Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Reduced weldability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

CO2 gas protection welding process of 800 MPa high-strength steel

InactiveCN102179601AUniform strengthUniform hardnessArc welding apparatusWelding/cutting media/materialsThumb oppositionOperability

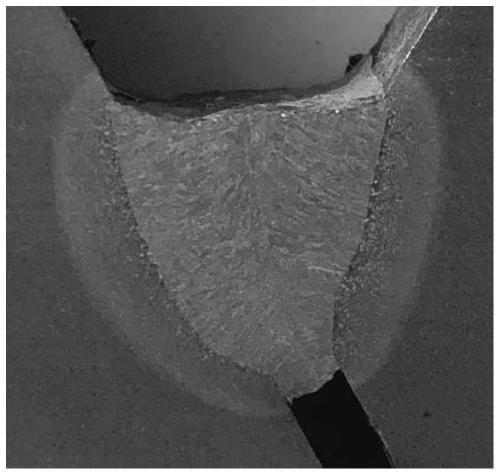

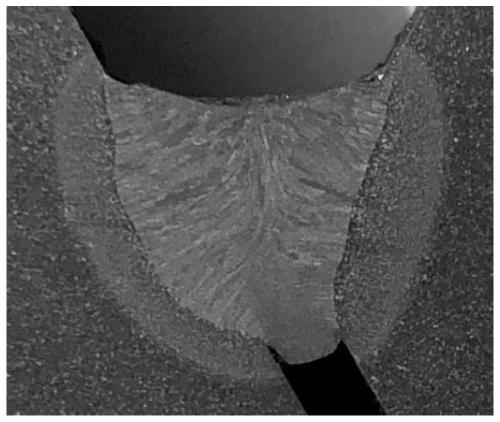

The invention discloses a CO2 gas protection welding process of 800 MPa high-strength steel. The CO2 protection welding process is characterized by comprising the following steps of: (1) machining a joint: machining an X-shaped groove on the joint; (2) using a solid welding wire with the diameter of 1.2 mm and the tensile strength of 800 MPa, wherein the solid welding wire comprises the following chemical components in percentage by weight: 0.04-0.10% of C, 0.30-0.80% of Si, 1.30-2.0% of Mn, 0.40-1.0% of Ni, 0.20-0.50% of Cr, 0.20-0.60% of Mo, 0.30-0.80% of Cu, 0.05-0.20% of Ti, 0.002-0.010% of B, less than and equal to 0.020% of P, less than and equal to 0.015% of S, less than and equal to 0.03% of Als, and the balance of Fe and inevitable impurities; (3) setting a welding mode: adopting CO2 gas protection welding and a DC power supply opposition method; and (4) welding: carrying out one-side welding with back formation on a first welding line, and then carrying out multilayer multipass welding, wherein interlayer temperature is less than and equal to 160 DEG C. The invention has the advantages of simple process, high operability and low welding energy consumption and welding cost and can be widely used for the technical fields of the gas protection welding of the high-strength steel.

Owner:武钢集团有限公司

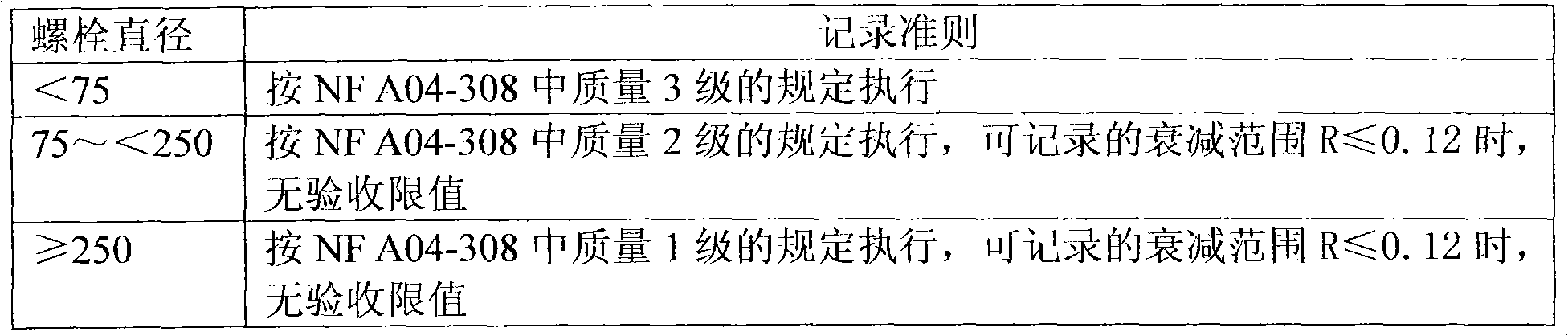

Production process of nuclear bolt

The invention mainly discloses a production process of a nuclear bolt. A 42CrMoE steel material is adopted as a raw material, and the nuclear bolt is produced by blank preparation, heat treatment, surface treatment and flaw detection, wherein the raw material of 42CrMoE comprises the following chemical components by mass percent: 0.38 to 0.48 of C, 0.10 to 0.40 of Si, 0.75 to 1.00 of Mn, no more than 0.025 of P, no more than 0.015 of S, 0.80 to 1.15 of Cr, 0.15 to 0.30 of Mo and the balance of Fe. The product obtained by production in the invention meets the requirements of nuclear 1-stage equipment, nuclear 2-stage equipment and nuclear 3-stage equipment, and the strength, the hardness and the impact resistance all reach standards.

Owner:浙江高强度紧固件有限公司

Weather resistance steel argon-rich gas shielded welding wire for high-intensity railway vehicle

InactiveCN101357425AMeet the high requirements of weld seam resistance to atmospheric corrosionGood weather resistanceWelding/cutting media/materialsSoldering mediaChemical compositionWeather resistance

The invention discloses an argon-rich gas-shielded welding wire of high-strength weathering steel used in railway cars, which is prepared by the following chemical components according to mass percentage: 0.2-0.35 percent of Cu, 0.3-0.7 percent of Cr, 0.2-to 0.6 percent of Ni, 0.05-0.1 percent of C, 0.3-0.5 percent of Si, 1.2-1.45 percent of Mn, P which is less than or equal to 0.015 percent, S which is less than or equal to 0.015 percent, the rest of Fe and unavoidable impurities. The welding wire is characterized by high weatherability, high strength, good flexibility, good resistance to welding cold crack, and the like, and the tensile strength thereof is more than 600MPa and the low-temperature impact property Axv is equal to or more than 146J at minus 40 DEG C. The welding wire adopts argon-rich gas as shield gas and has stabilized arcs, little splash, no air hole and good welding appearance when in welding. Furthermore, weld joints have an excellent matching effect with the high-strength weathering wheel used in the railway cars.

Owner:HUBEI KMK WELDING MATERIALS

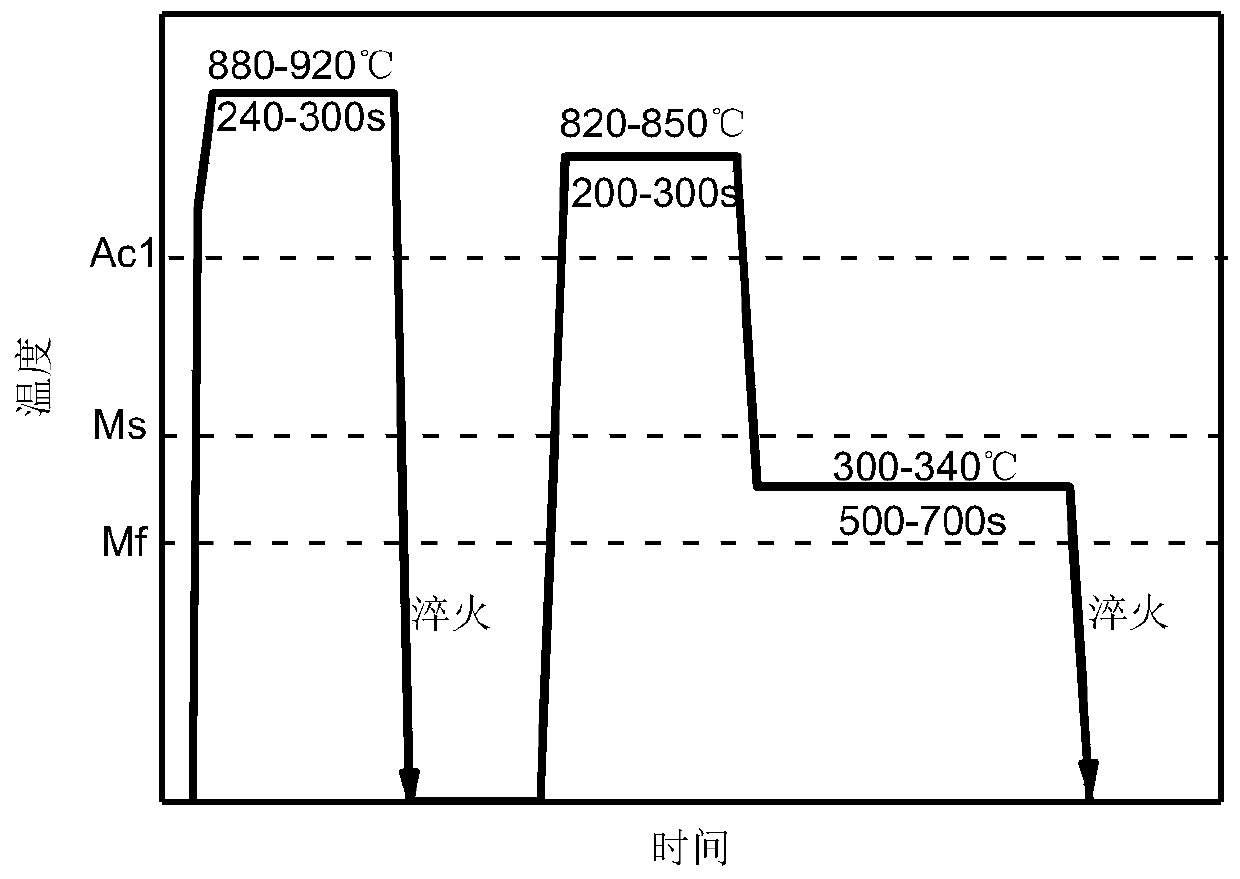

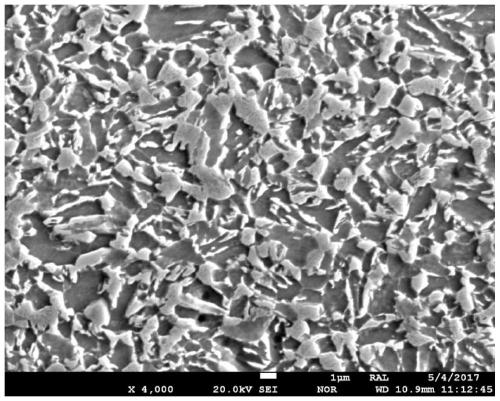

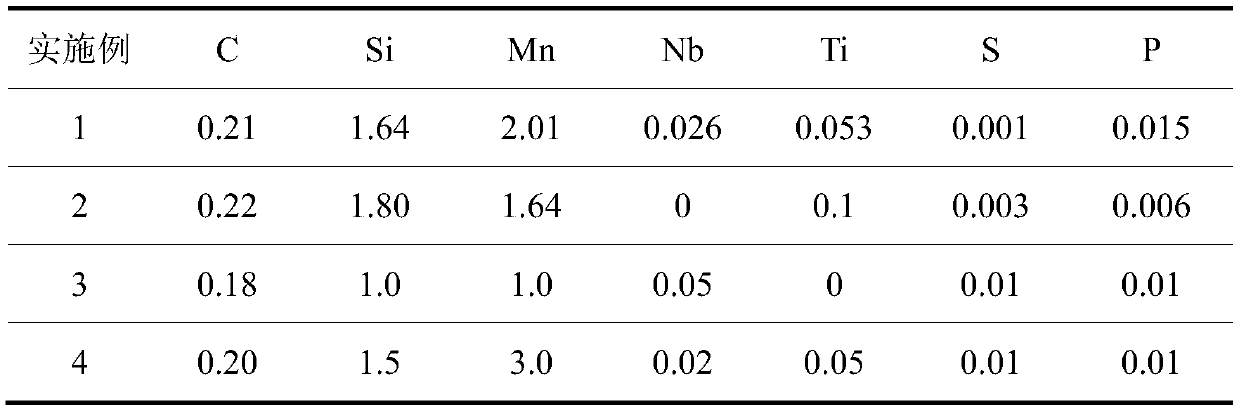

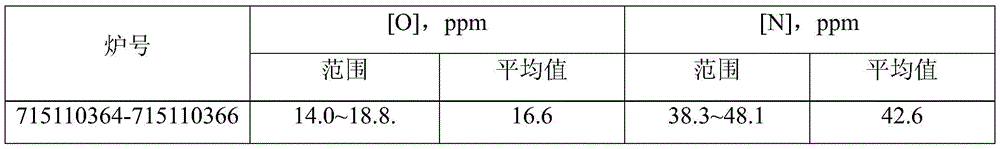

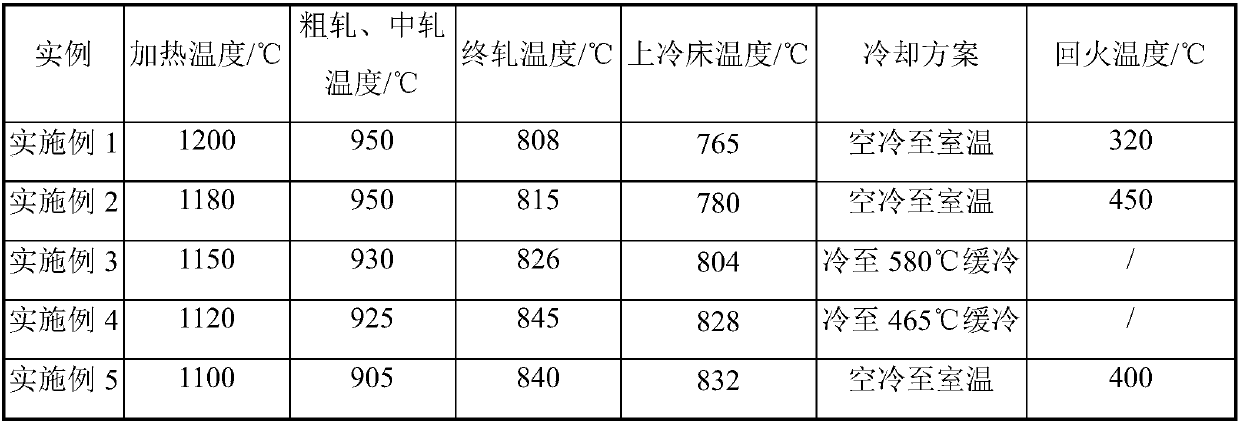

1180 MPa-grade ultrahigh-strength low-cost cold-rolled quenched partition steel and manufacturing method thereof

InactiveCN110093564AIncrease contentOrganizational stabilityUltimate tensile strengthMechanical property

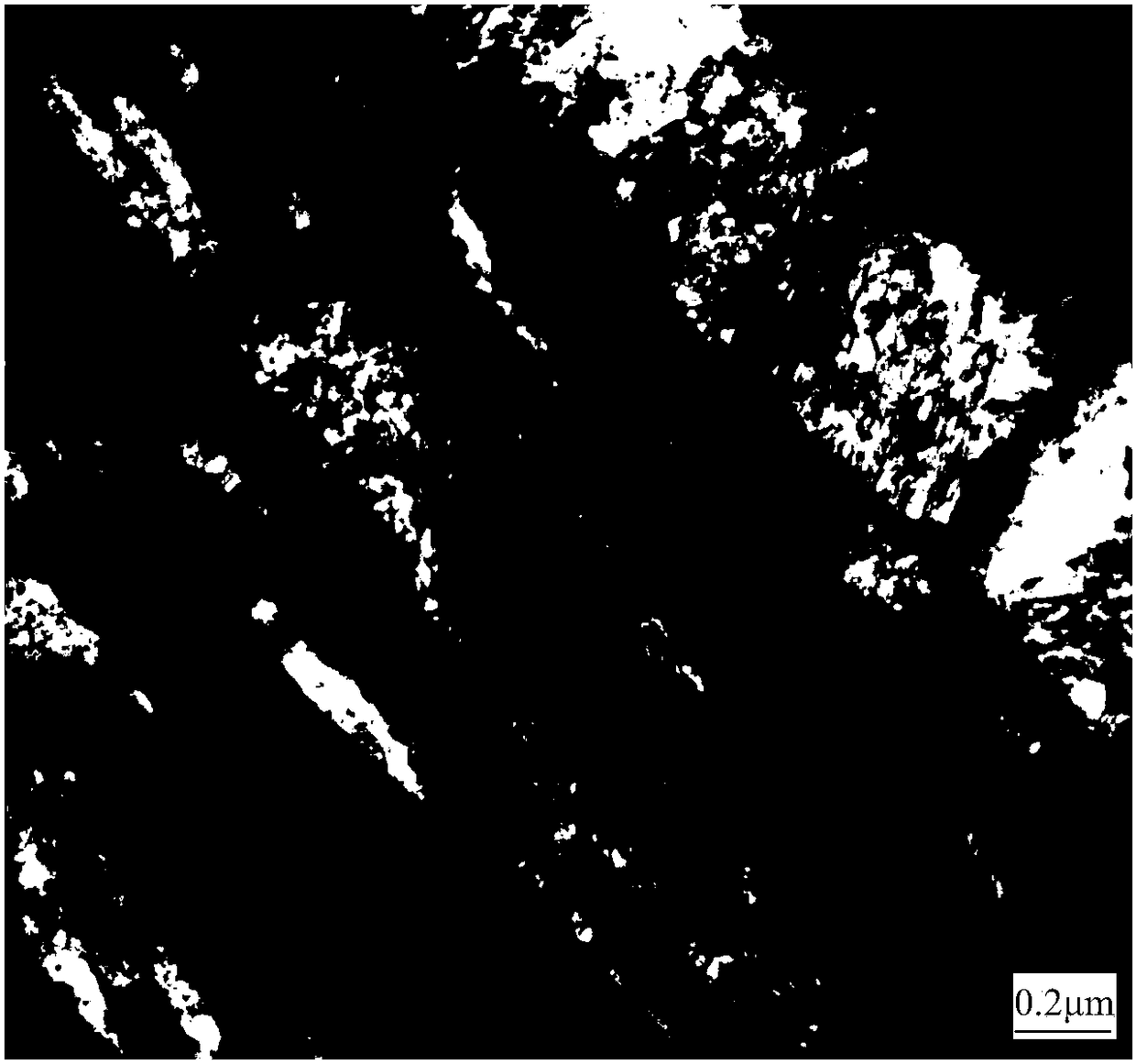

The invention relates to the field of third-generation advanced high-strength steel used for automobiles and discloses 1180 MPa-grade ultrahigh-strength low-cost cold-rolled quenched partition steel and a manufacturing method thereof. A steel plate comprises the chemical components including, by mass percent, 0.18-0.22% of C, 1.0-3.0% of Mn, 1.0-2.0% of Si, not greater than 0.05% of P, not greaterthan 0.02% of S, 0-0.05% of Nb, 0-0.2% of Ti and the balance iron and inevitable impurities. The steel plate manufacturing method relates to the process of steel smelting, hot rolling, cold rolling,pre-quenching and heat treatment, and finally, a ferrite-bainite-martensite-retained austenite mixed structure is obtained. According to the 1180 MPa-grade ultrahigh-strength low-cost cold-rolled quenched partition steel and the manufacturing method thereof, on the basis of traditional C-Mn-Si series quenched partition steel, Nb and Ti elements are added for refining the structure, pre-quenching treatment and a one-step partition process are adopted, finally the ultrahigh-strength quenched partition steel with the yield strength being 500-800 MPa, the tensile strength not smaller than 1180 MPa, the elongation after fracture not smaller than 20% and the product of strength and elongation not smaller than 24GPa.% is obtained, and the mechanical property is quite excellent.

Owner:NORTHEASTERN UNIV

High-Ni-Cu alloy glass mold and method for manufacturing same

The invention discloses a high-Ni-Cu alloy glass mold and a method for manufacturing the same. The high-nickel-copper alloy glass mold is prepared from the following components by mass ratio: 8.5-10.5% of Al, 14.0-16.0% of Ni, 7.5-9.5% of Zn, 0.8-1.2% of Si, 0.8-1.2% of Fe, 0.08-0.15% of Mn and the balance of Cu. The method for preparing the high-Ni-Cu alloy glass mold comprises the following steps: preparing a Zn-Cu alloy, wherein the mass ratio of Zn and Cu is 45:55, determining the use amount of the raw materials for preparing the high-Ni-Cu alloy glass mold, the Zn-Cu alloy and the electrolytic copper according to the mass ratio of the components for preparing the high-Ni-Cu alloy glass mold, smelting the raw materials and the electrolytic copper in an intermediate-frequency furnace until the temperature reaches 1,200-1,240 DEG C, adding the Zn-Cu alloy, heating until the smelting temperature reaches 1,280-1,300 DEG C, preserving temperature and casting at 1,260-1,280 DEG C, and carrying out stress-relief annealing. The high-Ni-Cu alloy glass mold disclosed by the invention has the advantages of high heat conductivity and heat resistance and good corrosion resistance and can adapt to the high-speed production requirements of the high-speed bottle making machine.

Owner:CHANGSHU JINNUO JINGGONG MOLD MFG

Smelting method for improving cutting performance of round steel for machinery

ActiveCN105567899AExacerbate the "hot crisp" phenomenonReduced weldabilityManufacturing convertersSlagContinuous casting

The invention relates to a low-cost smelting method of round steel, in particular to a low-cost smelting method for improving cutting performance of round steel for machinery. The method comprises a converter smelting procedure, an LF furnace external refining procedure and a bloom continuous casting procedure; the converter lime and limestone consumption is properly reduced to reasonably reduce the basicity of furnace slag to increase the converter terminal sulfur content; the converter tapping carbon content is properly increased; the reasonable tapping temperature is selected; and the furnace external refining process is optimized. The round steel for machinery, produced by the method, is simple in operation, low in cost, high in purity, excellent in cutting performance and excellent in casting property. Compared with a traditional process, the smelting method guarantees the sulfur content in a finished product, satisfies the cutting requirement of customers, reduces the production cost, and solves such technical difficulties as weak continuous casting performance, easy generation of nodules, low purity and unstable quality in traditionally produced easy-cut round steel for machinery.

Owner:ZENITH STEEL GROUP CORP +1

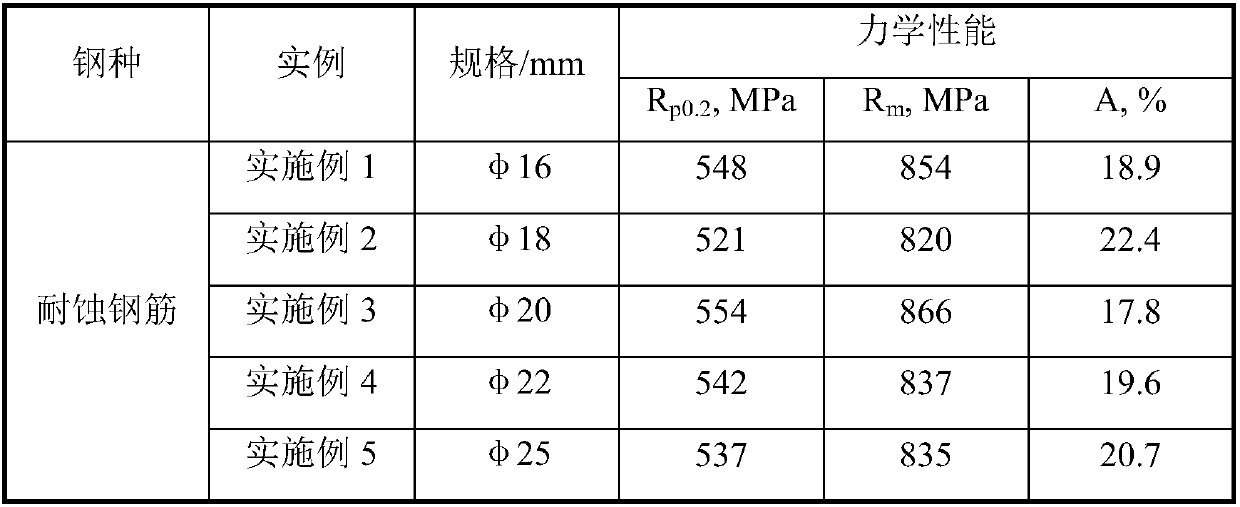

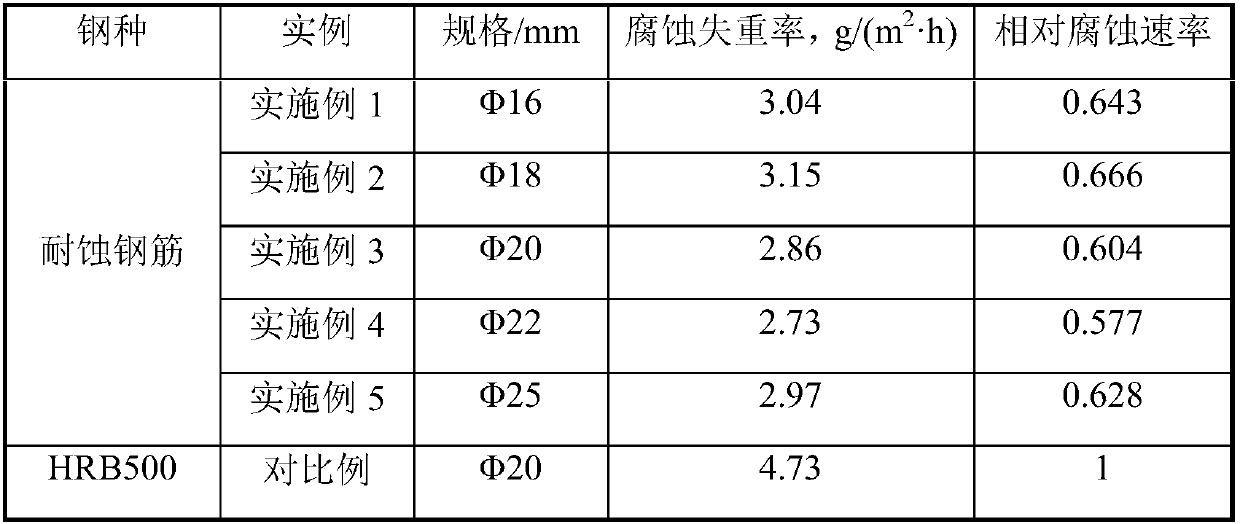

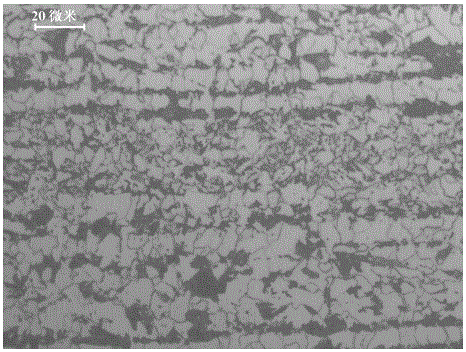

Corrosion-resisting rebar with yield strength in 500 MPa grade and production method

InactiveCN107723603AIncrease corrosion rateGood toughening effectProcess efficiency improvementChemical compositionRebar

The invention discloses a corrosion-resisting rebar with the yield strength in 500 MPa grade and a production method, and belongs to the technical field of corrosion-resisting steel for construction.The rebar comprises, by weight, the chemical components including 0.05-0.10% of C, 0.30-0.60% of Si, 1.20-1.50% of Mn, 1.00-1.50% of Cr, 0.10-0.20% of Ni, 0.20-0.40% of Cu, 0.10-0.20% of Mo, 0.06-0.10% of V, 0.010-0.025% of Ti, 0.035% or less of P, 0.010% or less of S and the balance Fe and inevitable residual impurity elements. According to the rebar, by adding small amounts of the alloying elements and fully using each individual element and the synergistic action among the elements, the corrosion resistance performance of the rebar is improved; the production method of the rebar comprises the steps of conventional smelting and casting and adoption of a controlled rolling and controlled cooling technology on a bar mill; noble metal elements in the rebar are low in contents, the toughness, the weldability and the corrosion resistance performance of the rebar are excellent, resources are saved, and the production cost is low.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Seawater corrosion resistant submerged arc welding wire

InactiveCN101664863AImprove matchCorrosion resistantWelding/cutting media/materialsSoldering mediaWeld seamUltimate tensile strength

A seawater corrosion resistant submerged arc welding wire is characterized in that the welding wire is made by the following chemical components according to mass percentage: 0.20-0.35 percent of Cu, 0.65-1.15 percent of Cr, 0.35-0.55 percent of Ni, 0.15-0.25 percent of Mo, 0.07-0.11 percent of C, 0.07-0.22 percent of Si, 1.0-1.38 percent of Mn, 0.05-0.1 percent of Nd, not more than 0.012 percentof P, not more than 0.012 percent of S, and the balance of iron and inevitable impurities. By reasonable design to the chemical components, the seawater corrosion resistant submerged arc welding wireis characterized by corrosion resistance, high strength, good toughness, strong anti-welding cold cracking ability and the like, with the tensile strength of greater than 600MPa and the minus 40 DEG C low temperature impact property of Axv of not less then 65J. After welding, the forming is beautiful, harmful defects such as crack, welding beading and undercut and the like do not exist, and the welding seam has good matching effect with the ocean engineering steel, thereby meeting the high requirements of seawater corrosion resistance, high strength, and high toughness of the welding seam.

Owner:HUBEI KMK WELDING MATERIALS

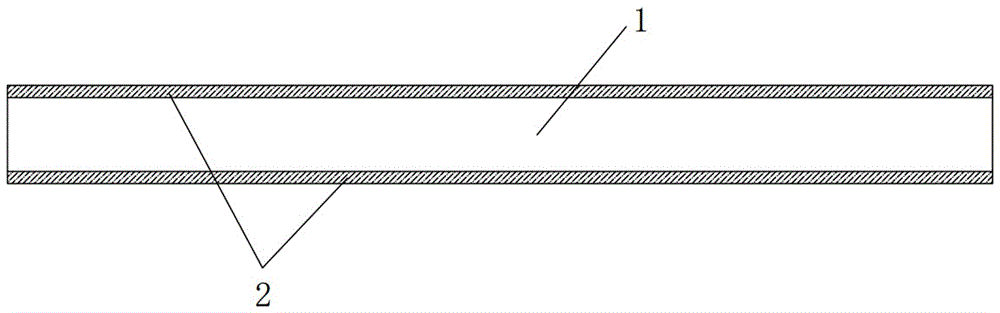

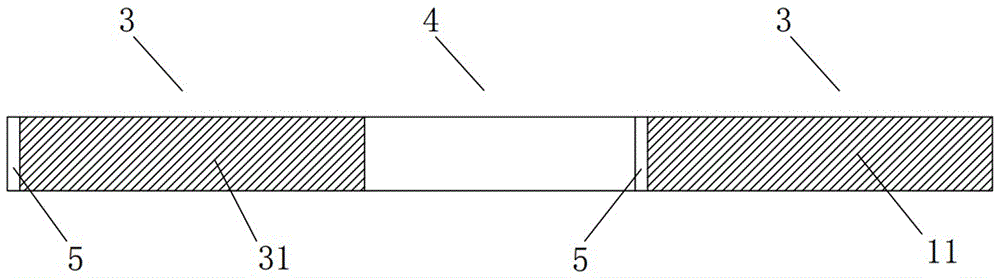

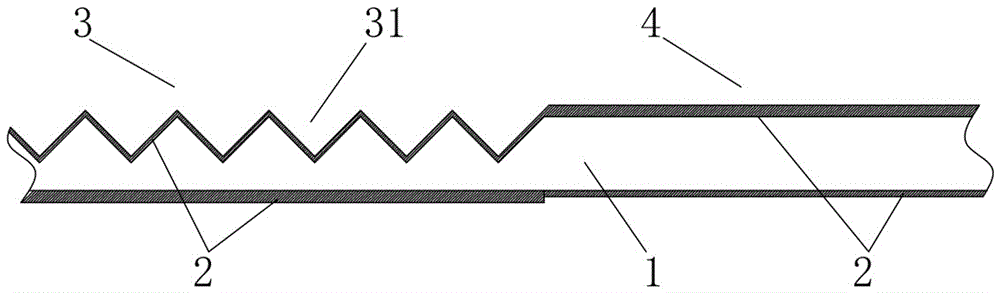

High-efficiency segmented twill soldering strip for photovoltaic module

InactiveCN106505123AIncrease profitIncrease output powerPhotovoltaic energy generationSemiconductor devicesTin platingEngineering

The invention relates to the technical field of a solar photovoltaic power generation system, in particular to the technical field of connection of a photovoltaic module battery piece, and discloses a high-efficiency segmented twill soldering strip for a photovoltaic module, The high-efficiency segmented twill soldering strip comprises a copper strip substrate and a soldering tin plating layer, wherein the soldering tin plating layer wraps the copper strip substrate, an upper surface and a lower surface of the soldering strip are respectively a twill surface and a plane, the twill surface comprises embossing segments and planar segments which are sequentially and alternatively arranged along a length direction of the soldering strip, and a plurality of V-shaped grooves are formed in embossing segment parts of the copper strip substrate in parallel, are coated by the soldering tin plating layer and are used for diffuse reflection of light projected on the V-shaped grooves. By the soldering strip, the influence on power generation efficiency of the photovoltaic module battery piece due to a light source blocked by the soldering strip and large reflection light loss of the soldering strip can be effectively reduced, the utilization ratio of the photovoltaic module on light is effectively improved, and the output power of the photovoltaic module is improved.

Owner:BAODING YITONG PV SCI & TECH

Welded steel tube for carrier roller and manufacturing method thereof

The invention discloses a welded steel tube for a carrier roller and a manufacturing method thereof. The welded steel tube comprises the compositions of, by mass, 0.050%-0.150% of C, 0.05%-0.26% of Si, 0.5%-1.50% of Mn, less than or equal to 0.010% of P, less than or equal to 0.005% of S, 0.02%-0.05% of Al, 0.1%-0.5% of Cr, 0.01%-0.05% of Nb, 0.01%-0.05% of V, 0.01%-0.05% of Ti and the balance Feand unavoidable impurities, a carbon equivalent Ceq is less than or equal to 0.4%, and a cold crack sensitivity index Pcm is less than or equal to 0.2%. The technical problems that machinability and the usage requirements of the welded steel tube for the carrier roller are inconsistent in the prior art, forming precision control is insufficient and the production requirements of the carrier rollercannot be met are solved. The technical effects that chemical elements of reasonable proportions are used, excellent cold-forming property and welding properties are achieved, the cracking of base metal or weld joints in pipe making is avoided effectively, and through reasonable hot rolling process design, the finished steel coil of hot rolling strip used for produced carrier rollers has a good shape and surface quality, good formability and abrasion resistance to adapt to the processing requirements of welded steel tubes used for the carrier rollers and meet the requirements for the use of welded steel tubes for the carrier rollers.

Owner:SHOUGANG CORPORATION +1

TC128GrB steel plate for oil bath tank truck and production method of TC128GrB steel plate

The invention discloses a TC128GrB steel plate for an oil bath tank truck and a production method of the TC128GrB steel plate. The TC128GrB steel plate comprises the following components in percentage by weight: 0.14%-0.24% of C, 0.15%-0.50% of Si, 1.30%-1.65% of Mn, no more than 0.015% of P, no more than 0.005% of S, no more than 0.30% of Cu, 0.020%-0.10% of V, 0.005%-0.020% of Nb, no more than 0.020% of Ti, 0.020%-0.050% of Al, no more than 0.53% of Cev, and the balance of Fe and inevitable impurities, wherein Cev=C+Mn / 6+(Cr+Mo+V) / 5 +(Ni+Cu) / 15. The TC128GrB steel plate is high in carbon content, relatively low in microalloy content and low in cost; the strength and toughness are matched; the mechanical property of the steel plate can completely meet the standard requirements of steel for the tank truck on TC128GrB steel; and the TC128GrB steel plate has high surplus, and is low in added precious metal content, and low in production cost.

Owner:WUYANG IRON & STEEL

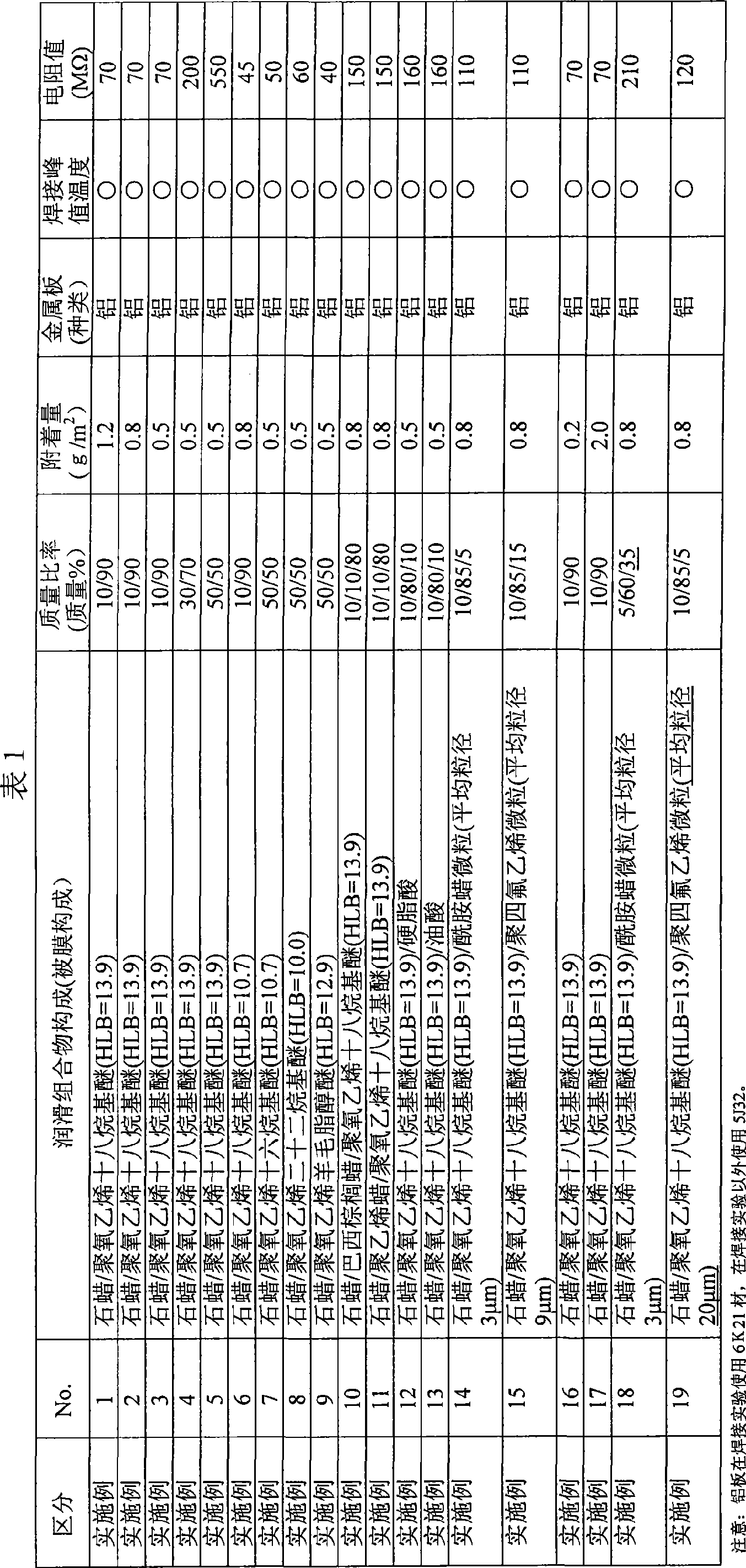

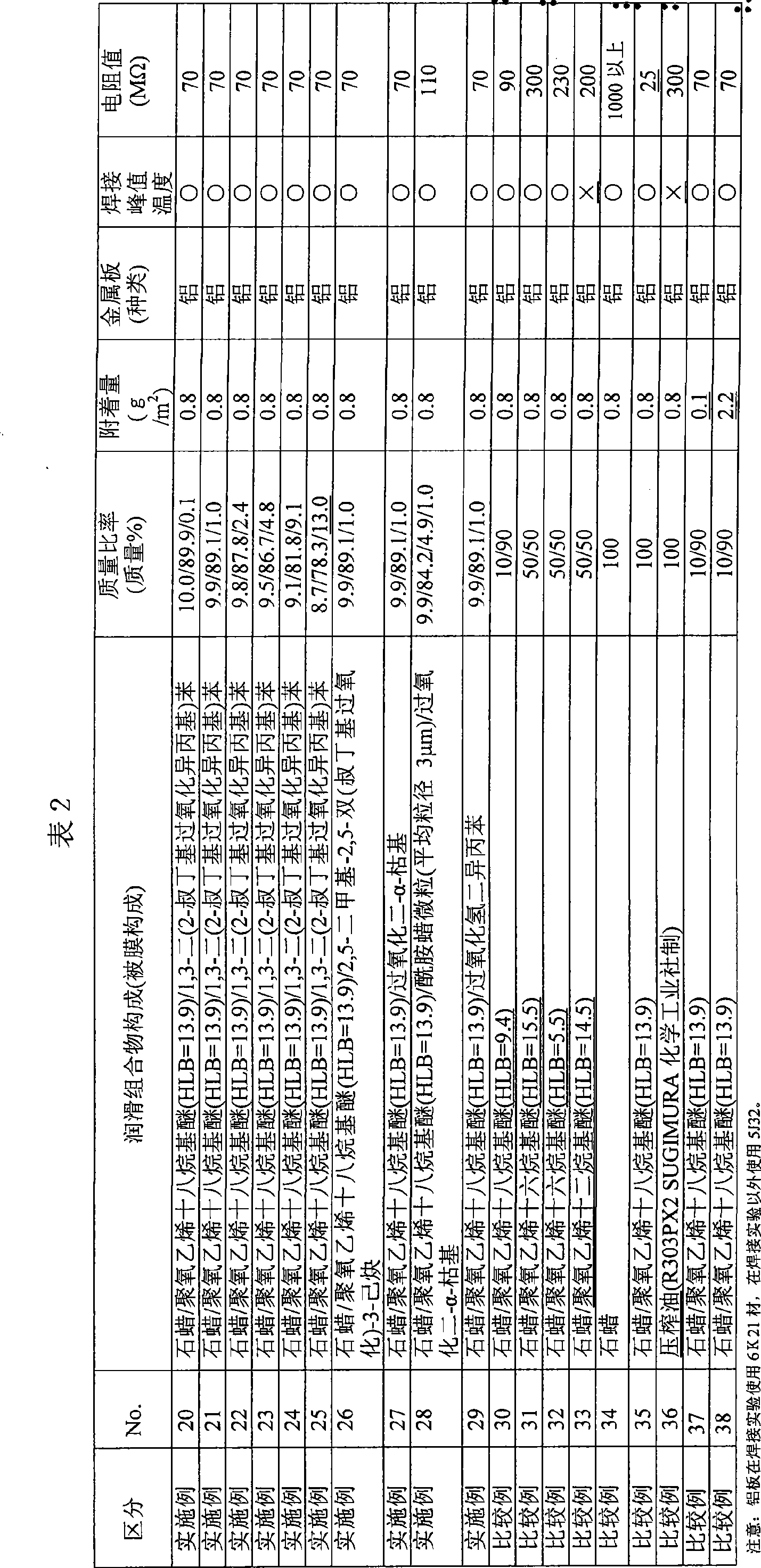

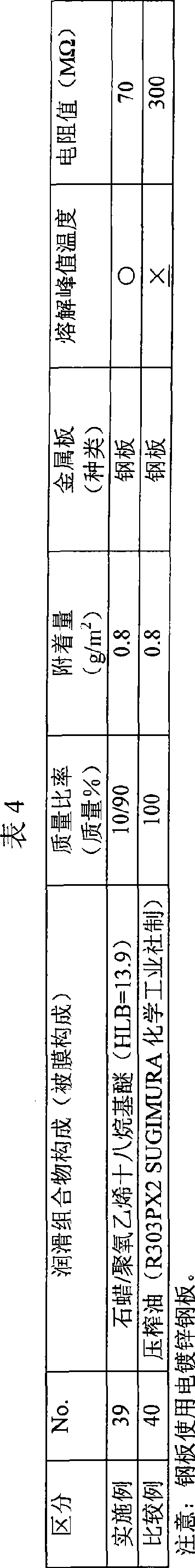

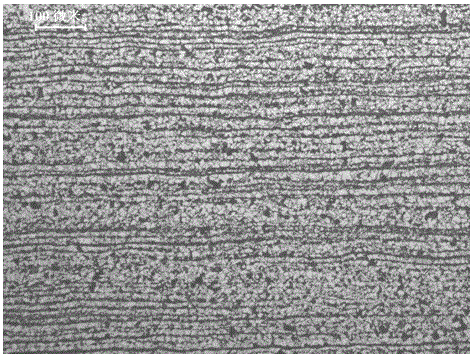

Lubrication composition, lubrication composition coated metal plate and manufacturing method thereof

InactiveCN101412942AImprove stabilityImprove removal effectLiquid surface applicatorsMetallic material coating processesParaffin waxAlcohol

The invention provides a lubricant composition capable of improving the punch forming property, demoulding property, block resistant property and welding property of stable metal plates, and a lubricant composition coated metal plate coated by the lubricant composition. Furthermore, the invention provides a manufacturing method of the lubricant composition coated metal plate for forming the lubricant composition coated layer having the properties on the metal plates in low cost, high efficiency without generating great environmental loads. The lubricant composition comprises waxes having paraffin and polyoxyethylene alkyl ethers, characterized in that, the melting peak temperature prescribed in the JIS K7121 is above 35 DEG C, and the polyoxyethylene alkyl ethers are selected from at least one of polyoxyethylene cetyl ether, polyoxyethylene octadecyl ether, polyoxyethylene docosyl ether and polyoxyethylene lanolin alcohol ether.

Owner:KOBE STEEL LTD

tc128grb steel plate for oil tanker and its production method

The invention discloses a TC128GrB steel plate for an oil bath tank truck and a production method of the TC128GrB steel plate. The TC128GrB steel plate comprises the following components in percentage by weight: 0.14%-0.24% of C, 0.15%-0.50% of Si, 1.30%-1.65% of Mn, no more than 0.015% of P, no more than 0.005% of S, no more than 0.30% of Cu, 0.020%-0.10% of V, 0.005%-0.020% of Nb, no more than 0.020% of Ti, 0.020%-0.050% of Al, no more than 0.53% of Cev, and the balance of Fe and inevitable impurities, wherein Cev=C+Mn / 6+(Cr+Mo+V) / 5 +(Ni+Cu) / 15. The TC128GrB steel plate is high in carbon content, relatively low in microalloy content and low in cost; the strength and toughness are matched; the mechanical property of the steel plate can completely meet the standard requirements of steel for the tank truck on TC128GrB steel; and the TC128GrB steel plate has high surplus, and is low in added precious metal content, and low in production cost.

Owner:WUYANG IRON & STEEL

Weather resistance steel argon-rich gas shielded welding wire for high-intensity railway vehicle

InactiveCN101357425BReduced weldabilityLow weather resistanceWelding/cutting media/materialsSoldering mediaWeather resistanceShielding gas

The invention discloses an argon-rich gas-shielded welding wire of high-strength weathering steel used in railway cars, which is prepared by the following chemical components according to mass percentage: 0.2-0.35 percent of Cu, 0.3-0.7 percent of Cr, 0.2-to 0.6 percent of Ni, 0.05-0.1 percent of C, 0.3-0.5 percent of Si, 1.2-1.45 percent of Mn, P which is less than or equal to 0.015 percent, S which is less than or equal to 0.015 percent, the rest of Fe and unavoidable impurities. The welding wire is characterized by weatherability, high strength, good flexibility, good resistance to weldingcold crack, and the like, and the tensile strength is more than 600MPa and the low-temperature impact property Axv is equal to or more than 146J at minus 40 DEG C. The welding wire adopts argon-rich gas as shield gas and has stabilized arcs, little splash, no air hole and good welding appearance when in welding. Furthermore, weld joints have an excellent matching effect with the high-strength weathering wheel used in the railway cars.

Owner:HUBEI KMK WELDING MATERIALS

Production technology of improved bolt

InactiveCN109868409ANice appearanceImprove the lubrication effectFurnace typesMetallic material coating processesChemical compositionMetallurgy

The invention mainly discloses a production technology of an improved bolt. The production technology comprises the steps that 42CrMoE rolled steel is adopted as a raw material, a blank is prepared, heat treatment is conducted, surface treatment is conducted, and defectoscopy is conducted, wherein the raw material 42CrMoE comprises the chemical components in percentage by mass: 0.38%-0.48% of C, 0.10%-0.40% of Si, 0.75%-1.00% of Mn, smaller than or equal to 0.025% of P, smaller than or equal to 0.015% of S, 0.80%-1.15% of Cr, 0.15%-0.30% of Mo, and the balance of Fe. According to the production technology of the improved bolt, products obtained through the technology meet the requirements of nuclear power first-level equipment, nuclear power second-level equipment and nuclear power third-level equipment, and the strength, the hardness and impact resistance are all up to the standard.

Owner:NINGBO QUNLI FASTENER MFG CO LTD

Bolt production process

InactiveCN109750221ANice appearanceImprove the lubrication effectFurnace typesMetallic material coating processesChemical compositionHardness

The invention mainly discloses a bolt production process. 42CrMoE steel is used as a raw material, and blank preparation, heat treatment, surface treatment and flaw detection are carried out, whereinthe raw material 42CrMoE comprises chemical compositions including, by mass, 0.38%-0.48% of the C content, 0.10%-0.40% of the Si content, 0.75%-1.00% of the Mn content, not larger than 0.025% of the Pcontent, not larger than 0.015% of the S content, 0.80%-1.15% of the Cr content, 0.15%-0.30% of the Mo content and the balance Fe. A product produced by the process meets the requirements of nuclearpower first, second and third stage equipment, and the strength, hardness and impact resistance are up to the standard.

Owner:慈溪市得鑫五金配件有限公司

Production process of bolts

InactiveCN109136734ANice appearanceImprove the lubrication effectFurnace typesHeat treatment furnacesChemical compositionMetallurgy

The invention mainly discloses a production process of bolts. 42CrMoE steel is adopted as a raw material, and the steps of blank preparation, thermal treatment, surface treatment and flaw detection are carried out, wherein the raw material 42CrMoE is prepared from, by mass, 0.38%-0.48% of C, 0.10%-0.40% of Si, 0.75%-1.00% of Mn, smaller than or equal to 0.025% of P, smaller than or equal to 0.015%of S, 0.80%-1.15% of Cr, 0.15%-0.30% of Mo and the balance Fe. The produced products meet the requirements of nuclear power first-level, second-level and third-level equipment, and the strength, hardness and impact force resistance all meet standards.

Owner:NINGBO ZEE AUTOMATION EQUIP

High-Ni-Cu alloy glass mold and method for manufacturing same

The invention discloses a high-Ni-Cu alloy glass mold and a method for manufacturing the same. The high-nickel-copper alloy glass mold is prepared from the following components by mass ratio: 8.5-10.5% of Al, 14.0-16.0% of Ni, 7.5-9.5% of Zn, 0.8-1.2% of Si, 0.8-1.2% of Fe, 0.08-0.15% of Mn and the balance of Cu. The method for preparing the high-Ni-Cu alloy glass mold comprises the following steps: preparing a Zn-Cu alloy, wherein the mass ratio of Zn and Cu is 45:55, determining the use amount of the raw materials for preparing the high-Ni-Cu alloy glass mold, the Zn-Cu alloy and the electrolytic copper according to the mass ratio of the components for preparing the high-Ni-Cu alloy glass mold, smelting the raw materials and the electrolytic copper in an intermediate-frequency furnace until the temperature reaches 1,200-1,240 DEG C, adding the Zn-Cu alloy, heating until the smelting temperature reaches 1,280-1,300 DEG C, preserving temperature and casting at 1,260-1,280 DEG C, and carrying out stress-relief annealing. The high-Ni-Cu alloy glass mold disclosed by the invention has the advantages of high heat conductivity and heat resistance and good corrosion resistance and can adapt to the high-speed production requirements of the high-speed bottle making machine.

Owner:CHANGSHU JINNUO JINGGONG MOLD MFG

Preparation method of novel stainless steel material

InactiveCN107245635AImprove corrosion resistanceHigh thermodynamic stabilityIncreasing energy efficiencyManganeseElectro-slag remelting

The invention provides a preparation method of a novel stainless steel material. The preparation method comprises the following steps: 1, smelting cast iron in a vacuum induction furnace, adding chromium, silicon and molybdenum when the cast iron begins to melt, adding tungsten, manganese, nickel, boron and vanadium for smelting when the cast iron is completely molten, and casting a consumable electrode; 2, carrying out vacuum arc remelting refining or electroslag remelting refining on the consumable electrode to prepare an electroslag ingot; 3, compressing the electroslag ingot into a stainless steel sheet, and then sequentially carrying out hot forging, first annealing and second annealing on the stainless steel sheet to prepare a stainless steel substrate; 4, carrying out hot rolling on the stainless steel substrate, and then carrying out deep cold rolling till a nanocrystalline stainless steel material layer is formed on the surface layer of the stainless steel substrate; and 5, dipping the stainless steel substrate obtained in step 4 into a sulfuric acid aqueous solution till a passivation film is formed on the stainless steel substrate, and then carrying out cold treatment on the stainless steel substrate obtained in step 4 by adopting a liquid nitrogen gasification method. By adoption of the preparation method provided by the invention, the corrosion resistance of a stainless steel material can be greatly improved, and the high strength and toughness can be guaranteed.

Owner:合肥博创机械制造有限公司

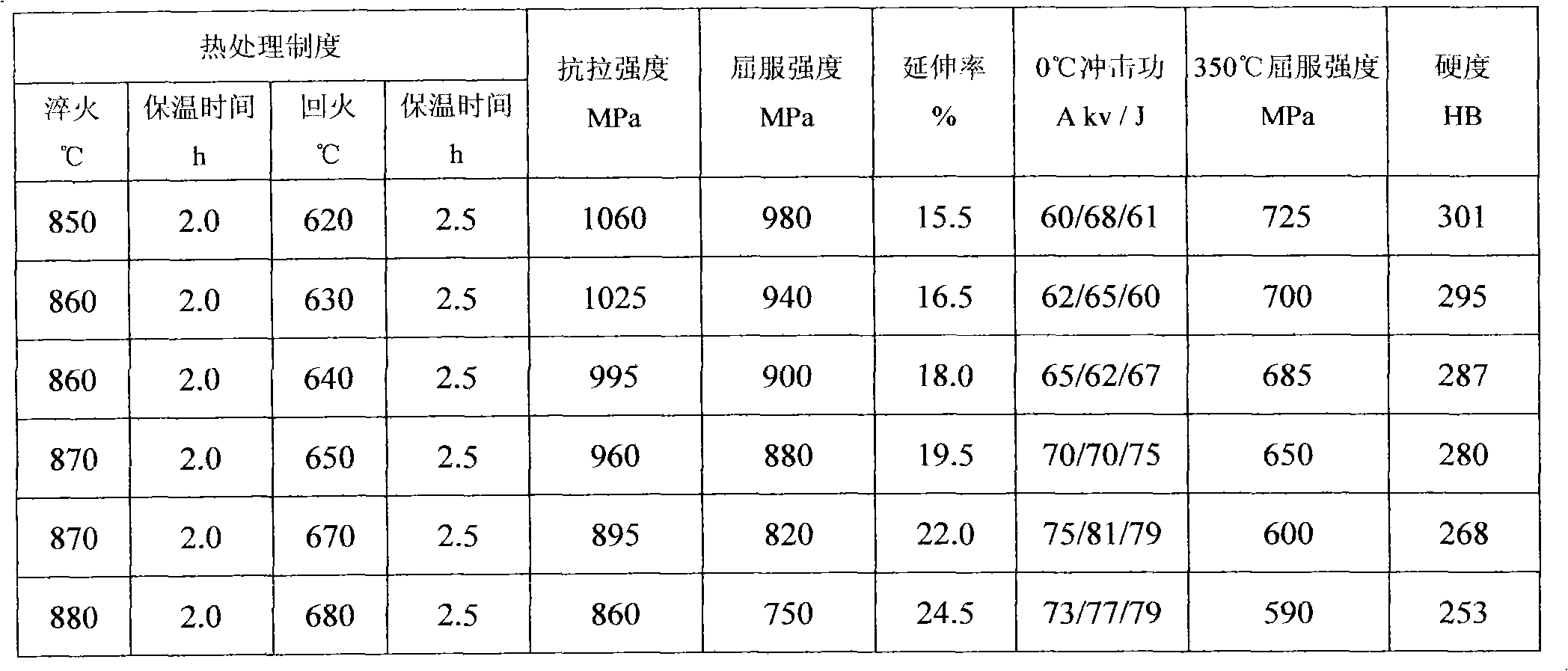

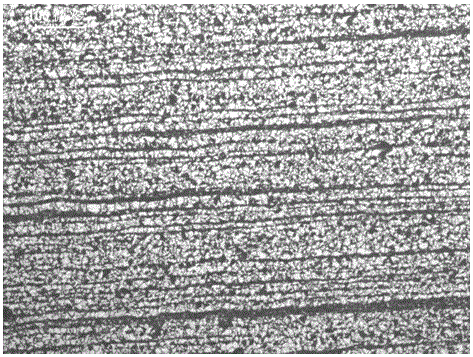

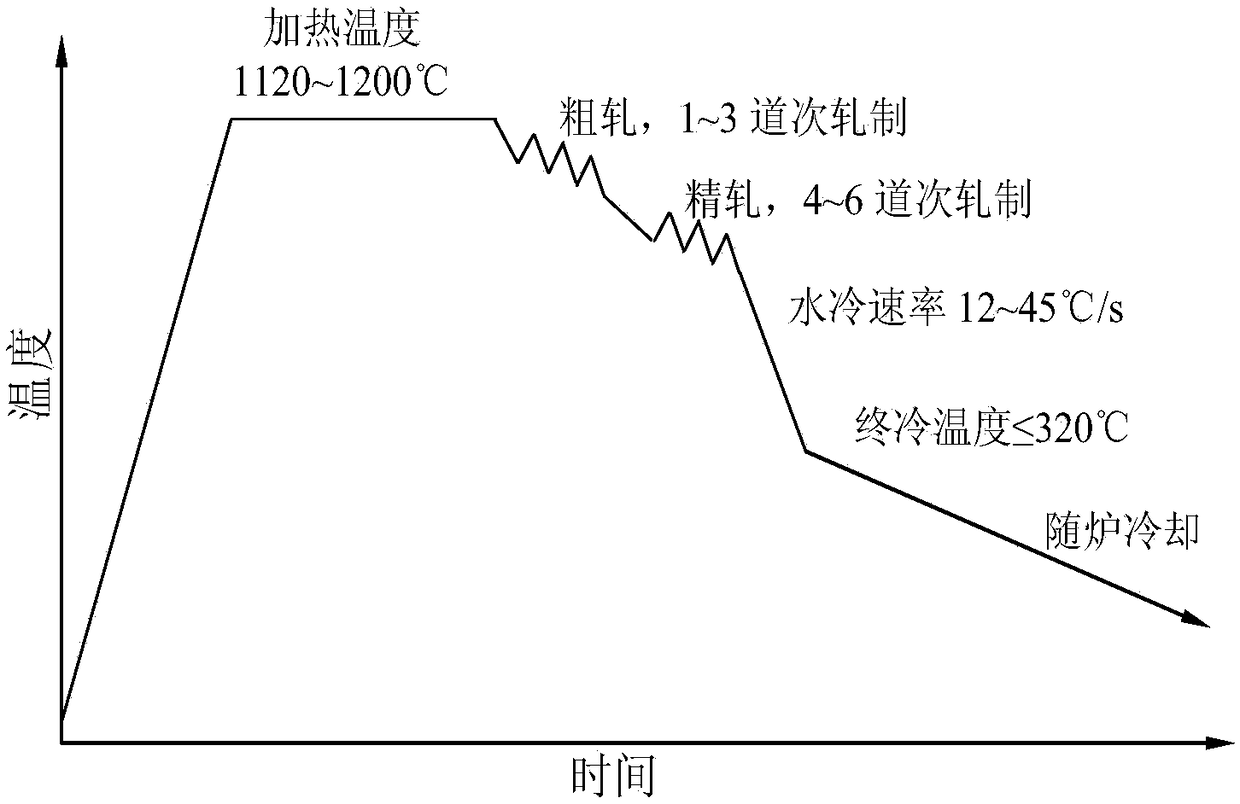

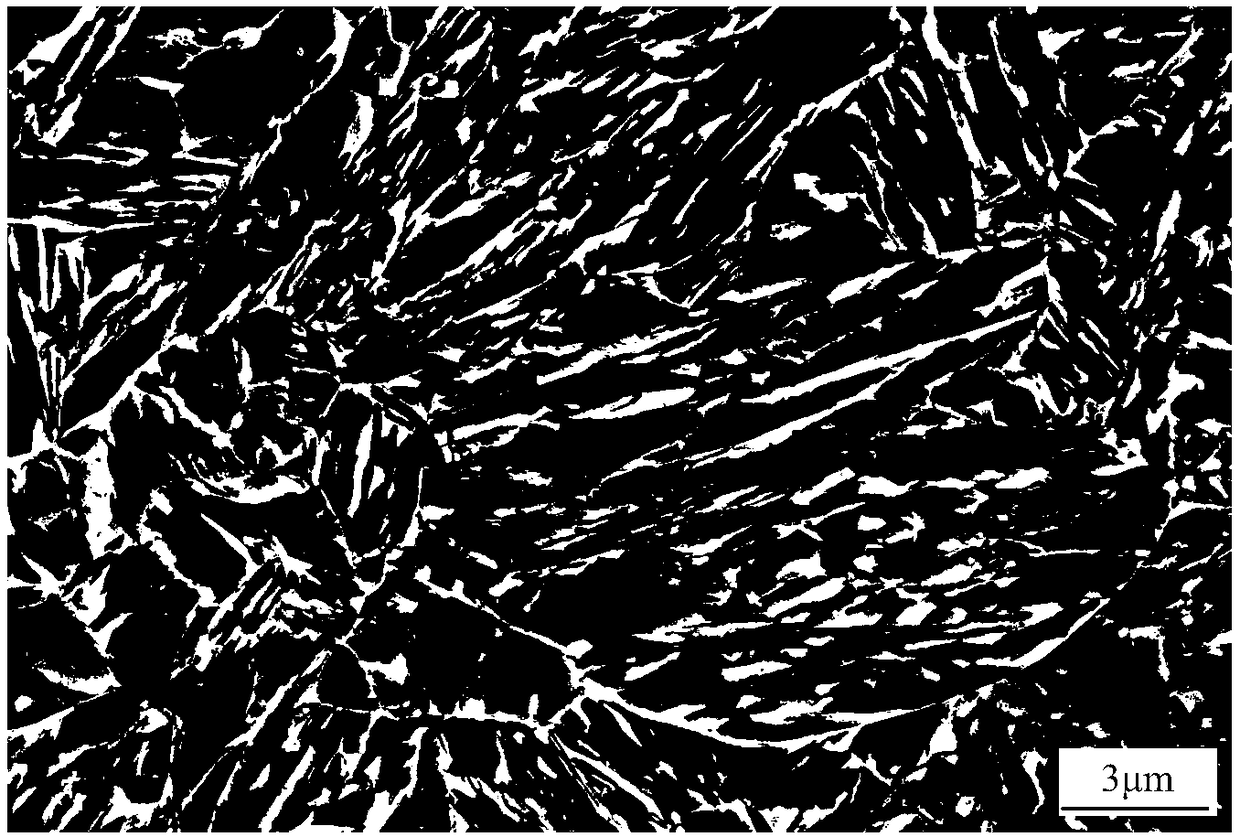

1,200 MPa-stage silicon-manganese-chromium-series hot-rolled low-carbon steel plate and preparation method thereof

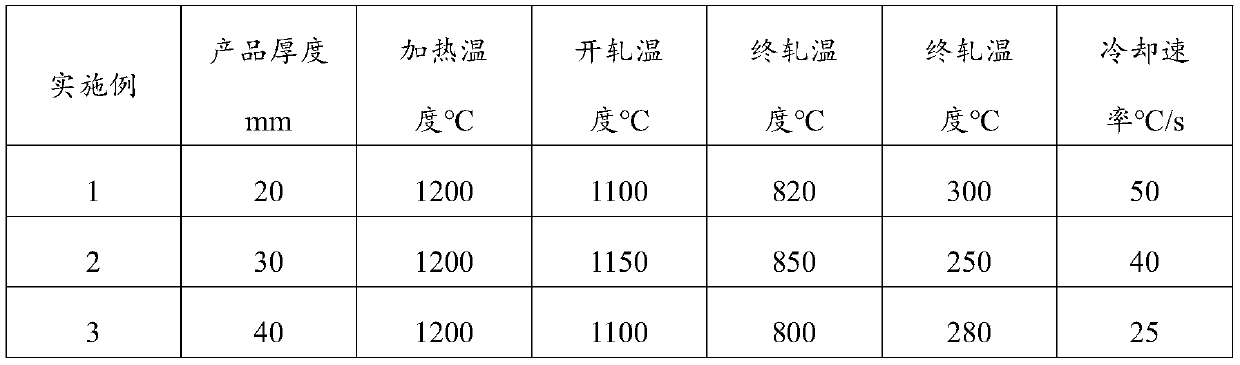

The invention discloses a 1,200 MPa-stage silicon-manganese-chromium-series hot-rolled low-carbon steel plate and a preparation method thereof. The hot-rolled low-carbon steel plate comprises, by weight, 0.06%-0.14% of C, 2.5%-3.5% of Mn, 1.0%-1.6% of Si, 0.5%-1.2% of Cr, 0.1%-0.3% of Mo, 0.1%-0.5% of Ni, 0.002%-0.010% of S, 0.003%-0.010% of P, 0.01%-0.05% of Al, 0.003%-0.005% of N and the balanceFe, the tensile strength is 1,250-1,360 MPa, and the elongation is 12.8%-16.9%. The preparation method comprises the steps that (1), heat preservation is conducted on a steel billet at the temperature of 1,120-1,200 DEG C; (2), a hot-rolled plate is prepared through rough rolling and fine rolling; and (3), water cooling is conducted till the temperature is lower than or equal to 320 DEG C, and the hot-rolled plate is put into an isothermal heating furnace to be cooled along with the furnace. According to the method, the operation process is simple, cold rolling is not needed, quenching and tempering treatment is not needed, the production cost is reduced, and industrialized production is easy to achieve.

Owner:NORTHEASTERN UNIV

Bolt production technology

The invention mainly discloses a bolt production technology. A 42CrMoE steel material is used as a raw material, and blank preparation, heat treatment, surface treatment and flaw detection are carriedout. The raw material 42CrMoE is prepared from chemical ingredients comprising, by mass, 0.38%-0.48% of C, 0.10%-0.40% of Si, 0.75%-1.00% of Mn, 0.025% or less of P, 0.015% or less of S, 0.80%-1.15%of Cr, 0.15%-0.30% of Mo and the balance Fe. The product obtained in the production meets the requirements of nuclear power level 1, 2 and 3 equipment, and the strength, hardness and impact resistanceall meet standards.

Owner:宁波铁锚电器有限公司

Non-preheating welding Q690D steel plate for coal mine machinery and preparation method of non-preheating welding Q690D steel plate

The invention discloses a non-preheating welding Q690D steel plate for coal mine machinery, and relates to the technical field of steel smelting. The non-preheating welding Q690D steel plate for coalmine machinery comprises the following chemical components of, in percentage by mass, 0.05% to 0.06% of C, 0.20% to 0.25% of Si, 1.7% to 1.8% of Mn, less than or equal to 0.010% of P, less than or equal to 0.005% of S, 0.4% to 0.5% of Cr, 0.008% to 0.012% of B, 0.01% to 0.03% of Ti, 0.01% to 0.03% of Zr and the balance Fe and inevitable impurities. According to the non-preheating welding Q690D steel plate for coal mine machinery, on the basis that Nb and Mo elements with high cost are not added, an online quenching process is adopted, and on the basis that the alloy cost is reduced and the process route is simplified, the steel plate finally meets the requirement for the preheating-free welding performance at the temperature of 0 to 20 DEG C through simple rolling and online quenching processes.

Owner:NANJING IRON & STEEL CO LTD +1

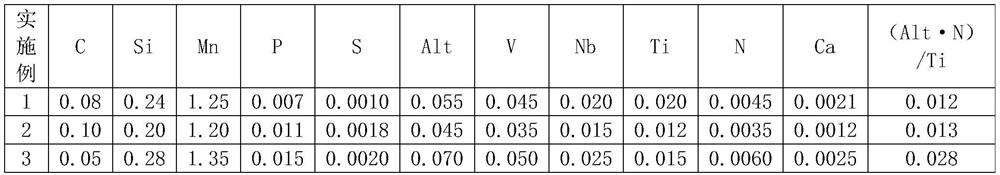

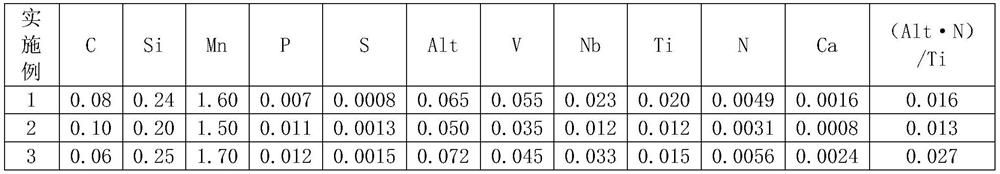

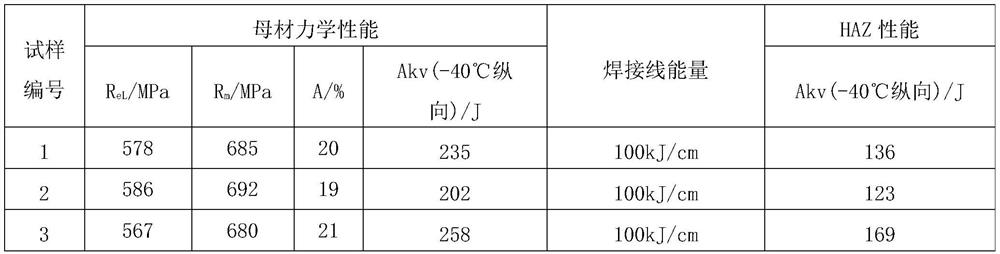

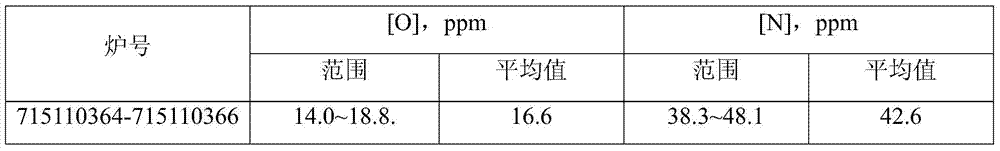

E420-W300 ultrahigh-strength ship plate steel and manufacturing method therefor

The invention discloses E420-W300 ultrahigh-strength ship plate steel, comprising the following chemical components in percentage by mass: 0.04-0.12% of C, 0.15-0.35% of Si, 1.20-1.40% of Mn, less than or equal to 0.020% of P, less than or equal to 0.0030% of S, 0.030-0.060% of V, 0.010-0.030% of Nb, 0.030-0.080% of Ant, 0.005-0.030% of Ti, 0.0005-0.0040% of Ca, less than or equal to 0.0060% of N.(Alt N) / Ti is controlled within 0.010-0.030; the yield strength is larger than or equal to 420 MPa; the tensile strength is larger than or equal to 530 MPa; the steel plate is suitable for high-strength ship plate steel with the welding linear energy within the range of 300 kJ / cm; and the average impact energy of HAZ of the steel plate at the temperature of -40 DEG C is 42 J or above.

Owner:NANJING IRON & STEEL CO LTD

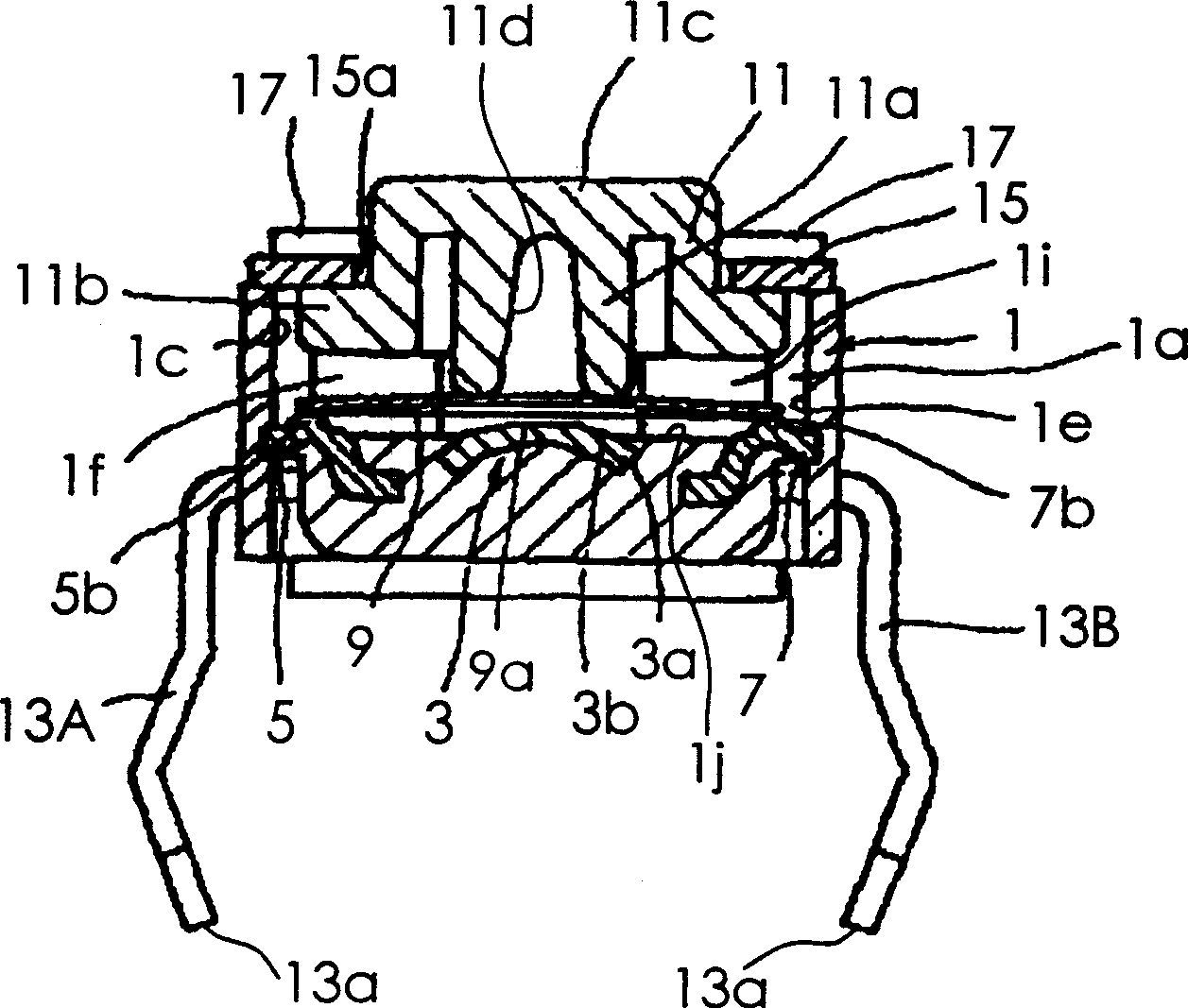

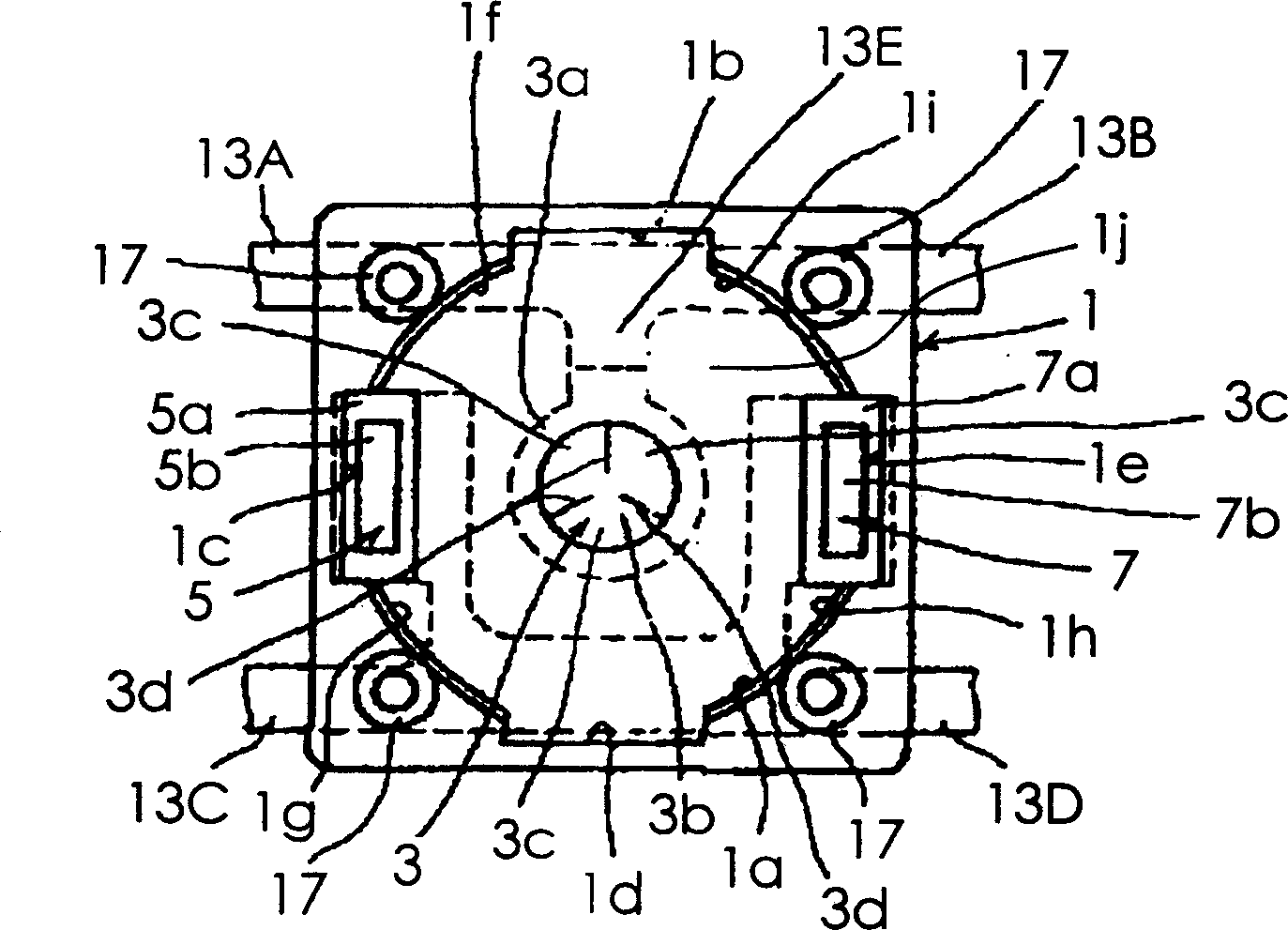

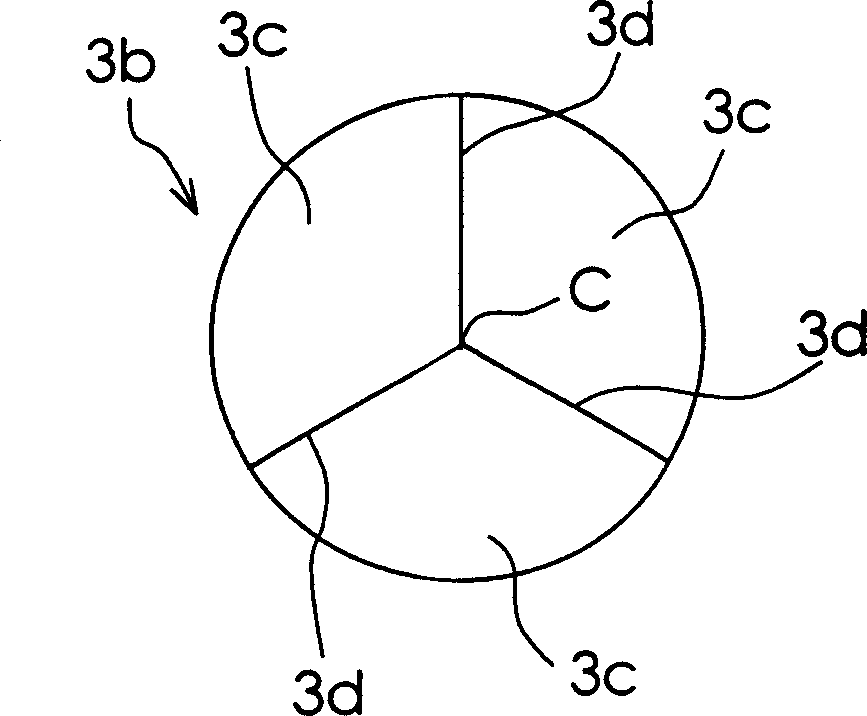

Press button type switch and its producing method

InactiveCN1409338AReduced weldabilityReduce the effect of platingContact surface shape/structureAcute angleEngineering

The invention provides a push-on switch capable of preventing inferior conduction between a ridge of a central part contact and the circumferential edge of a hole part of a movable contact. An acute angle between a virtual perpendicular L passing through a convergent point C of the ridge 3d of the central part contact 3 and perpendicularly extending to the bottom of a recess part of an insulating case body 1 and the ridge 3d is set to 83 degree-89 degree.

Owner:HOKURIKU ELECTRIC INDS

Production process of high-performance bolt

InactiveCN111254267ANice appearanceImprove the lubrication effectFurnace typesScrewsChemical compositionHardness

The invention mainly discloses a production process of a high-performance bolt. 42CrMoE steel is adopted as a raw material, and blank preparation, heat treatment, surface treatment and flaw detectionare carried out, wherein the raw material 42CrMoE comprises the following chemical components in percentage by mass: 0.38-0.48% of C, 0.10-0.40% of Si, 0.75-1.00% of Mn, less than or equal to 0.025% of P, less than or equal to 0.015% of S, 0.80-1.15% of Cr, 0.15-0.30% of Mo and the balance Fe. The product produced by the production process meets the requirements of nuclear power first-level, second-level and third-level equipment, and the strength, hardness and impact resistance all reach the standard.

Owner:余姚市晶易光伏发电有限公司

Supporting base wearing plate

ActiveCN106347399AHigh hardnessHigh yield strengthCargo supporting/securing componentsRare-earth elementAlloy

The invention discloses a supporting base wearing plate. With shape memory alloy as a matrix, the outer surface of the matrix is provided with a Titanium-plated coat, and the outer surface of the Titanium-plated coat is provided with a coated film. Rigidity, yield strength, strength of extension and impact resistance of the shape memory alloy is improved by adding high purity neodymium rare earth elements; compared with iron nickel titanium molybdenum shape memory alloy with a same percentage of iron atom and molybdenum atom, the adopted shape memory alloy has higher strength and corrosion-resistant performance at a temperature of -150DEG to +150 DEG C; the adopted shape memory alloy can bear big load action, has high security coefficient and prolongs service life; the coated film arranged on the outermost layer can improve corrosion-resistant performance, solvent resistance and oil resistance of the material itself, and is suitable for being applied to a position in which service environment is complex such as a bearing, supporting base and the like. Among them, properties of the coated film are affected when titanium atom content is too low, while too high content causes inferior compactness, thus proper content needs to be controlled.

Owner:江苏同庆车辆配件有限公司

CO2 gas protection welding process of 800 MPa high-strength steel

InactiveCN102179601BUniform strengthUniform hardnessArc welding apparatusWelding/cutting media/materialsHigh intensityUltimate tensile strength

The invention discloses a CO2 gas protection welding process of 800 MPa high-strength steel. The CO2 protection welding process is characterized by comprising the following steps of: (1) machining a joint: machining an X-shaped groove on the joint; (2) using a solid welding wire with the diameter of 1.2 mm and the tensile strength of 800 MPa, wherein the solid welding wire comprises the followingchemical components in percentage by weight: 0.04-0.10% of C, 0.30-0.80% of Si, 1.30-2.0% of Mn, 0.40-1.0% of Ni, 0.20-0.50% of Cr, 0.20-0.60% of Mo, 0.30-0.80% of Cu, 0.05-0.20% of Ti, 0.002-0.010% of B, less than and equal to 0.020% of P, less than and equal to 0.015% of S, less than and equal to 0.03% of Als, and the balance of Fe and inevitable impurities; (3) setting a welding mode: adoptingCO2 gas protection welding and a DC power supply opposition method; and (4) welding: carrying out one-side welding with back formation on a first welding line, and then carrying out multilayer multipass welding, wherein interlayer temperature is less than and equal to 160 DEG C. The invention has the advantages of simple process, high operability and low welding energy consumption and welding cost and can be widely used for the technical fields of the gas protection welding of the high-strength steel.

Owner:武钢集团有限公司

A support seat wear plate

ActiveCN106347399BHigh hardnessHigh yield strengthCargo supporting/securing componentsRare-earth elementAlloy

The invention discloses a supporting base wearing plate. With shape memory alloy as a matrix, the outer surface of the matrix is provided with a Titanium-plated coat, and the outer surface of the Titanium-plated coat is provided with a coated film. Rigidity, yield strength, strength of extension and impact resistance of the shape memory alloy is improved by adding high purity neodymium rare earth elements; compared with iron nickel titanium molybdenum shape memory alloy with a same percentage of iron atom and molybdenum atom, the adopted shape memory alloy has higher strength and corrosion-resistant performance at a temperature of -150DEG to +150 DEG C; the adopted shape memory alloy can bear big load action, has high security coefficient and prolongs service life; the coated film arranged on the outermost layer can improve corrosion-resistant performance, solvent resistance and oil resistance of the material itself, and is suitable for being applied to a position in which service environment is complex such as a bearing, supporting base and the like. Among them, properties of the coated film are affected when titanium atom content is too low, while too high content causes inferior compactness, thus proper content needs to be controlled.

Owner:江苏同庆车辆配件有限公司

E550-W100 ultrahigh-strength ship plate steel and manufacturing method thereof

InactiveCN112322966AReduce plasticityReduce toughnessFurnace typesMetal rolling arrangementsUltimate tensile strengthWeld line

The invention discloses E550-W100 ultrahigh-strength ship plate steel. The E550-W100 ultrahigh-strength ship plate steel comprises the following chemical components in percentage by mass: 0.04%-0.12%of C, 0.15%-0.35% of Si, 1.50%-1.70% of Mn, less than or equal to 0.020% of P, less than or equal to 0.0030% of S, 0.030%-0.060% of V, 0.010%-0.030% of Nb, 0.030%-0.080% of Alt, 0.005%-0.030% of Ti, 0.0005%-0.0040% of Ca and less than or equal to 0.0060% of N, wherein (Alt.N) / Ti is controlled to be 0.010 to 0.030. The yield strength of an obtained steel plate is larger than or equal to 550 MPa, the tensile strength of the steel plate is larger than or equal to 670 MPa, the steel plate is suitable for high-strength ship plate steel with the welding line energy within the range of 100 kJ / cm, andthe average impact energy of the HAZ of the steel plate at the temperature of -40 DEG C is 55 J or above.

Owner:NANJING IRON & STEEL CO LTD

A smelting method for improving the cutting performance of round steel for machinery

ActiveCN105567899BExacerbate the "hot crisp" phenomenonReduced weldabilityManufacturing convertersSlagContinuous casting

Owner:ZENITH STEEL GROUP CORP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com