Household garbage and biomass crushing device

A pulverizing device, a technology for domestic waste, applied in grain processing and other directions, can solve the problems of limited application range of pulverized materials, inability to completely pulverize, and large crushing resistance, to solve the shortage of energy supply, eliminate secondary pollution, and be easy to select and manufacture materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

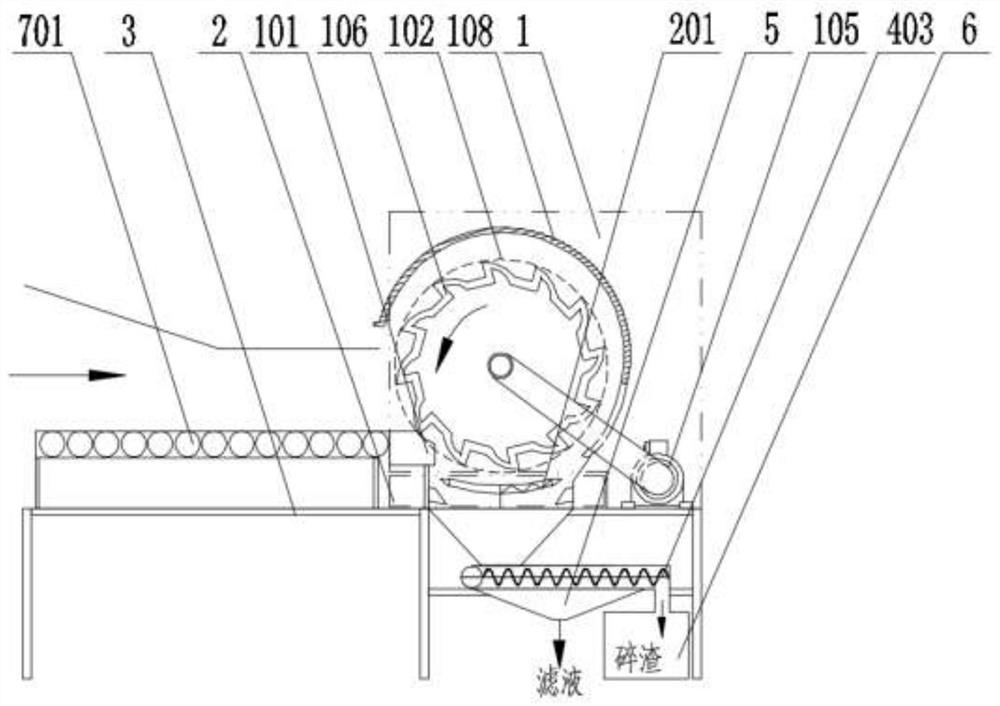

[0049] refer to Figure 1-4 , this embodiment mainly includes a rod saw type sawing mechanism 1, a cutting type crushing mechanism 2, a support 3, a filtrate debris separation mechanism 4, a filtrate collecting device 5, a pulverized material collecting mechanism 6, and a pushing mechanism 7. Rod-saw sawing mechanism 1, cutting-type crushing mechanism 2, and filtrate and slag separation mechanism 4 are successively installed on the bracket 3, and the materials after the first round of crushing by rod-saw-type sawing mechanism 1 enter the cutting-type crushing mechanism 2 to continue The second round of cutting type pulverization, rod saw type sawing mechanism 1, cutting type pulverization mechanism 2 pulverize domestic garbage or various biomass or the filtrate and slag produced by shells are collected by the filtrate slag separation mechanism 4, and the filtrate slag The separation mechanism 4 discharges the separated filtrate to the filtrate collection mechanism 5 , and disc...

Embodiment 2

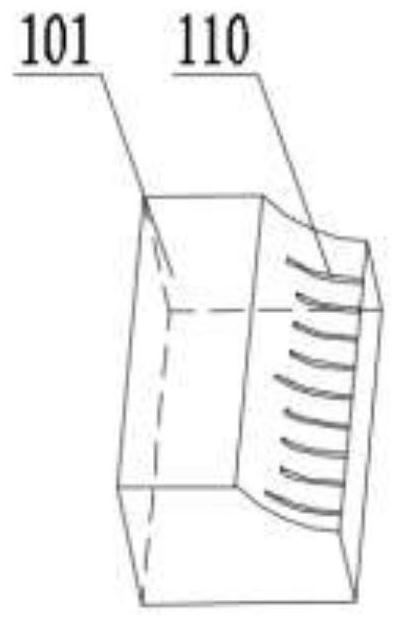

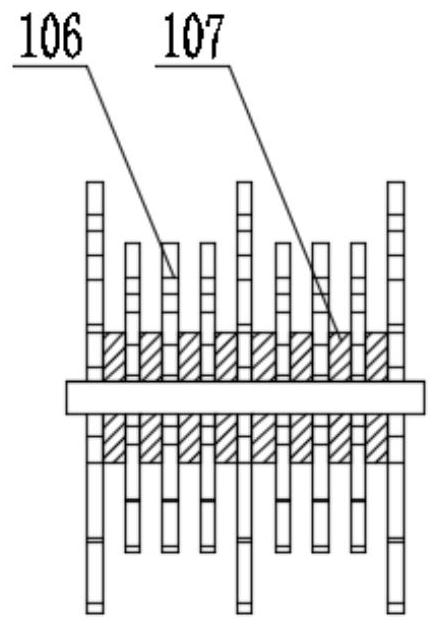

[0055] refer to Figure 5-9 The difference between this embodiment and Embodiment 1 is that the rod saw sawing mechanism 1 in this embodiment mainly includes a wear-resistant pier 101, a combined circular saw rod 102, a differential roller 103 and a first power mechanism 105. The combined circular saw rod 102 is composed of a plurality of toothed circular saw blades 106 with different diameters and specifications fixed on the same main shaft, and an elastic paddle 109 is also provided on the annular spacer 107 between the circular saw blades 106. The surface of the differential speed drum 103 is evenly arranged in a staggered sawtooth structure, and the rod saw sawing mechanism 1 composed of toothed circular saw blades 106 of different diameters and differential speed drum 103 can be adapted to domestic garbage or different types of biomass or kitchen shells. and other waste crushing.

[0056] The cutting-type pulverizing mechanism 2 is composed of four sets of planetary arra...

Embodiment 3

[0061] refer to Figure 10-11 The difference between this embodiment and Embodiment 2 is that the rod saw sawing mechanism 1 mainly includes a wear-resistant pier 101, two differential combined circular saw rods 104 and a first power mechanism 105, and a single combined circular saw rod 105. The saw rod is composed of a plurality of toothed circular saw blades 106 of the same diameter and specifications fixed on the same main shaft, and the circular saw blades 106 on the two differential speed combined circular saw rods 104 are arranged evenly and interlaced with each other to form a rod saw sawing mechanism. 1. It can be adapted to the crushing of household garbage or different types of biomass or kitchen shellfish and other wastes.

[0062] The cutting-type pulverizing mechanism 2 is composed of three sets of rotating cutting blades 201 arranged in parallel and a second power mechanism 202. The structure of the rotating cutting blades 201 is a four-leaf rotating cutting blad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com