1,200 MPa-stage silicon-manganese-chromium-series hot-rolled low-carbon steel plate and preparation method thereof

A technology of grade silico-manganese-chromium-based and low-carbon steel sheet, applied in the field of 1200MPa grade silico-manganese-chromium-based hot-rolled low-carbon steel sheet and its preparation, which can solve the problems of high energy consumption, dependence on equipment capacity, cumbersome processes, etc., and achieve the operation process. Simple, reduce production costs, and achieve the effect of industrialized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

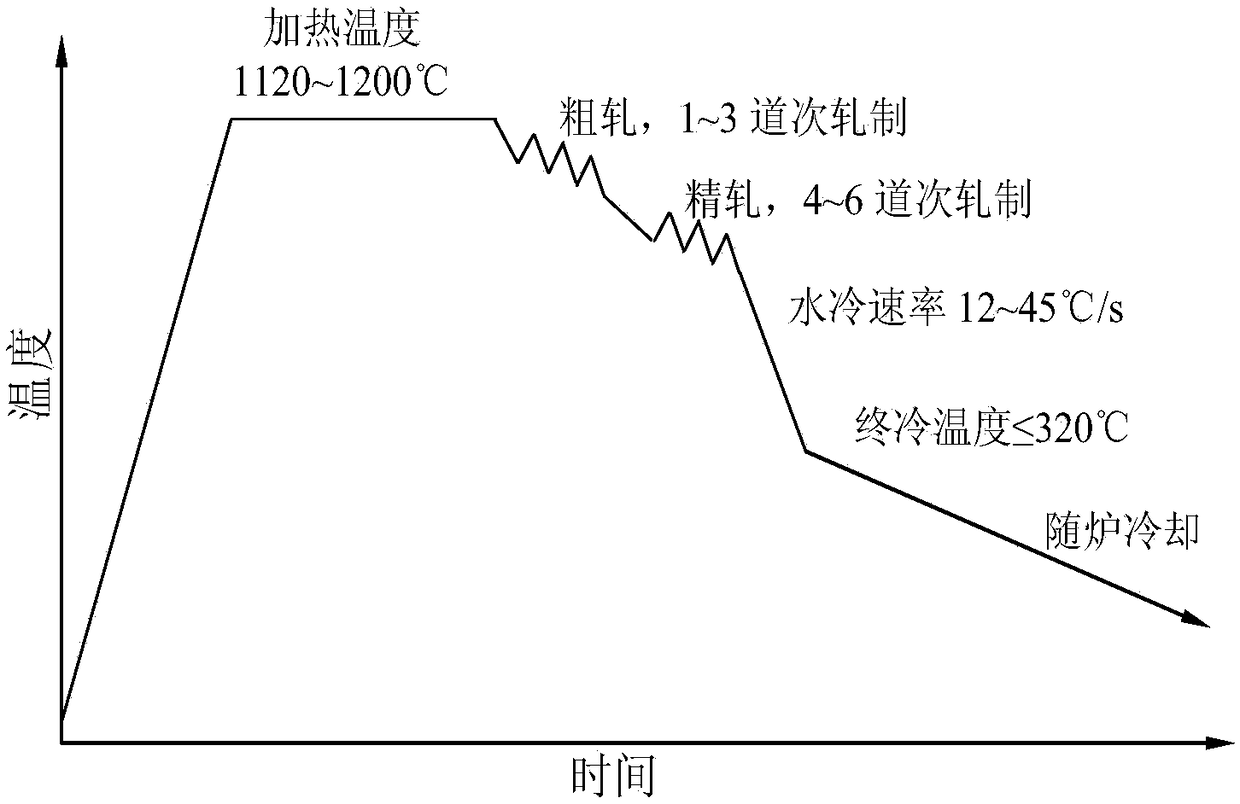

[0031] The method flow is as follows figure 1 shown;

[0032] A steel billet with a thickness of 140.0mm is placed in a heating furnace and kept at 1200°C for 4 hours; the composition of the steel billet by weight percentage is: C 0.06%, Mn 3.5%, Si 1.6%, Cr 1.2%, Mo 0.3%, Ni 0.5% %, S 0.002%, P0.010%, Al 0.05%, N 0.005%, the balance is Fe and its unavoidable impurities;

[0033] The heat-preserved steel billet is made into a hot-rolled plate with a thickness of 30.0mm through rough rolling and finish rolling; the final rolling temperature of the rough rolling is 1100°C, the rough rolling is carried out in 2 passes, and the pass reduction rate is 19-20%. Roll to 90.0mm; the start rolling temperature of finish rolling is 950°C, the finish rolling temperature is 890°C, finish rolling is carried out 4 times, the reduction rate of each pass is 21-25%, and the finish rolling is 30.0mm;

[0034] Water-cool the hot-rolled sheet to ≤320°C, and control the cooling rate of the hot-rol...

Embodiment 2

[0036] Method is with embodiment 1, and difference is:

[0037](1) Billet components by weight percentage: C 0.10%, Mn 3.0%, Si 1.3%, Cr 0.8%, Mo0.2%, Ni0.3%, S 0.008%, P 0.003%, Al 0.01%, N 0.004 %, the balance is Fe and its unavoidable impurities; the thickness of the steel billet is 80.0mm, and it is kept at 1150°C for 3h;

[0038] (2) Make a hot-rolled sheet with a thickness of 15.0mm; wherein the finish rolling temperature of the rough rolling is 1100°C, the rough rolling is carried out 1 pass, the pass reduction rate is 25%, and the rough rolling reaches 60.0mm; The rolling temperature is 930°C, the finish rolling temperature is 865°C, the finish rolling is carried out 5 times, the finish rolling reaches 15.0mm, and the pass reduction rate is 21-28%;

[0039] (3) Water cooled to 260°C, the cooling rate is 32°C / s; the tensile strength of 1200MPa grade silicomanganese chromium series hot-rolled low carbon steel plate is 1305MPa, the elongation is 14.4%, the yield strength...

Embodiment 3

[0041] (1) Billet components by weight percentage: C 0.14%, Mn 2.5%, Si 1.0%, Cr 0.5%, Mo0.1%, Ni0.1%, S 0.010%, P 0.010%, Al 0.03%, N 0.003 %, the balance is Fe and its unavoidable impurities; the thickness of the steel billet is 50.0mm, and it is kept at 1120°C for 2h;

[0042] (2) Make a hot-rolled sheet with a thickness of 5.0mm; wherein the finishing temperature of the rough rolling is 1050°C, the rough rolling is carried out for 3 passes, the rough rolling reaches 27.0mm, and the pass reduction rate is 18-19%; The starting temperature of rolling is 890°C, the finishing rolling temperature of finish rolling is 820°C, and the finish rolling is carried out in 6 passes to 5.0mm, and the pass reduction rate is 21-29%;

[0043] (3) Water cooled to room temperature with a cooling rate of 45°C / s; the tensile strength of 1200MPa-grade silicon-manganese-chromium hot-rolled low-carbon steel plate is 1360MPa, the elongation is 12.8%, the yield strength is 960MPa, and the impact ener...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com