Double-channel dry-type desulfurization device for ocean vessel

A technology for ocean-going ships and desulfurization devices, which is applied in the direction of separation methods, dispersed particle separation, chemical instruments and methods, etc. It can solve the problems of cargo reduction, hull size expansion restrictions or changes, etc., and achieves low corrosion and good desulfurization reactions effect, the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to deepen the understanding of the present invention, the present invention will be described in further detail below with reference to the embodiments and the accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation on the protection scope of the present invention.

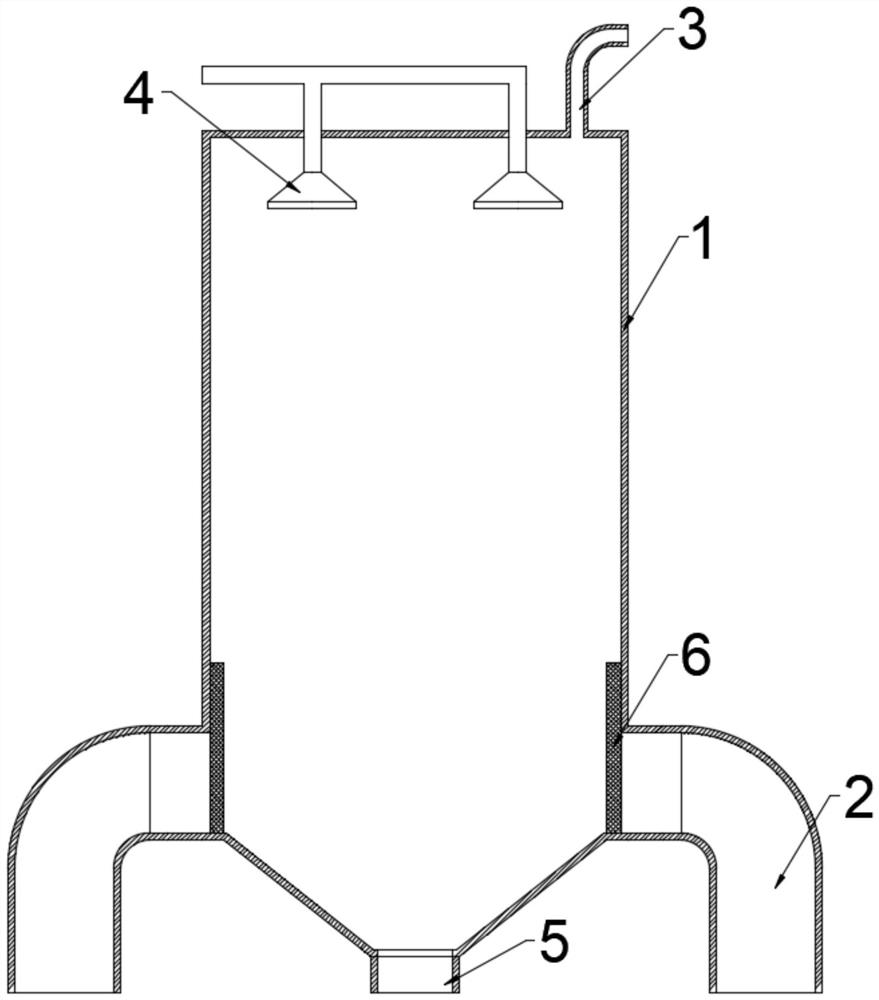

[0016] Dry desulfurization chamber 1, air inlet pipe 2, air outlet pipe 3, material spraying device 4, material discharge pipe 5, ventilating sealing plate 6.

[0017] like figure 1 shown:

[0018] A dual-channel dry desulfurization device for ocean-going ships is characterized in that it comprises a dry desulfurization chamber 1, a material spraying device 4 and a ventilating sealing plate 6, and the top of the dry desulfurization chamber 1 is provided with a material spraying device 4 , There is a ventilating sealing plate 6 around the inner bottom of the dry desulfurization chamber 1. By using the spray-type dry desulfurization me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com