Production method for ASTM A514 GrE high-strength steel plates

A production method and high-strength steel plate technology, applied in the field of metallurgy, can solve problems such as tight supply of thick plates, and achieve the effects of solving tight supply, optimizing rolling and quenching and tempering processes, and controlling rolling and cooling parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

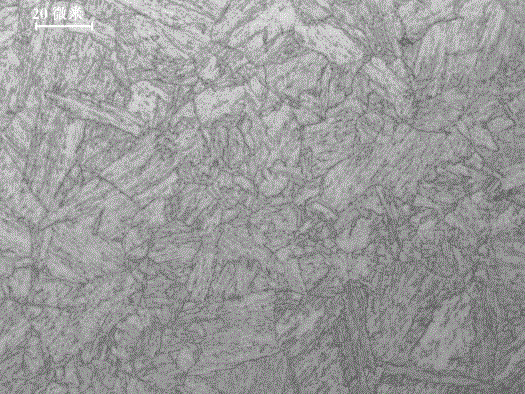

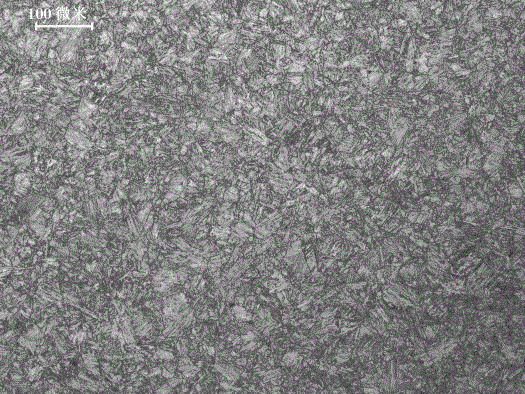

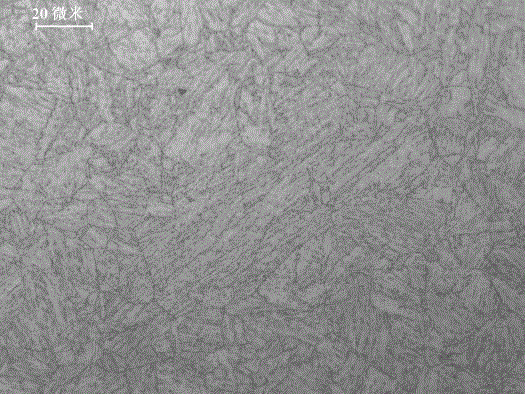

Image

Examples

Embodiment 1

[0032] The actual composition (by weight percentage) of the A514GrE steel plate in this example is: C: 0.15%, Si: 0.42%, Mn: 1.59%, P: 0.015%, S: 0.005%, Cr: 1.62%, Mo: 0.46% , Ti: 0.040%, Ni: 0.008%, the balance is Fe and unavoidable impurities; the thickness of the steel plate is 150mm.

[0033] The production method is as follows:

[0034] (1) Steel plates are produced by die casting;

[0035] (2) Rolling process: Type II controlled rolling process is adopted. After the first stage of rolling, the cooling red temperature is 820°C, the second stage is 800°C for starting rolling, 710°C for final rolling, and the cumulative reduction rate is 55%. , back to red at 630°C.

[0036] (3) Heat treatment process: the steel plate is quenched and tempered (2 times of quenching + tempering). Quenching process: the temperature is 930°C, the holding time is 80min, the steel plate 2 is quenched and then tempered. The tempering temperature is 655°C. The coefficient is 5min / mm, and the sa...

Embodiment 2

[0039] The actual composition (by weight percentage) of the A514GrE steel plate in this example is: C: 0.18%, Si: 0.50%, Mn: 1.65%, P: 0.012%, S: 0.002%, Cr: 1.82%, Mo: 0.56% , Ti: 0.048%, Ni: 0.008%, the balance is Fe and unavoidable impurities; the thickness of the steel plate is 163mm.

[0040] The production method is as follows:

[0041] (1) Steel plates are produced by die casting;

[0042] (2) Rolling process: Type II controlled rolling process is adopted. After the first stage of rolling, the temperature of cooling back to red is 840°C, the temperature of starting rolling in the second stage is 820°C, the temperature of final rolling is 720°C, and the cumulative reduction rate is 55%. , back to red at 600°C.

[0043] (3) Heat treatment process: the steel plate is quenched and tempered (2 times of quenching + tempering). Quenching process: the temperature is 940°C, the holding time is 90min, the steel plate is quenched twice and then tempered. The tempering temperature ...

Embodiment 3

[0046] The actual composition (by weight percentage) of the A514GrE steel plate in this example is: C: 0.20%, Si: 0.55%, Mn: 1.70%, P: 0.005%, S: 0.001%, Cr: 2.0%, Mo: 0.60%, Ti: 0.046%, Ni: 0.008%, the balance is Fe and unavoidable impurities; the thickness of the steel plate is 177.8mm.

[0047] Production method of the present invention is as follows:

[0048] (1) Steel plates are produced by die casting;

[0049] (2) Rolling process: Type II controlled rolling process is adopted. After the first stage of rolling, the cooling red temperature is 830°C, the second stage is 805°C for starting rolling, 705°C for final rolling, and the cumulative reduction rate is 50%. , back to red at 615°C.

[0050] (3) Heat treatment process: the steel plate is quenched and tempered (2 times of quenching + tempering), quenching process: the temperature is 950 ° C, the holding time is 100 min, the steel plate is quenched twice and then tempered, the tempering temperature is 650 ° C, heated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com