Special environment-friendly high polymer material for optical cable and preparation method thereof

A polymer material and special technology, which is applied in the field of special environment-friendly polymer materials for optical cables and its preparation, can solve problems such as poor performance stability, poor processing fluidity, and excessive addition of additives. Simple and easy to implement, less dependent on equipment, improved mechanical properties and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

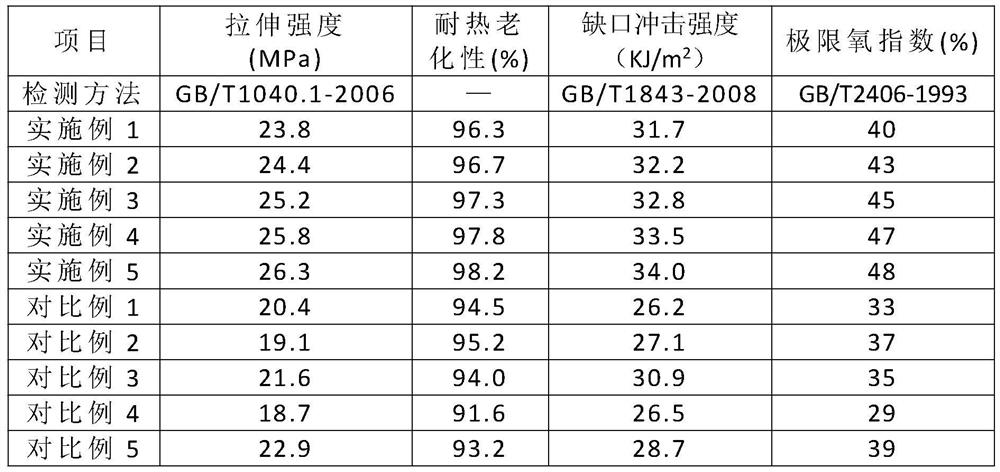

Examples

Embodiment 1

[0029]A special environmentally friendly polymer material for optical cables, characterized in that it is made of the following components in parts by weight: acrylonitrile ionized modified poly 2,5-bis(1,2,4-triazole- 1-yl) 15 parts of 2,3,5,6-tetrafluoro-tere-phenylenedimethanol terephthalate, 60 parts of high-density polyethylene, 10 parts of fluorine-containing hyperbranched polyethylene copolymer, 5 parts of vinyl hyperbranched polyurethane 1.5 parts of 3,4,5-trifluorophenylboronic acid, 1 part of initiator, and 0.5 parts of antioxidant.

[0030] The antioxidant is antioxidant 101; the initiator is azobisisobutyronitrile; the grade of the high-density polyethylene is HDPE 5070.

[0031] The preparation method of the ionized acrylonitrile modified poly 2,5-bis(1,2,4-triazol-1-yl) terephthalate 2,3,5,6-tetrafluoro-tere-xylylenedimethanol ester , including the following steps:

[0032] Step D1, adding 2,5-bis(1,2,4-triazol-1-yl)terephthalic acid, 2,3,5,6-tetrafluoro-tereph...

Embodiment 2

[0038] A special environmentally friendly polymer material for optical cables, characterized in that it is made of the following components in parts by weight: acrylonitrile ionized modified poly 2,5-bis(1,2,4-triazole- 1-yl) 17 parts of 2,3,5,6-tetrafluoro-tere-phenylenedimethanol terephthalate, 63 parts of high-density polyethylene, 11 parts of fluorine-containing hyperbranched polyethylene copolymer, 6 parts of vinyl hyperbranched polyurethane 1.7 parts of 3,4,5-trifluorophenylboronic acid, 1.2 parts of initiator, and 0.6 parts of antioxidant.

[0039] The antioxidant is composite antioxidant B225; the initiator is azobisisoheptanonitrile; the grade of the high-density polyethylene is HDPE TR480.

[0040] The preparation method of the ionized acrylonitrile modified poly 2,5-bis(1,2,4-triazol-1-yl) terephthalate 2,3,5,6-tetrafluoro-tere-xylylenedimethanol ester , including the following steps:

[0041] Step D1, adding 2,5-bis(1,2,4-triazol-1-yl)terephthalic acid, 2,3,5,6-t...

Embodiment 3

[0047] A special environmentally friendly polymer material for optical cables, characterized in that it is made of the following components in parts by weight: acrylonitrile ionized modified poly 2,5-bis(1,2,4-triazole- 1-yl) 20 parts of 2,3,5,6-tetrafluoro-tere-phenylenedimethanol terephthalate, 65 parts of high-density polyethylene, 13 parts of fluorine-containing hyperbranched polyethylene copolymer, 6.5 parts of vinyl hyperbranched polyurethane 2 parts of 3,4,5-trifluorophenylboronic acid, 1.5 parts of initiator, and 0.7 parts of antioxidant.

[0048] The antioxidant is antioxidant 1076; the initiator is lauroyl peroxide; the grade of the high-density polyethylene is HDPE 9001.

[0049] The preparation method of the ionized acrylonitrile modified poly 2,5-bis(1,2,4-triazol-1-yl) terephthalate 2,3,5,6-tetrafluoro-tere-xylylenedimethanol ester , including the following steps:

[0050] Step D1, adding 2,5-bis(1,2,4-triazol-1-yl)terephthalic acid, 2,3,5,6-tetrafluoro-terepht...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com