A kind of preparation method of epoxy plasticizer

A plasticizer and epoxy technology, applied in the field of preparation of epoxidized soybean oil, can solve problems such as explosion danger, and achieve the effects of short reaction time, low energy consumption and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

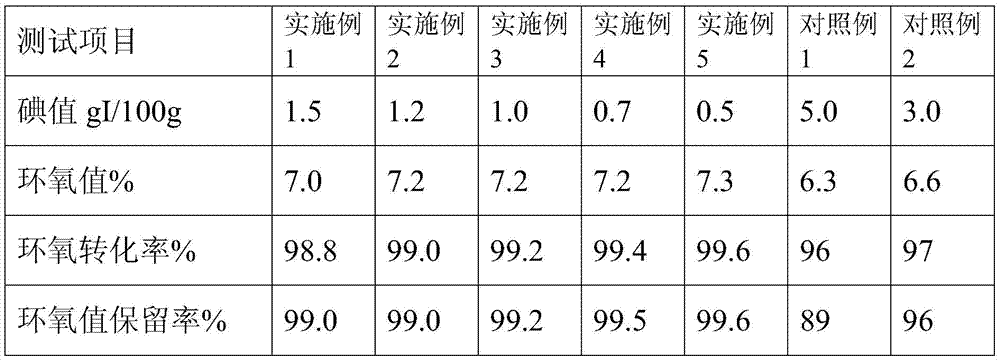

Examples

Embodiment 1

[0027] Take 120g of formic acid with a mass concentration of 90% and 500g of hydrogen peroxide with a mass concentration of 50%, mix evenly, and put it into the reactor together with 880g of soybean oil with an iodine value of 130gI / 100g, stir rapidly, and the reaction temperature gradually increases, and the temperature rises to 60 ℃, open the external cooling circulation pipe, and the internal heating pipe, the reaction solution is introduced into the cooling circulation pipe for reaction, the reaction temperature is controlled at 70 ~ 85 ℃, the reaction is 4 hours, and the sampling test epoxy value is 7.0% (g O / 100g oil ) to finish the reaction, centrifuge the water phase, and dehydrate to obtain epoxy soybean oil.

Embodiment 2

[0029] Take 140g of formic acid with a mass concentration of 90% and 365g of hydrogen peroxide with a mass concentration of 70%, mix evenly, and put it into the reactor together with 880g of soybean oil with an iodine value of 130gI / 100g, stir rapidly, and the reaction temperature gradually increases, and the temperature rises to 70 ℃, open the external cooling circulation pipe, and the internal heating pipe, introduce the reaction liquid into the cooling circulation pipe for reaction, control the reaction temperature 70 ~ 85 ℃, react for 4 hours, take a sample to test the epoxy value, greater than 7.0%, end the reaction, carry out The water phase is separated by centrifugation and dehydrated to obtain epoxidized soybean oil.

Embodiment 3

[0031] Take 50 g of formic acid with a mass concentration of 96% and 400 g of hydrogen peroxide with a mass concentration of 70%, mix evenly, and put it into the reactor together with 880 g of soybean oil with an iodine value of 130 gI / 100 g, stir rapidly, and the reaction temperature gradually increases, and the temperature rises to 60 ℃, open the external cooling circulation pipe, and the internal heating pipe, introduce the reaction liquid into the cooling circulation pipe for reaction, control the reaction temperature 70 ~ 85 ℃, react for 4 hours, take a sample to test the epoxy value, greater than 7.0%, end the reaction, carry out The water phase is separated by centrifugation and dehydrated to obtain epoxidized soybean oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com