Combined method for producing high-quality lube base oil and environmentally friendly aromatic oil

A technology of lubricating base oil and combination method, which is applied in the treatment of hydrocarbon oil, petroleum industry, hydrotreating process, etc., and can solve the problems of decreased yield of the target product of cracking reaction, low yield, inability to produce environmentally friendly aromatic oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

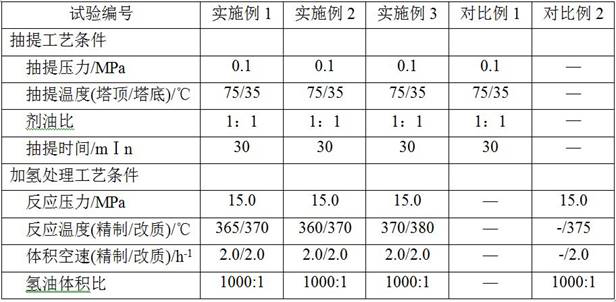

Embodiment 1

[0040] Taking Daqing minus three-line distillate oil, solvent dewaxing, solvent purification, white soil refined Class I 250SN base oil is raw material, and its nature is shown in Table 1. The top of the tower is 75 ° C, the extraction of the bottom temperature is 35 ° C, and the pressure is 0.1MPa, the extraction solvent is furfural and ethanol mixed solvent, wherein the ethanol content is 5% of the total solvent weight, solvent and raw oil. The mass ratio is 1: 1, the taking the effluent and extracting the oil solvent recovered with nitrogen steaming, the residual pressure is 500 mmHg, and the gas is 0.5 l / kg, the temperature is 130 ° C. The pressure of the residual oil after recovery solvent is 15.0 MPa, hydrotreating / hydrogenation modification volume vacuum speed (2.0H -1 / 2.0h -1 ), The hydrogen supply ratio is 1000: 1, the specific results obtained are shown in Table 3-4.

Embodiment 2

[0042] Hydrogenation catalysts Select FF-36 (molybdenum-nickel type) and FHUDS-5 (molybdenum-cobalt type), which is 1: 1, and the hydrotreating catalyst properties are shown in Table 2.

[0043] The properties of the raw material oil are shown in Table 1. The top of the tower is 75 ° C, the extraction of the bottom temperature is 35 ° C, and the pressure is 0.1MPa, the extraction solvent is furfural and ethanol mixed solvent, wherein the ethanol content is 5% of the total solvent weight, solvent and raw oil. The mass ratio is 1: 1, the taking the effluent and extracting the oil solvent recovered with nitrogen steaming, the residual pressure is 500 mmHg, and the gas is 0.5 l / kg, the temperature is 130 ° C. The pressure of the residual oil after recovery solvent is 15.0 MPa, hydrotreating / hydrogenation modification volume vacuum speed (2.0H -1 / 2.0h -1 ), The hydrogen supply ratio is 1000: 1, the specific results obtained are shown in Table 3-4.

Embodiment 3

[0045] Hydrogenation catalysts Select FF-36 (molybdenum-nickel type) and FHUDS-5 (molybdenum-cobalt type), which is 1: 1, and the hydrotreating catalyst properties are shown in Table 2.

[0046] Taking Maoming minus three, reduced four-wire mixed distillate oil, solvent dewaxing, solvent refining, white soil refined Class I 400SN base oil as raw material, the nature of the raw material oil is shown in Table 1. The top of the tower is 75 ° C, the extraction of the bottom temperature is 35 ° C, and the pressure is 0.1MPa, the extraction solvent is furfural and ethanol mixed solvent, wherein the ethanol content is 5% of the total solvent weight, solvent and raw oil. The mass ratio is 1: 1, the taking the effluent and extracting the oil solvent recovered with nitrogen steaming, the residual pressure is 500 mmHg, and the gas is 0.5 l / kg, the temperature is 130 ° C. The pressure of the residual oil after recovery solvent is 15.0 MPa, hydrotreating / hydrogenation modification volume v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com