High-strength Q630GJ steel plate and production method thereof

A technology of Q630GJ and production method, which is applied in the field of high-strength Q630GJ steel plate and its production, can solve the problems of increasing steel plate production cost, complex process, long cycle, etc., to increase tempering stability, reduce residual stress and brittleness, and improve strength and toughness effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

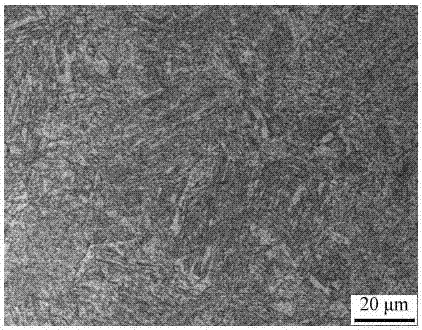

Embodiment 1

[0029] The thickness of the high-strength Q630GJ steel plate in this example is 10 mm, and the V-Ni-Nb-Ti microalloy composition design is adopted. The chemical composition and mass percentage are: C: 0.07%, Si: 0.20%, Mn: 1.40%, P: 0.012%, S: 0.005%, Alt: 0.015%, V: 0.040%, Ni: 0.40%, Nb: 0.02%, Ti: 0.025%, and the balance is Fe and trace unavoidable impurities.

[0030] The production process of the high-strength Q630GJ steel plate of this embodiment includes rolling and heat treatment, and the specific steps are as follows:

[0031] (1) Rolling process: Type II controlled rolling process is adopted, the cumulative reduction in the first stage reaches 40%, and the thickness of the steel is 80mm; the starting temperature of the second stage is 900°C, and the final rolling temperature is 780°C. After rolling, the steel plate enters the ACC quickly. After cooling, the red temperature is 500°C.

[0032] (2) Heat treatment process: the steel plate is tempered, the tempering temp...

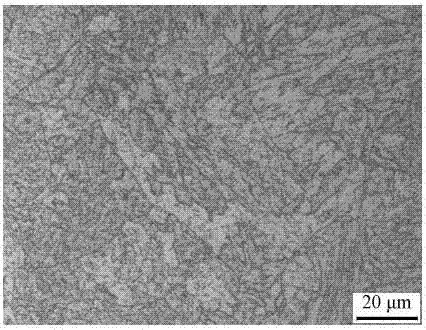

Embodiment 2

[0035] The thickness of the high-strength Q630GJ steel plate in this example is 30mm, and the V-Ni-Nb-Ti microalloy composition design is adopted. Its chemical composition and mass percentage are: C: 0.10%, Si: 0.30%, Mn: 1.45%, P: 0.010%, S: 0.010%, Alt: 0.045%, V: 0.041%, Ni: 0.45%, Nb: 0.025%, Ti: 0.015%, and the balance is Fe and trace unavoidable impurities.

[0036] The production process of the high-strength Q630GJ steel plate of this embodiment includes rolling and heat treatment, and the specific steps are as follows:

[0037] (1) Rolling process: Type II controlled rolling process is adopted, the cumulative reduction in the first stage reaches 35%, and the thickness of the steel is 100mm; the starting temperature of the second stage is 890°C, the final rolling temperature is 815°C, and the rolled steel plate enters the ACC quickly. After cooling, the red temperature is 532°C.

[0038] (2) Heat treatment process: Temper the steel plate, the tempering temperature is 2...

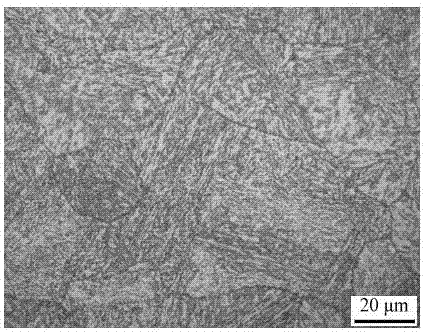

Embodiment 3

[0041] The thickness of the high-strength Q630GJ steel plate in this embodiment is 50 mm, and the V-Ni-Nb-Ti microalloy composition design is adopted. The chemical composition and mass percentage are: C: 0.14%, Si: 0.60%, Mn: 0.95%, P: 0.020%, S: 0.003%, Alt: 0.040%, V: 0.044%, Ni: 0.38%, Nb: 0.028%, Ti: 0.018%, and the balance is Fe and trace unavoidable impurities.

[0042] The production process of the high-strength Q630GJ steel plate of this embodiment includes rolling and heat treatment, and the specific steps are as follows:

[0043](1) Rolling process: Type II controlled rolling process is adopted. The cumulative reduction in stage I reaches 36%, and the thickness of the steel is 120mm; After cooling, the red temperature is 550°C.

[0044] (2) Heat treatment process: the steel plate is tempered, the tempering temperature is 250°C, and the total heating time is 75min.

[0045] The mechanical properties and organization of the steel plate obtained are shown in Table 1; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com