Energy-saving and cost-reducing technology for directly utilizing smelting of aluminium scraps

An aluminum smelting and direct technology, applied in the field of energy-saving and consumption-reducing processes, can solve the problems of unreasonable utilization of alloy component resources and waste of energy, and achieve the effect of reducing waste discharge, improving the quality of recycled aluminum, and achieving obvious effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

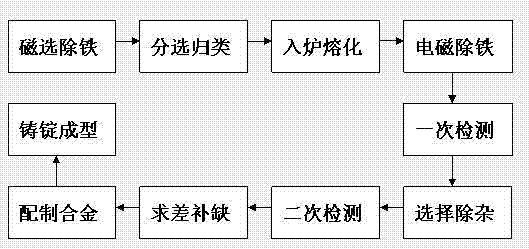

[0017] An energy-saving and consumption-reducing process for directly utilizing waste aluminum smelting, comprising the following steps:

[0018] An energy-saving and consumption-reducing process for directly utilizing waste aluminum smelting, comprising the following steps:

[0019] Step 1: put the collected scrap aluminum into the magnet sorting machine with the conveyor belt, and carry out simple physical method to remove iron;

[0020] Step 2: Carry out manual sorting of waste aluminum according to different varieties, and generally the same and similar ones are classified into one category;

[0021] Step 3: put the sorted and classified waste aluminum into the smelting furnace for melting;

[0022] Step 4: Use a high temperature resistant (inner and outer cavity water circulation) electromagnetic device to remove the elemental components in the waste aluminum melt through adsorption for a second time;

[0023] Step 5: Sampling the molten aluminum scrap in the smelting f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com