Method for preparing lithium sulfide from lithium sulfate

A lithium sulfate and lithium sulfide technology, applied in chemical instruments and methods, lithium compounds, inorganic chemistry, etc., can solve the problems of cumbersome preparation methods and high prices of lithium sulfide, and achieve the effects of easy control of the reaction, simple steps and low reaction temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

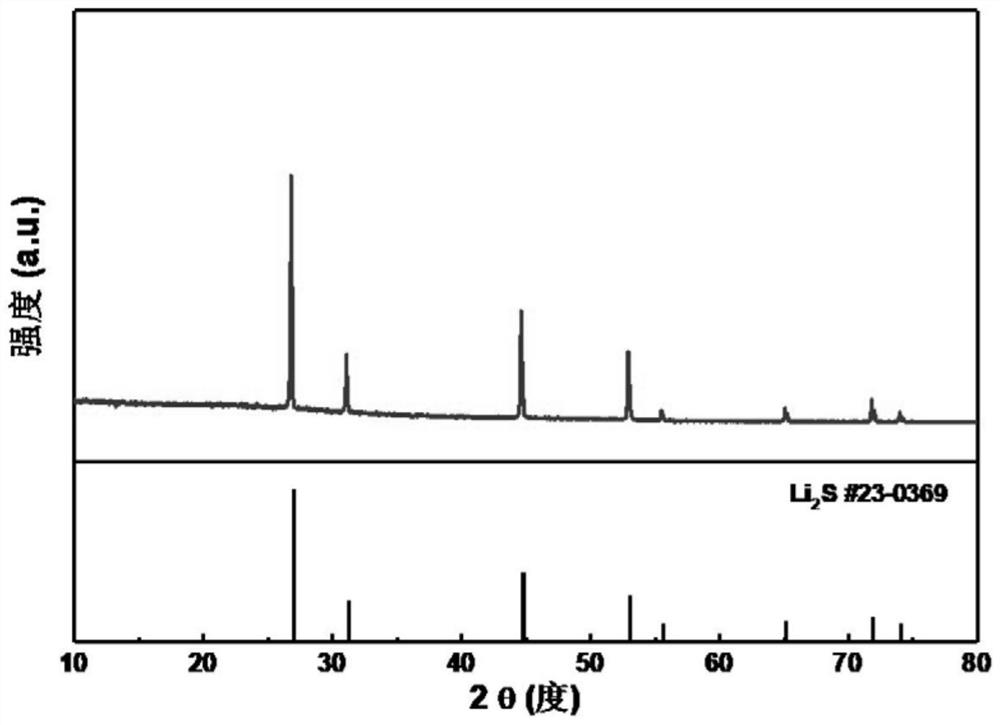

[0026] Under the protection of argon atmosphere, weigh lithium hydride and lithium sulfate in a molar ratio of 8:1, pour them into an agate mortar and mix thoroughly, then transfer them to the reactor and heat to 500°C at a heating rate of 2°C / min. , keep the temperature for 2h, cool down to room temperature after the reaction is completed, extract the gas in the reactor and reach a vacuum state, transfer it to an argon protective atmosphere, open the reactor, and take out the powder to obtain a powder containing lithium sulfide. Then, the above powder is dissolved with absolute ethanol, and the filtrate is heated at 50°C for 10 h after suction filtration to evaporate, and then the lithium sulfide powder can be obtained. figure 1 According to its corresponding X-ray diffraction pattern, the obtained product is a single phase of lithium sulfide.

Embodiment 2

[0028] Under the protection of argon atmosphere, weigh lithium hydride and lithium sulfate in a molar ratio of 8:2, pour them into an agate mortar and mix thoroughly, then transfer them to the reactor and heat to 200°C at a heating rate of 1°C / min. , keep the temperature for 100h, cool down to room temperature after the reaction is completed, extract the gas in the reactor and reach a vacuum state, transfer it to an argon protective atmosphere, open the reactor, and take out the powder to obtain a powder containing lithium sulfide. Then, the above powder was dissolved in absolute ethanol, and after suction filtration, the filtrate was heated at 80° C. for 1 h to evaporate, and then the lithium sulfide powder was obtained.

Embodiment 3

[0030] Under the protection of helium atmosphere, weigh lithium hydride and lithium sulfate in a molar ratio of 8:0.5, pour them into an agate mortar and mix thoroughly, then transfer them to the reactor and heat to 800°C at a heating rate of 5°C / min. , kept for 1 h, cooled to room temperature after the reaction, pumped out the gas in the reactor and reached a vacuum state, transferred it to a helium protective atmosphere, opened the reactor, and took out the powder to obtain a powder containing lithium sulfide. Then, the above powder was dissolved in absolute ethanol, and after suction filtration, the filtrate was heated at 60° C. for 5 h to evaporate, and then the lithium sulfide powder was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com