Antibacterial and mildew-proof fabric

A kind of fabric, the technology of aloe neoglycoside, applied in the field of textile fabrics, can solve the problems of high price, poor compatibility of organic substrates, affecting performance stability, etc., and achieve high production efficiency, low production cost and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

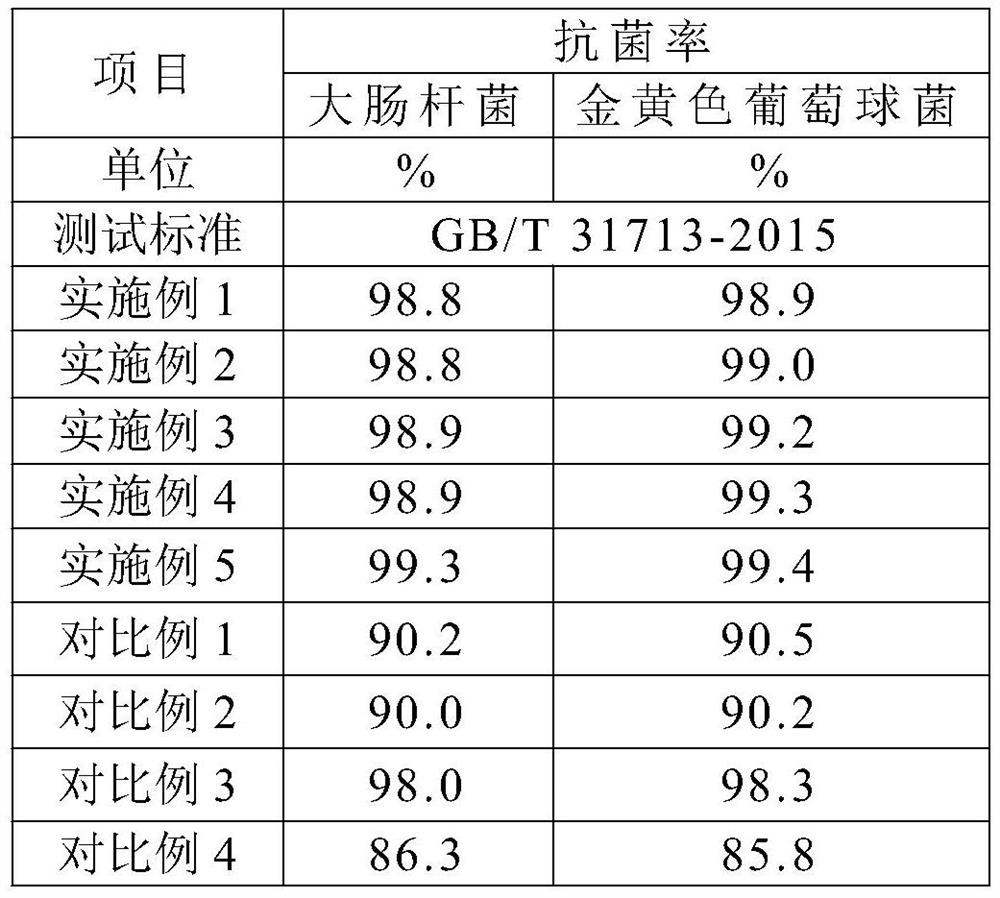

Examples

Embodiment 1

[0025] A bacteriostatic and mildew resistant fabric, characterized in that its preparation method comprises the following steps:

[0026] Step S1. Copolymerization of aloin D / N-[4-(sulfonamide)phenyl]acrylamide / (Z)-2-(2-aminothiazol-4-yl)-2-pentenoic acid / ene adenine Preparation of the compound: Aloin D, N-[4-(sulfonamide)phenyl]acrylamide, (Z)-2-(2-aminothiazol-4-yl)-2-pentenoic acid, ene Purine and azobisisobutyronitrile were added to dimethyl sulfoxide, stirred for 4 hours at 70°C under a nitrogen atmosphere, then precipitated in water, and then washed with ether for 3 times, and then placed in vacuum Dry to constant weight at 80-90℃ in a drying oven to obtain aloin D / N-[4-(sulfonamide)phenyl]acrylamide / (Z)-2-(2-aminothiazol-4-yl)- 2-pentenoic acid / ene adenine copolymer; the aloin D, N-[4-(sulfonamide)phenyl]acrylamide, (Z)-2-(2-aminothiazol-4-yl) The mass ratio of -2-pentenoic acid, adenine, azobisisobutyronitrile, and dimethyl sulfoxide is 1:2:1:0.5:0.03:12;

[0027] Step S...

Embodiment 2

[0031] A bacteriostatic and anti-fungal fabric is characterized in that its preparation method comprises the following steps:

[0032] Step S1. Copolymerization of aloin D / N-[4-(sulfonamide)phenyl]acrylamide / (Z)-2-(2-aminothiazol-4-yl)-2-pentenoic acid / ene adenine Preparation of the compound: Aloin D, N-[4-(sulfonamide)phenyl]acrylamide, (Z)-2-(2-aminothiazol-4-yl)-2-pentenoic acid, ene Purine and azobis-isoheptonitrile were added to N,N-dimethylformamide, stirred for 4.5 hours at 72°C in a helium atmosphere, then precipitated in water, and then washed with ether 4 Then, it was dried to constant weight at 82℃ in a vacuum drying oven to obtain aloin D / N-[4-(sulfonamide)phenyl]acrylamide / (Z)-2-(2-aminothiazole-4 -Yl)-2-pentenoic acid / ene adenine copolymer; the aloin D, N-[4-(sulfonamide)phenyl]acrylamide, (Z)-2-(2-aminothiazole- The mass ratio of 4-yl)-2-pentenoic acid, adenine, azobisisoheptonitrile, and N,N-dimethylformamide is 1:2:1:0.5:0.035:15;

[0033] Step S2. Preparation o...

Embodiment 3

[0037] A bacteriostatic and mildew resistant fabric, characterized in that its preparation method comprises the following steps:

[0038] Step S1. Copolymerization of aloin D / N-[4-(sulfonamide)phenyl]acrylamide / (Z)-2-(2-aminothiazol-4-yl)-2-pentenoic acid / ene adenine Preparation of the compound: Aloin D, N-[4-(sulfonamide)phenyl]acrylamide, (Z)-2-(2-aminothiazol-4-yl)-2-pentenoic acid, ene Purine and azobisisobutyronitrile were added to N,N-dimethylacetamide, and the reaction was stirred for 5 hours at 75°C in a neon atmosphere, and then precipitated in water, and then washed with ether 3 -6 times, and then placed in a vacuum drying oven at 85 ℃ to dry to constant weight to obtain aloin D / N-[4-(sulfonamide)phenyl]acrylamide / (Z)-2-(2-aminothiazole) -4-yl)-2-pentenoic acid / ene adenine copolymer; the aloin D, N-[4-(sulfonamide)phenyl]acrylamide, (Z)-2-(2-amino The mass ratio of (thiazol-4-yl)-2-pentenoic acid, adenine, azobisisobutyronitrile, and N,N-dimethylacetamide is 1:2:1:0.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com