Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "No handling issues" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

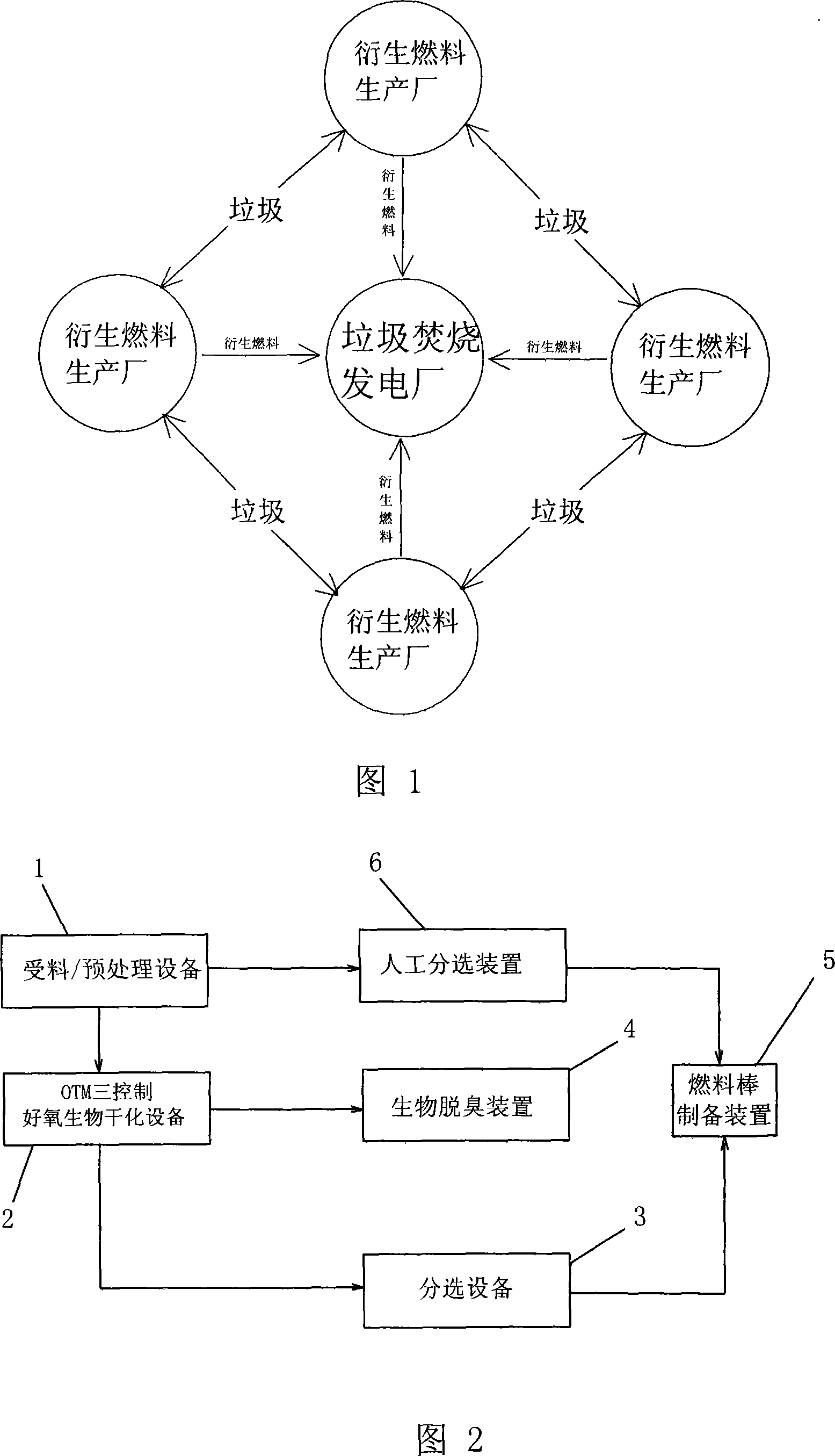

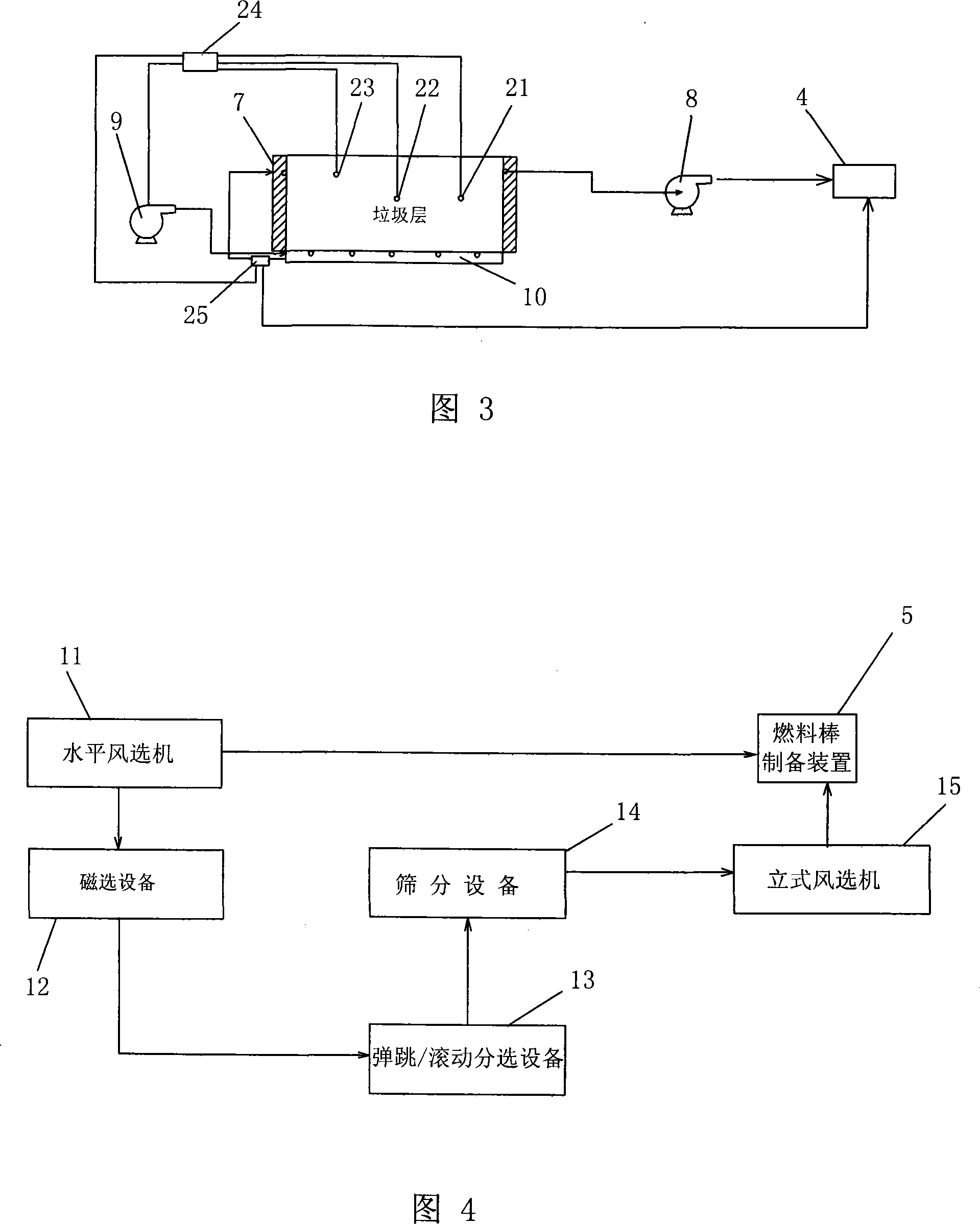

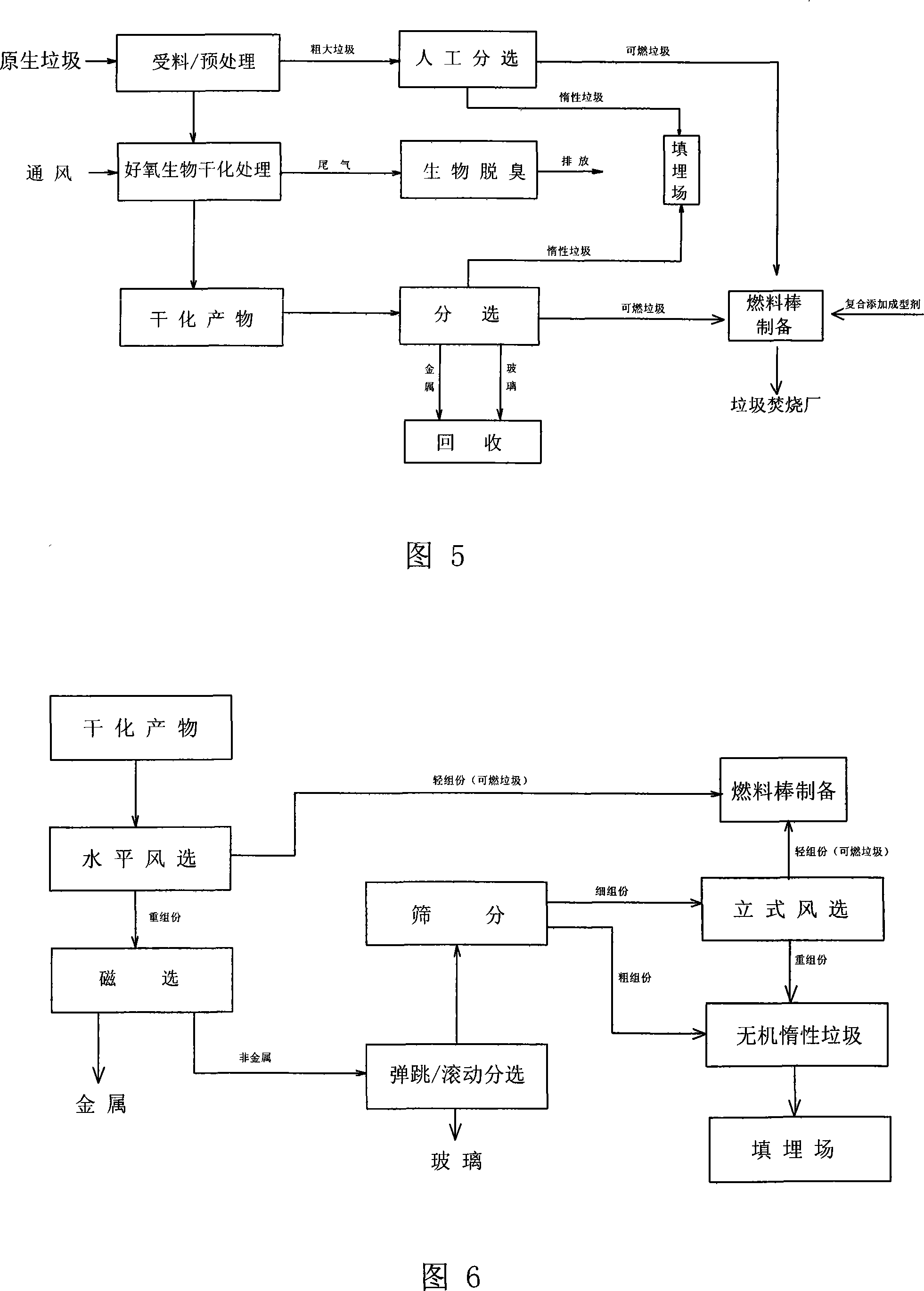

Method for sectional processing living garbage

ActiveCN101168163AAchieve reductionImprove incineration effectSolid waste disposalBiofuelsEnvironmental engineeringRefuse Disposals

The invention discloses a method of sectioned refuse treatment, which is first transmitting domestic garbage to a plurality of derivative fuel preparation factories arranged around a burning factory, employing biological anhydration to prepare for derivative fuel in each derivative fuel preparation factory, and then transferring derivative fuel to the burning factory for burning. The treating method of employing biological anhydration fuel burning burns anhydration garbage into a technique conforms to burning for energy making requirement of foreign relax derivative fuel (RDF), thereby reducing unit refuse treatment investment, decreasing unit refuse treatment cost, and increasing treatment profit and environmental profit. What is more important, the treatment mode of the invention is capable of realizing combination of relax and anhydration treatment and collective burning of refuse, which provides a novel method for refuse integrated treatment of city and countryside.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION TECHCAL DEV BEIJING +2

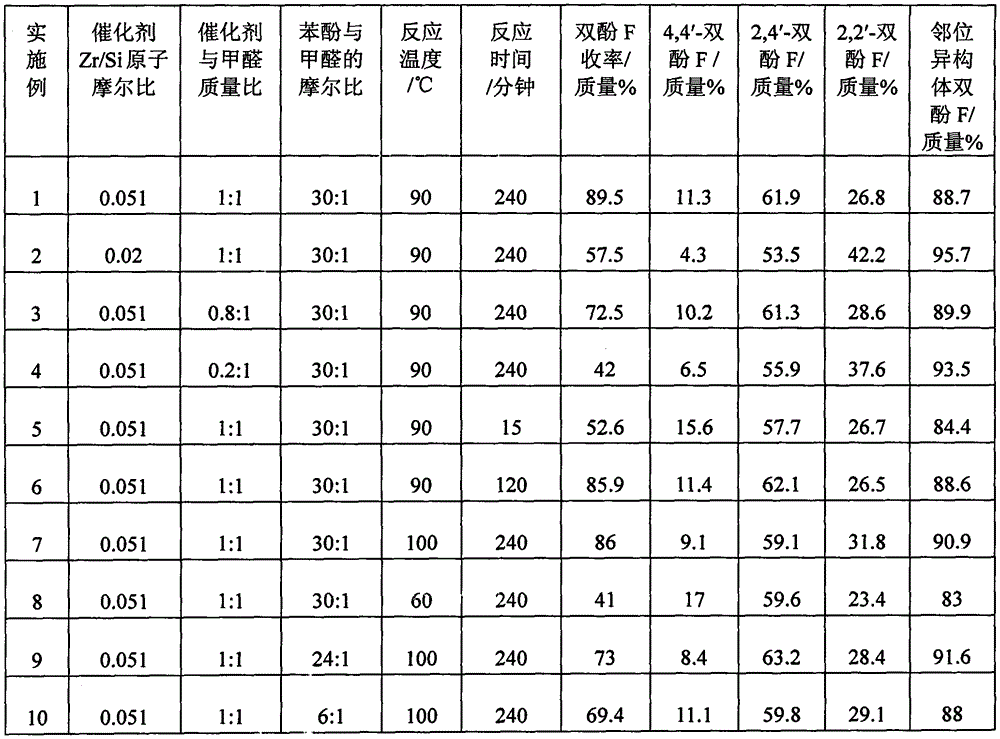

Preparation method of bisphenol F with high ortho-isomeride content

InactiveCN104130109AHigh ortho contentEasy to makeOrganic chemistryOrganic compound preparationMolecular sieveWastewater

The invention discloses a preparation method of bisphenol F with high ortho-isomeride content. The preparation method comprises the following step: through an acidic mesoporous molecular sieve Zr-SBA-15 catalyst, catalyzing phenol and formaldehyde aqueous liquor with the mass percentage of 35-40%, to synthesize the bisphenol F, wherein the adopted acidic mesoporous molecular sieve Zr-SBA-15 catalyst is synthesized in one step, and the activity of the catalyst can be regulated by regulating the mole ratio of Zr / Si atoms of the catalyst. The preparation method is simple in technology, high in catalysis efficiency, the bisphenol F with high ortho-isomeride content can be obtained, the catalyst is easily separated and recovered and repeatedly used, and no equipment corrosion and waste water treatment problems exist, so that the preparation method is an environment-friendly high-efficiency preparation method of the bisphenol F with high ortho content.

Owner:XIANGTAN UNIV

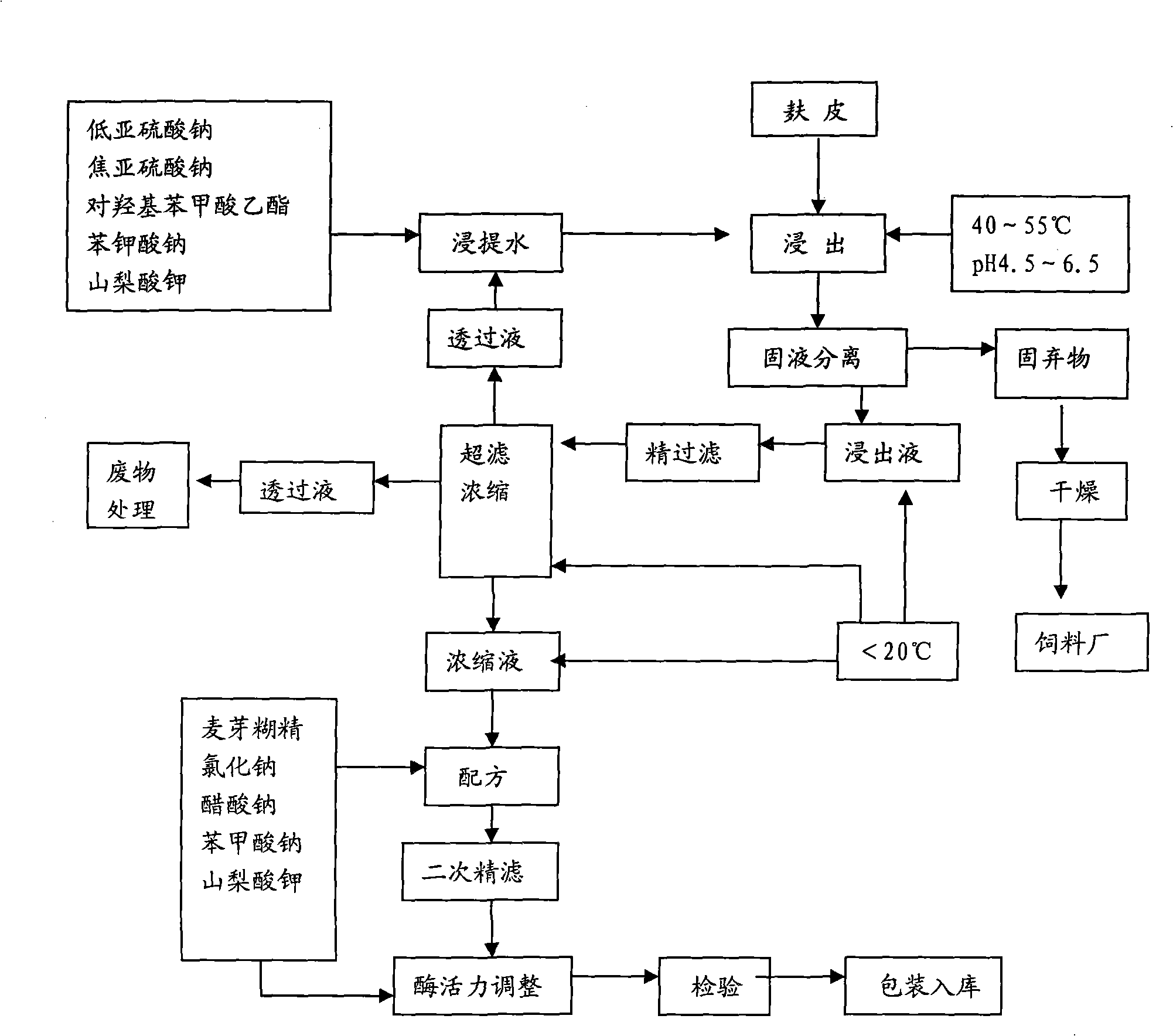

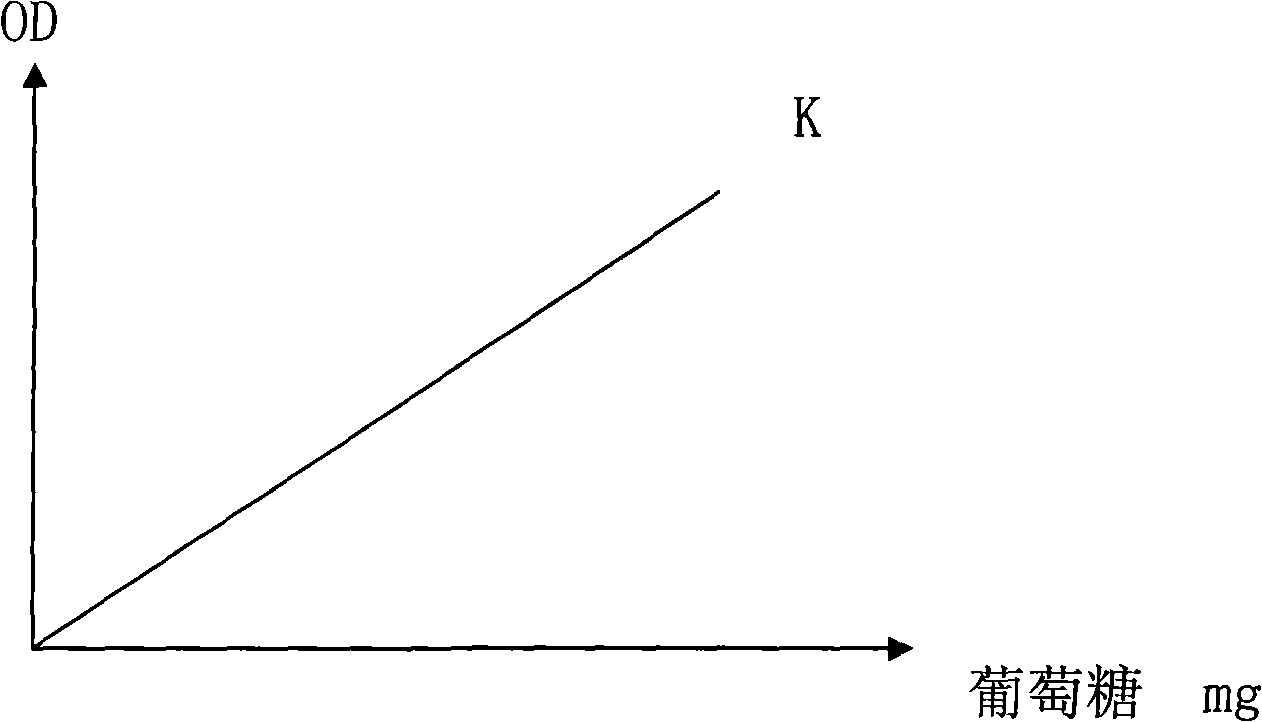

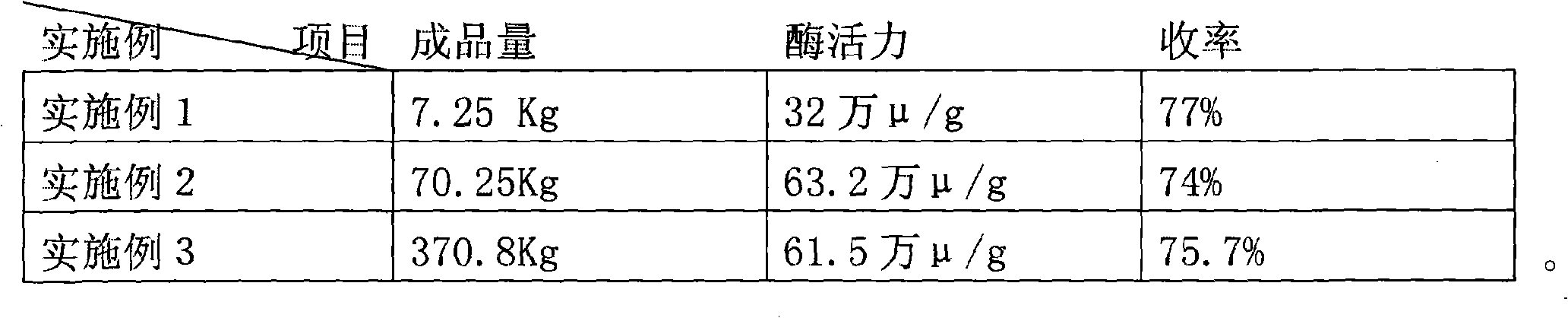

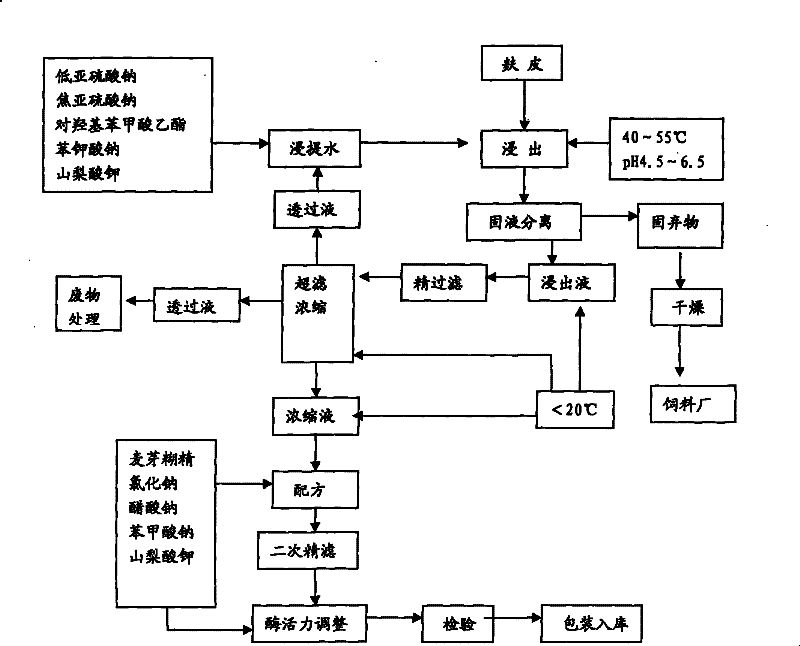

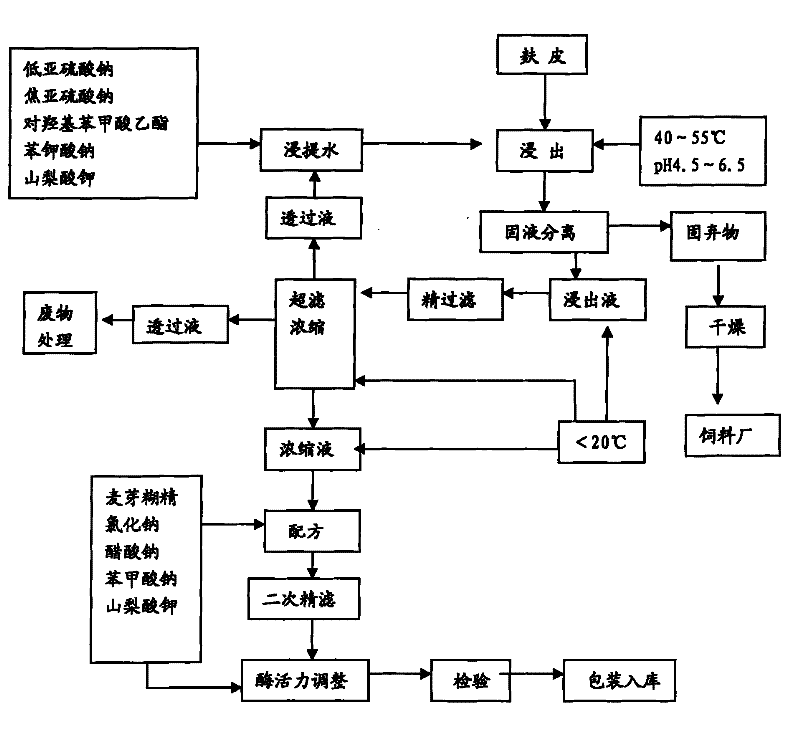

Preparation of liquid beta-diastase

The invention relates to a preparation method of a liquid Beta-diastase, which is characterized by taking wheat bran as raw material. The preparation method comprises the following technological steps: the extraction of the wheat bran, solid-liquid separation, the fine filtration of an extract, ultra-filtration concentration, prescription, secondary fine filtration and the adjustment of enzyme activity. The preparation method adopts a preservative with proper matching and proper temperature and Ph so as to effectively inhibit bacterial growth and avoid putrefaction and enzyme deactivation; the obtained products have low content of impurity, contains low concentrate of industrial salt compared with that of a solid enzyme preparation and meets the requirements of General Standard for Food Additives easily. The preparation method of the invention is a brand new preparation technology of the liquid Beta-diastase and has the advantages of simple technology, high production efficiency, low production cost and being suitable for industrialized production.

Owner:无锡赛德生物工程有限公司

Dimer acid and synthetic method thereof

PendingCN109879745AHigh yieldImprove product qualityOrganic compound preparationCarboxylic compound preparationNitrogenNitrogen gas

The invention relates to a dimer acid and a synthetic method thereof. According to the synthetic method, eleostearic acid is taken as a raw material, in the presence of a polymerization inhibitor, stirring is carried out while purging with nitrogen, heating is carried out to 180-230 DEG C for reaction, and a dimer acid product is obtained after the reaction is finished. The dimer acid is synthesized by adopting the method disclosed by the invention, the molecular formula of the dimer acid is C34H58(COOH)2, and the content of the dimer acid in the product is more than or equal to 55%. Accordingto the method, eleostearic acid is used as the raw material to synthesize the dimer acid, a catalyst is not needed, the reaction conditions are relatively mild, the process is simple, and the dimer acid yield is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

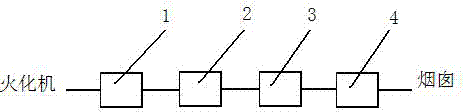

Cremation machine flue gas dry method post-treatment system

Owner:WEIHAI HANGTAI ENVIRONMENT PROTECTION EQUIP

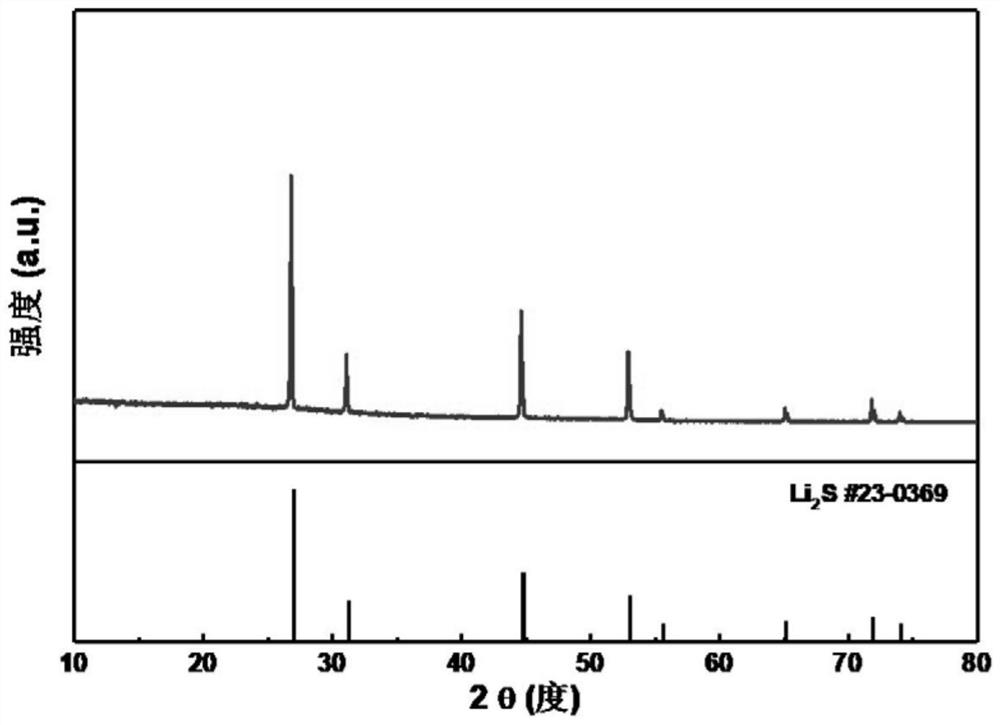

Method for preparing lithium sulfide from lithium sulfate

ActiveCN112520763AGuaranteed purityNo handling issuesLithium compoundsSecondary cellsLithium sulphateMaterial synthesis

The invention belongs to the technical field of material synthesis, and particularly relates to a method for preparing lithium sulfide from lithium sulfate. Aiming at the common defects of high price,difficulty in purity guarantee and the like of commercial lithium sulfide, the invention discloses a method for preparing high-purity lithium sulfide by using a simple heating method, lithium hydrideand lithium sulfate are used as raw materials, the lithium sulfide powder can be obtained through simple processes of heating, heat preservation, purification and the like, the method is simple and rapid, and the lithium sulfide with relatively high purity can be prepared at low cost.

Owner:ZHEJIANG UNIV OF TECH

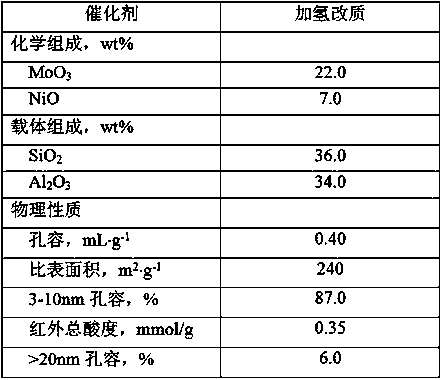

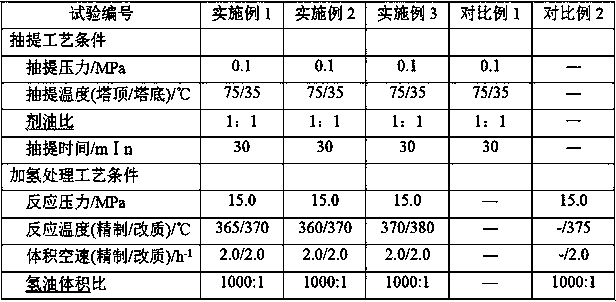

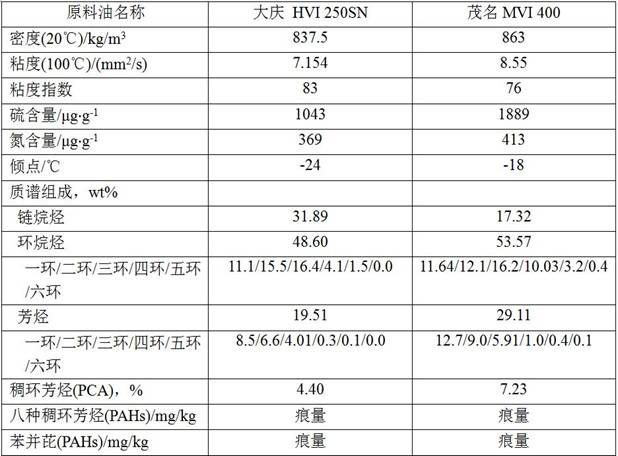

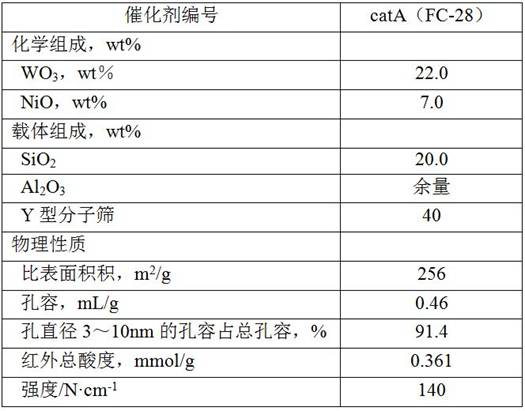

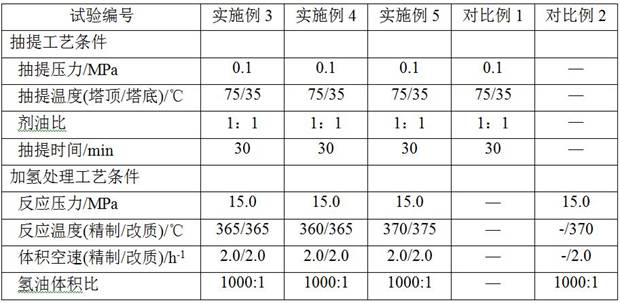

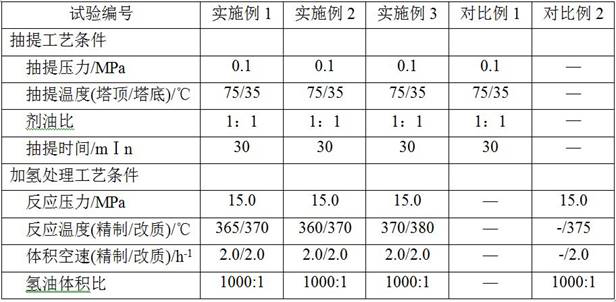

Combined method for producing high-quality lubricant base oil and environment-friendly aromatic hydrocarbon oil

ActiveCN111378499AEliminate steric hindranceImprove denitrification effectTreatment with hydrotreatment processesPolycyclic aromatic hydrocarbonEnvironmental engineering

The invention discloses a combined method for producing lubricant base oil and environment-friendly aromatic hydrocarbon oil. API I lubricant base oil with very low polycyclic aromatic hydrocarbon content produced by three old processes is subjected to solvent extraction, and the extraction depth is controlled, so that aromatic hydrocarbon in raffinate oil is further reduced; then through hydrofining and hydro-upgrading, the color and stability are improved, the viscosity index is increased, and the indexes of API III type lubricant base oil are reached; meanwhile, the aromatic hydrocarbon isenriched into the extract oil, so that the content of polycyclic aromatic hydrocarbon (3.0%, aromatic hydrocarbon content) in the extract oil is 20%, and the excellent rubber filling oil for the tireindustry is obtained. According to the method disclosed by the invention, two products with high additional values can be obtained at the same time by modifying the base oil I; and the method has theadvantages of high target product yield, low operation cost and no waste treatment in the processing process.

Owner:CHINA PETROLEUM & CHEM CORP +1

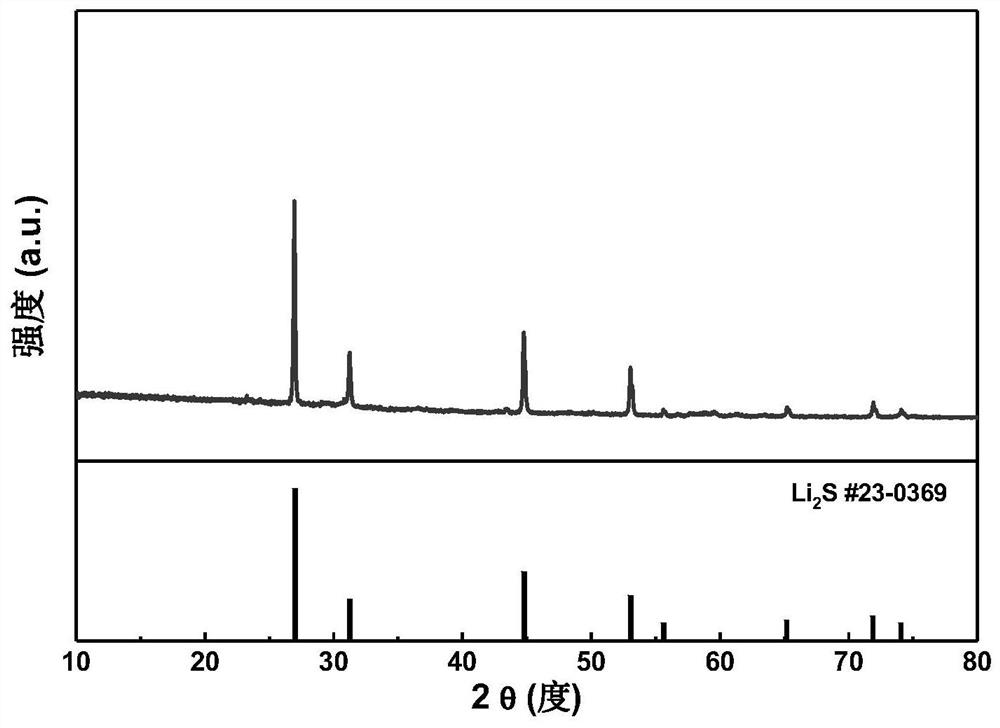

Method for preparing lithium sulfide by solid-liquid mixing and heating

PendingCN112125283AGuaranteed purityNo handling issuesAlkali metal sulfides/polysulfidesPositive electrodesMaterial synthesisPhysical chemistry

The invention belongs to the technical field of material synthesis, and particularly relates to a method for preparing lithium sulfide through solid-liquid mixing and heating. The invention disclosesa method for preparing high-purity lithium sulfide in order to overcome the defects that the demand of a scientific research institution for lithium sulfide is increased and an existing preparation method is tedious in step and harsh in condition. According to the method, the lithium sulfide powder with relatively high purity can be obtained only by simply mixing and heating the raw materials andcarrying out subsequent purification treatment, the preparation method provided by the invention is simple and convenient, industrial production is easy to realize, the manufacturing cost is low, andthe purity of the obtained lithium sulfide is relatively high.

Owner:ZHEJIANG UNIV OF TECH

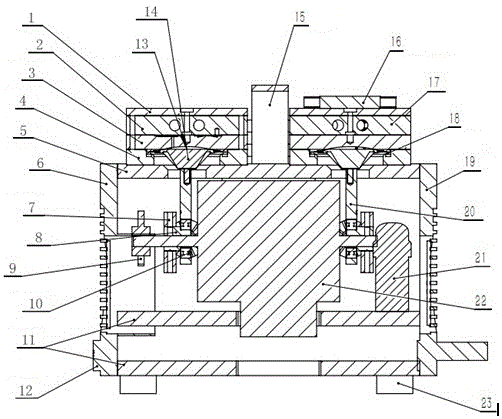

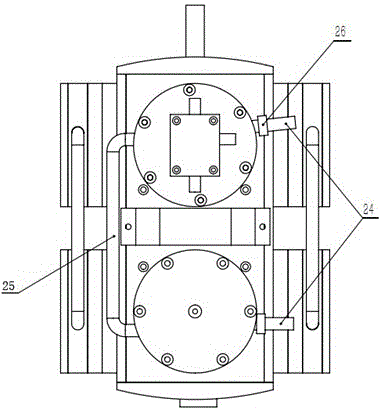

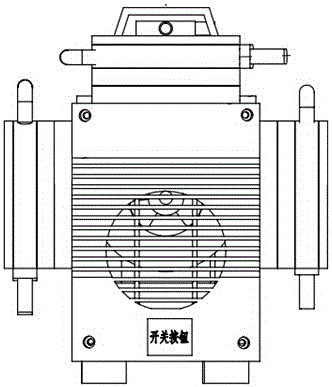

Multi-functional diaphragm vacuum pump

ActiveCN105003426AReduce volumeReduce weightPositive displacement pump componentsFlexible member pumpsBall valveWheel drive

The invention discloses a multi-functional diaphragm vacuum pump. The multi-functional diaphragm vacuum pump comprises a casing, wherein the casing consists of a ventilating top plate, a left intermediate ventilating plate with air inlet and outlet pipe connectors, a right intermediate ventilating plate with air inlet and outlet pipe connectors, ventilating baseplates, ventilating seats in which elastic rubber is arranged and an upper cover plate, a control switch is arranged at the lower part of the casing, and a control switch hood, a control line hood, a middle baseplate and a lower baseplate are mounted on the casing; a ball valve and an air path connecting pipe are arranged on each of the air inlet and outlet pipe connectors, a handle is arranged above the casing, the ventilating top plate is provided with a multi-way connector, and three-way eccentric wheels driven by a motor and rubber diaphragms driven by three-way eccentric wheel connecting rods are arranged at the inner part of the casing. The multi-functional diaphragm vacuum pump disclosed by the invention can be started under normal pressure, any lubricating liquid and any sealing liquid are not used for an overflowing part, water pollution and oil pollution do not exist, water cooling is not needed, the size is small, the weight is light, gear rotating does not exist, the operation is stable, and the noise is low; when requirements for the vacuum degree and the pumping rate are high, the three eccentric wheels extract the same reaction kettle at the same time, the multi-functional diaphragm vacuum pump is maintenance-free in design, energy-saving and high-efficiency, and the operating cost and the maintenance cost are reduced for customers.

Owner:NANTONG SIMENGTE VACUUM TECH CO LTD

Standing modified timber, standing timber modifier, and preparation methods thereof

InactiveCN104982243ASmall investmentShort processing cycleHorticulture methodsChemistryTranspiration

The invention provides a standing modified timber, a preparation method of the standing modified timber, a standing timber modifier, and a preparation method of the standing timber modifier. The preparation method of the standing modified timber includes steps: the growing standing timber is drilled, the standing timber modifiers are injected to holes via the holes, and the modifiers are infiltrated and diffused into the whole standing timber by employing the transpiration effect of trees. The standing modified timber prepared by employing the process is the standing modified timber with high density, small shrinkage coefficient, and high anti-bending strength, and the modification method is advantaged by no environmental pollution, low energy consumption, short processing cycle, and simple and easy operation.

Owner:BEIHUA UNIV

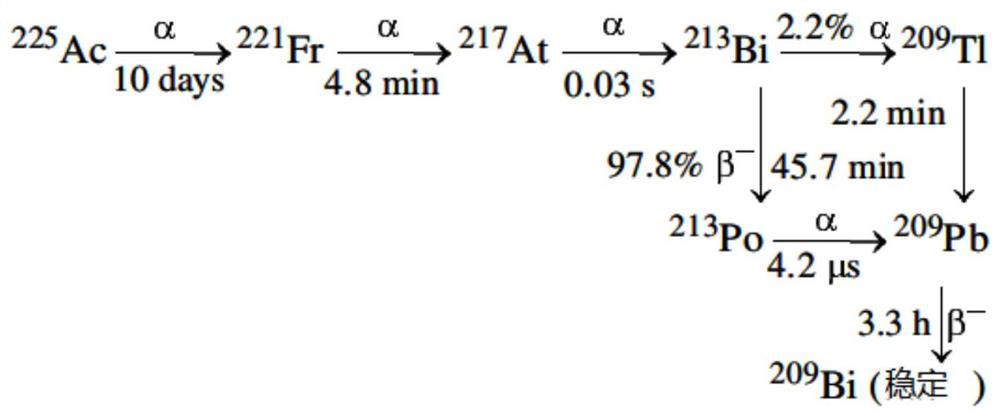

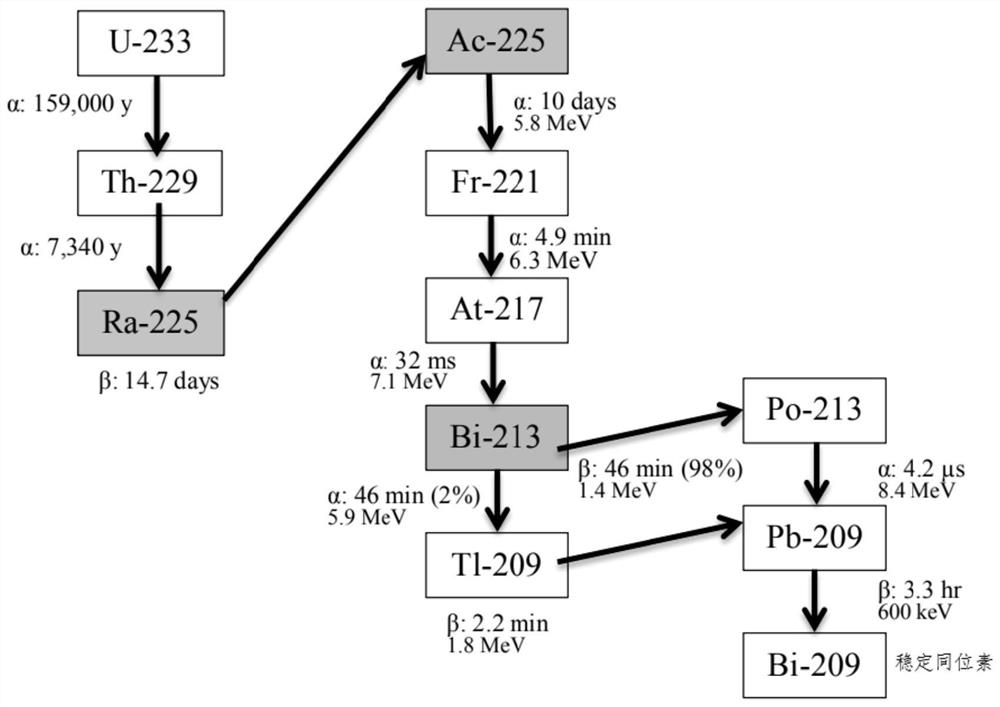

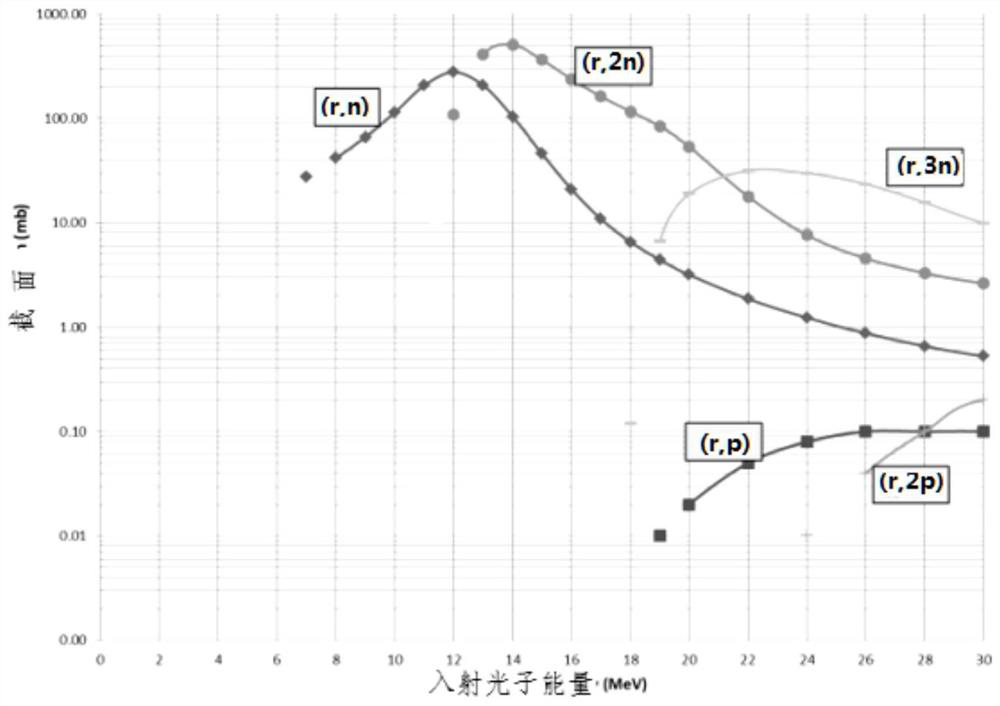

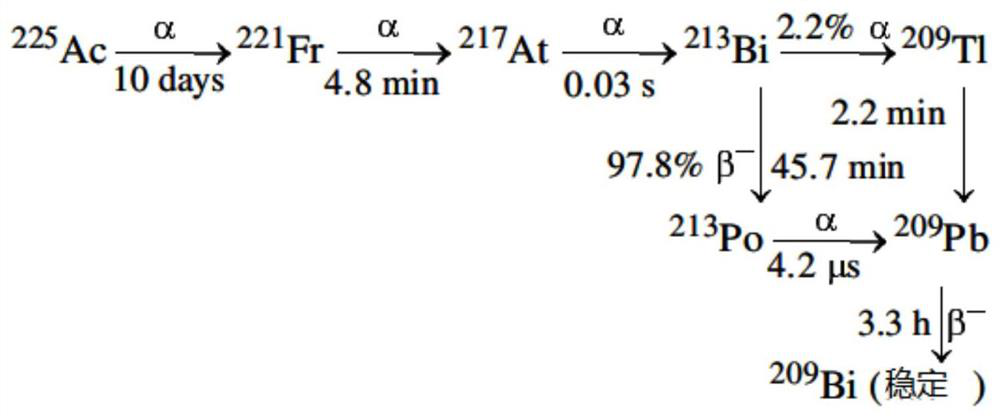

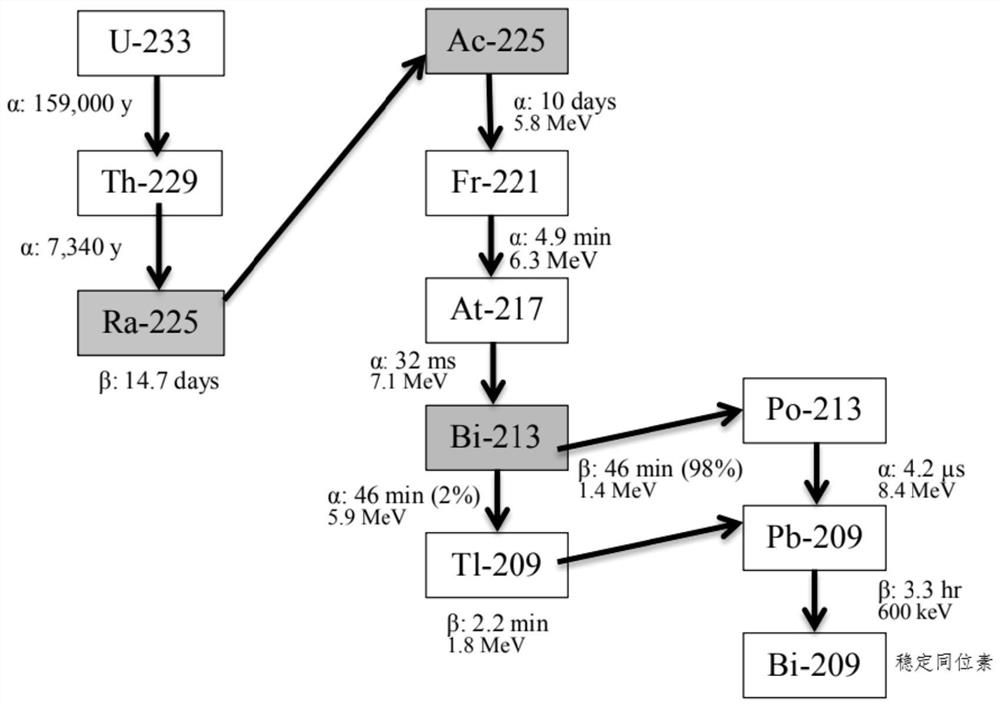

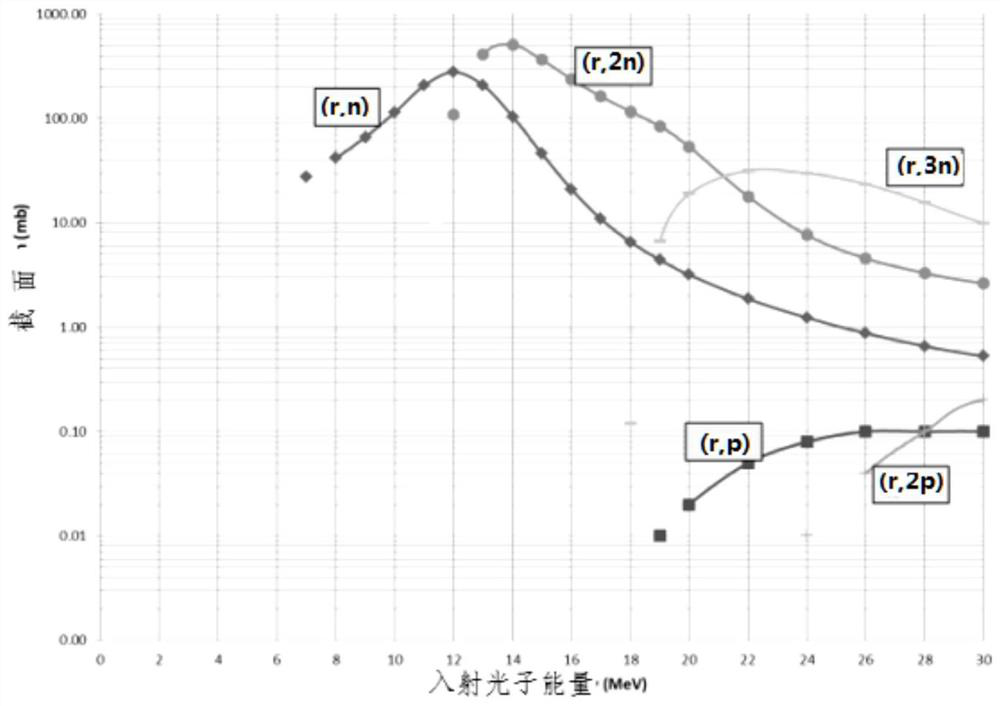

Method and device for producing medical isotope 225Ac

ActiveCN111724926ANo handling issuesIncrease productionSpecific isotope recoveryRadioactive wasteWaste treatment

The invention belongs to the field of medical radioactive therapy nuclide, particularly relates to a method and a device for producing medical isotope 225Ac, and solves the problems that an existing method for producing 225Ac is low in yield, high in cost and complicated in process and the like. High-power high-energy electron beams are converted into braking radiation to bombard a 226Ra sample target, 225Ac is generated through a photonuclear reaction, and finally, the 226Ra sample target is chemically dissolved to separate out 225Ac so that the method does not need expensive 229Th and is lowin cost, simple and convenient and does not have the problem of radioactive waste treatment.

Owner:西安迈斯拓扑科技有限公司

Dimer acid as well as preparation method and application thereof

ActiveCN109880532ASimple preparation processEnvironmentally friendly and economicalDrying-oil polymerisationAdditivesDimer acidOrganic chemistry

The invention relates to a dimer acid as well as a preparation method and application thereof. The molecular formula of the dimer acid is C34H58(COOH)2, and the content of a monocyclic dimer acid is more than 70%. The invention also provides a preparation method of the dimer acid, the dimer acid is prepared by taking tung oil or eleostearic acid as a raw material, the preparation process is simple, and the environmental friendliness and economy are good. The prepared dimer acid can be used for preparing polyamide resin, hot melt adhesive, lubricating oil and the like, and the application rangeis wide.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation of liquid beta-diastase

Owner:无锡赛德生物工程有限公司

Fresh preservation method for fresh and alive marine products

InactiveCN102048228AQuality improvementExtended shelf lifeFood preservationEnvironmental resistanceEngineering

The invention relates to a fresh preservation method for fresh and alive marine products. The method comprises the following steps of: placing the fresh marine and alive products into a sealed container; extracting gas from the sealed container by using a vacuum pump; introducing carbon dioxide gas from the outside to the sealed container; and placing and storing the sealed container at a low-temperature constant-temperature place. Compared with the prior art, the method has the advantages of saving electric energy, reducing production cost and meeting environmentally-friendly requirement, along with higher fresh preservation quality, longer fresh preservation period and no 'three wastes' treatment the like.

Owner:孙会敏

Thermal modifying method suitable for logs or thick lumbers

ActiveCN106003321ANot corrosiveNo handling issuesWood treatment detailsThermal wood treatmentThermodynamicsProcess engineering

The invention provides a thermal modifying method suitable for logs or thick lumbers. The method comprises the following wood treatment steps: woods with a water content of 7-8% are put in a treatment kiln; nitrogen is filled in the treatment kiln; the temperature in the kiln rises to 100 DEG C within 1 hour, rises to 140-150 DEG C at a speed of 10-15 DEG C / h, and rises to 160-180 DEG C at a speed of 20-25 DEG C / h; a heat source is closed; the nitrogen in the kiln is discharged out of the kiln; meanwhile, normal-temperature nitrogen is filled in the kiln, so that the temperature in the kiln is reduced at a speed of 30-40 DEG C / h; after the temperature in the kiln is reduced to 100 DEG C, air is introduced in the kiln; and meanwhile, atomized water is sprayed into the kiln. The heat treatment is performed under normal-pressure drying condition, so that the operation is safe, the treatment environment is not corroded, the treatment period is obviously shortened, and the production efficiency is high; and the treated woods have double-layer structures, so that the surface layer stability and durability are improved, the internal wood chemical structures are not changed, and the total wood mechanical strength is kept basically invariable.

Owner:HENAN IINKHIGH OVERALL FURNITURE CO LTD

Dimer fatty acid and synthetic method thereof

ActiveCN109880530AHigh yieldImprove product qualityDrying-oil polymerisationAdditivesNitrogenNitrogen gas

The invention relates to dimer fatty acid and a synthetic method thereof. The method comprise the following steps: stirring while purging with nitrogen in the presence of a polymerization inhibitor and a linoleic acid dispersing agent, heating to 240-280 DEG C, beginning to feed-batch eleostearic acid, and maintaining a reaction for a period of time after feeding-batch to obtain a dimer fatty acidproduct. The dimer fatty acid is prepared by adopting the method disclosed by the invention, the molecular formula of the dimer fatty acid is C34H58(COOH)2, and the content of the dimer fatty acid inthe product is more than or equal to 70%. According to the method, the eleostearic acid is used as the raw material to synthesize the dimer fatty acid, a catalyst is not needed, the reaction conditions are relatively mild, the process is simple, and the dimer fatty acid yield is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

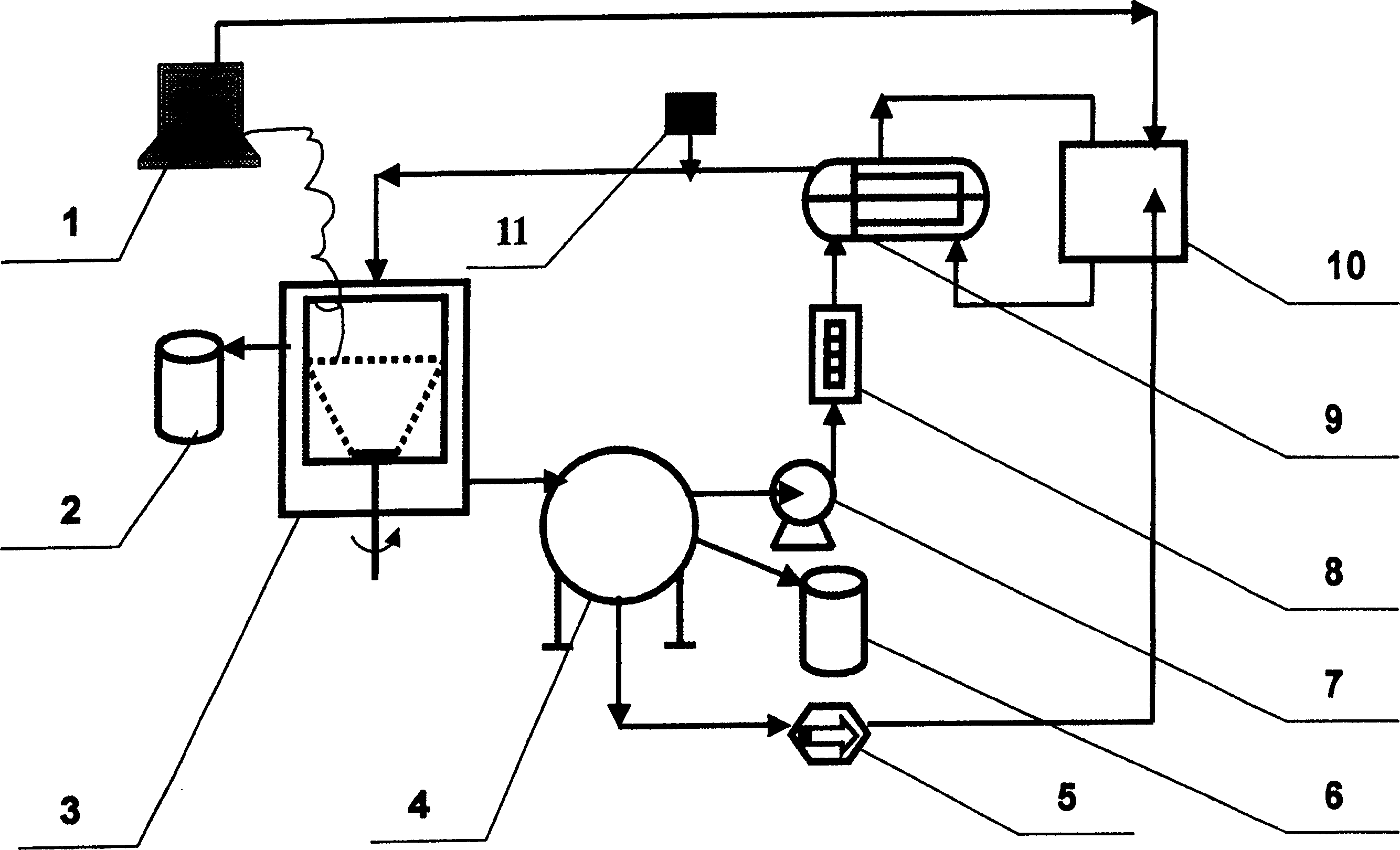

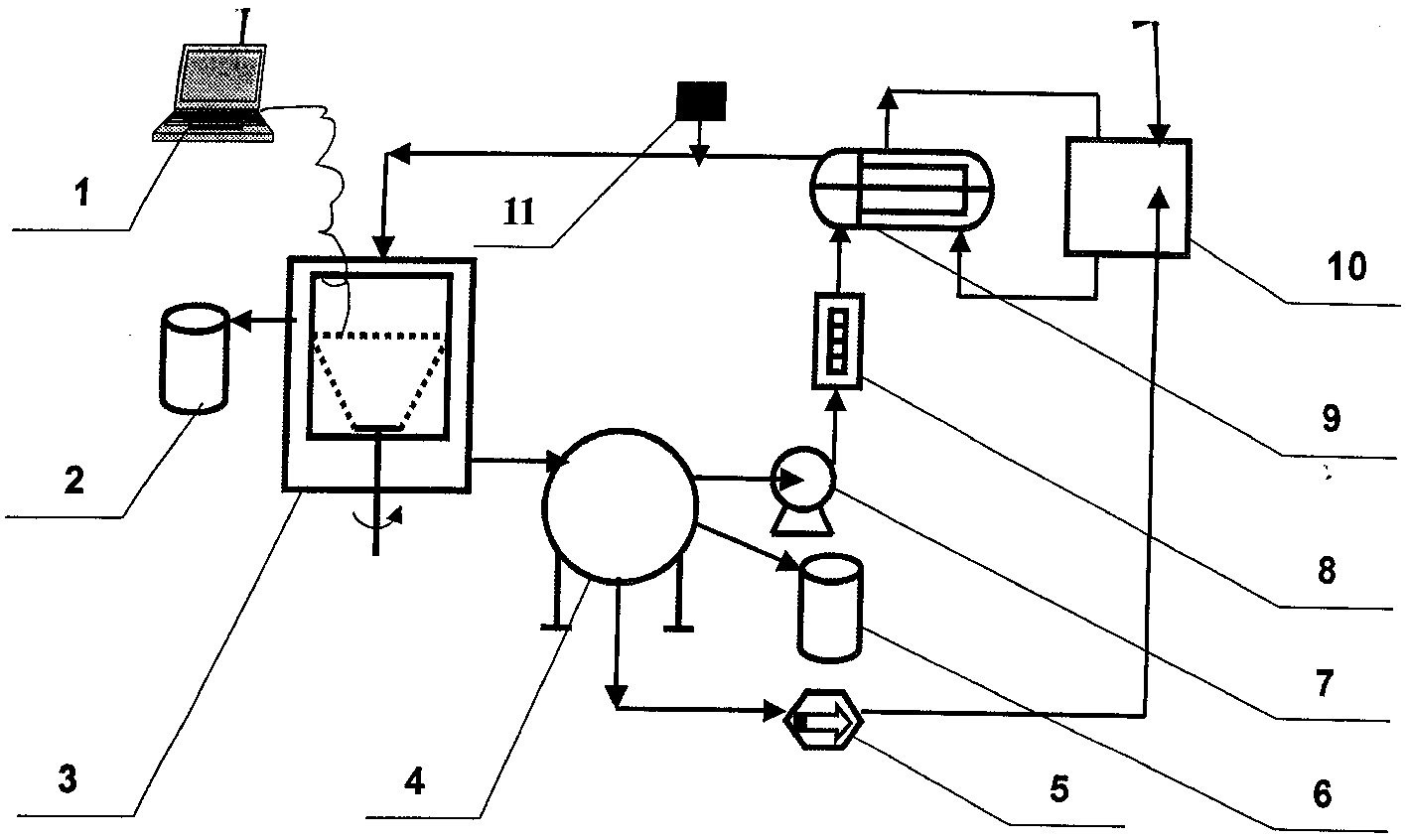

Low temp method for concentrating extracting solution of Chinese herbal medicine and its devices

InactiveCN1251662CEasy to separateNo handling issuesPharmaceutical product form changeSolventEnergy consumption

A method and apparatus for low-temp concentrating of liquid extract of Chinese-medicinal material is disclosed. The said method includes cooling to over-cold temp, physically generating ice crystal, and centrifugal separation of solvent from solute.

Owner:SUN YAT SEN UNIV

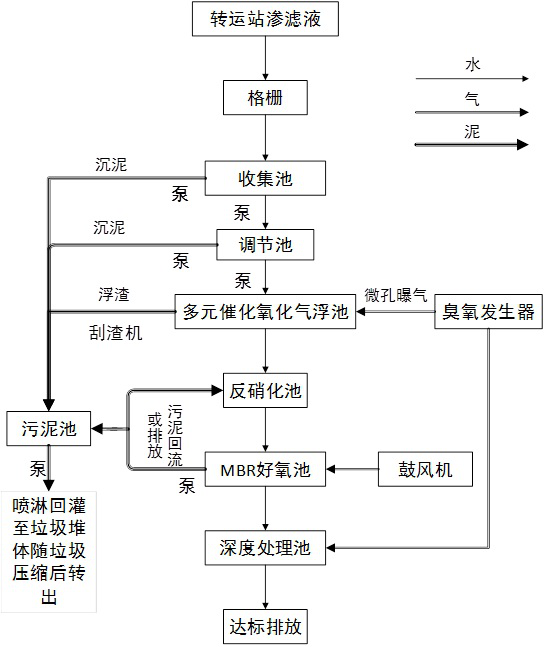

Leachate treatment method suitable for small and medium-sized refuse transfer stations

InactiveCN112979090AEasy to solveImprove biodegradabilityWater contaminantsTreatment involving filtrationSludgeOrganic matter

The invention relates to a leachate treatment method suitable for small and medium-sized refuse transfer stations, which comprises the following steps of: filtering refuse leachate by using a grid to remove massive refuse; adjusting the pH to 6.5-7.5; carrying out electro-catalysis ozone micro-aeration air flotation modification and deslagging; removing nitrogen through denitrification, and biochemically degrading organic matters; carrying out deep treatment, and recycling or discharging the treated wastewater; recharging the sludge into the garbage heap, compressing and then transferring the product out along with the station body. According to the treatment method disclosed by the invention, the use of chemicals is reduced as much as possible while the treatment quality of the landfill leachate of the transfer station is ensured, unnecessary processes and equipment are reduced, and the treatment investment, operation and maintenance costs of the landfill leachate of the transfer station are reduced to the greatest extent.

Owner:XUZHOU XUGONG ENVIRONMENTAL TECH CO LTD

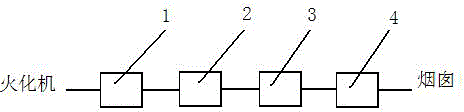

Cremation machine all-dry-method posttreatment system

ActiveCN103157338AAdvanced processLow water consumptionCombination devicesExhaust gasProcess engineering

The invention relates to the technical field of cremation machines, in particular to a cremation machine all-dry-method posttreatment system which is characterized by comprising a smoke gas and water isolation type shock cooling device, a powder spraying device, a dust remover and adsorption equipment. A processing technology includes the following steps: enabling high-temperature smoke gas which is generated by a cremation machine to enter the smoke gas and water isolation type shock cooling device for cooling, enabling the smoke gas in a pipeline to be mixed and contact with powdery absorbents which are sprayed by the powder spraying device through a powder spraying process, enabling the absorbents to react with sulfur oxides and acidic materials in the smoke gas to produce powdery calcium compounds, and enabling the smoke gas to be conducted at least two levels of dust removing through the dust remover, trapping dust and sparkles in the smoke gas through the dust remover, wherein off gas after dust removing enters the adsorption equipment, residual infinitesimal noxious substances are absorbed by the adsorption equipment, and the off gas is discharged from a chimney. According to the cremation machine all-dry-method posttreatment system, cooling water is recycled, and therefore generation of water of secondary pollution is completely eliminated. In addition, the cremation machine all-dry-method posttreatment system has the advantages that blocking is not easy, the equipment cannot easily be corroded, energy is saved, consumption is low, damage to the equipment is small, service life of the equipment is prolonged, environment is protected, and the like.

Owner:WEIHAI HANGTAI ENVIRONMENT PROTECTION EQUIP

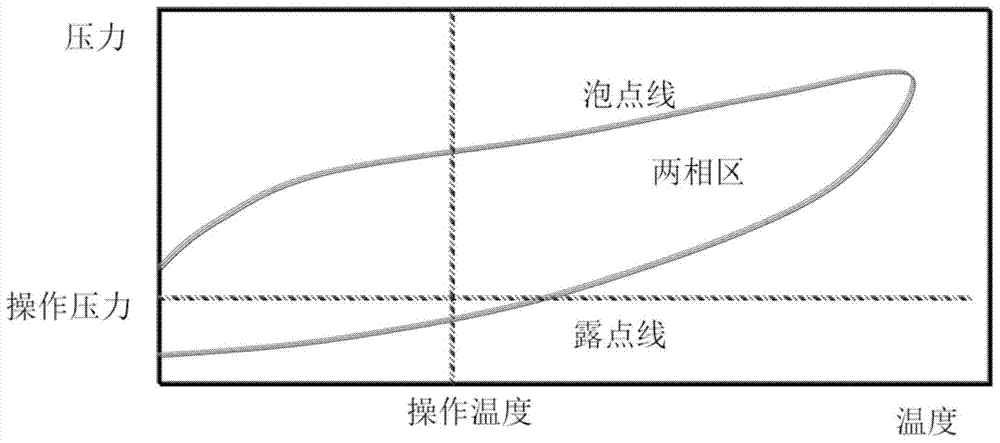

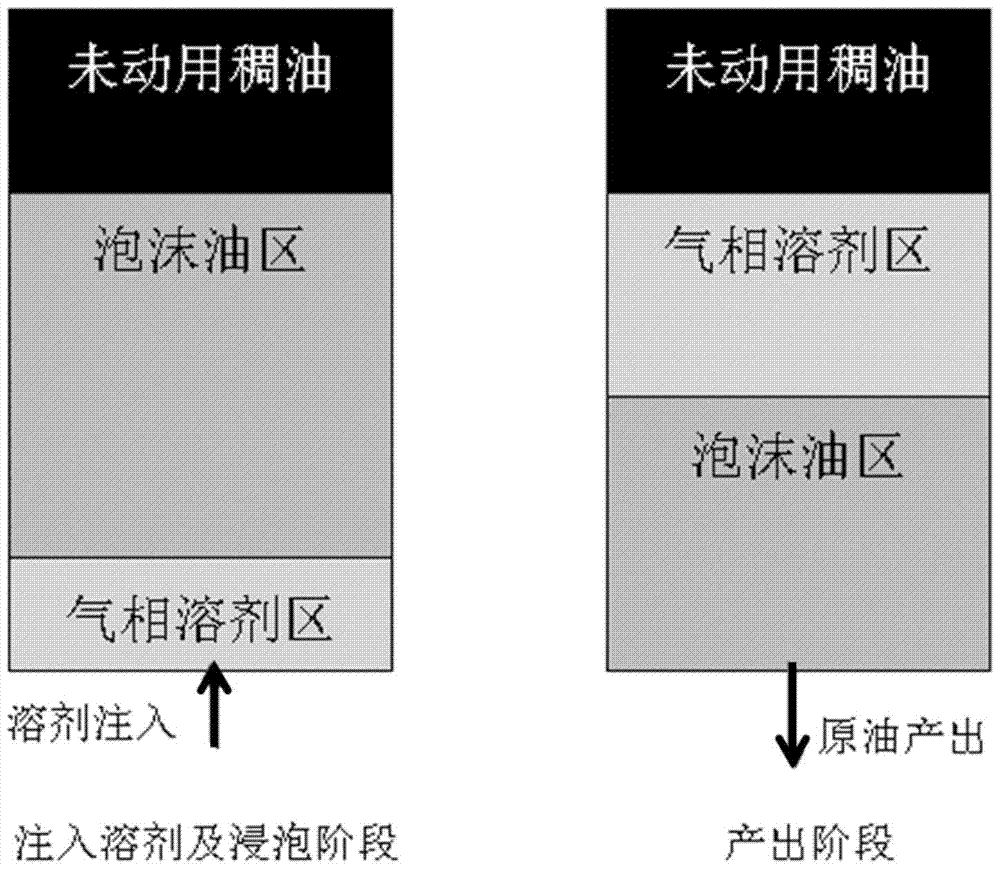

A single horizontal well solvent-assisted production method

The invention provides a single horizontal well solvent-assisted production method. The method includes: step 1: deploying a single horizontal well pattern, and the distance between the horizontal section of the horizontal well and the bottom of the reservoir is less than 1m; step 2: injecting C1-C4 organic compounds through a long pipe at a pressure greater than the dew point of the compound gas solvent Composite gas solvent with CO2; Step 3: Shut down the well for 1-2 days, heat the horizontal section of the horizontal well, and stop heating when it reaches 50-70°C; Step 4: Use long pipes with thin oil, short Pipe oil production is used for production, and the production process lasts for two days. When the downhole pressure is lower than 1MPa, the compound gas solvent is injected through the long pipe, and step 3 is repeated. The injection volume of the compound gas solvent is 1-3 times the volume of the solvent chamber; Step 5: Repeat Step 2-Step 4. When the recovery rate reaches more than 50% and the mining efficiency is lower than the economic limit, stop mining. The mining method of the invention has low cost per well, low requirements on drilling technology, no water process and low energy consumption.

Owner:PETROCHINA CO LTD

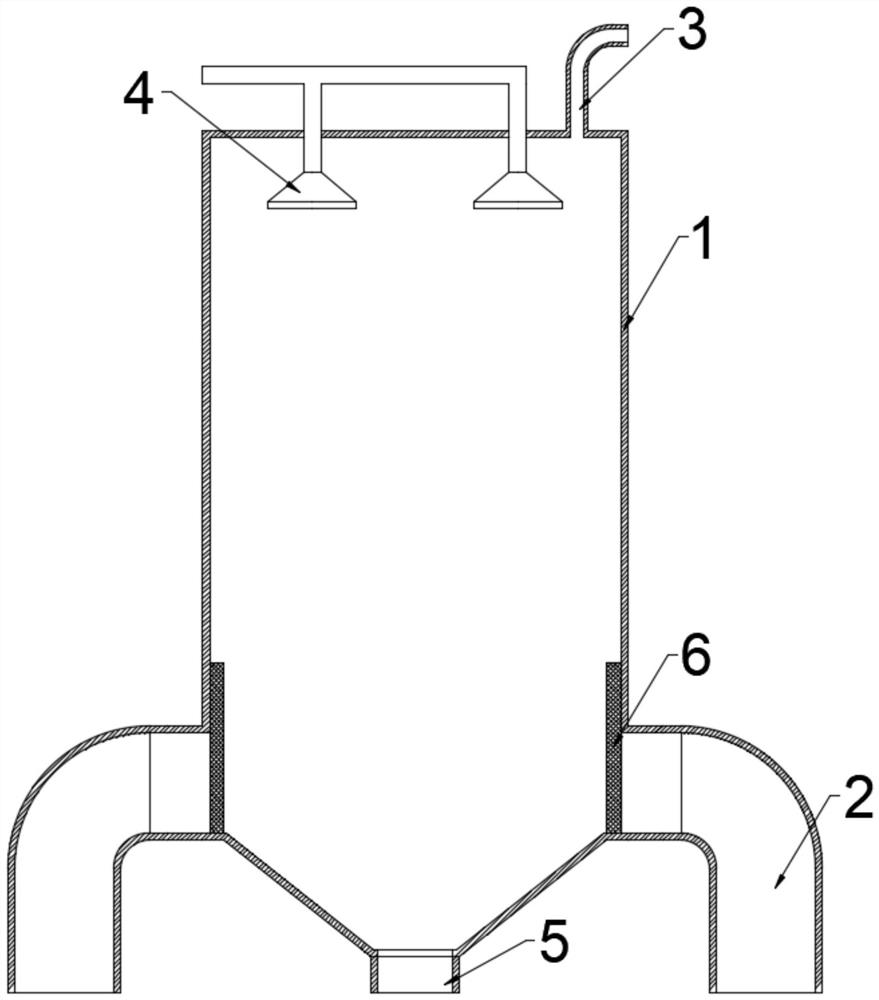

Double-channel dry-type desulfurization device for ocean vessel

PendingCN114733349AAchieve desulfurization effectEnter into realizationGas treatmentDispersed particle separationThermodynamicsMechanical engineering

The double-channel dry-type desulfurization device comprises a dry-type desulfurization cavity, a material spraying device and a breathable sealing plate, the dry-type desulfurization cavity is in the shape of a rectangular shell, air inlet pipes are arranged at the bottoms of the two sides of the dry-type desulfurization cavity, a conical discharging hopper is arranged at the bottom of the dry-type desulfurization cavity in a hollow mode, and the material spraying device is arranged at the bottom of the conical discharging hopper. A gas outlet pipe is arranged on the right side of the top of the dry-type desulfurization cavity, a material spraying device is arranged at the top of the dry-type desulfurization cavity and comprises a spray head and a material pipe, the spray head is arranged at the top end in the dry-type desulfurization cavity and communicated with the outer side of the top of the dry-type desulfurization cavity through the material pipe, and the breathable sealing plates are arranged at an opening of a gas inlet pipe of the dry-type desulfurization cavity. According to the invention, calcium carbonate powder subjected to high-temperature calcination is sprayed into the dry-type desulfurization cavity through the material spraying device, so that dry-type desulfurization of tail gas is completed, and the calcium carbonate powder is prevented from entering the gas inlet pipe through the breathable sealing plate.

Owner:江苏俊华海洋工程装备有限公司

Thermal modification method for logs or thick square lumber

ActiveCN106003321BNot corrosiveNo handling issuesWood treatment detailsThermal wood treatmentChemical structureSurface layer

The invention provides a thermal modifying method suitable for logs or thick lumbers. The method comprises the following wood treatment steps: woods with a water content of 7-8% are put in a treatment kiln; nitrogen is filled in the treatment kiln; the temperature in the kiln rises to 100 DEG C within 1 hour, rises to 140-150 DEG C at a speed of 10-15 DEG C / h, and rises to 160-180 DEG C at a speed of 20-25 DEG C / h; a heat source is closed; the nitrogen in the kiln is discharged out of the kiln; meanwhile, normal-temperature nitrogen is filled in the kiln, so that the temperature in the kiln is reduced at a speed of 30-40 DEG C / h; after the temperature in the kiln is reduced to 100 DEG C, air is introduced in the kiln; and meanwhile, atomized water is sprayed into the kiln. The heat treatment is performed under normal-pressure drying condition, so that the operation is safe, the treatment environment is not corroded, the treatment period is obviously shortened, and the production efficiency is high; and the treated woods have double-layer structures, so that the surface layer stability and durability are improved, the internal wood chemical structures are not changed, and the total wood mechanical strength is kept basically invariable.

Owner:HENAN IINKHIGH OVERALL FURNITURE CO LTD

A kind of dimer acid and preparation method thereof

ActiveCN109879744BHigh yieldImprove product qualityOrganic compound preparationCarboxylic compound preparationPtru catalystDimer acid

The invention relates to a dimer acid and a preparation method thereof. In the presence of a polymerization inhibitor and a dispersant, nitrogen purging is carried out while stirring, the temperature is raised to 180-230° C., tungoleic acid is added for reaction, and a dimer acid product is obtained after the reaction is completed. . The dimer acid of the present invention is prepared by adopting the above-mentioned method of the present invention, and the molecular formula of the dimer acid is C 34 h 58 (COOH) 2 , The content of dimer acid in the product is ≥60%. The invention uses tungoleic acid as a raw material to synthesize dimer acid without using a catalyst, relatively mild reaction conditions, simple process and high yield of dimer acid.

Owner:CHINA PETROLEUM & CHEM CORP +1

A combined method for producing high-quality lubricating oil base oil and environment-friendly aromatic hydrocarbon oil

ActiveCN111378500BImprove denitrification effectHigh saturationTreatment with hydrotreatment processesPolycyclic aromatic hydrocarbonProcess engineering

Owner:CHINA PETROLEUM & CHEM CORP +1

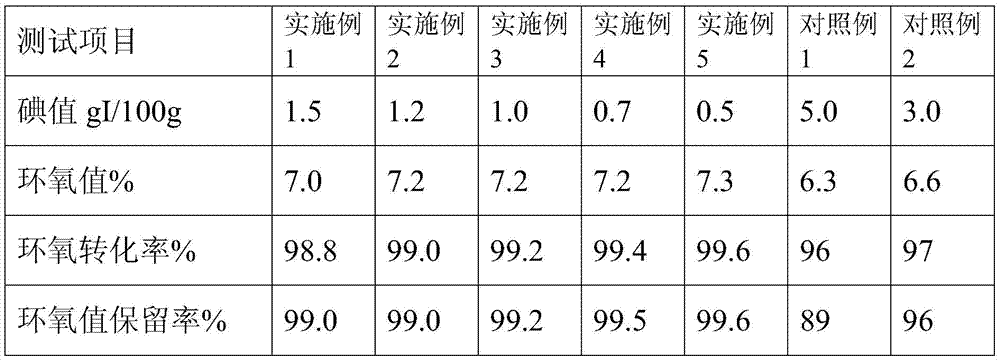

A kind of preparation method of epoxy plasticizer

ActiveCN104560407BHigh selectivityImprove conversion rateFatty acid chemical modificationOrganic chemistryHigh concentrationDistillation

The invention discloses a method for preparing an epoxy plasticizer. The method comprises the following steps: mixing high-concentration hydrogen peroxide and high-concentration formic acid at normal temperature, thereby obtaining a high-concentration peroxide formic acid mixture; adding the mixture and soybean oil into reaction equipment once, carrying out self-initiation reaction to release heat to the temperature of 60-70 DEG C, controlling the reaction temperature to 70-90 DEG C, reacting for 3-4 hours until the epoxide number is more than 7.0 percent, stopping the reaction, centrifugally separating the aqueous phase, performing dewatering and filtration on the crude oil phase, thereby obtaining the product. The method disclosed by the invention is short in reaction time, high in product selectivity, high in conversion rate and few in ring-opening reaction byproducts, the epoxide number of the product is more than 7.0 percent, the iodine value is less than 2gI / 100g, and the epoxide number retention rate is more than 99 percent; and moreover, the operations of alkali wash / washing / standing are not needed in the product preparation process, wastewater containing formic acid is distilled and recycled by a distillation tower, wastewater treatment is not needed, the wastewater is avoided, the waste solid treatment problem is solved, and the method is low in energy consumption, small in wastewater amount, short in manufacture procedure and high in product quality.

Owner:中山联成化学工业有限公司

A production medical isotope 225 AC method and device

ActiveCN111724926BNo handling issuesIncrease productionSpecific isotope recoveryRadioactive wasteNuclear reaction

Owner:西安迈斯拓扑科技有限公司

Combined method for producing high-quality lube base oil and environmentally friendly aromatic oil

ActiveCN111378499BEliminate steric hindranceImprove denitrification effectTreatment with hydrotreatment processesPolycyclic aromatic hydrocarbonProcess engineering

The invention discloses a combined method for producing lubricating oil base oil and environment-friendly aromatic hydrocarbon oil. The API Class I lubricating oil base oil with very low content of condensed ring aromatics produced by the "old three sets" process is subjected to solvent extraction, and the extraction depth is controlled to further reduce the aromatics in the raffinate oil; Hydrogen modification, improve color and stability, increase viscosity index, reach API Ⅲ lubricating base oil index; at the same time, aromatics are enriched in the extracted oil, so that the content of condensed ring aromatics in the extracted oil is <3.0%, and the content of aromatics is >20% , to obtain excellent rubber filler oil for tire industry. The method of the invention can simultaneously obtain two kinds of high value-added products by modifying the class I base oil, and has the advantages of high yield of the target product, low operation cost and no waste disposal in the processing process.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for extracting and purifying cordycepin from Cordyceps militaris culture fluid

ActiveCN105646627BReduce manufacturing costSimple processSugar derivativesSugar derivatives preparationLiquid mediumEvaporation

The invention provides a method for extracting purified cordycepin from cordyceps militaris nutrient solution. The method comprises the steps of: taking a cordyceps militaris nutrient solution as a raw material, filtering or centrifuging, and concentrating a supernatant by rotary evaporation; filling a macroporous resin column with a concentrated liquid, then eluting with water and ethanol, collecting an ethanol eluant and concentrating; and crystallizing at low temperature. According to the method, the liquid medium is used, extracting by macroporous resin and eluting by using water and an alcohol solvent are conducted; and the process has no serious contamination or waste liquid disposal. Compared to the complex extraction process of the prior art, the three-step extraction method of the invention has the advantages of low production cost, simple process and easiness to mass production. The generated cordycepin is in white needle or crystalline shape, and has high purity reaching more than 95%, which is improved significantly compared to the 90% in the prior art.

Owner:CHANGSHU JINDA TECH CO LTD

Tail end curing system applied to zero discharge of wastewater

The invention relates to a tail end curing system applied to zero discharge of wastewater. A wastewater buffer tank 1 is connected with a wastewater atomization device 3 through a wastewater deliverypump 2. Wastewater is pressurized and delivered to the wastewater atomization device from the wastewater buffer tank through the wastewater delivery pump and is atomized under the assistance of compressed air, the atomized wastewater is directly sprayed into a drying evaporation tower 4, and the atomized wastewater is evaporated by utilizing waste heat of flue gas. A flue gas inlet is formed in the top of the drying evaporation tower and connected with a high-temperature flue in front of an air pre-heater, a flue gas outlet is located in the bottom of the drying evaporation tower and connectedwith a low-temperature flue behind the air pre-heater, a wastewater inlet is formed in the lower portion of the interior of the high-temperature flue gas inlet, a wastewater atomization device is connected to the side of the wastewater inlet, and an outlet of an air compressor is connected above the atomization device. According to the invention, the tail end curing system after concentration treatment of the wastewater treatment system is optimized, and the prior art is organized and integrated, so that the defects of huge equipment, large occupied area, complex operation and the like of theexisting tail end curing system are well overcome.

Owner:JIANGSU JINGYUAN ENVIRONMENTAL PROTECTION

A kind of preparation method of the bisphenol f of high ortho isomer content

InactiveCN104130109BHigh ortho contentEasy to makeOrganic chemistryOrganic compound preparationMolecular sieveWastewater

The invention discloses a preparation method of bisphenol F with high ortho-isomeride content. The preparation method comprises the following step: through an acidic mesoporous molecular sieve Zr-SBA-15 catalyst, catalyzing phenol and formaldehyde aqueous liquor with the mass percentage of 35-40%, to synthesize the bisphenol F, wherein the adopted acidic mesoporous molecular sieve Zr-SBA-15 catalyst is synthesized in one step, and the activity of the catalyst can be regulated by regulating the mole ratio of Zr / Si atoms of the catalyst. The preparation method is simple in technology, high in catalysis efficiency, the bisphenol F with high ortho-isomeride content can be obtained, the catalyst is easily separated and recovered and repeatedly used, and no equipment corrosion and waste water treatment problems exist, so that the preparation method is an environment-friendly high-efficiency preparation method of the bisphenol F with high ortho content.

Owner:XIANGTAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com