Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

249results about How to "Suitable for continuous large-scale production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

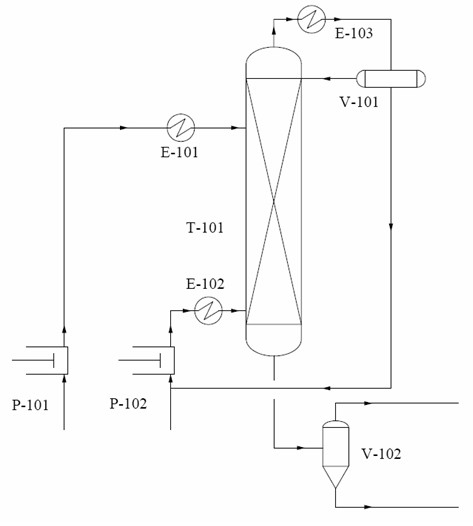

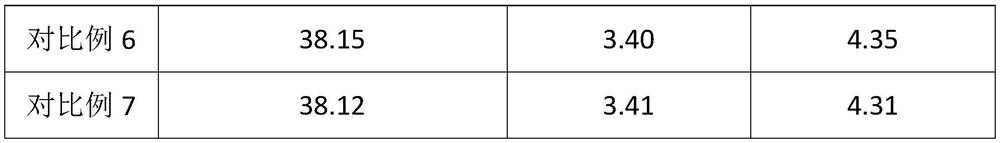

Catalytic distillation production method for biodiesel

InactiveCN102628006AExpand sourceHigh yieldFatty acid esterificationBiofuelsTrans esterificationPtru catalyst

The invention provides a method for continuously producing biodiesel. The method comprises the following specific steps of: preheating grease and a low-carbon alcohol according to a certain proportion, and pumping into a catalytic distillation tower filled with a solid acid or a basic catalyst; feeding the grease from the upper part of the tower in a liquid form; feeding the low-carbon ethanol from the lower part of the tower in a steam form; inversely contacting the grease and the low-carbon ethanol; performing an esterification or ester exchange reaction on a solid acid or alkali catalyst bed layer in the tower; condensing the low-carbon alcohol evaporated on the top and making a part reflow to the tower top; circularly using the remaining part; and treating a bottom discharged material by using a sedimentation laminating device to obtain biodiesel from an upper layer and side product glycerol from a lower layer. A catalytic distillation process based on a solid acid or alkali catalyst is adopted, and reaction and separation processes are integrated, so that the consumption of a large quantity of low-carbon alcohols is lowered, and the yield of biodiesel is up to 99 percent; the solid acid or alkali catalyst can be used repeatedly; and the method for producing biodiesel has the advantages of energy saving, environmental friendliness, suitability for continuous scale production, and good market prospect.

Owner:SOUTHEAST UNIV

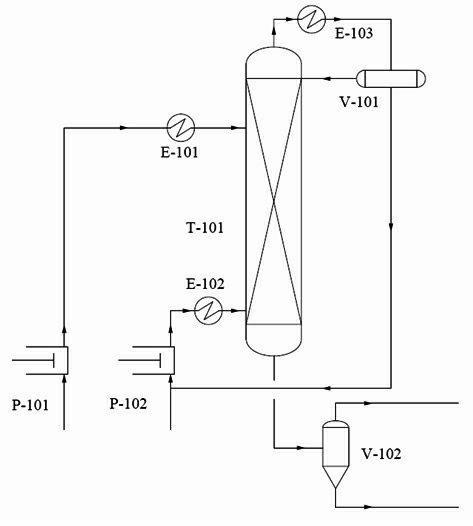

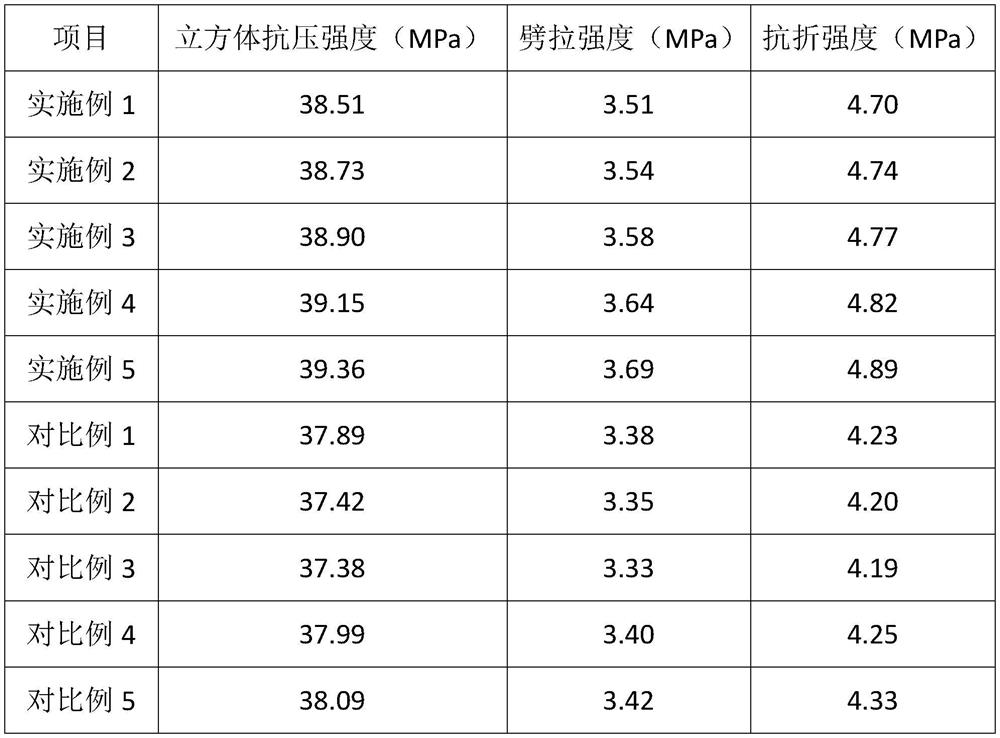

Recycled concrete and preparation method thereof

The invention discloses recycled concrete, which is characterized by being prepared from the following raw materials in parts by weight: 150-180 parts of cement, 250-300 parts of modified recycled aggregate, 400-450 parts of fine river sand, 5-10 parts of attapulgite, 1-3 parts of porous beta-cyclodextrin cross-linked polymer nanofibers, 50-65 parts of blast furnace slag, 1-3 parts of mullite fibers, 2-5 parts of diazoalkyl urea, 4-8 parts of sulfonate-terminated hyperbranched waterborne polyurethane emulsion, 2-4 parts of additives and 75-90 parts of water. The recycled concrete is prepared from the following raw materials in parts by weight: 2-4 parts of carboxyl-terminated liquid fluororubber and 1-3 parts of water-soluble hyperbranched epoxy resin. The invention also discloses a preparation method of the recycled concrete. The recycled concrete disclosed by the invention is excellent in comprehensive performance, high in strength, low in water absorption rate, good in durability and workability and good in workability.

Owner:曹均云

Concrete water reducer and preparation method thereof

The invention relates to a concrete water reducing agent. The concrete water reducing agent is characterized by being prepared from the following raw materials in parts by weight: 10 to 20 parts of acarboxyl modified N-vinyl carbazole / polyethylene glycol mono-allyl ether / 5-vinyl-1,2,4-oxadiazole-3-carboxylic acid ethyl ester copolymer, 5 to 10 parts of 3-aminopyrazine-2-carboxylic acid modified epoxy terminated hyperbranched poly(amine-ester), 2 to 4 parts of rare earth metal organic framework, 3 to 6 parts of N-sulfo chitosan and 30 to 40 parts of water. The invention also provides a preparation method of the concrete water reducing agent. The concrete water reducing agent is low in mixing amount, strong in water reducing performance and good in plasticizing effect, has no negative influence on the comprehensive performance of concrete, can obviously improve the flowability and the working performance of cement concrete of machine-made sand, improves the strength, the durability andthe thawing-freezing resistance of concrete, and is good in adaptability to the concrete.

Owner:苏州朗达材料科技有限公司

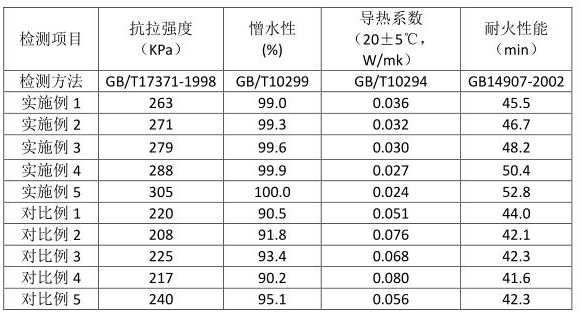

Building energy-saving thermal insulation material and preparation method thereof

The invention discloses a building energy-saving thermal insulation material, which is characterized being prepared from the following raw materials by weight: 15-25 parts of cement, 15-20 parts of blast furnace water granulated slag, 35-40 parts of volcanic ash, 5-8 parts of surface function modified porous hollow aluminum oxide nanofibers, 2-4 parts of rare earth fluoride hollow nano ions, 3-6 parts of Lambda-cyhalothric acid modified aminated beta-cyclodextrin and 1-3 parts of a coupling agent. The invention also discloses a preparation method of the building energy-saving thermal insulation material. The building energy-saving thermal insulation material disclosed by the invention is excellent in comprehensive performance, strong in thermal insulation property, good in aging resistance, weather resistance and flame retardance, excellent in performance stability and mechanical property, green and environment-friendly in use, high in durability, weather resistance, corrosion resistance, freeze thawing resistance and reliability, and wide in application range.

Owner:康亚男

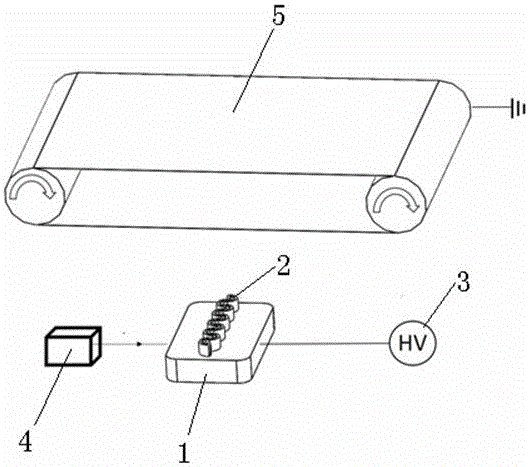

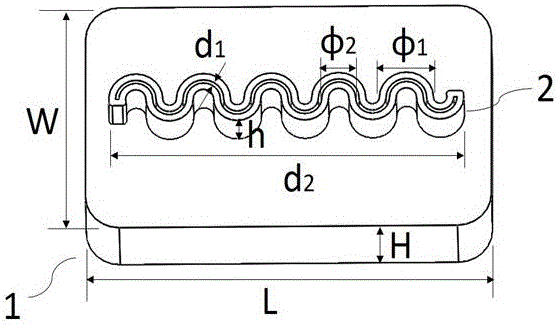

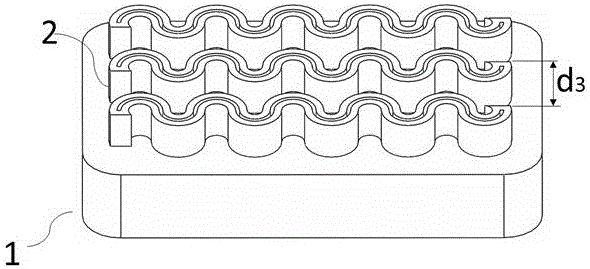

Electrostatic spinning nanofiber generating device

ActiveCN106757418AImprove stabilitySuitable for continuous large-scale productionFilament/thread formingViscous liquidFiber

The invention discloses an electrostatic spinning nanofiber generating device. The electrostatic spinning nanofiber generating device comprises a fiber generator, a fiber collecting device and a high-voltage generator, wherein the fiber generator comprises a spinning cavity, silk spray thread slots and a liquid storage tank; a slit is formed in each silk spray thread slot, and is communicated with the inner part of the spinning cavity; the liquid storage tank is communicated with the spinning cavity; each silk spray thread slot adopts a structure with twists and turns; the fiber collecting device is placed right above the silk spray thread slots; the high-voltage generator is provided with a high-voltage terminal and a ground terminal. According to the electrostatic spinning nanofiber generating device disclosed by the invention, nanofibers are produced by using viscous liquid as raw materials and utilizing an electrostatic spinning principle. Compared with the prior art, the core of the electrostatic spinning nanofiber generating device disclosed by the invention is the fiber generator with the bent slits; through the adoption of the fiber generator, the change of the concentration of spinning liquid, which is caused by solvent evaporation, is effectively inhibited, so that the producing stability of the nanofibers is greatly improved; besides, the uniformity and the production efficiency of produced fiber films are improved, so that the electrostatic spinning nanofiber generating device is suitable for the continuous scale production of nanofibers.

Owner:上海云同新材料科技有限公司

Concrete air entraining agent with good foam stability

The invention discloses a concrete air entraining agent with good foam stability. Characterized in that it is characterized in that it comprises, the feed additive is prepared from the following raw materials in parts by weight: 20 to 30 parts of a rosin-based hyperbranched surfactant, 5 to 10 parts of 1,4-cyclohexanedimethanol bis(3,4-epoxycyclohexaneformic acid)ester / 4,4-cyclohexanedimethanol bis(3,4-epoxycyclohexaneformic acid) ester, 0.1 to 1.5 parts of phytolaccaside C, 5 to 10 parts of 2-acrylic-hexahydro-4,7-methylene-1H-indenyl ester / 2-hydroxy-3-butenyl glucosinolate / vinyltrimethoxysilane / polyethylene glycol monoallyl ether copolymer, 8 to 15 parts of hyperbranched polyglycerol and 70 to 90 parts of water. The invention also discloses a preparation method of the concrete air entraining agent. The concrete air entraining agent disclosed by the invention is good in air entraining effect, good in compounding property with other additives and high in adaptability to concrete, and can effectively improve the bubble stability of fresh concrete, remarkably improve the strength of the concrete and improve the workability, durability and freezing resistance of the concrete.

Owner:石旭艳

Environment-friendly modified ABS composite plastic and preparation method thereof

The invention discloses an environment-friendly modified ABS composite plastic. The composite material is characterized by being prepared from the following components in parts by weight: 60-80 parts of ABS resin, 20-30 parts of mercaptotriazolyl polyamide, 6-10 parts of unsaturated hyperbranched polyamide, 3-5 parts of N-[4-cyano-3-(trifluoromethyl) phenyl] methyl epoxy acrylamide, 1-2 parts of an initiator, 4-6 parts of a plasticizer, 2-4 parts of a coupling agent and 5-8 parts of nano boron fibers. The invention also discloses a preparation method of the environment-friendly modified ABS composite plastic. The environment-friendly modified ABS composite plastic is remarkable in environment-friendly flame-retardant effect, excellent in weather resistance, heat resistance and mechanical properties, and good in durability and wear resistance.

Owner:董宪金

Environment-friendly plastic adhesive and preparation method thereof

InactiveCN112795341ASimple manufacturing methodEasy to operateNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyPolymer science

The invention discloses an environment-friendly plastic adhesive and a preparation method thereof. The adhesive comprises the following components in parts by weight: 5-8 parts of rosin-based hyperbranched epoxy resin, 3-5 parts of epoxidized SBS, 4-7 parts of filler, 12-20 parts of allyl furoate / N-vinyl caprolactam / N-trihydroxymethyl methacrylamide / N-(4-cyano-3-trifluoromethylphenyl)methacrylamide / trifluoroethyl methacrylate copolymer, 3-5 parts of isocyanate group ionized modified 2,5-bis(diethylamino)phenyl-1,3,4-diazole, 0-0.3 part of dibutyltin dilaurate and 70-80 parts of a mixed solvent. The invention also provides a preparation method of the environment-friendly plastic adhesive. The environment-friendly plastic adhesive provided by the invention is high in bonding strength, good in environmental protection property, durability and aging resistance, fast in curing, high in reliability and good in weather resistance and moisture resistance.

Owner:张攸

Wear-resistant ecological environment-friendly lubricating oil and preparation method thereof

The invention discloses wear-resistant ecological environment-friendly lubricating oil. The wear-resistant ecological environment-friendly lubricating oil is characterized by comprising the followingcomponents in parts by weight: 50 to 60 parts of base oil, 10 to 20 parts of single-ended epoxy polyether modified amine-terminated hyperbranched polyester, 3 to 7 parts of single-ended hydroxypropylsilicone oil modified black phosphorus, 0.5 to 1.5 parts of silicon boride, 0.2 to 0.5 part of a coupling agent, 0.5 to 1.3 parts of a viscous agent, 0.2 to 0.6 part of a dispersing agent and 0.4 to 1part of an antioxidant. The invention also discloses a preparation method of the wear-resistant ecological environment-friendly lubricating oil. The wear-resistant ecological environment-friendly lubricating oil disclosed by the invention is good in lubricating effect, good in compression resistance and wear resistance, excellent in stability and safe and environment-friendly to use.

Owner:江苏智摩金属抗磨修复有限责任公司

Environment-friendly plastic pipe and preparation method thereof

The invention discloses an environment-friendly plastic pipe which is characterized by being prepared from the following raw materials in parts by weight: 70-80 parts of benzophenone benzotriazolyl polyphenyl ether, 3-6 parts of benzidine disulfonic acid, 10-20 parts of hyperbranched sulfonated polyetheretherketone, 1-3 parts of epoxy SBS resin, 3-5 parts of epoxy plasticizer, 2-4 parts of 3-glycidyl ether oxypropyl triethoxysilane, 10-20 parts of inorganic fiber, 3-6 parts of antioxidant and 3-5 parts of phosphorus pentoxide. The invention further discloses a preparation method of the environment-friendly plastic pipe. The environment-friendly plastic pipe is excellent in wear resistance, flame retardance, environment friendliness, aging resistance, processability, mechanical property and performance stability.

Owner:姚计化

Anti-aging plastic material and preparation method thereof

The invention discloses a preparation method of an anti-aging plastic material. The preparation method is characterized by comprising the following steps: step S1, preparing 5-allyl-3-methoxysalicylic acid methyl ester / 2-[3-(2H-benzotriazol-2-yl)-4-hydroxyphenyl]ethyl methacrylate / 2-acrylamido-2-methylpropanesulfonic acid / acrylonitrile / lambda-cyhalothric acid copolymer; step S2, preparing a benzoguanamine / 2,5-bis(1,2,4-triazol-1-yl)terephthalic acid polycondensation polymer; and step S3, forming the plastic material. The invention also provides the anti-aging plastic material prepared according to the preparation method of the anti-aging plastic material. The anti-aging plastic material provided by the invention is good in comprehensive performance, good in performance stability and excellent in anti-aging performance, weather resistance and mechanical performance.

Owner:纪道红

Wear-resistant high-temperature-resistant high-strength composite material

The invention provides a wear-resistant high-temperature-resistant high-strength composite material. The composite material is prepared from the following components in parts by weight: 50-60 parts ofphenolic hydroxyl-terminated hyperbranched polyether ketone, 25-35 parts of a methacryloyloxypropylsilazane / trans-2-(4-chlorophenyl)vinylboric acid / 2, 3, 4, 5, 6-pentafluoro-1-vinylphenylsulfonate / allyltriethoxysilane / vinylsulfonic acid copolymer, 10-15 parts of cordierite-based glass fibers, 1-5 parts of nano boron fibers, 0.5-1.5 parts of phosphorus pentoxide, 1-3 parts of a basic catalyst, 0.8-1.8 parts of an antioxidant, 0.5-1.5 parts of a lubricant and 3-5 parts of a flexibilizer. The invention also discloses a preparation method of the wear-resistant high-temperature-resistant high-strength composite material. The wear-resistant high-temperature-resistant high-strength composite material disclosed by the invention is good in mechanical property, good in wear resistance and weather resistance, excellent in high-temperature resistance and performance stability and long in service life.

Owner:邓华斌

Blast furnace gas organic sulfur removal method

PendingCN111909734AEasy to removeSafe removalGas contaminants removalProcess engineeringEnvironmental engineering

The invention relates to a blast furnace gas organic sulfur removal method, which is characterized by comprising the following steps: S1, primarily filtration of blast furnace gas; s2, absorption by an absorption tower; s3, desorptive regeneration; and S4, desorptive regeneration again. The invention also discloses the desulfurized blast furnace gas prepared according to the blast furnace gas organic sulfur removal method. The method for removing the organic sulfur from the blast furnace gas is simple in process, easy to operate, suitable for continuous large-scale production, capable of rapidly, safely and efficiently removing the organic sulfur from the blast furnace gas, good in removal effect, high in efficiency, small in secondary pollution and capable of achieving organic unificationof economic benefits, social benefits and ecological benefits.

Owner:国家电投集团远达环保装备制造有限公司

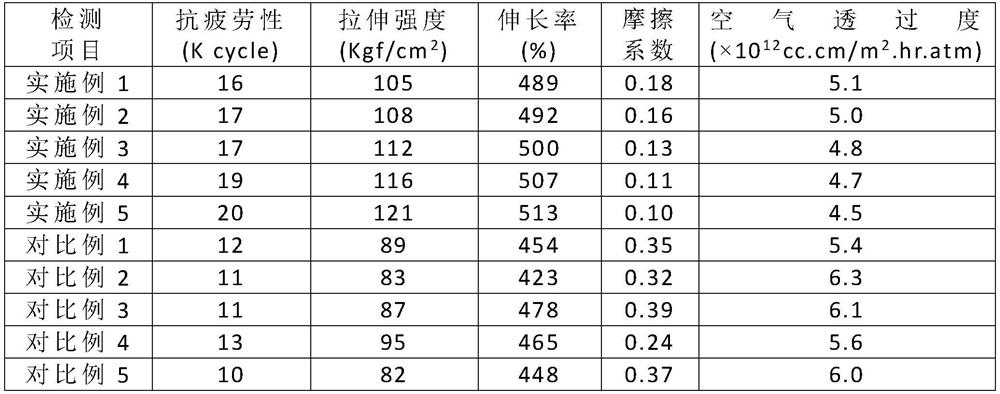

Environment-friendly tire rubber material and preparation method thereof

The invention discloses an environment-friendly tire rubber material and a preparation method thereof. The material is prepared from the following components in parts by weight: 30-40 parts of sulfonamide / carboxyl-terminated liquid fluororubber polycondensate, 10-15 parts of castor oil-based hyper-branched epoxy resin, 40-60 parts of diacetone acrylamide / N-(4-cyano-3-trifluoromethylphenyl) methacrylamide / 2-(ethyleneoxy) ethylamine / 4-acyl-18 crown ether-6 copolymer, 15-25 parts of fly ash 4-8 parts of graphene hollow nano fibers, 3-5 parts of a vulcanizing agent, 1-3 parts of a vulcanization accelerator and 1-2 parts of a coupling agent. The invention also discloses a preparation method of the environment-friendly tire rubber material. The environment-friendly tire rubber material disclosedby the invention is excellent in environmental protection property and fatigue resistance, and good in mechanical property, road holding property, wear resistance, air tightness and performance stability.

Owner:王玉龙

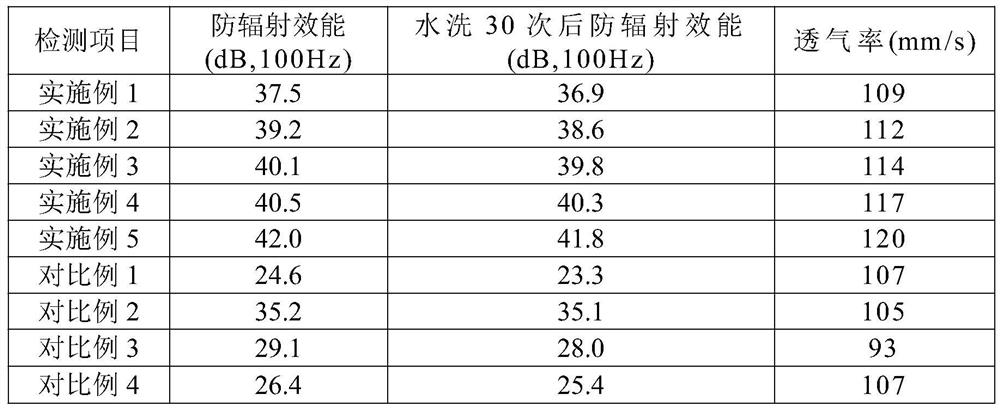

Radiation-proof breathable antibacterial fabric

InactiveCN112030554ASimple preparation processEasy to operate and controlCarbon fibresLight resistant fibresPolymer scienceHyperbranched polyester

The invention provides a radiation-proof breathable antibacterial fabric. The fabric is characterized by comprising a base cloth layer and a weather-proof breathable functional layer arranged on the base cloth layer, and the base cloth layer is formed by weaving warp yarn and weft yarn; the warp yarn is nano-silver modified graphene fibers; the weft yarn is functional synthetic fibers; the functional synthetic fibers are prepared from the following raw materials in parts by weight of 10-20 parts of carboxyl-terminated hyperbranched polyester, 50-70 parts of polyester chips, 1-3 parts of cationic modified hydroxylated fullerene, 2-5 parts of graphene-coated nano aluminum powder and 1-3 parts of a coupling agent; and the coupling agent is at least one of a silane coupling agent KH550, a silane coupling agent KH560 and a silane coupling agent KH570. The invention further discloses a preparation method of the radiation-proof breathable antibacterial fabric. The radiation-proof breathable antibacterial fabric disclosed by the invention is good in skin affinity, remarkable in electromagnetic-radiation-proof effect, good in durability, breathability and wearing comfort, excellent in comprehensive performance and low in preparation cost.

Owner:朱建余

Environment-friendly fireproof coating and preparation method thereof

InactiveCN111995922AShort processEasy to operateFireproof paintsAnti-corrosive paintsPhosphoric Acid EstersPolymer science

The invention discloses an environment-friendly fireproof coating, the coating is prepared from the following components in parts by weight: 10-20 parts of vinyl-modified hyperbranched polyphosphate,5-10 parts of acrylate-modified p-aminophenyl calixpyrrole, 50-70 parts of 1, 3-bis (oxiranylmethyl)-5-(2-propenyl)-1, 3, 5-triazine-2, 4, 6 (1H, 3H, 5H)-triketone / 3, 3 '-diamino-4, 4'-difluorodiphenyl sulfone polycondensate, 0.5-1.5 parts of an initiator, 15-25 parts of an inorganic filler, 1-3 parts of a defoamer and 1-3 parts of a dispersant. The invention also provides a preparation method ofthe environment-friendly fireproof coating. The environment-friendly fireproof coating disclosed by the invention is good in comprehensive performance, remarkable in fireproof and flame-retardant effects, good in water resistance, decoration and storage stability, environment-friendly and pollution-free.

Owner:邵敏

Preparation method of regenerated fiber fabric

ActiveCN111118724AImprove performanceGood performance and stabilityWarp knittingConjugated synthetic polymer artificial filamentsPolyesterFiber

The present invention relates to a preparation method of a regenerated fiber fabric. The method comprises the following steps of (1) raw material warping, wherein regenerated semi-dull FDYs and modified regenerated DTYs are warped by a warping machine, because regenerated fiber raw material yarns have the relatively high hardness, the resistance of a tension device is set to be 6 in the warping process to ensure the flatness of the yarns in the warping process, and the warped raw materials are store for 24-30 h and then are conveyed to a weaving workshop for use; (2) weaving and slitting, wherein the warped raw materials in the step (1) are woven by a warp knitting machine in proportion to obtain a gray fabric, and slitting is performed to obtain a slit gray fabric; and (3) after-finishing, wherein the prepared gray fabric in the step (2) is subjected to white body carding, ironing and pre-setting process treatment, and then dyeing, softening, fabric arranging, plush hot air treatment,napping, carding, ironing and shearing are performed to prepare the finished fabric. The preparation method is simple and feasible, recycling of waste polyester fabrics can be realized in a high-speed, quick an efficient manner, and wastes are turned into wealth.

Owner:CHANGSHU XINXIN WARP & KNITTING

Antibacterial and mildew-proof fabric

InactiveCN111607889ASimple manufacturing methodSuitable for continuous large-scale productionWeft knittingMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention provides an antibacterial and mildew-proof fabric. The antibacterial and mildew-proof fabric is characterized in that a preparation method of the antibacterial and mildew-proof fabric comprises the following steps of: S1, preparing an aloe neoglycoside D / N-[4-(sulfonamide) phenyl ] acrylamide / (Z)-2-(2-aminothiazole-4-yl)-2-pentenoic acid / enadenine copolymer; S2, preparing copolymer fibers; S3, weaving; and S4, carrying out after-finishing. The antibacterial and mildew-proof fabric disclosed by the invention has excellent comprehensive performance, remarkable antibacterial andmildew-proof effects, good weather resistance, antistatic property, air permeability and moisture absorption performance and wearing comfort, and has relatively high economic value and social value.

Owner:江兰春

Green and environment-friendly UV coating and preparation method thereof

The invention discloses a green and environment-friendly UV coating. The composition comprises the following components in parts by weight: 25-35 parts of polymerized water-soluble hyperbranched polyamide, 10-15 parts of N, N-dimethylformamide. N, N'-bis(2-ethoxyl)-N, N'-bis(trimethoxysilylpropyl)-ethylenediamine / 2, 3'-difluoro fumarate oligomer, 1-2 parts of 2-(5-phenyl-1H-tetrazole-1-base)-3-thiophene-crylic acid, 3-5 parts of an aqueous photoinitiator, 10-20 parts of inorganic filler, 0.5-1.5 parts of a dispersing agent, 0.3-0.6 parts of a flatting agent, 0.4-0.8 parts of a defoamer, 1-2 parts of an emulsifier and 10-20 parts of water. The invention further discloses a preparation method of the green and environment-friendly UV coating. The green and environment-friendly UV coating disclosed by the invention is excellent in comprehensive performance, good in mechanical property, performance stability, weather resistance, water resistance and fire resistance, high in adhesive force to a base material, safe to use and environment-friendly.

Owner:肇庆英克斯化工有限公司

Environment-friendly water-based adhesive and preparation method thereof

InactiveCN111117555ASimple manufacturing methodEasy constructionNon-macromolecular adhesive additivesRosin adhesivesMeth-Adhesive

The invention discloses an environment-friendly water-based adhesive. The water-based adhesive comprises the following raw materials in parts by weight: 30-40 parts of acrylic acid modified amino-terminated water-soluble hyperbranched polyamide, 10-15 parts of (chloromethyl)boronic acid pinacol ester ionic-modified N,N'-bis(2-hydroxyethyl)-N,N'-bis(trimethoxysilylpropyl)ethylenediamine / hydrogenated acrylic acid rosin, -3-6 parts of triethoxysilyl propyl maleic acid, 5-10 parts of polyethylene glycol diacrylate, 4-8 parts of attapulgite, 1-3 parts of fullerene-based carbon quantum dots, 0.5-1.5parts of an emulsifier, 25-35 parts of deionized water, 3-6 parts of a cosolvent, 1-3 parts of a photoinitiator and 0.5-1 part of a coupling agent. The invention also discloses a preparation method of the environment-friendly water-based adhesive. The environment-friendly water-based adhesive disclosed by the invention has the advantages of good water resistance, higher peel strength, sufficientinitial adhesion, excellent water resistance and weather resistance, good storage and transportation stability, safer use process, greenness, environmental protection and high economic value, social value and ecological value.

Owner:庄明磊

Fair-faced concrete and preparation method thereof

InactiveCN112341076ASimple manufacturing methodEasy to operate and controlAggregate (composite)Metal-organic framework

The invention discloses fair-faced concrete and a preparation method thereof. The concrete is prepared from the following components in parts by weight: 30-40 parts of cement, 15-25 parts of volcanicash, 3-6 parts of nano hybrid hyperbranched polymer HB-SiO2, 75-85 parts of silica sand, 85-95 parts of coarse aggregate, 3-5 parts of basalt fibers, 1-3 parts of graphene oxide fibers, 7.5-8.5 partsof a composite additive, 15-20 parts of water, 1-3 parts of a carboxyl metal organic framework, 1-3 parts of zirconium citrate and 2-5 parts of zinc oxide nanofibers. The invention also provides a preparation method of the fair-faced concrete. The fair-faced concrete provided by the invention is better in comprehensive performance, higher in compressive strength and flowability, lower in bleedingrate, better in durability, environmental protection property and decorative effect, very good in appearance, smooth in surface and less in pores.

Owner:韩昌龙

Environment-friendly putty powder and preparation method thereof

InactiveCN111849238ASimple manufacturing methodReduce manufacturing costFilling pastesEpoxyPolymer science

The invention discloses environment-friendly putty powder which is characterized in comprising the following components in parts by weight: 20-30 parts of palygorskite, 10-20 parts of montmorillonite,15-20 parts of white cement, 1-3 parts of lambda-carrageenan modified polyquaternium-10, 2-4 parts of rosin modified cationic guar gum, 1-3 parts of konjac gum, 0.5-1.5 parts of epoxy-terminated hyperbranched polyphosphate and 0.5-1.5 parts of amino-terminated hyperbranched polybenzimidazole. The invention further provides a preparation method of the environment-friendly putty powder. The environment-friendly putty powder disclosed by the invention is good in comprehensive performance, sufficient in strength and adhesive force, high in hardness, good in water resistance, free of phenomena ofhollowing, peeling, cracking and falling off after being wetted by water, and safe and environment-friendly to use.

Owner:刘超

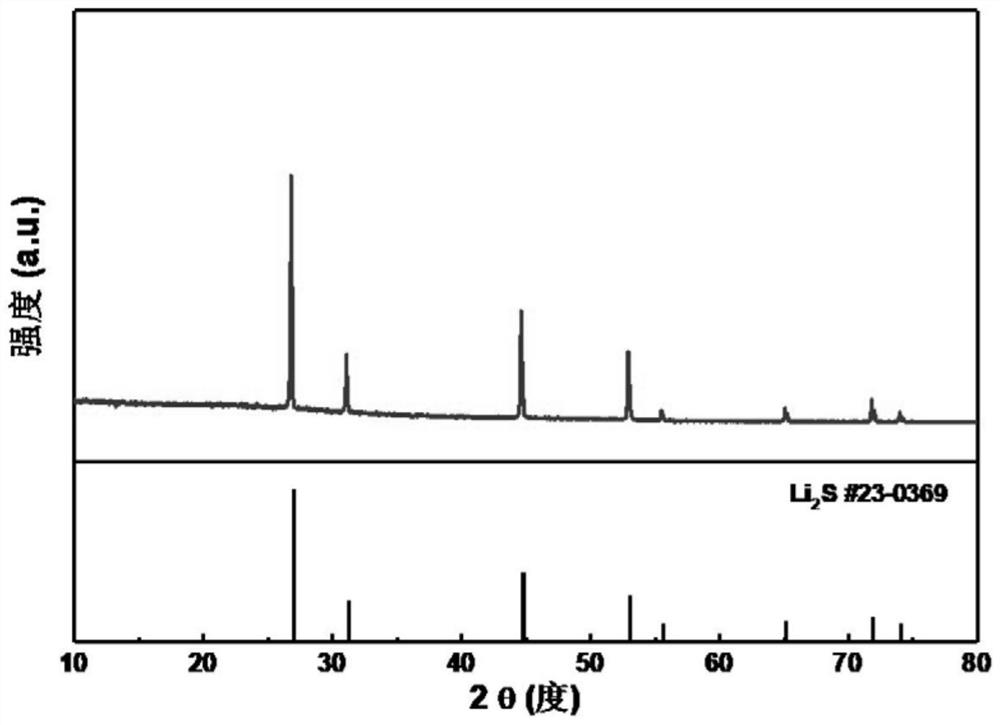

Method for preparing lithium sulfide from lithium sulfate

ActiveCN112520763AGuaranteed purityNo handling issuesLithium compoundsSecondary cellsLithium sulphateMaterial synthesis

The invention belongs to the technical field of material synthesis, and particularly relates to a method for preparing lithium sulfide from lithium sulfate. Aiming at the common defects of high price,difficulty in purity guarantee and the like of commercial lithium sulfide, the invention discloses a method for preparing high-purity lithium sulfide by using a simple heating method, lithium hydrideand lithium sulfate are used as raw materials, the lithium sulfide powder can be obtained through simple processes of heating, heat preservation, purification and the like, the method is simple and rapid, and the lithium sulfide with relatively high purity can be prepared at low cost.

Owner:ZHEJIANG UNIV OF TECH

Heat-preservation and heat-insulation macromolecular environment-friendly material and preparation method thereof

The invention discloses a heat-preservation and heat-insulation macromolecular environment-friendly material which is characterized by being prepared from the following raw materials in parts by weight: 80-100 parts of linear thermoplastic phenolic resin, 35-45 parts of 4-chlorobenzene chloromethyldimethylsilane modified 1, 3-bis (oxiranylmethyl)-5-(2-propenyl)-1, 3, 5-triazine-2, 4, 6 (1H, 3H, 5H)-trione / diniconazole / 1-(4-chlorophenyl) vinylboronic acid pinacol ester / 4-triethoxysilyl vinylbenzocyclobutene copolymer, 5-8 parts of a foaming agent, 2-5 parts of a basic catalyst, 1-3 parts of anantioxidant, 5-10 parts of a plasticizer, 15-25 parts of a solid waste-based porous material, 3-5 parts of cordierite powder and 2- 5 parts of a coupling agent. The invention further discloses a preparation method of the heat-preservation and heat-insulation macromolecular environment-friendly material. The heat-preservation and heat-insulation macromolecular environment-friendly material disclosed by the invention is excellent in comprehensive performance, remarkable in heat preservation and insulation effect, low in manufacturing cost, good in environment friendliness, excellent in fire resistance, flame retardance, high temperature resistance, weather resistance and mechanical property and high in economic value, social value and ecological value.

Owner:HUNAN CHENLI NEW MATERIAL CO LTD

Heating anti-pilling fabric

ActiveCN112064168ASimple manufacturing methodEasy to operate and controlWoven fabricsMonocomponent polyesters artificial filamentEpoxyPolymer science

The invention discloses heating anti-pilling fabric. The fabric is characterized by being formed by weaving warp yarns and weft yarns; the warp yarns are blended yarns of heating fiber and wool fiber;the weft yarns are blended yarns of viscose fiber and functional heating fiber; and the functional heating fiber is prepared from the following raw materials in parts by weight: 60-70 parts of polyester chips, 2-5 parts of opal powder, 3-6 parts of graphene oxide fiber, 1-3 parts of rare earth oxide La<2>Zr<2>O<7> nanostructure fiber, 2-4 parts of hydroxyl-terminated nano hybrid hyperbranched polymer, 5-10 parts of epoxy-terminated amino hyperbranched poly (amine-ester), 1-3 parts of surface-coated butyl stearate, 0.5-1.5 parts of diallyl terephthalate, 0.3-0.6 part of an initiator and 1-2 parts of a coupling agent. The invention further provides a preparation method of the heating anti-pilling fabric. The heating anti-pilling fabric is good in comprehensive performance, remarkable in heating effect, good in performance stability, durable, comfortable to wear and excellent in hygroscopicity and skin affinity.

Owner:GEFENG GARMENTS CO LTD

Environment-friendly waterproof material and preparation method thereof

The invention discloses an environment-friendly waterproof material which is characterized by being prepared from the following raw materials in parts by weight: 30-50 parts of 3, 6-dibromo-9-vinyl carbazole / bisphenol S polycondensate, 15-20 parts of vinyl-terminated polyurethane prepolymer modified coal pitch, 10-15 parts of vinyl-terminated nitrile rubber, 3-6 parts of hyperbranched polysiloxaneand 0.07-0.1 part of initiator. The invention also provides a preparation method thereof. The environment-friendly waterproof material disclosed by the invention is good in comprehensive performance,remarkable in waterproof effect, good in performance stability, weather resistance and high and low temperature resistance, and relatively small in environmental pollution.

Owner:郭琳

Special environment-friendly high polymer material for optical cable and preparation method thereof

InactiveCN112920493AImprove production efficiencyImprove the qualified rate of finished productsPolymer scienceAcrylonitrile

The invention discloses a special environment-friendly high polymer material for optical cables, and the material is characterized in that the material is prepared from the following components in parts by weight: 15 to 25 parts of acrylonitrile ionized modified poly (2, 5-bis (1, 2, 4-triazole-1-yl) terephthalic acid 2, 3, 5, 6-tetrafluoroterephthalyl alcohol ester, 60 to 70 parts of high-density polyethylene, 10 to 15 parts of fluorine-containing hyperbranched polyethylene copolymer, 5 to 8 parts of vinyl hyperbranched polyurethane, 1.5 to 2.5 parts of 3, 4, 5-trifluorophenylboronic acid, 1 to 2 parts of initiator and 0.5 to 1.0 part of an antioxidant. The invention further provides a preparation method of the special environment-friendly high polymer material for the optical cable. The special environment-friendly high-molecular material for the optical cable, disclosed by the invention, is excellent in comprehensive performance, performance stability, flame retardance, aging resistance, heat resistance, impact resistance and mechanical property.

Owner:余光明

Environment-friendly building board and preparation method thereof

The invention discloses an environment-friendly building board, which is prepared from the following raw materials in parts by weight: 20 to 30 parts of waste thermoplastic ABS plastic, 60 to 80 partsof modified 9-fluorenone-2,7-dicarboxylic acid / 3,6-diaminocarbazole polycondensate, 10 to 15 parts of 1,3-divinyltetraethoxydisilane modified glass fiber / mullite fiber composite material, 1 to 3 parts of an initiator, 2 to 4 parts of probenazole and 5 to 10 parts of a plasticizer. The invention further discloses a preparation method of the environment-friendly building board. The environment-friendly building board disclosed by the invention has the advantages of excellent comprehensive performance, good performance stability, excellent flame retardance and weather resistance, high strength,high toughness, long service life and good environment friendliness.

Owner:郭琳

Composite nanofiltration membrane and preparation method thereof

InactiveCN112058105ASimple manufacturing methodImprove production efficiencyMembranesReverse osmosisNanofiltrationOrganic chemistry

The invention discloses a preparation method of a composite nanofiltration membrane, which is characterized by comprising the following steps: S1, modifying amino-modified fullerene with quaternary ammonium salt 15; S2, preparing a primary product of the composite nanofiltration membrane; and S3, preparing a composite nanofiltration membrane finished product. The invention also provides the composite nanofiltration membrane prepared according to the preparation method of the composite nanofiltration membrane. The composite nanofiltration membrane disclosed by the invention is excellent in rejection rate, water flux and pollution resistance, good in mechanical property and performance stability and wide in application range.

Owner:CHENGDU ZHIA TECH CO LTD

Self-cleaning flame-retardant corrosion-resistant fluorosilicone powder coating

ActiveCN111925707AWide variety of sourcesLow equipment requirementsFireproof paintsAntifouling/underwater paintsMeth-Boronic acid

The invention discloses a self-cleaning flame-retardant corrosion-resistant fluorine-silicon powder coating. The coating is prepared from the following components in parts by weight: 50-60 parts of afilm-forming copolymer, 4-8 parts of amino-terminated hyperbranched compound quaternary ammonium salt, 1-3 parts of lignosulfonic acid, 0.1-0.2 part of phosphorus pentoxide, 3-7 parts of a functionalaid, 10-15 parts of an inorganic filler and 1-3 parts of rare earth fluoride nanofibers, wherein the film-forming copolymer is prepared from 2-trimethylsiloxy-1,1,1,5,5,5-hexafluoro-2-penten-4-one, (E)-4-(2-cyano-3-ethoxy-3-oxo-1-propenyl)phenylboronic acid pinacol ester, trimethyl 4-phosphonobutenoate, N-hydroxysuccinimide methacrylate and 1,3-bis(oxiranylmethyl)-5-(2-propenyl)1,3,5-triazinyl-2,4,6(1H,3H,5H)-trione through a free radical polymerization reaction. The powder coating disclosed by the invention is remarkable in self-cleaning effect, good in performance stability, corrosion resistance, weather resistance, wear resistance, film-forming property and flame retardance, excellent in bonding property with a base material, superior in comprehensive performance, and safe and environment-friendly to use.

Owner:东莞市正荣实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com