Recycled concrete and preparation method thereof

A technology of recycled concrete and recycled aggregate, which is applied in the field of building materials, can solve the problems that the performance improvement effect of recycled concrete needs to be further improved, the interface effect and compatibility are not good, etc., and is beneficial to environmental protection, social benefits and ecological benefits. High, powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

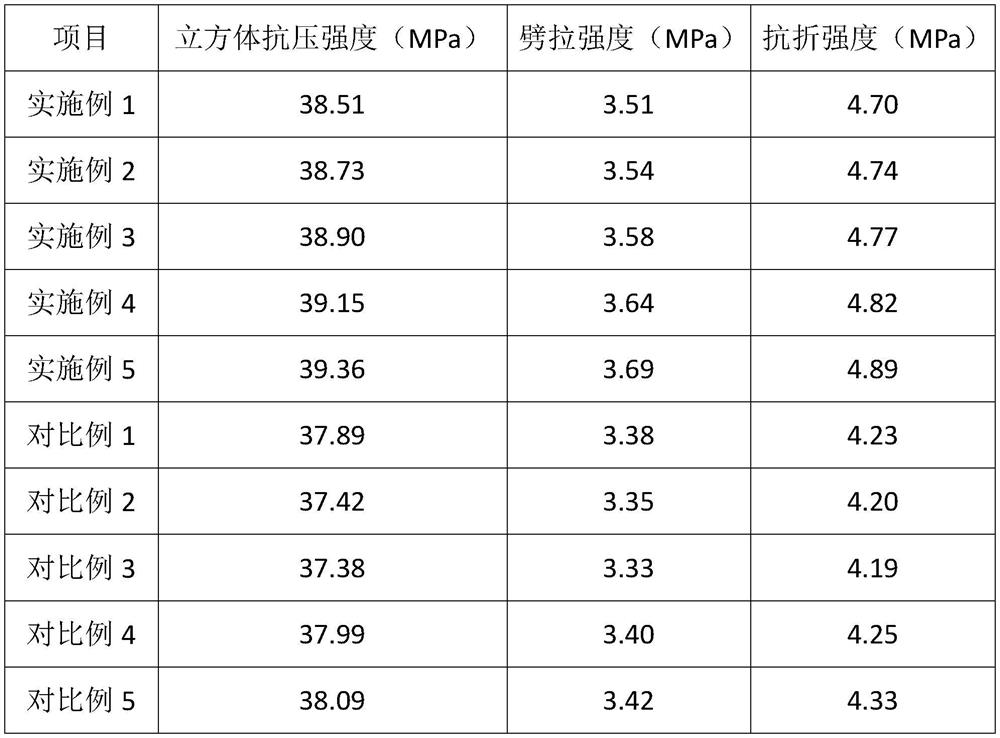

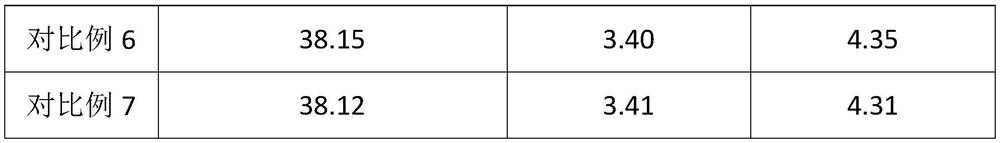

Examples

Embodiment 1

[0032] A recycled concrete is characterized in that it is made of the following raw materials in parts by weight: 150 parts of cement, 250 parts of modified recycled aggregate, 400 parts of fine river sand, 5 parts of attapulgite, porous β-cyclopaste 1 part of fine cross-linked polymer nanofiber, 50 parts of blast furnace slag, 1 part of mullite fiber, 2 parts of diazolidinyl urea, 4 parts of terminal sulfonate type hyperbranched water-based polyurethane emulsion, 2 parts of admixture, 75 parts of water share.

[0033] The raw materials for preparing the recycled concrete also include: 2 parts of carboxyl-terminated liquid fluororubber and 1 part of water-soluble hyperbranched epoxy resin.

[0034] The cement is Portland cement with a label of 52.5; the admixture is LEX-9P admixture.

[0035] The preparation method of the modified recycled aggregate comprises the following steps: stirring and breaking up the recycled aggregate obtained after sorting, cleaning, crushing and si...

Embodiment 2

[0039] A recycled concrete is characterized in that it is made of the following raw materials in parts by weight: 160 parts of cement, 260 parts of modified recycled aggregate, 410 parts of fine river sand, 6 parts of attapulgite, porous β-cyclopaste 1.5 parts of fine cross-linked polymer nanofiber, 55 parts of blast furnace slag, 1.5 parts of mullite fiber, 3 parts of diazolidinyl urea, 5 parts of terminal sulfonate type hyperbranched water-based polyurethane emulsion, 2.5 parts of admixture, 80 parts of water share.

[0040] The raw materials for preparing the recycled concrete also include: 2.5 parts of carboxyl-terminated liquid fluororubber and 1.5 parts of water-soluble hyperbranched epoxy resin.

[0041] The cement is Portland cement with a label of 52.5R; the admixture is LEX-9P admixture.

[0042] The preparation method of the modified recycled aggregate comprises the following steps: stirring and breaking up the recycled aggregate obtained after sequentially sorting...

Embodiment 3

[0046] A recycled concrete is characterized in that it is made of the following raw materials in parts by weight: 165 parts of cement, 280 parts of modified recycled aggregate, 430 parts of fine river sand, 7.5 parts of attapulgite, porous β-cyclopaste 2 parts of fine cross-linked polymer nanofibers, 57 parts of blast furnace slag, 2 parts of mullite fiber, 3.5 parts of diazolidinyl urea, 6 parts of terminal sulfonate type hyperbranched water-based polyurethane emulsion, 3 parts of admixture, 83 parts of water share.

[0047] The raw materials for preparing the recycled concrete also include: 3 parts of carboxyl-terminated liquid fluororubber and 2 parts of water-soluble hyperbranched epoxy resin.

[0048] The cement is Portland cement with a label of 62.5; the admixture is LEX-9P admixture.

[0049] The preparation method of the modified recycled aggregate comprises the following steps: stirring and breaking up the recycled aggregate obtained after sequentially sorting, clea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com