Method for synchronously activating, inerting, removing impurities and melting calcium aluminate by using low-magnesium aluminum ash

A technology of calcium aluminate and aluminum ash, which is applied in the preparation of calcium aluminate, alkaline earth metal aluminate/alumina/aluminum hydroxide, etc. It can solve the problems of reducing the desulfurization performance of calcium aluminate and the difficulty of synthesis and purification of calcium aluminate , to meet the requirements of industrial production, low production cost, and reduce the synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

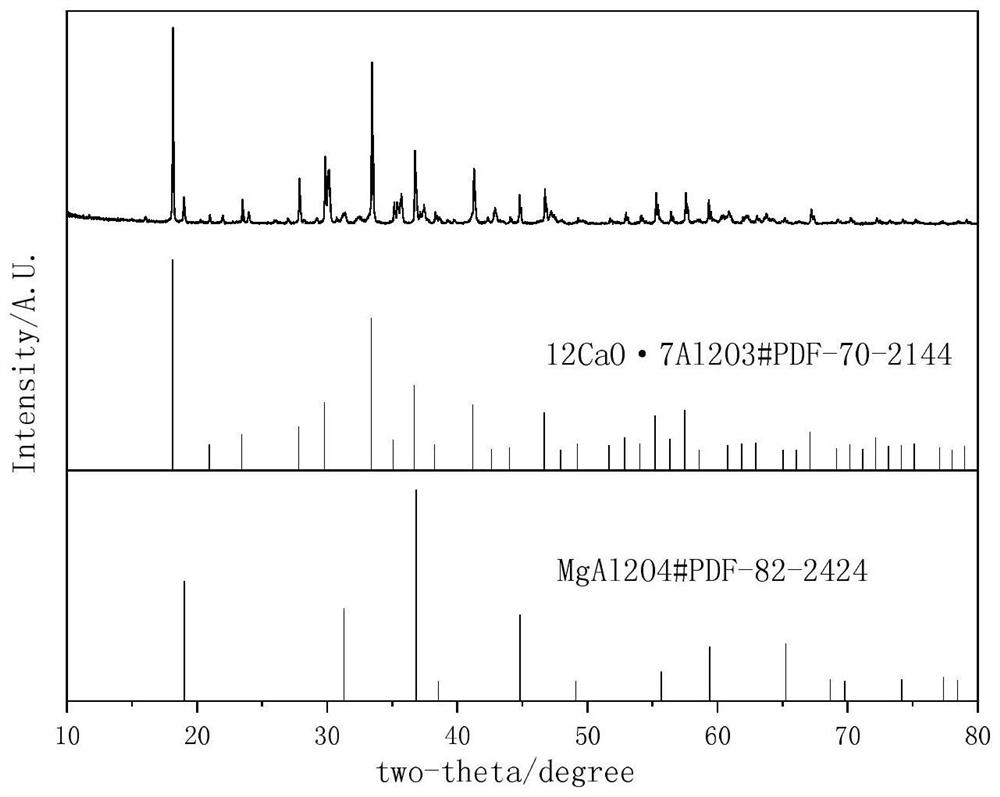

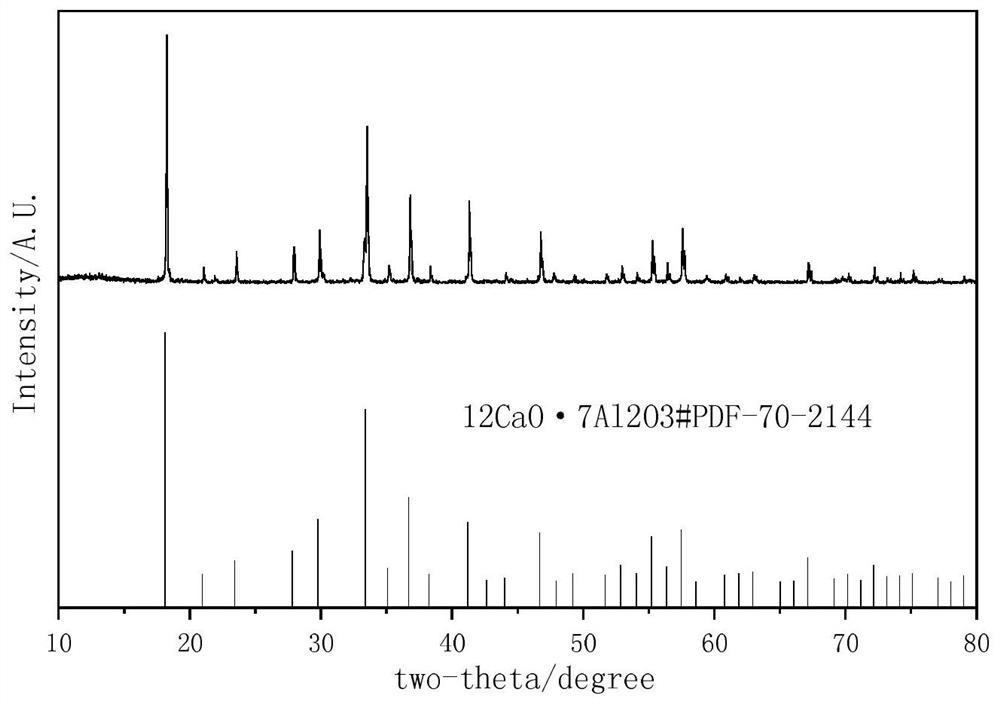

Embodiment 1

[0028] Using aluminum ash (aluminum content 63.6%, oxygen content 1.8%) of an aluminum smelter as raw material, the method firstly mixes aluminum ash slag with calcium-containing additives, and the calcium-containing additives are limestone, slaked lime, quicklime mixture (limestone: slaked lime: Quicklime=40%:10%:50%), the ratio control range of aluminum ash and calcium-containing additives is Al:(Ca+Mg)=1:1.15; the material after mixing is wet ball milled, and the liquid-solid ratio of the ball mill is 1 : 0.9, the ball milling speed is 20r / min, and the ball milling time is 6h; after the ball milling, the material is washed and solid-liquid separation is carried out, and finally the dried sample is placed in an air atmosphere for two-stage controlled temperature roasting, wherein the roasting temperature of one stage is 800°C , the roasting time is 2h; the second-stage roasting temperature is 1450°C, and the roasting time is 2h, and the obtained product is calcium aluminate s...

Embodiment 2

[0030] Using aluminum ash (aluminum content 63.6%, oxygen content 1.8%) of an aluminum smelter as raw material, the method firstly mixes aluminum ash slag with calcium-containing additives, and the calcium-containing additives are limestone, slaked lime, quicklime mixture (limestone: slaked lime: Quicklime=20%:20%:60%), the ratio control range of aluminum ash and calcium-containing additives is Al:(Ca+Mg)=1:1.21; the material after mixing is wet-type ball milled, and the liquid-solid ratio of the ball mill is 1 : 0.3, the ball milling speed is 10r / min, and the ball milling time is 12h; after the ball milling, the material is washed and solid-liquid separation is carried out, and finally the dried sample is placed in an air atmosphere for two-stage controlled temperature roasting, wherein the roasting temperature of one stage is 400°C , the roasting time is 4h; the second-stage roasting temperature is 1350°C, and the roasting time is 3h. The obtained product is calcium aluminate...

Embodiment 3

[0032] Using aluminum ash (70.6% aluminum content, 1.0% oxygen content) of an aluminum smelter as raw material, the method firstly mixes aluminum ash slag with calcium-containing additives, and the calcium-containing additives are limestone, slaked lime, and quicklime mixture (limestone: slaked lime: Quicklime=20%:30%:50%), the ratio control range of aluminum ash and calcium-containing additives is Al:(Ca+Mg)=1:1.18; the material after mixing is wet ball milled, and the liquid-solid ratio of the ball mill is 1 : 0.7, the ball milling speed is 30r / min and the ball milling time is 8h; after the ball milling, the material is washed and solid-liquid separation is carried out, and finally the dried sample is placed in an air atmosphere for two-stage controlled temperature roasting, wherein the roasting temperature of one stage is 800°C. The roasting time is 4 hours; the second-stage roasting temperature is 1350°C, and the roasting time is 2 hours. The obtained product is a calcium a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com