Lightning protection system for wind turbine blade

A lightning protection system and wind power blade technology, which is applied in the direction of wind power generation, wind engine, wind engine assembly, etc., can solve the problem that the surface of the air receptor and the surface of the base cannot be bonded face to face, the air receptor at the tip of the blade cannot be disassembled, Complicated electrical connection and other issues, to achieve the effect of improving uneven electric field distribution, good lightning protection effect, and sufficient electrical contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

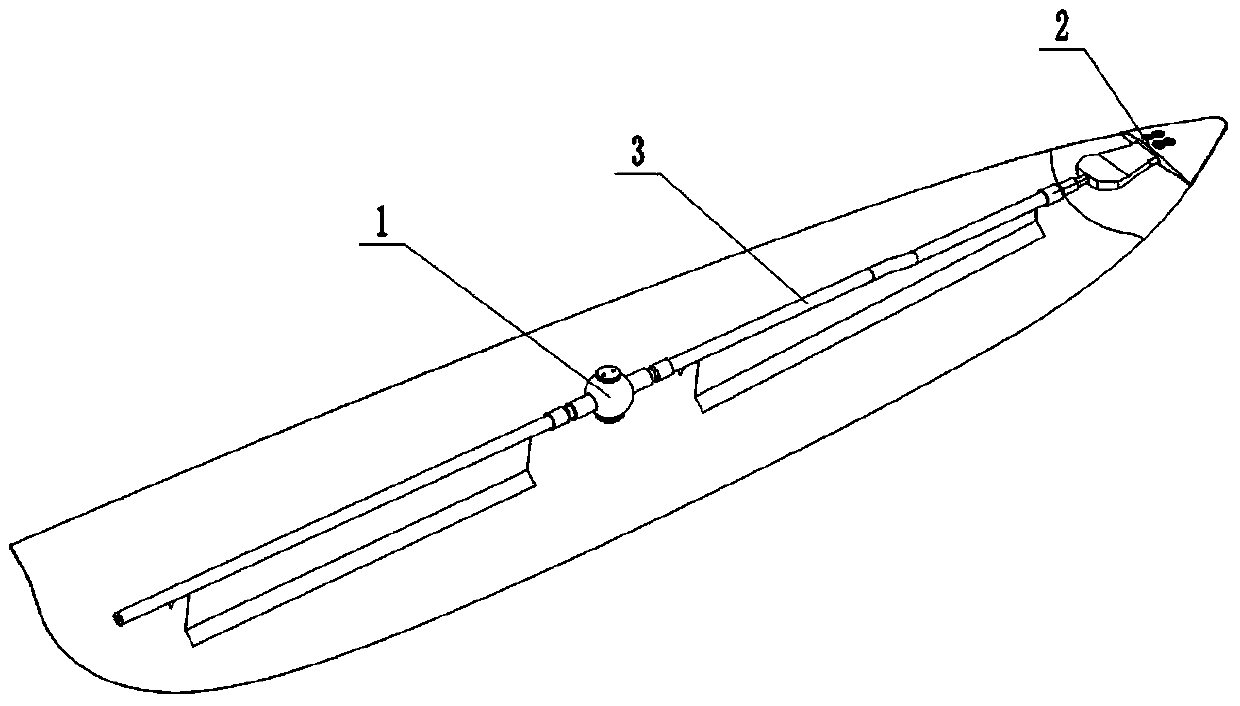

[0025] Basic as attached figure 1 Shown: a lightning protection system for wind power blades, including a blade body lightning-termination unit 1 , a blade-tip lightning-termination unit 2 and wires 3 .

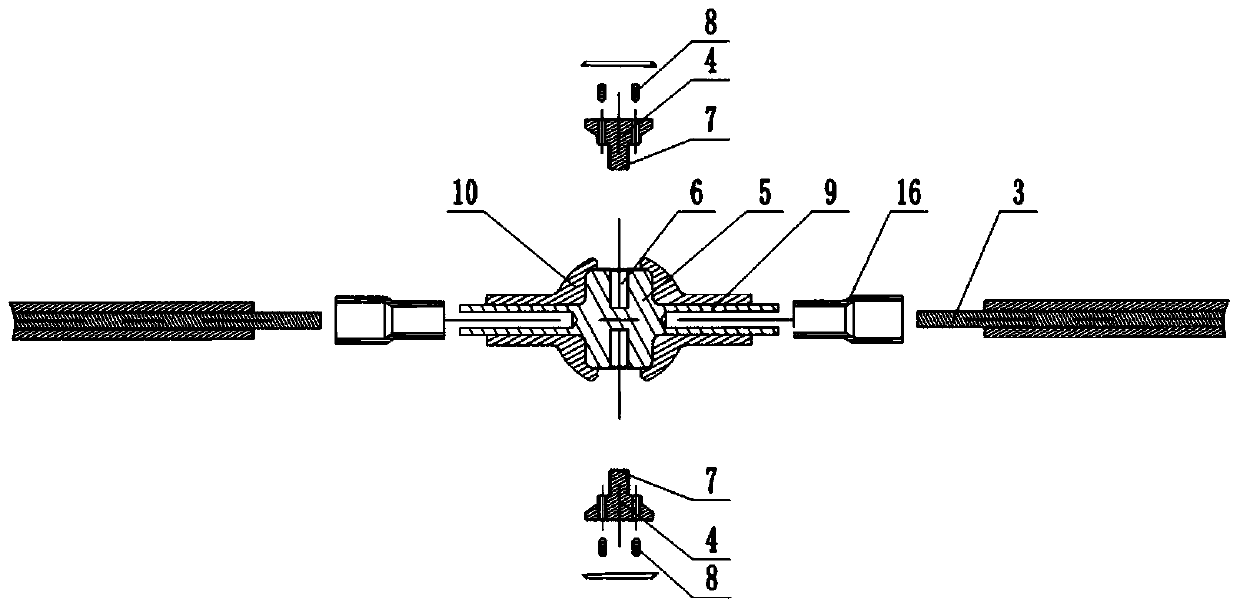

[0026] combine figure 2 As shown, the blade body air-termination unit 1 includes the blade body air-termination device 4 and the blade-body air-termination device base 5. Both the upper and lower end faces are provided with threaded holes 6 perpendicular to the end faces, and the lower end of the blade air-termination device 4 is provided with a threaded column 7 matching the threaded hole 6, and the threaded column 7 is threadedly connected with the threaded hole 6. Also be provided with aperture on 4, be provided with set screw 8 in the aperture. Metal tubes 9 are provided at both ends of the air-termination base 5 of the blade body, and an insulating sealing layer 10 is provided on the outer surface of the air-termination unit 1 of the blade body.

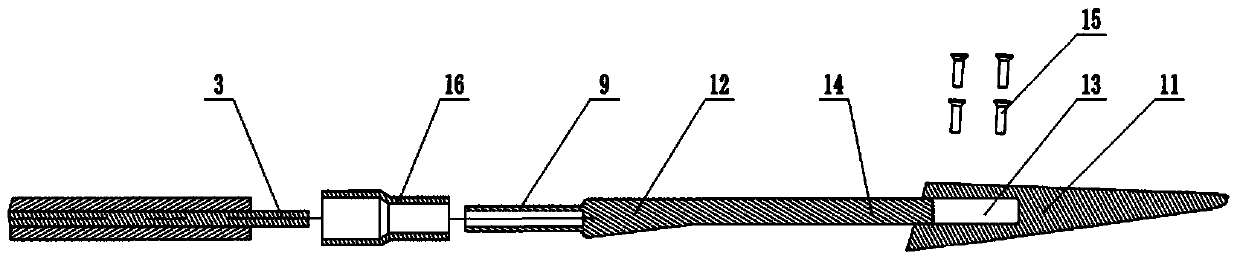

[0027] combine im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com