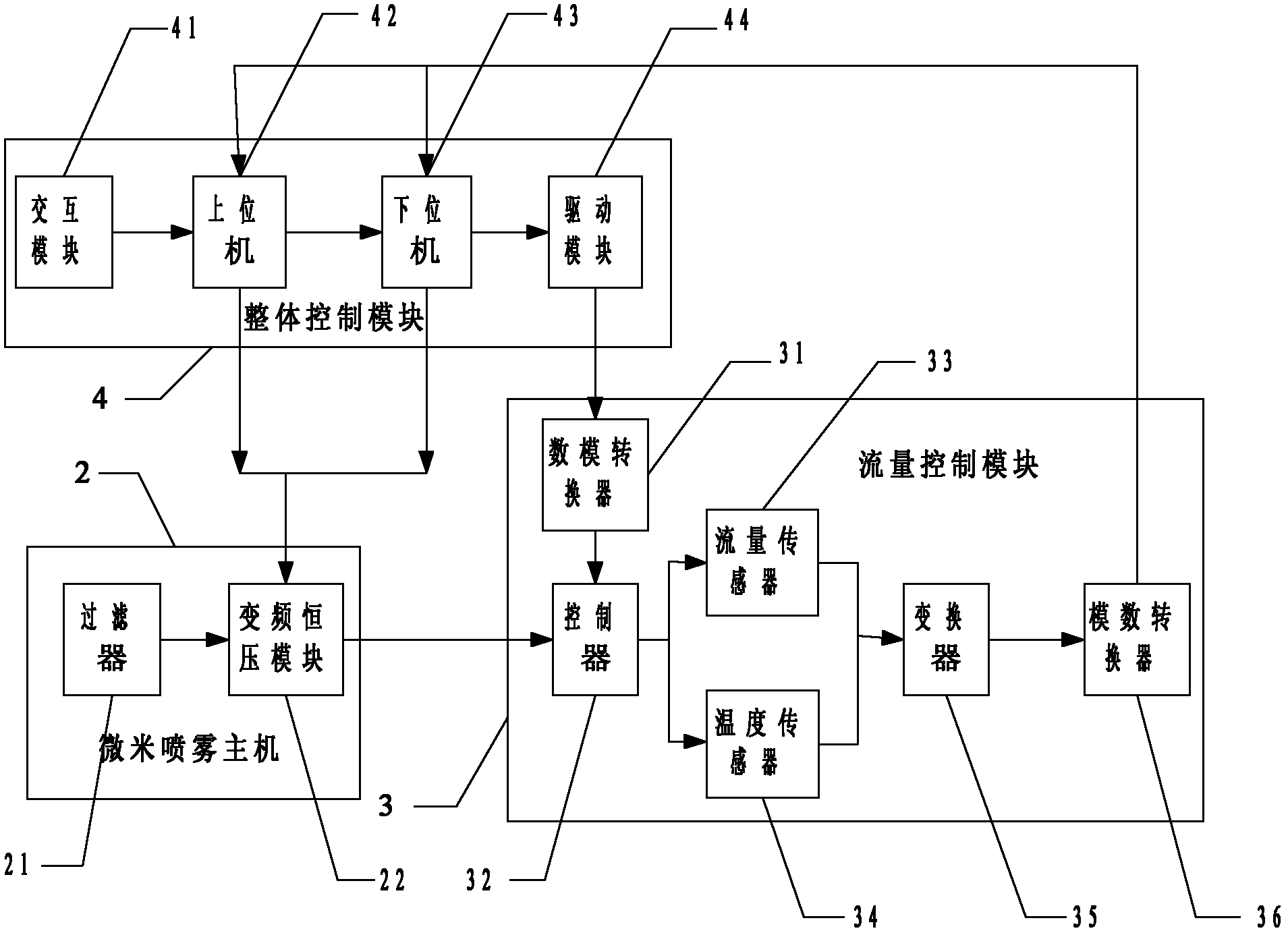

[0060] In embodiment 1, the upper computer is a 6U 19-inch control box as a whole.

[0061] The lower computer is the actual executor of the control system action, and also the executor of the protection and monitoring of the high-pressure dust removal equipment. Its calculation volume and scale are not as heavy and huge as that of the upper computer, but the requirements for real-time performance and stability are higher, which is the fundamental guarantee for the stability and durability of the control system.

[0062] The interactive module includes a remote interactive module and a local interactive module; for the remote interactive module, the control system only provides 485 bus interface and Windows system control software.

[0063] For the local interactive module, the control system provides a human-computer interaction interface and RS485 communication bus, which can monitor and control any node of the whole machine.

[0064] The local interactive module adopts emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com