Tailings-based filling cement produced by fine-grained tailings replacing part of fly ash

A technology for replacing parts and binders, applied in cement production and other directions, can solve the problems of increasing and rising costs of binders, achieve good economic and social benefits, solve supply shortages, widely applicable significance and promotion value effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

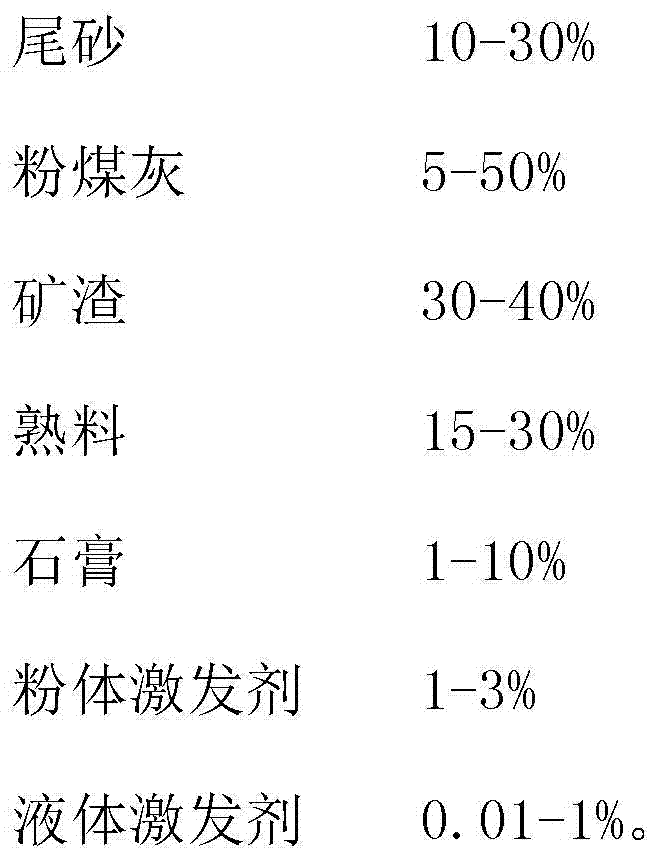

Method used

Image

Examples

Embodiment 1

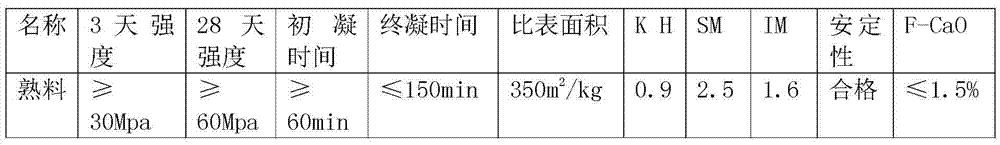

[0038] Preparation of fly ash-based cement, the ratio of raw materials is shown in Table 7

[0039] Table 7

[0040]

[0041] The filling cement is prepared by the following steps,

[0042] 1. Grind clinker, slag and gypsum together, the grinding time is 50 minutes, and the fineness is controlled at a specific surface area ≥ 380m 2 / Kg;

[0043] 2. Grind the fly ash and powder activator together, the grinding time is 30 minutes, and the fineness is controlled at a specific surface area ≥ 450m 2 / Kg;

[0044] 3. Evenly mix the separately ground materials and liquid activator.

Embodiment 2

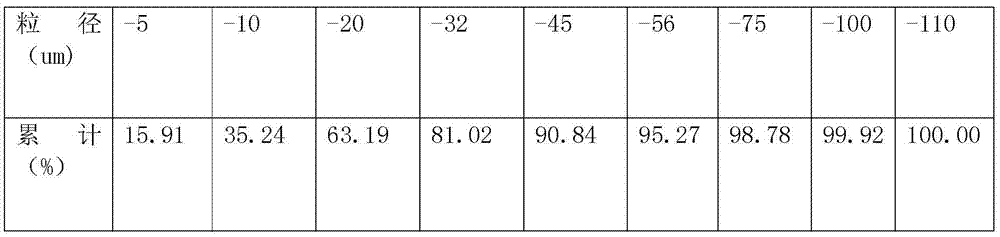

[0046] Preparation of tailings-based cement, the ratio of raw materials is shown in Table 8

[0047] Table 8

[0048]

[0049] The filling cement is prepared by the following steps,

[0050] 1. Dry the tailings through a drying oven in advance, and the moisture after drying is ≤1.0%;

[0051] 2. Grinding clinker, slag and gypsum together, the grinding time is 50 minutes, and the fineness is controlled at a specific surface area ≥ 380m 2 / Kg;

[0052] 3. Tailings, fly ash and powder activator are ground together, the grinding time is 30 minutes, and the fineness is controlled at a specific surface area ≥ 450m 2 / Kg;

[0053] 4. Mix the separately ground materials and liquid activator evenly.

Embodiment 3

[0055] Preparation of tailings-based cement, the ratio of raw materials is shown in Table 9

[0056] Table 9

[0057]

[0058] The filling cement is prepared by the following steps,

[0059] 1. Dry the tailings through a drying oven in advance, and the moisture after drying is ≤1.0%;

[0060] 2. Grinding clinker, slag and gypsum together, the grinding time is 50 minutes, and the fineness is controlled at a specific surface area ≥ 380m 2 / Kg;

[0061] 3. Tailings, fly ash and powder activator are ground together, the grinding time is 30 minutes, and the fineness is controlled at a specific surface area ≥ 450m 2 / Kg;

[0062] 4. Mix the separately ground materials and liquid activator evenly.

[0063] one. Detection Indicator

[0064] ① Fineness, the main detection of specific surface area;

[0065] ②Age strength: 3-day and 28-day compressive strength of standard sand and tailings;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com