Lubrication composition, lubrication composition coated metal plate and manufacturing method thereof

A technology for lubricating compositions and metal plates, which is applied in the direction of lubricating compositions, metal material coating processes, and devices for coating liquid on the surface, etc., which can solve the problem of insufficient stamping formability of metal plates and insufficient lubricity, etc. Problems, to achieve the effect of economical efficiency, reduced cohesiveness, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0098] Next, regarding the lubricating composition of the present invention, the lubricating composition-coated metal sheet, and the method for producing a lubricating composition-coated metal sheet, specifically Be explained.

no. 1 Embodiment

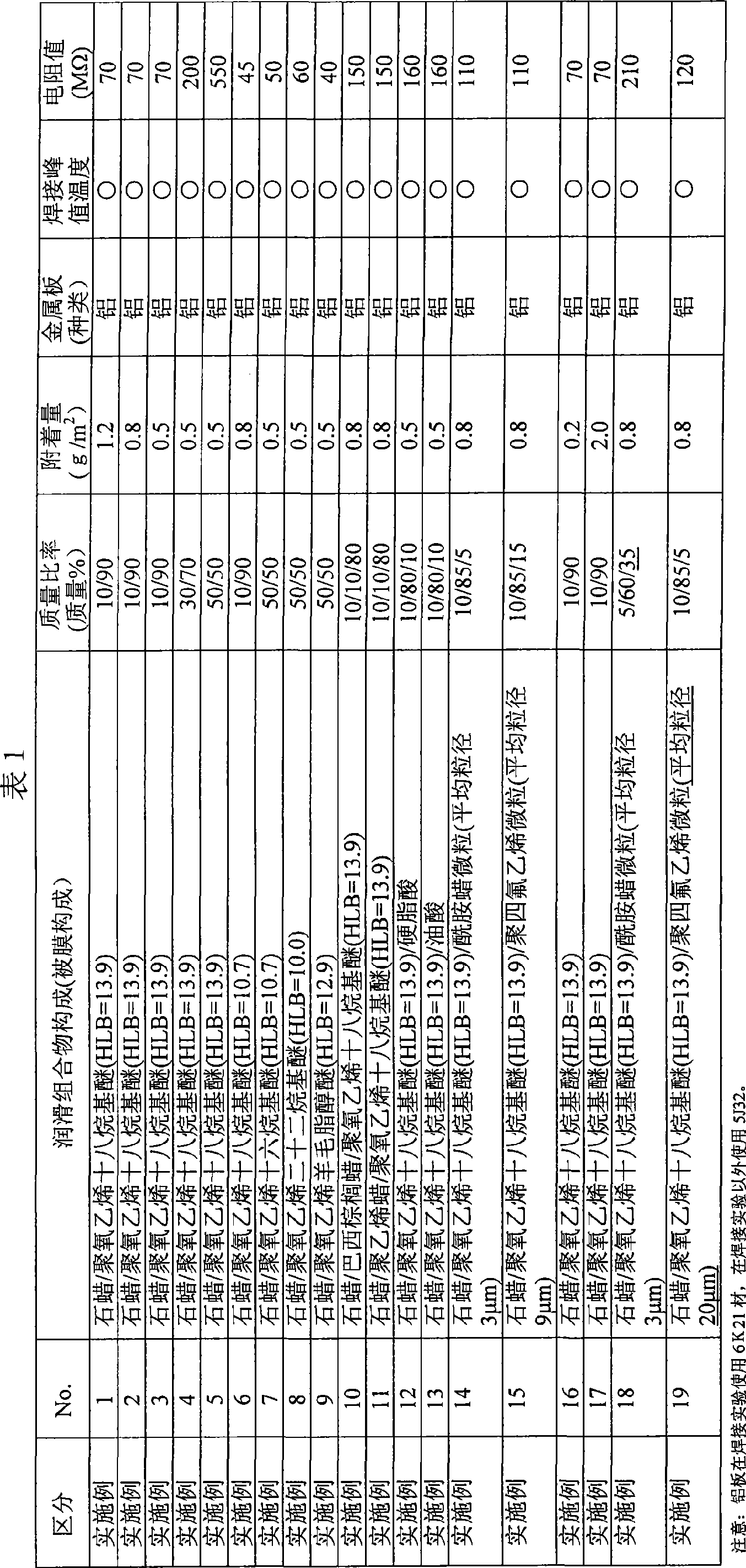

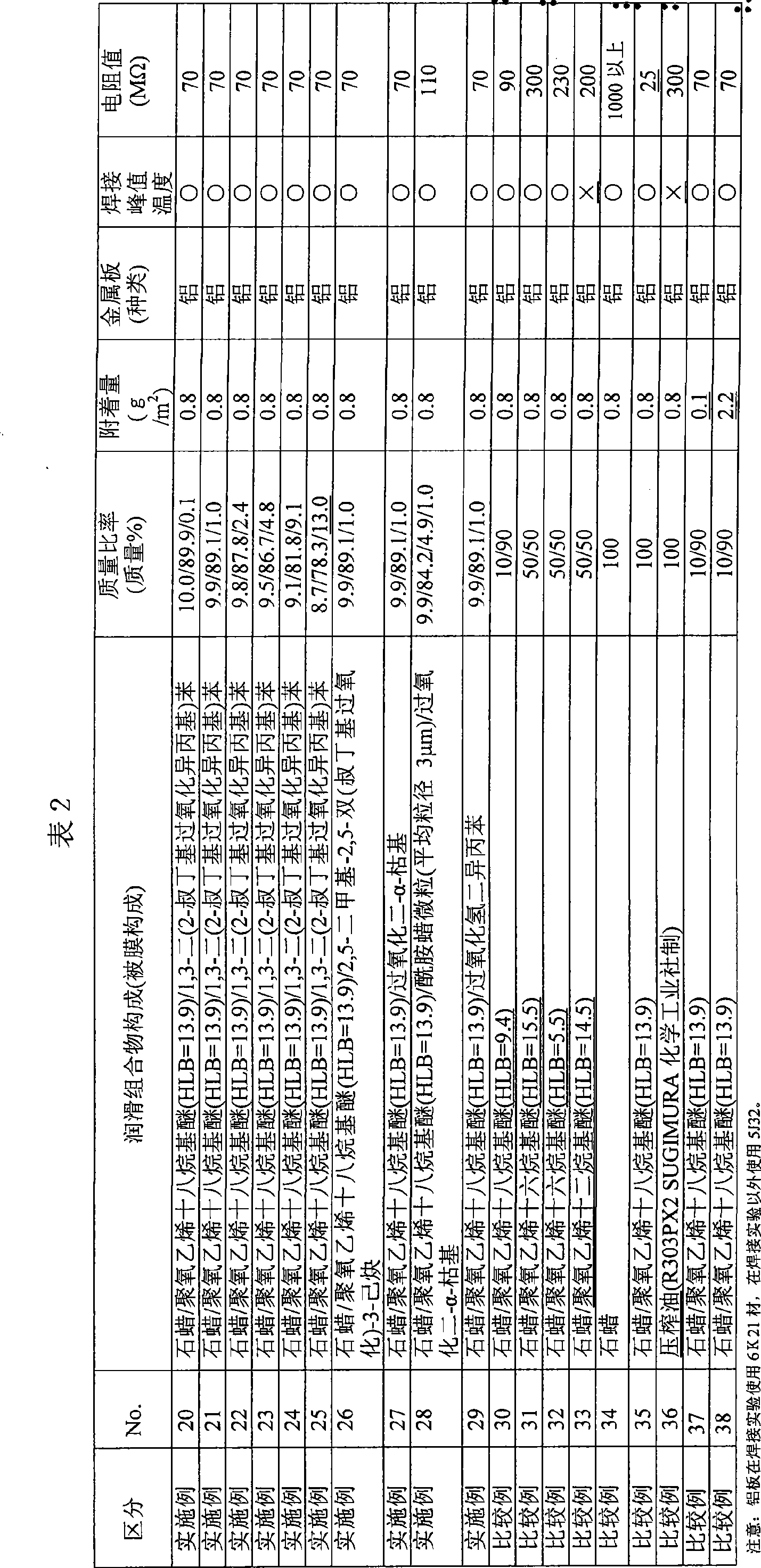

[0100] A coating layer composed of the lubricating composition shown in Table 1 was formed on both sides or one side of a metal plate (thickness: 1 mm), and a plurality of lubricating composition-coated metal plates were produced, and their characteristics were evaluated.

[0101]

[0102] According to the compounding quantity shown in Table 1, the lubricating composition was prepared. When preparing, use an oil bath to heat to about 90°C to make it melt, and stir until it is homogeneous.

[0103] Next, the lubricating composition was heated to 90° C. to melt it, and applied to the surface of a metal plate (thickness 1 mm) shown in Table 1 using an electrostatic oiler (manufactured by Lubtic Co., Ltd.). Allow to cool to form a lubricating coating.

[0104]

[0105] The lubricating composition was prepared in the compounding quantity shown in Table 1, and it was dissolved in toluene to prepare a paint (paint concentration: 5% by mass) containing the lubricating composition...

no. 2 Embodiment

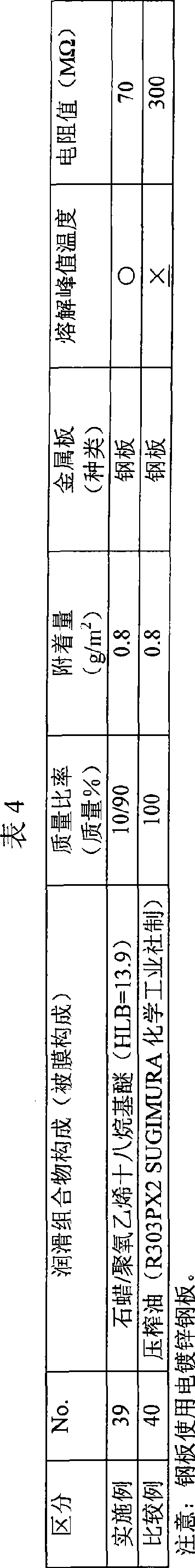

[0139] For single side 0.8g / m 2 In the same way as in Example 1 above, the lubricating composition shown in Table 4 is coated on electro-galvanized steel sheets (thickness 1mm, plating adhesion: 30g / m 2 ) formed on both sides of the lubricating composition-coated metal plate, the characteristics were evaluated in the same manner as in the above-mentioned first example.

[0140] It should be noted that the melting peak temperature of the lubricating composition, electrical resistance, and the method of measuring the amount of the lubricating composition attached to the metal plate coated with the lubricating composition, as well as stability, formability, release property, blocking resistance, and weldability The evaluation method and evaluation criteria are the same as those of the above-mentioned first embodiment.

[0141] These results are shown in Tables 4 and 5. It should be noted that in Table 4, values that do not satisfy the scope of the present invention are underl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com