Solar cell packaging rubber film and preparation method thereof

A solar cell and encapsulation adhesive film technology, which is applied in circuits, adhesives, photovoltaic power generation, etc., can solve the problems of reduced photoelectric conversion efficiency of solar cells, damage of solar cell components, and corrosion of metal electrodes of cells, so as to prolong the outdoor service life, The effect of reducing permanent deformation and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

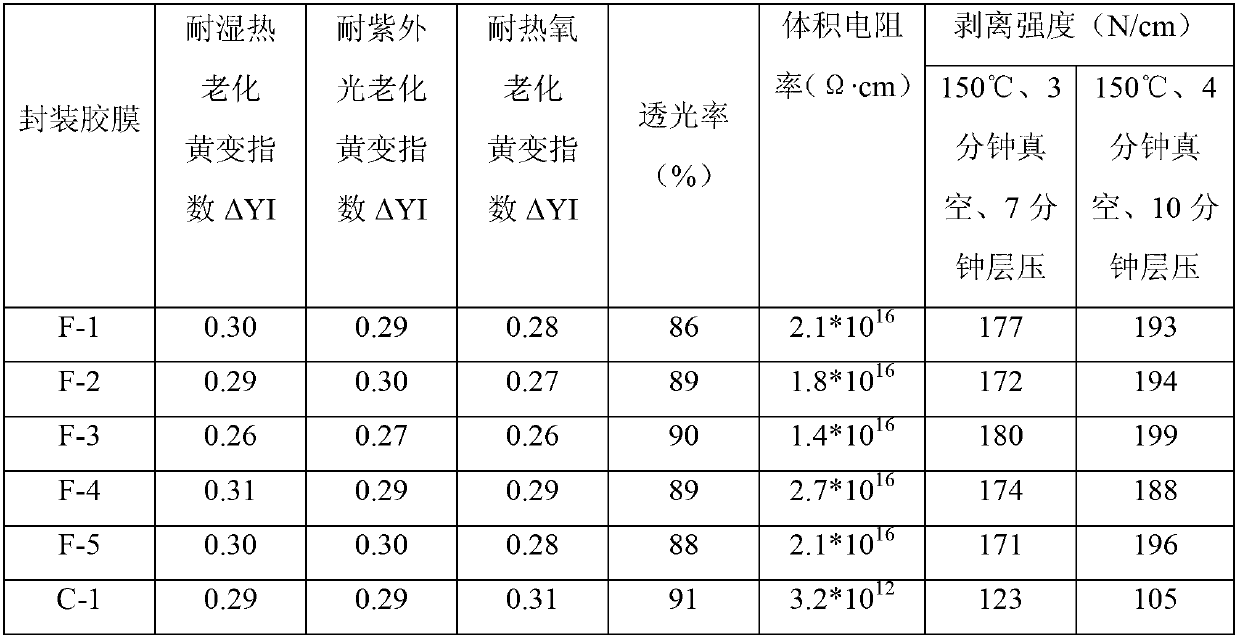

Examples

Embodiment 1

[0070] Add 5 parts by mass of polar resin polyethylene grafted maleic anhydride copolymer, 1 mass part of crosslinking curing agent tert-butyl peroxide 2-ethylene glycol in 100 parts by mass of polymer resin ethylene-butene copolymer raw material Hexyl carbonate, 0.1 parts by mass of crosslinking curing accelerator triallyl isocyanurate, 0.5 parts by mass of tackifier r-glycidyl ether oxypropyl tertiary oxysilane, 0.2 parts by mass of antioxidant Agent bis(2,4-dicumylphenyl)pentaerythritol diphosphite, 0.1 parts by mass of UV light stabilizer polysuccinic acid (4-hydroxy-2,2,6,6-tetramethyl-1- 1 piperidine ethyl alcohol) ester and 0.1 parts by mass of UV absorber 2-hydroxyl-4-methoxybenzophenone are mixed evenly and put into an extruder for mixing and plasticizing, and the temperature of the extruder is controlled at 83°C. The obtained extrudate was cast and calendered to form a film, cooled and drawn to shape, and finally a solar cell encapsulating adhesive film F-1 with a th...

Embodiment 2

[0072] Add 2 parts by mass of polar resin polybutene grafted maleic anhydride copolymer, 1 mass part of crosslinking curing agent tert-butyl peroxide 2-ethylene glycol to 100 parts by mass of polymer resin ethylene-propylene copolymer raw material Hexyl carbonate, 0.1 parts by mass of crosslinking curing accelerator triallyl isocyanurate, 0.5 parts by mass of tackifier r-glycidyl ether oxypropyl tertiary oxysilane, 0.2 parts by mass of antioxidant Agent bis(2,4-dicumylphenyl)pentaerythritol diphosphite, 0.1 parts by mass of UV light stabilizer polysuccinic acid (4-hydroxy-2,2,6,6-tetramethyl-1- 1 piperidine ethyl alcohol) ester and 0.1 parts by mass of ultraviolet light absorber 2-hydroxyl-4-methoxyl-5-sulfonic acid benzophenone, after mixing evenly, drop into an extruder for mixing and plasticizing, and extrude The temperature of the machine was controlled at 82°C, and the obtained extrudate was cast and calendered to form a film, cooled and pulled to shape, and finally a sol...

Embodiment 3

[0074] Add 10 parts by mass of polar resin POE grafted acrylate copolymer, 1 mass part of crosslinking curing agent tert-butyl peroxide 2-ethylhexyl in 100 parts by mass of polymer resin ethylene-butene copolymer raw material Carbonate, 0.1 parts by mass of crosslinking curing accelerator triallyl isocyanurate, 0.5 parts by mass of tackifier r-glycidyl ether oxypropyl tertiary oxysilane, 0.2 parts by mass of antioxidant three (2,4-di-tert-butylphenyl) phosphite, 0.1 parts by mass of UV light stabilizer polysuccinic acid (4-hydroxy-2,2,6,6-tetramethyl-1-1 piperidine Ethanol) ester and 0.1 parts by mass of UV absorber N-(ethoxycarbonylphenyl)-N'-methyl-N'-phenylmethyl ether are mixed evenly and then put into the extruder for mixing and plasticization, extruding The exit temperature was controlled at 88°C, and the obtained extrudate was cast and calendered to form a film, cooled and pulled to shape, and finally a solar cell encapsulating adhesive film F-3 with a thickness of 0.5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com