tc128grb steel plate for oil tanker and its production method

A production method and steel plate technology, which is applied in the field of steel for tank cars, can solve the problems of difficult production and high price, and achieve the effects of low production cost, good welding performance, and good low-temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

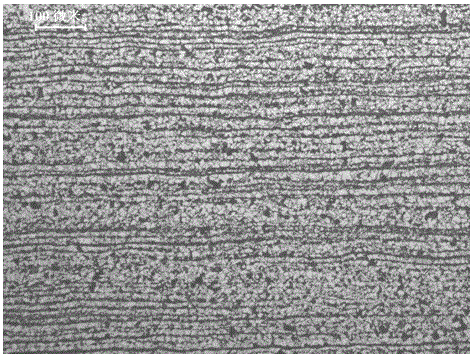

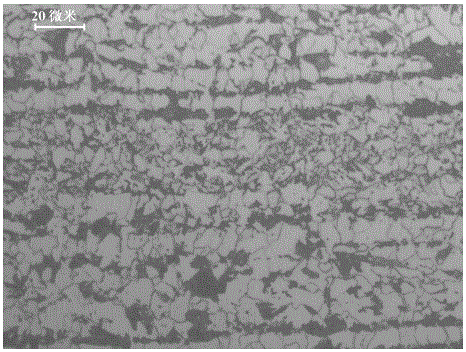

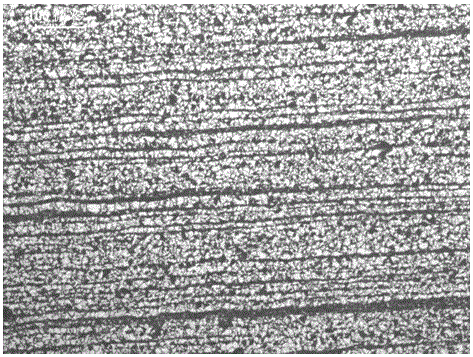

Image

Examples

Embodiment 1

[0020] Embodiment 1: The TC128GrB steel plate for the oil tanker is produced by the following method.

[0021] (1) The chemical composition (weight) of the billet is: C 0.15%, Si 0.15%, Mn 1.65%, P 0.012%, S 0.002%, Cu 0.25%, V 0.095%, Nb 0.006%, Ti 0.016%, Al 0.032 %, Cev 0.46%, the balance is Fe and unavoidable inclusions. In order to avoid cracking on the surface of low-alloy high-strength billets, the billets are required to be stacked for more than 24 hours to release stress.

[0022] (2) The TC128GrB steel plate for the oil tanker is produced by the following process steps:

[0023] A. Heating process: steel billets are stacked for 30 hours before being loaded into the furnace; low temperature and slow heating, the maximum heating temperature is 1250°C, to ensure that the billets are evenly burned through, and the heating speed is 1.5min / mm (calculated as 1.5 minutes per millimeter thickness of steel plate) , The temperature in the soaking section is 1220℃~1240℃, and t...

Embodiment 2

[0032] Embodiment 2: The TC128GrB steel plate for the oil tanker is produced by the following method.

[0033] (1) The chemical composition (weight) of the billet is: C 0.16%, Si 0.37%, Mn 1.55%, P 0.011%, S 0.004%, Cu 0.18%, V 0.070%, Nb 0.017%, Ti 0.011%, Al 0.020 %, Cev 0.44%, the balance is Fe and unavoidable inclusions. In order to avoid cracking on the surface of low-alloy high-strength billets, the billets are required to be stacked for more than 24 hours to release stress.

[0034] (2) The TC128GrB steel plate for the oil tanker is produced by the following process steps:

[0035] A. Heating process: billets are loaded into the furnace after being stacked for 30 hours; low temperature and slow heating, the maximum heating temperature is 1245°C, to ensure that the billets are evenly burned through, the heating speed is 2.0min / mm, the temperature of the soaking section is 1220°C ~ 1230°C, The heating time of the hot section is 100 minutes to ensure that the ingot is even...

Embodiment 3

[0043] Embodiment 3: The TC128GrB steel plate for the oil tanker is produced by the following method.

[0044] (1) The chemical composition (weight) of the billet is: C 0.23%, Si 0.40%, Mn 1.32%, P 0.008%, S 0.005%, Cu 0.05%, V 0.065%, Nb 0.010%, Ti 0.002%, Al 0.021 %, Cev 0.48%, the balance is Fe and unavoidable inclusions. In order to avoid cracking on the surface of low-alloy high-strength billets, the billets are required to be stacked for more than 24 hours to release stress.

[0045] (2) The TC128GrB steel plate for the oil tanker is produced by the following process steps:

[0046] A. Heating process: billets are stacked for 30 hours before being loaded into the furnace; low temperature and slow heating, the maximum heating temperature is 1250°C, to ensure that the billets are evenly burned through, the heating speed is 1.0min / mm, the temperature of the soaking section is 1230°C ~ 1240°C, The heating time of the hot section is 150 minutes to ensure that the ingot is e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com