Non-preheating welding Q690D steel plate for coal mine machinery and preparation method of non-preheating welding Q690D steel plate

A technology for coal mine machinery and steel plates, applied in the field of Q690D steel plates for welding coal mine machinery without preheating and its preparation, can solve the problems of reduced production efficiency, time-consuming production process, high manufacturing cost, etc., to reduce alloy costs, simplify process routes, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

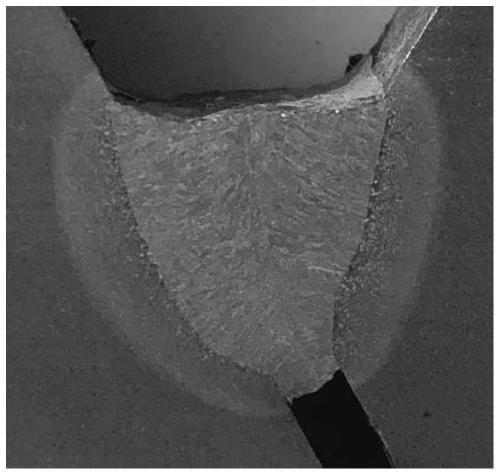

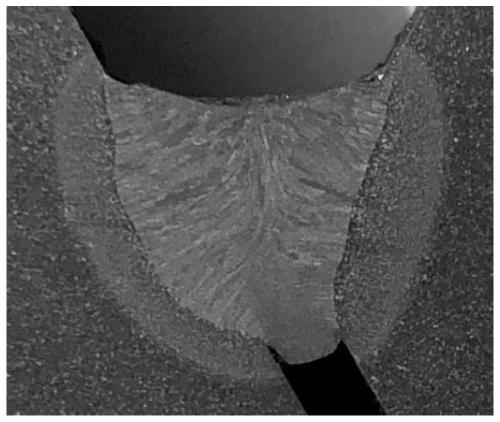

[0028] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

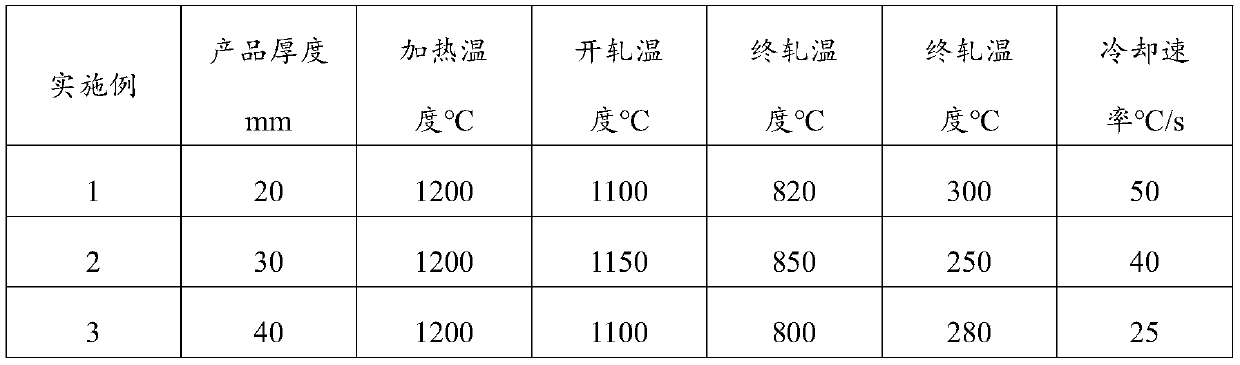

[0029] A non-preheating welded Q690D steel plate for coal mine machinery and its preparation method provided in Examples 1-4, the process flow: converter smelting→LF→RH→slab casting→slab heating→hot rolling→online DQ cooling→offline tempering , where the billet is heated to 1200°C, the soaking time is 1h, the starting rolling temperature is 1100-1150°C, the final rolling temperature is 800-850°C, and the steel plate is cooled to ≤300°C at a rate of 25-50°C / s after final rolling , and then air-cooled to room temperature, the steel plate was tempered off-line at 400 °C for 1 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com