Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Resistant to chemical media" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-borne perfluoroalkyl fluorocarbon emulsion, water-borne cable anti-icing paint containing same and preparation method thereof

ActiveCN101798366AImprove stabilityIncrease crosslink densityAntifouling/underwater paintsPaints with biocidesCelluloseEmulsifying wax

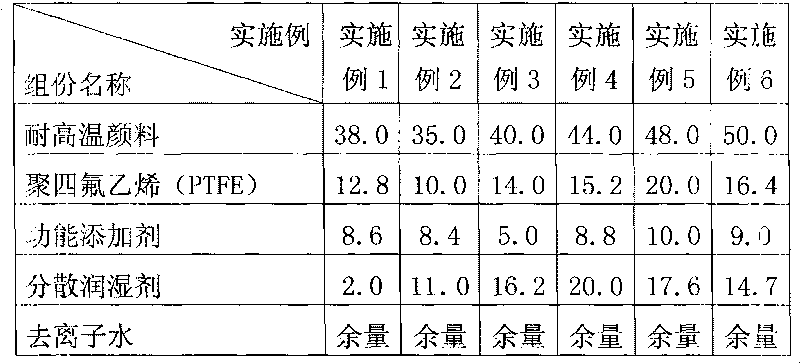

The invention relates to a water-borne cable anti-icing paint containing water-borne perfluoroalkyl fluorocarbon emulsion, which comprises the following raw materials in percentage by weight: 58 to 62 percent of aqueous perfluoroalkyl fluorocarbon emulsion, 1.5 to 2.5 percent of water-borne polytetrafluoroethylene emulsifying wax, 15 to 20 percent of water-borne color paste, 0.1 to 0.5 percent of pH regulator, 1 to 2 percent of amino resin cross-linking agent or water-borne polyurethane cross-linking agent, 0.1 to 0.2 percent of antiseptic preservative, 1 to 1.2 percent of cellulose and the balance of deionized water, wherein the water-borne color paste is the mixture of the water-borne color paste with one color or the water-borne color paste with more than two colors. The water-borne cable anti-icing paint of the invention is big in water repellent angle, low in surface energy, excellent in water repellent and oil repellent properties, safe and environment-friendly, can firmly adhere to the surface of a cable in a low temperature and cold environment and is obvious in anti-icing function.

Owner:CHANGZHOU GUANGHUI CHEM

Wood-plastic profiles and manufacturing method therefor

ActiveCN101181789APromote environmental protectionReduce releaseWood treatment detailsWood veneer joiningEnvironmental resistanceVolumetric Mass Density

The invention provides a wood-plastic sectional material that is synthesized by fast-growing wood veneer, corner offal of artificial boards that take the fast-growing wood as raw material and water-soluble phenol aldehyde resin adhesive and produced through production procedures of material selection-treatment-drying-gumming-gelatin-mould pressing-solidifying-post solidify. The density of the sectional material is 900-1300kg / m<3>, the hardness is 55-120MPa, the scale length is 500-5000mm, the width is 100-1300mm, the thickness is 15-200mm, 24-hour absorbing water thickness expansion rate is 0.6-3 percent and the formaldehyde release quantity is less than 1.5MG / L. The invention enhances the utilization of the fast-growing wood and the wood-plastic sectional material produced has high density and is a high quality material with the advantages of waterproof, heatproof, oil proof, age resistant, fungus resistant, chemical mediator resistant and better security, thereby being applicable to being used for making furniture, floor, decoration material, building moulding board, structure parts, motherboard of containers, track ties, and so on. The invention can also promote the utilization of the fast-growing wood and virtuous circle of the utilization of the wood, thereby having great environmental protection value.

Owner:SHANGHAI XINGJIA NUOHUA MATERIALS TECH

Biologic waterproof glue and usage

InactiveCN1727424AImprove adhesionImprove impermeabilityNatural rubber adhesivesStarch adhesivesEmulsionAdhesive

A biologic water-proof adhesive for building, wood, metal, ceramic, glass, etc is prepared from glutinous rice, water, ethene-vinyl acetate emulsion, dioctyl phthalate, PVC, tung oil, acrylic emulsion and natural rubber. Its advantages are high weatherability, adhesion, tension strength, elongation percentage for breaking and resistance to water, acid and alkali.

Owner:赵春发 +1

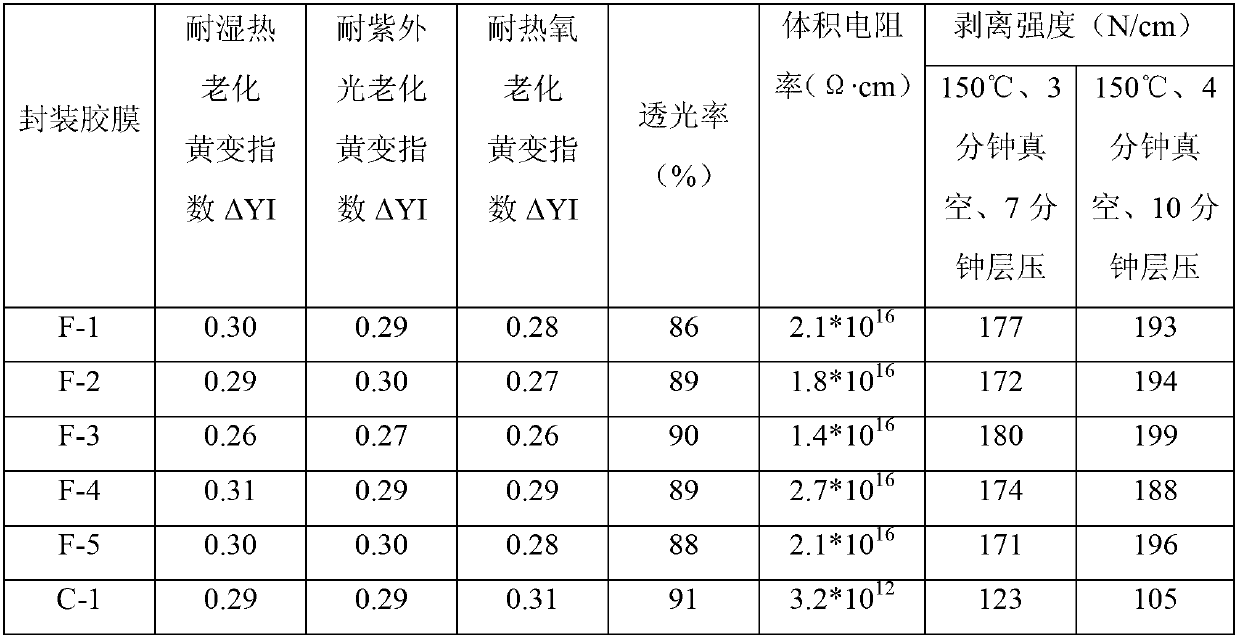

Solar cell packaging rubber film and preparation method thereof

ActiveCN102863914ALow priceRelative density is smallNon-macromolecular adhesive additivesFilm/foil adhesivesCross-linkPolymer science

The invention relates to a solar cell packaging rubber film and a preparation method thereof. The solar cell packaging rubber film comprises the following components in parts by mass: 100 parts of polymer resin, 1-50 parts of polar resin, 0.5-2 parts of cross-linking curing agent, 0.05-0.2 part of cross-linking curing accelerator, 0.2-0.6 part of tackifier, 0.1-0.5 part of antioxidant, 0.05-0.25 part of ultraviolet stabilizer and 0.05-0.25 part of ultraviolet absorber. The preparation method of the solar cell packaging rubber film comprises the following steps of: 1) evenly mixing the raw materials according to proportions to obtain mixture; and 2) pouring the mixture into an extruder for mixing and plasticizing to obtain extruded materials, casting and calendaring the extruded materials to form a film, shaping through cooling and drawing, and finally winding the film. The solar cell packaging rubber film provided by the invention has the advantages that the light transmittance is higher, the film can effectively resist aging and the electric insulating performance is not changed fundamentally after the film is used for a long time; and the preparation method provided by the invention has the advantages that the processing efficiency is high, the cost is low and the large-scale production can be realized.

Owner:宁波威克丽特功能塑料有限公司

High temperature and high pressure-resistant type graphene-modified phenolic heavy-duty anti-corrosive coating for oil pipe

InactiveCN109517492AStrong adhesionImprove wear resistancePretreated surfacesAnti-corrosive paintsAdhesion forceEpoxy

The invention relates to a high temperature and high pressure-resistant type graphene-modified phenolic heavy-duty anti-corrosive coating for an oil pipe. The high temperature and high pressure-resistant type graphene-modified phenolic heavy-duty anti-corrosive coating consists of a primer and a topcoat, wherein the primer consists of a component A and a component B; the topcoat consists of a component A and a component B; the component A of the topcoat is prepared from the following components in percentage by mass: 20 to 60% of epoxy resin, 10 to 20% of organic solvent, 0 to 1.5% of graphene, 2 to 10% of pigment, 10 to 30% of filler, and 0 to 2% of adjuvant, and the sum of mass percentages of the components of the component A of the topcoat is 100%; the component B of the topcoat is an epoxy curing agent; the mass of the component B of the topcoat accounts for 8 to12% of the total mass of the component A of the topcoat. The high temperature and high pressure-resistant type graphene-modified phenolic heavy-duty anti-corrosive coating has the excellent properties of strong adhesion force, strong abrasion-resistant property, chemical medium-resistant property, high temperature and high pressure-resistant property, and the like.

Owner:天津宝坻紫荆创新研究院

Heat-resistant antistatic coating

InactiveCN101993647AEasy to cleanEasy maintenanceEpoxy resin coatingsElectrically-conductive paintsEpoxySolvent

The invention relates to a heat-resistant antistatic coating which is especially applicable to working at high temperature. The heat-resistant antistatic coating provided by the invention can maintain good electrical conductivity and does not influence the properties of manufactured products. The heat-resistant antistatic coating is prepared from 55-65% of polyester resin, 55-65% of epoxy resin, 27-40% of filling material, 4-5% of leveling agent, 3-4% of curing agent, 40-70% of resin, 20-40% of electrically conductive powder, 1-20% of solvent, 1-3% of dispersing aid, 1-5% of titanium white, 0.1-0.3% of coupling agent, 35-55% of acrylic emulsion, 1-4% of graphite powder, 1-4% of carbon black and 45-65% of diluent.

Owner:杨紫萱

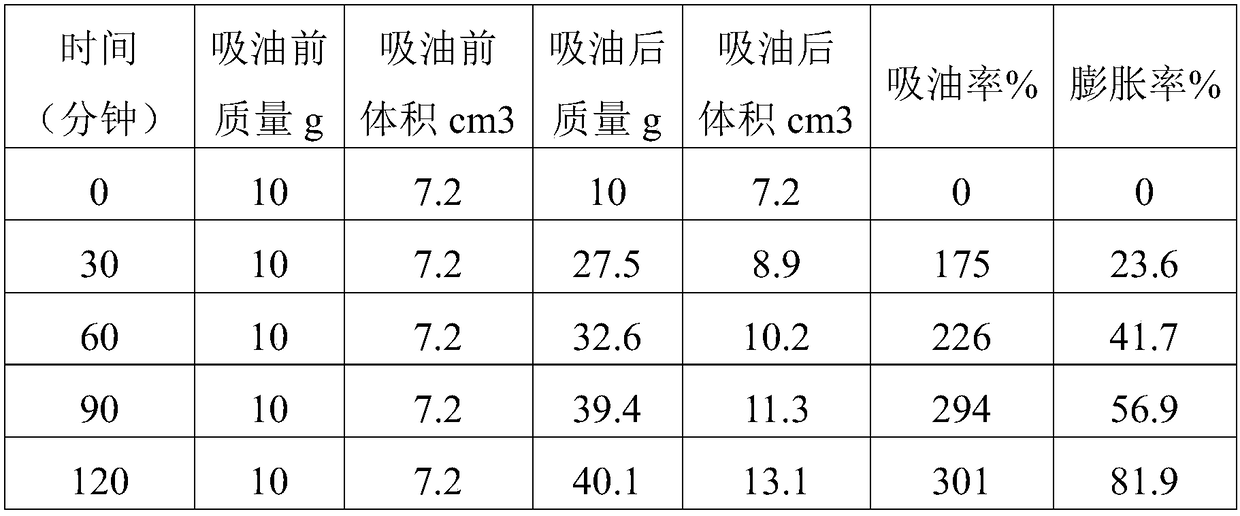

High-density oil-based drilling fluid plugging liquid and preparation method and application thereof

The invention discloses a high-density oil-based drilling fluid plugging liquid which comprises, by weight percentage, 3-6% of aluminum alloy particles GYD, 5-6% of non-permeating treatment agent BYD,3-9% of high acid soluble calcium particles KGD, and the balance drilling fluid. The high-density oil-based drilling fluid plugging liquid has good dispersion in high-density oil-based mud, does notsettle, does not float and has high temperature resistance, high compressive strength and high overall acid solubility, the overall concentration of the plugging liquid is not high, and the plugging liquid is favorable for acidification transformation of a later oil layer after entering the formation.

Owner:KMS OIL FIELD CHEM & TECHNICAL SERVICES LTD BEIJING +1

Recycled ethylene propylene diene monomer/reclaimed isobutylene-isoprene rubber (REPDM/RIIR) elastomer and preparation method thereof

The invention discloses a recycled ethylene propylene diene monomer / reclaimed isobutylene-isoprene rubber (REPDM / RIIR) elastomer and a preparation method thereof, and relates to an elastomer material and the preparation method thereof. The waterproof material is prepared from the following components in parts by mass: 100 parts of combined REPDM and RIIR, 1-2 parts of brimstone, 0.9-2 parts of accelerant, 2.5-8 parts of vulcanizing activator, and 0-20 parts of carbon black. The material has good process compatibility by combination of the EPDM and the IIR; better combination property can be obtained. Blend rubber can be vulcanized by the brimstone, peroxide, esters and resin; the vulcanization rates of the brimstone, the peroxide, the esters and the resin are approximate; a co-vulcanization material is easily formed. According to the REPDM / RIIR elastomer, the EPDM and the IIR are completely replaced by the REPDM and the RIIR; the cost of the waterproof material is reduced by matching with a fortifier and a vulcanizing agent; the waterproof material is easily formed; the adhesiveness between the waterproof material and a matrix is improved. An experiment research proves that the REPDM / RIIR waterproof material with excellent ozone resistance, weather fastness, low temperature resistance, resistance to chemical mediator and hot air aging resistance is prepared.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

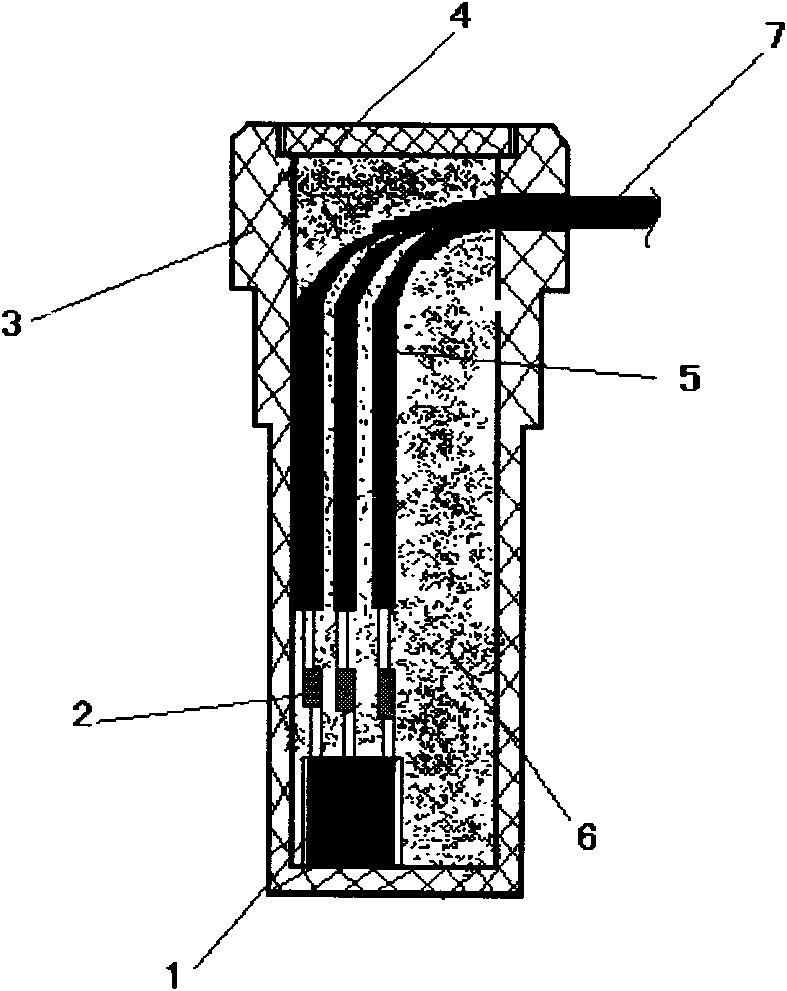

A battery temperature sensing device and its preparation method

InactiveCN102261960AHigh precisionReduce volumeThermometer detailsThermometers using electric/magnetic elementsSignal processing circuitsEngineering

The invention relates to a temperature sensing device of a storage battery, which is characterized by comprising a shell (3), a sealing cover (4), a lead (5) and a sensing chip (1); the sensing chip (1) is located at the bottom of the shell (3), the upper end of the sensing chip (1) is provided with a chip pin, and the chip pin and the lead (5) form a welding part (2) of the chip pin and the lead in a welding manner; one part of the lead (5) passes through the temperature sensing device, and the part passing through the temperature sensing device is provided with a shrinkable tube (7); and the shell (3) is internally provided with an encapsulating material (6). The temperature sensing device solves the problem of low accuracy of the current temperature sensing device of the storage battery, and can be widely used in temperature test for acid containing liquid, wherein a temperature test range is from -55 DEG C to +125 DEG C; and in addition, the digital temperature sensing device needs no signal processing circuit, and the output signals can be shared by a plurality of control devices.

Owner:CHINA NORTH VEHICLE RES INST

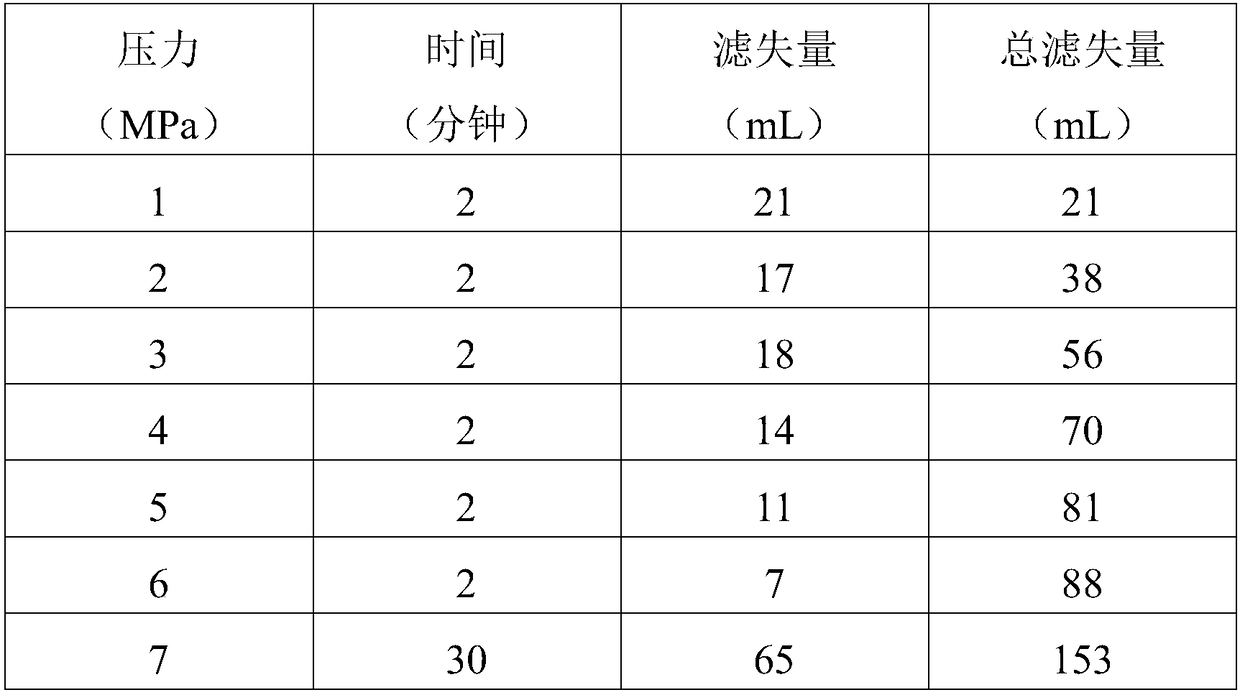

High-acid-solubility plugging liquid during drilling

ActiveCN108441195AGood acid solubilityConducive to acidification modificationDrilling compositionSolubilityAlloy

The invention discloses high-acid-solubility plugging liquid during drilling. The high-acid-solubility plugging liquid during drilling is prepared from the following components in percentage by weight: 2-4% of aluminum alloy particles GYD, 3-5% of flexible polymer materials, 4-5% of superfine calcium and the balance of drilling fluid. The high-acid-solubility plugging liquid during drilling has anacid solubility rate of 80% or higher, and can be used in oil-based drilling fluid. The high-acid-solubility plugging liquid during drilling further has a relatively good bridge plugging function anda relatively good filling function, and has a very good plugging effect for pore and seam type leakage.

Owner:KMS OIL FIELD CHEM & TECHNICAL SERVICES LTD BEIJING +1

A scientific timber material

The invention provides a technical wood material, comprising a core board, the raw materials of the core board and the parts by weight of each raw material are 22-34 parts of balsa wood powder; 16-29 parts of bamboo charcoal powder; low floating fiber alkali-free chopped 11-19 parts of glass fiber; 4-9 parts of polyolefin elastomer; 9-16 parts of composite vegetable dye; 16-23 parts of basalt fiber; 17-21 parts of cyanuric chloride; 7-15 parts of glycidyl methacrylate 11-26 parts of fatty alcohol polyoxyethylene ether; 13-25 parts of epoxy silane crosslinking agent. The invention has the characteristics of high hardness and light specific gravity, and its properties of compression resistance, bending resistance and impact resistance are superior to those of natural wood. Environmental protection, flame retardant, moisture-proof, insect-proof, no deformation, high hardness, not afraid of water immersion, easy maintenance, high wear resistance, longer service life, etc. Simultaneously, the present invention also adds compound vegetable dyes, endows multiple colors, and simultaneously the color and luster is brighter, and the three-dimensional sense of texture is stronger.

Owner:龙门县品汐竹木制品有限公司

Polyarmide fiber composite material and preparation technology thereof

The invention discloses a polyarmide fiber composite material. The polyarmide fiber composite material comprises polyarmide fibers, a modifier maleic anhydride grafted POE, chitosan modified montmorillonite, and a compatibilizer. The invention also discloses a preparation technology of the polyarmide fiber composite material. POE is grafted and modified by maleic anhydride, so the modified POE can be well fused with the polyarmide fibers and other raw material components, thereby the heat resistance temperature of the composite material is improved, the permanent deformation decreases, and the tensile strength, the tearing strength and other main performance performances are greatly improved; and the modified montmorillonite is used to well enhance the toughness of the polyarmide fibers, so the polyarmide fiber material with high performances and good comprehensive performances is obtained.

Owner:SUZHOU YUNSHU NEW MATERIAL TECH

Preparation method of fiberboard for musical instrument bamboo fiber material

InactiveCN110576496AKeep the lookMaintain mechanical propertiesWood treatment detailsReed/straw treatmentCompression moldingAdhesive

The invention provides a preparation method of a fiberboard for a musical instrument bamboo fiber material. The preparation method comprises the following steps of 1), oxidizing and desugarizing natural plant fibers such as bamboo to obtain continuous bamboo natural fibers; 2), impregnating the surface modified continuous bamboo natural fibers with synthetic resin adhesive; and 3), carrying out compression molding on bamboo fibers impregnated with synthetic resin in a mold, taking forming curing temperature as the heat curing peak temperature of the synthetic resin adhesive, and preparing theplant fiber reinforced composite material after thermal curing molding. The preparation method of the fiberboard for the musical instrument bamboo fiber material has the advantages of low production cost, good mechanical property and good acoustic performance.

Owner:李刚

Compound wax emulsion

The invention discloses a composite wax emulsion, which is prepared by mixing the following components: wax, emulsifier and deionized water. The compounded wax emulsion of the present invention is compounded with three components of palm wax, liquid paraffin and beeswax, and emulsified by a high-performance emulsifier. The wax emulsion has the advantages of high stability, low viscosity, rust resistance, heat and humidity resistance, high and low temperature resistance, chemical medium resistance, water resistance and the like.

Owner:张耀忠

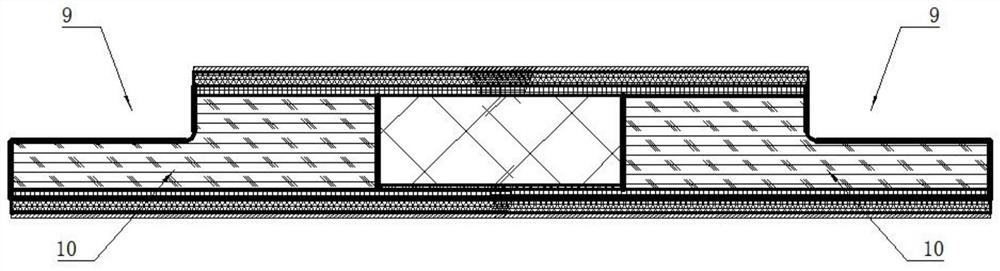

3D woven composite floor and manufacturing process thereof

ActiveCN113858728AHigh hardnessGood fire resistanceFireproof paintsSynthetic resin layered productsMoisture resistanceInsulation layer

The invention provides a 3D woven composite floor and a manufacturing process thereof, and belongs to the technical field of floors. The composite floor sequentially comprises, from top to bottom: an upper fireproof layer, an upper glass fiber composite cloth layer, an upper glass fiber gridding cloth layer, a 3D woven PU core material layer, a sound insulation layer, a lower glass fiber gridding cloth layer, a lower glass fiber composite cloth layer and a bottom fireproof layer, wherein the whole composite floor is infiltrated and reinforced by resin adhesive; and fireproof plates are arranged on the periphery of the 3D woven PU core material layer. The invention further provides a manufacturing process of the 3D woven composite floor. The composite floor has the advantages of sound insulation, fire prevention, light weight, stripping resistance, aging resistance, medium resistance, moisture resistance, high strength and difficulty in deformation.

Owner:CHANGCHUN INTER CITY RAILWAY VEHICLE ACCESSORIES

RIIR/REPDM elastomer and preparation method thereof

The invention relates to recycled butyl rubber and a preparation method thereof and especially relates to an RIIR / REPDM elastomer and a preparation method thereof. The RIIR / REPDM elastomer comprises 100 parts of RIIR and REPDM as waterproof materials, 1-2 parts of sulfur, 0.9-2 parts of a promoter, 2.5-8 parts of a vulcanization activator and 0-20 parts of carbon black. RIIR and REPDM have good technical compatibility. Through use of REPDM in RIIR, good integrated performances are obtained and RIIR machining performances are improved. The RIIR and REPDM used simultaneously can adopt the same vulcanization system, have similar vulcanization rates and easily form a co-vulcanization material. The preparation method utilizes RIIR and REPDM to completely replace EPDM and IIR, reduces a waterproof material cost and improves adhesion of the waterproof material and a base. The RIIR / REPDM waterproof material obtained by the preparation method has excellent performances of ozone resistance, weatherability, low temperature resistance, chemical medium resistance and hot air ageing resistance.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

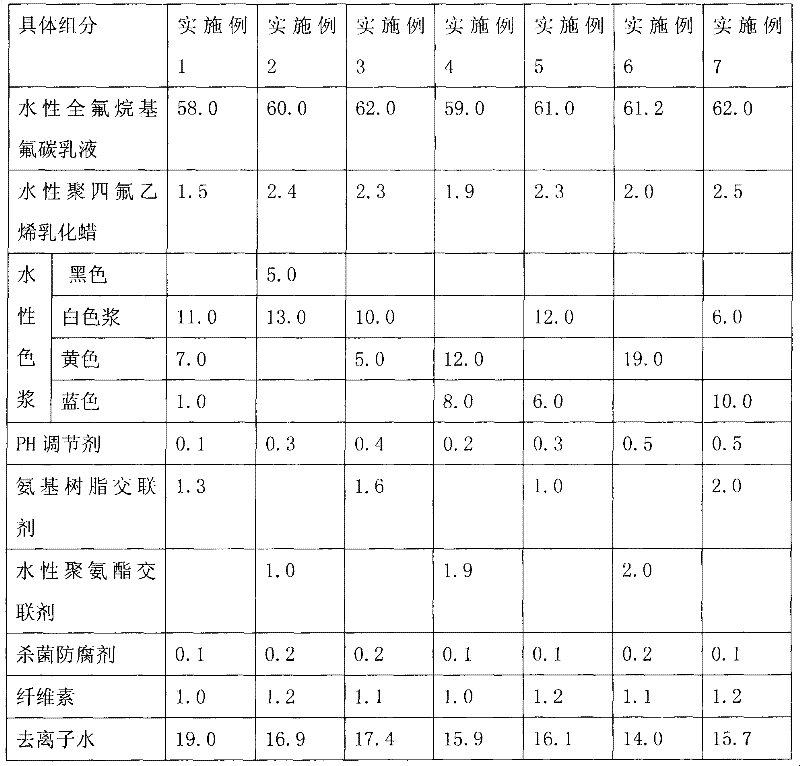

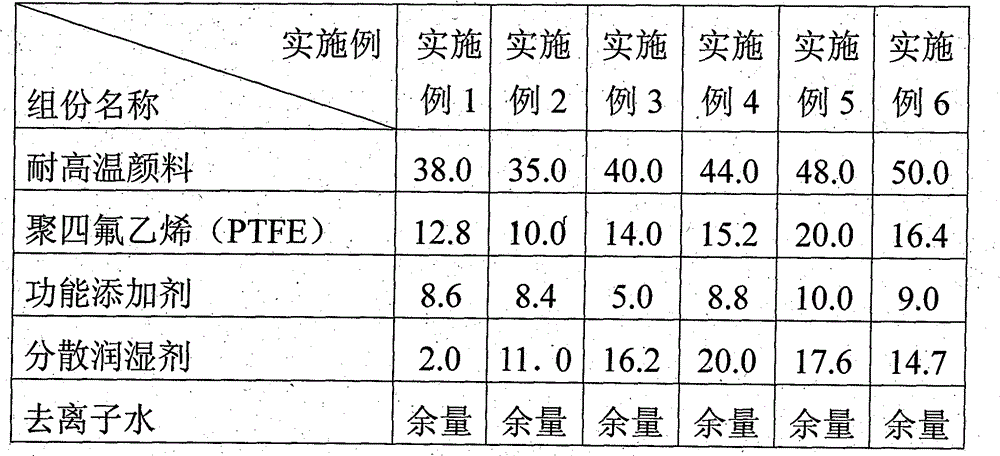

Brown colorant for water Teflon high-temperature cloth and preparing method thereof

InactiveCN101748597AGood storage stabilityImprove temperature resistanceFibre treatmentEmulsionTemperature resistance

The invention discloses a brown colorant for water Teflon high-temperature cloth and a method for preparing the brown colorant. The brown colorant is composed of a high-temperature resisting pigment, polytetrafluoroethylene, a functional additive agent, a dispersing wetting agent and deionized water. The materials comprise, by weight percent, 35 to 50 percent of the high-temperature resisting pigment, 10 to 20 percent of the polytetrafluoroethylene, 5 to 10 percent of the functional additive agent, 2 to 20 percent of the dispersing wetting agent, and the balance of deionized water. The brown colorant can be prepared through mixing and grinding all the constituents and implementing quality test, vacuum defoamation and filtering packing. The brown colorant for the water Teflon (PTFE) high-temperature cloth by the method is characterized by long storage stability, good temperature resistance (reaching to more than 400 DEG C), excellent chemical resistance, bright color, good compatibility with PTFE emulsion and high color intensity. The grain diameters can realize that D99 is less than or equal to 5 microns (namely, the average diameter of 99 percent of the grains is less than or equal to 5 microns), and the brown colorant and the method conform to national environmental requirements because the deionized water is taken as base material. The brown colorant has the advantages of simple preparation process, low preparation cost and easy industrialized production.

Owner:SUZHOU SUNMUN TECH CO LTD

Water-based perfluoroalkyl fluorocarbon emulsion, water-based cable anti-icing coating containing the emulsion and preparation method thereof

ActiveCN101798366BImprove stabilityIncrease crosslink densityAntifouling/underwater paintsInsulated cablesCellulosePolymer chemistry

Owner:CHANGZHOU GUANGHUI CHEM

Shielded incident acoustic wave material

A material for shielding incident sound waves contains PVC (5-60 wt%), tungsten powder (10-90), and assistant (5-30). Its advantages are better mechanical and sound shielding performance, high resistance to fire and chemical corrosion, high machinability, and no poison. Its sound shielding index can reach 22.7 db.

Owner:SHANGHAI JIAO TONG UNIV

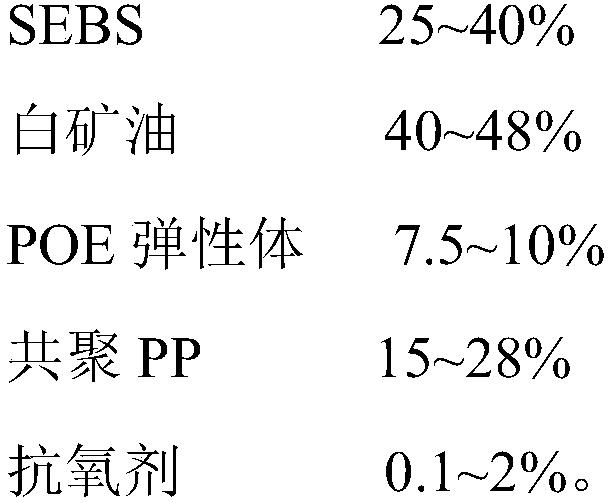

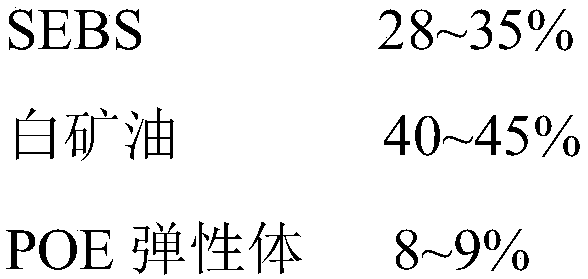

Novel rubber material of run-flat tire

InactiveCN109233183AHigh impact strengthHigh elongation at breakSpecial tyresElastomerRubber material

The invention relates to the field of rubber materials, in particular to a novel rubber material of a run-flat tire. The novel rubber material is prepared from the following raw materials by weight percent: 25 to 40 percent of SEBS, 40 to 48 percent of white mineral oil, 7.5 to 10 percent of POE elastomer, 15 to 28 percent of copolymer PP, and 0.1 to 2 percent of antioxidant. The invention provides the novel rubber material of the run-flat tire which is resistant to high temperature and aging.

Owner:东莞市塑高塑化科技有限公司

Technological composite decorative material

The invention provides a technological composite decorative material, comprising a core board, the raw materials of the core board and the parts by weight of each raw material are 22-34 parts of balsa wood powder; 16-29 parts of bamboo charcoal powder; 11-19 parts of cut glass fiber; 4-9 parts of polyolefin elastomer; 9-16 parts of composite vegetable dye; 16-23 parts of soybean protein fiber; 17-21 parts of cyanuric chloride; polyhexamethylene guanidine propionate 7‑15 parts; 11‑26 parts of chitosan quaternary ammonium salt; 13‑25 parts of triethanolamine; 3‑9 parts of gallic acid. The invention has the characteristics of high hardness and light specific gravity, and its properties of compression resistance, bending resistance and impact resistance are superior to those of natural wood. Environmental protection, flame retardant, moisture-proof, moth-proof, no deformation, high hardness, not afraid of water immersion, easy maintenance, high wear resistance, longer service life, etc. Simultaneously, the present invention also adds compound vegetable dyes, endows multiple colors, and simultaneously the color and luster is brighter, and the three-dimensional sense of texture is stronger.

Owner:龙门县品汐竹木制品有限公司

Brown colorant for water Teflon high-temperature cloth and preparing method thereof

InactiveCN101748597BGood storage stabilityImprove temperature resistanceFibre treatmentEmulsionTemperature resistance

The invention discloses a brown colorant for water Teflon high-temperature cloth and a method for preparing the brown colorant. The brown colorant is composed of a high-temperature resisting pigment, polytetrafluoroethylene, a functional additive agent, a dispersing wetting agent and deionized water. The materials comprise, by weight percent, 35 to 50 percent of the high-temperature resisting pigment, 10 to 20 percent of the polytetrafluoroethylene, 5 to 10 percent of the functional additive agent, 2 to 20 percent of the dispersing wetting agent, and the balance of deionized water. The brown colorant can be prepared through mixing and grinding all the constituents and implementing quality test, vacuum defoamation and filtering packing. The brown colorant for the water Teflon (PTFE) high-temperature cloth by the method is characterized by long storage stability, good temperature resistance (reaching to more than 400 DEG C), excellent chemical resistance, bright color, good compatibility with PTFE emulsion and high color intensity. The grain diameters can realize that D99 is less than or equal to 5 microns (namely, the average diameter of 99 percent of the grains is less than or equal to 5 microns), and the brown colorant and the method conform to national environmental requirements because the deionized water is taken as base material. The brown colorant has the advantages of simple preparation process, low preparation cost and easy industrialized production.

Owner:SUZHOU SUNMUN TECH CO LTD

Shielded incident acoustic wave material

A material for shielding incident sound waves contains PVC (5-60 wt%), tungsten powder (10-90), and assistant (5-30). Its advantages are better mechanical and sound shielding performance, high resistance to fire and chemical corrosion, high machinability, and no poison. Its sound shielding index can reach 22.7 db.

Owner:SHANGHAI JIAOTONG UNIV

A kind of RIIR/repdm elastomer and preparation method thereof

An RIIR / REPDM elastomer and a preparation method thereof, relating to a regenerated butyl rubber and a preparation method thereof, the waterproof material RIIR and REPDM are combined with a total amount of 100 parts, 1-2 parts of sulfur, and 0.9-2 parts of an accelerator. 2.5-8 parts of vulcanization active agent, 0-20 parts of carbon black. Both RIIR and REPDM have good process compatibility. Adding part of REPDM to RIIR can not only obtain better comprehensive performance, but also improve the machinability of RIIR. The two glues can use the same vulcanization system, and the vulcanization rate is relatively close, and it is easy to form co-vulcanized materials. The present invention uses RIIR and REPDM to completely replace EPDM and IIR, which reduces the cost of waterproof materials, improves the adhesion between waterproof materials and substrates, and makes the RIIR / REPDM waterproof materials obtained in the final research have ozone resistance, weather resistance, and Low temperature, chemical medium resistance, heat air aging resistance and other excellent properties.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

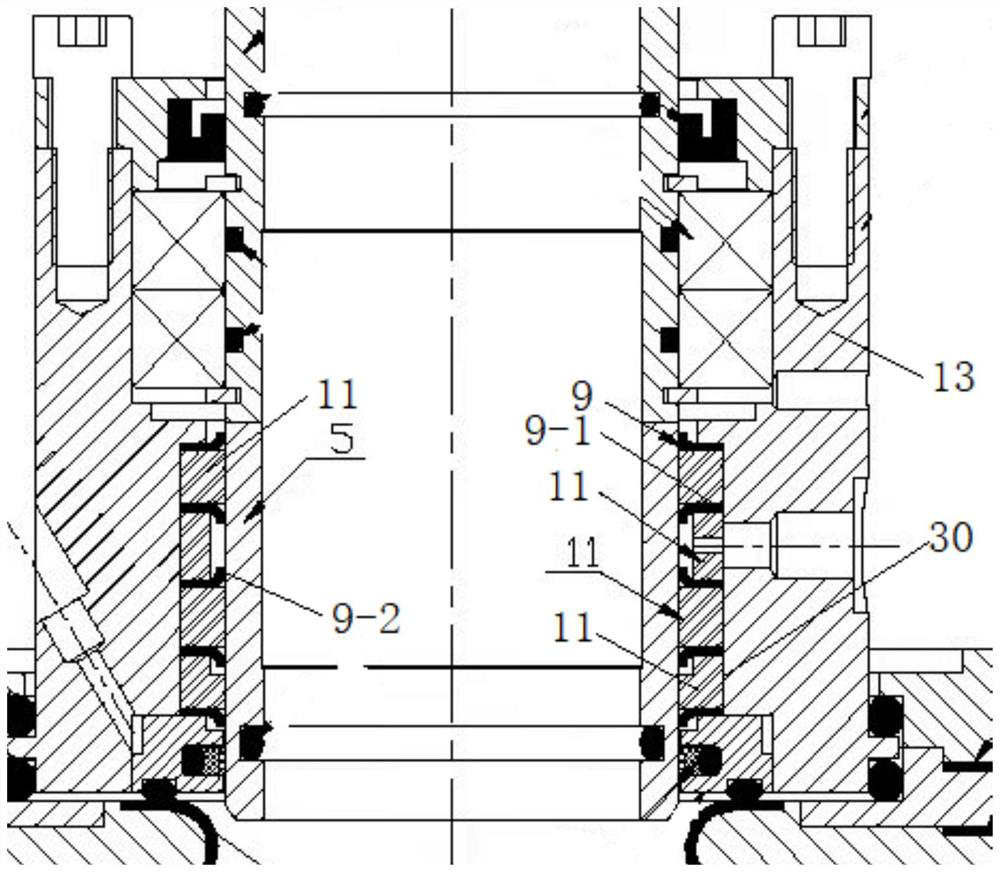

Sealing structure for enamel reaction kettle

PendingCN114392701AGood corrosion resistanceGuaranteed tightnessChemical/physical/physico-chemical stationary reactorsCarbide siliconCorrosion resistant

The invention relates to a sealing structure for enamel reaction kettles.The sealing structure comprises a bearing box with a first through hole formed in the bottom, a first shaft sleeve is rotatably arranged on the inner side of the first through hole and made of ceramic or silicon carbide, and a plurality of bushing rings arranged at intervals are fixed in the first through hole in a matched mode; an elastic sealing lip piece is arranged between every two adjacent bushing rings, each sealing lip piece comprises an annular body, a lip opening part is arranged on the inner side of each annular body, the annular bodies are fixed between the inner side end faces of the adjacent bushing rings in a matched mode, and the lip opening parts are attached to the outer side of the first shaft sleeve and bent in an arc shape. The novel sealing structure is good in sealing performance, a gas supply or liquid sealing system does not need to be used, the part in contact with materials is made of corrosion-resistant non-metal materials, and the novel sealing structure can tolerate more chemical media.

Owner:ZHENJIANG OUSA IND SEAL CO LTD

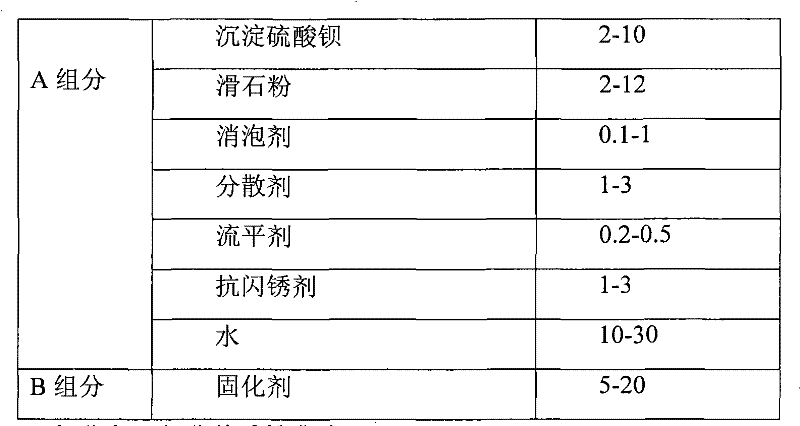

Waterborne polyurethane modified epoxy steel structure anti-corrosive paint and preparation method thereof

InactiveCN101735706BResistant to chemical mediaHigh film strengthAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyPublic Facility

The invention belongs to the paint technical field, in particular relates to a waterborne polyurethane modified epoxy steel structure anti-corrosive paint and a preparation method thereof. The component A of the paint is a dispersion of modified E-20 and the component B used as curing agent is a waterborne dispersion which is prepared through modification by using epoxy and hydrophilic groups. The system has the advantages of common waterborne paints, overcomes the defects of the waterborne epoxy anti-corrosive paint and has the advantages of polyurethane and epoxy materials. The waterborne epoxy anti-corrosive paint prepared by using the system as the base material has great development prospect in the field of steel structures such as bridges, pipes, containers, industrial plants and public facilities.

Owner:TONGJI UNIV

Wood-plastic profiles and manufacturing method therefor

ActiveCN101181789BGood adhesionWater resistantWood treatment detailsWood veneer joiningAdhesive cementWood veneer

The invention provides a wood-plastic sectional material that is synthesized by fast-growing wood veneer, corner offal of artificial boards that take the fast-growing wood as raw material and water-soluble phenol aldehyde resin adhesive and produced through production procedures of material selection-treatment-drying-gumming-gelatin-mould pressing-solidifying-post solidify. The density of the sectional material is 900-1300Kg / m<3>, the hardness is 55-120MPa, the scale length is 500-5000mm, the width is 100-1300mm, the thickness is 15-200mm, 24-hour absorbing water thickness expansion rate is 0.6-3 percent and the formaldehyde release quantity is less than 1.5MG / L. The invention enhances the utilization of the fast-growing wood and the wood-plastic sectional material produced has high density and is a high quality material with the advantages of waterproof, heatproof, oil proof, age resistant, fungus resistant, chemical mediator resistant and better security, thereby being applicable to being used for making furniture, floor, decoration material, building moulding board, structure parts, motherboard of containers, track ties, and so on. The invention can also promote the utilization of the fast-growing wood and virtuous circle of the utilization of the wood, thereby having great environmental protection value.

Owner:SHANGHAI XINGJIA NUOHUA MATERIALS TECH

Soft superhigh specific gravity composite materials for acoustic insulation and noise elimination

A soft composition with ultrahigh specific weight for isolating sound and reducing noise contains high-molecular polymer (5-30 wt.%), tungsten powder (10-90), plasticizer (3-10), stabilizer (1-5) and coupling agent (1-10). Its advnatages are high sound isolating and mechanical performance, high resistance to fire and chemical corrosion, no poison and high machinability.

Owner:SHANGHAI JIAOTONG UNIV

Modified wood-plastic composite material

The invention discloses a modified wood-plastic composite material which is prepared by using polyphenylene sulfide, wood flour, compound glass fiber powder and polyethylene plastic powder as main raw materials, and the polyphenylene sulfide is subjected to heat treatment before being added, so that the effect of improving the crystallinity of the polyphenylene sulfide is achieved, and the glass transition of the composite material during extrusion is reduced; the formed composite material fiber is large in density, higher in strength and not prone to breakage, the compatibilizer is added, the cross section bonding of the compound glass fiber and the polyphenylene sulfide can be improved, the produced wood-plastic composite material obtains higher strength, crystalline PE chain links in the POE elastomer added in the preparation process can be cross-linked with the cross-linking agent added in the auxiliaries, the amorphous ethylene long chain can provide elasticity, so that the aims of improving the toughness of the wood-plastic composite material while improving the mechanical property of the wood-plastic composite material are fulfilled, and the quality of the modified wood-plastic composite material is better.

Owner:ANHUI KOJO NEW MATERIAL TECH CO LTD

Temperature sensing device of storage battery and manufacture method thereof

InactiveCN102261960BHigh precisionReduce volumeThermometer detailsThermometers using electric/magnetic elementsSignal processing circuitsEngineering

The invention relates to a temperature sensing device of a storage battery, which is characterized by comprising a shell (3), a sealing cover (4), a lead (5) and a sensing chip (1); the sensing chip (1) is located at the bottom of the shell (3), the upper end of the sensing chip (1) is provided with a chip pin, and the chip pin and the lead (5) form a welding part (2) of the chip pin and the lead in a welding manner; one part of the lead (5) passes through the temperature sensing device, and the part passing through the temperature sensing device is provided with a shrinkable tube (7); and the shell (3) is internally provided with an encapsulating material (6). The temperature sensing device solves the problem of low accuracy of the current temperature sensing device of the storage battery, and can be widely used in temperature test for acid containing liquid, wherein a temperature test range is from -55 DEG C to +125 DEG C; and in addition, the digital temperature sensing device needs no signal processing circuit, and the output signals can be shared by a plurality of control devices.

Owner:CHINA NORTH VEHICLE RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com