High-efficiency segmented twill soldering strip for photovoltaic module

A photovoltaic module, segmented technology, applied in the connection of photovoltaic module cells, solar photovoltaic power generation systems, can solve the problems of increased solder thickness on non-welding surfaces, poor use of light sources, and unfavorable end-customer welding, etc. Achieve the effect of increasing output power, saving consumption and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

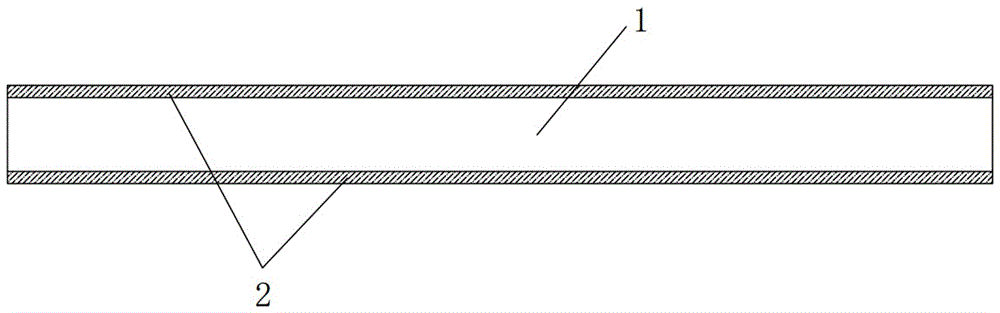

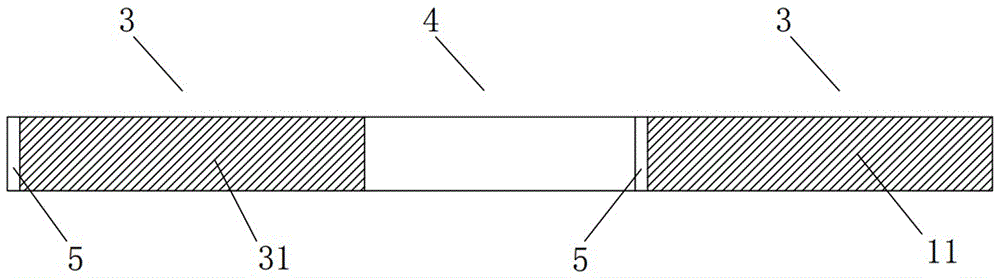

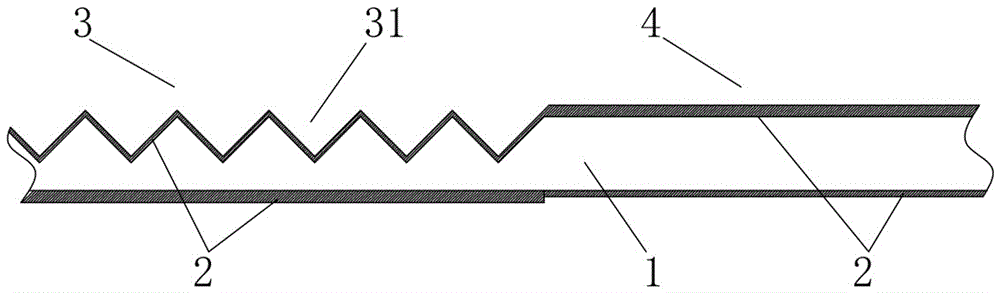

[0024] In order to solve the problems in the prior art that photovoltaic ribbons block cells and reflect light loss, which reduces the light utilization rate of photovoltaic module cells, the present invention provides a high-efficiency segmented twill ribbon for photovoltaic modules, which consists of The copper strip substrate 1 and the solder plating layer 2 covering the copper strip substrate 1 are composed. The upper and lower sides of the solder strip are twill surfaces and flat surfaces respectively, and the twill surface includes embossed segments 3 and flat segments 4 that are alternately distributed along the length direction of the solder strip. See figure 2 , the copper strip substrate 1 is provided with a plurality of V-shaped grooves 31 distributed in parallel in the embossing section 3, and is covered by a solder coating 2, see image 3 and Figure 4 , which is used to diffusely reflect the light projected on it, so that most of the light is diffusely reflecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com