Leachate treatment method suitable for small and medium-sized refuse transfer stations

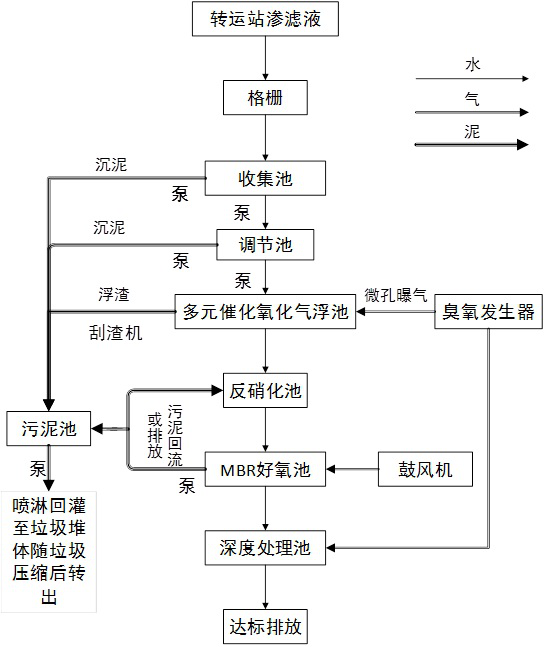

A transfer station and leachate technology, applied in filtration treatment, contaminated groundwater/leachate treatment, neutralized water/sewage treatment, etc., can solve the problem of high evaporation and crystallization equipment and operating costs, application limitations of anaerobic treatment process, Difficult to recycle and utilize biogas to achieve significant market advantages, reduce labor costs, and improve biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] S1: Filter the landfill leachate through the coarse and fine grids in turn, and then pass it into the collection tank, control the hydraulic retention time of the material to 12h, adjust the water quality, and obtain the primary mixed solution; among them, the distance between the coarse grids is 50mm, and the fine grids Spacing 9mm;

[0049] S2: The primary mixed solution is pumped into the adjustment tank by the pump, and the residence time is 2 hours. Under the automatic control of the pH online controller, alkaline chemicals are added to adjust the pH value, and the pH of the primary mixed solution is adjusted to 6.5; after the wastewater pH is adjusted Obtain the secondary mixed solution; wherein, the pump is a small submersible screw pump with a flow rate of 1m3 / h, a rated power of 0.28kw / h, a rated voltage of 220v, and a head of 50m;

[0050] S3: Pass the secondary mixed liquid into the heterogeneous catalytic oxidation ozone flotation tank, perform electrocataly...

Embodiment 2

[0056]S1: Filter the landfill leachate through coarse grids in turn, and then pass it into the collection tank, control the hydraulic retention time of the material to 8h, adjust the water quality, and obtain a mixed solution; among them, the spacing between the coarse grids is 60mm, and the spacing between the fine grids is 12mm ;

[0057] S2: The primary mixed solution is pumped into the adjustment tank by the pump, and the residence time is 3 hours. Under the automatic control of the pH online controller, alkaline chemicals are added to adjust the pH value, and the pH of the primary mixed solution is adjusted to 7.5; after the pH adjustment of the wastewater Obtain the secondary mixture;

[0058] S3: Pass the secondary mixed liquid into the heterogeneous catalytic oxidation ozone air flotation tank, perform electrocatalytic ozone combined oxidation + ozone micro-aeration air flotation, and obtain the tertiary mixed liquid after a residence time of 6 hours; the thickness of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com